N170801 man imaging therm DCT416 Euro.indd - Service

N170801 man imaging therm DCT416 Euro.indd - Service

N170801 man imaging therm DCT416 Euro.indd - Service

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

ENGLISH<br />

measurement of a target with a shiny or metallic<br />

surface. Experimentation may be required to<br />

benchmark temperatures, and experience will<br />

help you choose the best setting for specific<br />

measurements.<br />

The <strong>imaging</strong> <strong>therm</strong>ometer has emissivity adjustable<br />

from 0.1 to 1.0 in increments of 0.01. Refer to the<br />

Nominal Emissivity Table in this <strong>man</strong>ual. The<br />

reference to emissivity settings in the table are<br />

suggestions for typical situations and your particular<br />

situation may differ.<br />

NOTE: Calibration of this product was performed at<br />

0.95 emissivity.<br />

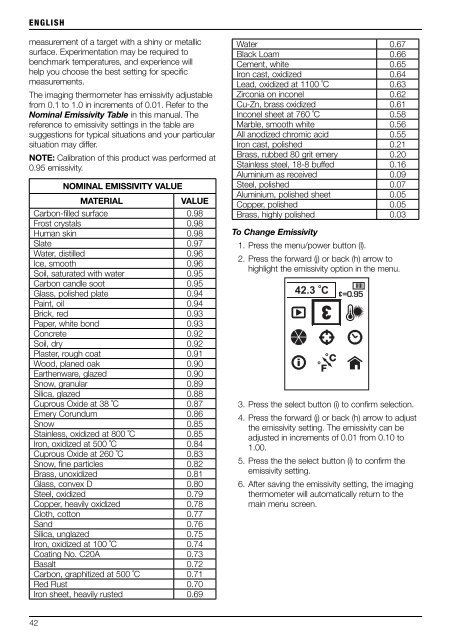

NOMINAL EMISSIVITY VALUE<br />

MATERIAL VALUE<br />

Carbon-filled surface 0.98<br />

Frost crystals 0.98<br />

Hu<strong>man</strong> skin 0.98<br />

Slate 0.97<br />

Water, distilled 0.96<br />

Ice, smooth 0.96<br />

Soil, saturated with water 0.95<br />

Carbon candle soot 0.95<br />

Glass, polished plate 0.94<br />

Paint, oil 0.94<br />

Brick, red 0.93<br />

Paper, white bond 0.93<br />

Concrete 0.92<br />

Soil, dry 0.92<br />

Plaster, rough coat 0.91<br />

Wood, planed oak 0.90<br />

Earthenware, glazed 0.90<br />

Snow, granular 0.89<br />

Silica, glazed 0.88<br />

Cuprous Oxide at 38 ˚C 0.87<br />

Emery Corundum 0.86<br />

Snow 0.85<br />

Stainless, oxidized at 800 ˚C 0.85<br />

Iron, oxidized at 500 ˚C 0.84<br />

Cuprous Oxide at 260 ˚C 0.83<br />

Snow, fine particles 0.82<br />

Brass, unoxidized 0.81<br />

Glass, convex D 0.80<br />

Steel, oxidized 0.79<br />

Copper, heavily oxidized 0.78<br />

Cloth, cotton 0.77<br />

Sand 0.76<br />

Silica, unglazed 0.75<br />

Iron, oxidized at 100 ˚C 0.74<br />

Coating No. C20A 0.73<br />

Basalt 0.72<br />

Carbon, graphitized at 500 ˚C 0.71<br />

Red Rust 0.70<br />

Iron sheet, heavily rusted 0.69<br />

42<br />

Water 0.67<br />

Black Loam 0.66<br />

Cement, white 0.65<br />

Iron cast, oxidized 0.64<br />

Lead, oxidized at 1100 ˚C 0.63<br />

Zirconia on inconel 0.62<br />

Cu-Zn, brass oxidized 0.61<br />

Inconel sheet at 760 ˚C 0.58<br />

Marble, smooth white 0.56<br />

All anodized chromic acid 0.55<br />

Iron cast, polished 0.21<br />

Brass, rubbed 80 grit emery 0.20<br />

Stainless steel, 18-8 buffed 0.16<br />

Aluminium as received 0.09<br />

Steel, polished 0.07<br />

Aluminium, polished sheet 0.05<br />

Copper, polished 0.05<br />

Brass, highly polished 0.03<br />

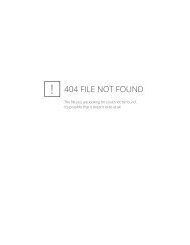

To Change Emissivity<br />

1. Press the menu/power button (l).<br />

2. Press the forward (j) or back (h) arrow to<br />

highlight the emissivity option in the menu.<br />

3. Press the select button (i) to confirm selection.<br />

4. Press the forward (j) or back (h) arrow to adjust<br />

the emissivity setting. The emissivity can be<br />

adjusted in increments of 0.01 from 0.10 to<br />

1.00.<br />

5. Press the the select button (i) to confirm the<br />

emissivity setting.<br />

6. After saving the emissivity setting, the <strong>imaging</strong><br />

<strong>therm</strong>ometer will automatically return to the<br />

main menu screen.