i137 GEO binnen - GeoTechniek

i137 GEO binnen - GeoTechniek

i137 GEO binnen - GeoTechniek

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

DEFORMATION MONITORING OF THE UNDERGROUND METRO STATION ROTTERDAM CS<br />

the required measuring range of the measuring<br />

instrument;<br />

the required accuracy and frequency of measuring;<br />

the hazard warning levels;<br />

the way of communication.<br />

This paper will focus on the deformation monitoring<br />

of the metro station only. All other monitoring<br />

parameters are beyond the scope of this paper and<br />

will not be discussed.<br />

HAZARD WARNING LEVELS<br />

In order to make corrective actions effective, it is<br />

essential to compare the measured parameters with<br />

predefined hazard warning levels. These levels form<br />

an important part of the monitoring specifications<br />

(Berkelaar, 2006).<br />

The main criteria for the hazard warning levels were<br />

to assure the structural integrity of the station and<br />

safe operation of metro traffic. The structural<br />

engineers of RPW determined the levels based on the<br />

structural integrity whereas the RET provided<br />

specifications for safe metro operation. Two types of<br />

hazard warning levels were defined:<br />

the call or warning value; when exceeding this limit<br />

the contractor has to communicate this with RPW<br />

and take actions to prevent further exceeding of<br />

this value;<br />

the intervention value; when exceeding this limit<br />

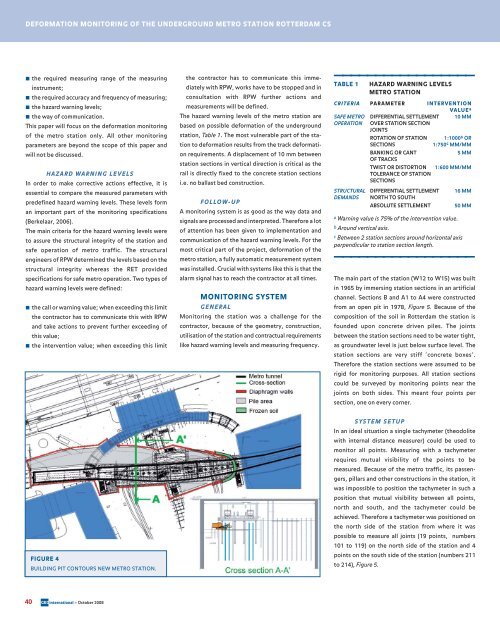

FIGURE 4<br />

BUILDING PIT CONTOURS NEW METRO STATION.<br />

40 <strong>GEO</strong>international – October 2008<br />

the contractor has to communicate this immediately<br />

with RPW, works have to be stopped and in<br />

consultation with RPW further actions and<br />

measurements will be defined.<br />

The hazard warning levels of the metro station are<br />

based on possible deformation of the underground<br />

station, Table 1. The most vulnerable part of the station<br />

to deformation results from the track deformation<br />

requirements. A displacement of 10 mm between<br />

station sections in vertical direction is critical as the<br />

rail is directly fixed to the concrete station sections<br />

i.e. no ballast bed construction.<br />

FOLLOW-UP<br />

A monitoring system is as good as the way data and<br />

signals are processed and interpreted. Therefore a lot<br />

of attention has been given to implementation and<br />

communication of the hazard warning levels. For the<br />

most critical part of the project, deformation of the<br />

metro station, a fully automatic measurement system<br />

was installed. Crucial with systems like this is that the<br />

alarm signal has to reach the contractor at all times.<br />

MONITORING SYSTEM<br />

GENERAL<br />

Monitoring the station was a challenge for the<br />

contractor, because of the geometry, construction,<br />

utilisation of the station and contractual requirements<br />

like hazard warning levels and measuring frequency.<br />

_________________<br />

TABLE 1 HAZARD WARNING LEVELS<br />

METRO STATION<br />

CRITERIA PARAMETER INTERVENTION<br />

VALUEa SAFE METRO DIFFERENTIAL SETTLEMENT 10 MM<br />

OPERATION OVER STATION SECTION<br />

JOINTS<br />

ROTATION OF STATION 1:1000b OR<br />

SECTIONS 1:750c MM/MM<br />

BANKING OR CANT<br />

OF TRACKS<br />

5 MM<br />

TWIST OR DISTORTION<br />

TOLERANCE OF STATION<br />

SECTIONS<br />

1:600 MM/MM<br />

STRUCTURAL DIFFERENTIAL SETTLEMENT 16 MM<br />

DEMANDS NORTH TO SOUTH<br />

ABSOLUTE SETTLEMENT 50 MM<br />

a Warning value is 75% of the intervention value.<br />

b Around vertical axis.<br />

c Between 2 station sections around horizontal axis<br />

perpendicular to station section length.<br />

_________________<br />

The main part of the station (W12 to W15) was built<br />

in 1965 by immersing station sections in an artificial<br />

channel. Sections B and A1 to A4 were constructed<br />

from an open pit in 1978, Figure 5. Because of the<br />

composition of the soil in Rotterdam the station is<br />

founded upon concrete driven piles. The joints<br />

between the station sections need to be water tight,<br />

as groundwater level is just below surface level. The<br />

station sections are very stiff ‘concrete boxes’.<br />

Therefore the station sections were assumed to be<br />

rigid for monitoring purposes. All station sections<br />

could be surveyed by monitoring points near the<br />

joints on both sides. This meant four points per<br />

section, one on every corner.<br />

SYSTEM SETUP<br />

In an ideal situation a single tachymeter (theodolite<br />

with internal distance measurer) could be used to<br />

monitor all points. Measuring with a tachymeter<br />

requires mutual visibility of the points to be<br />

measured. Because of the metro traffic, its passengers,<br />

pillars and other constructions in the station, it<br />

was impossible to position the tachymeter in such a<br />

position that mutual visibility between all points,<br />

north and south, and the tachymeter could be<br />

achieved. Therefore a tachymeter was positioned on<br />

the north side of the station from where it was<br />

possible to measure all joints (19 points, numbers<br />

101 to 119) on the north side of the station and 4<br />

points on the south side of the station (numbers 211<br />

to 214), Figure 5.