FLEISCHWIRTSCHAFT international 1/2017

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Volume 32 _D42804 F<br />

Journal for meat production,<br />

processing and research<br />

<strong>international</strong><br />

1_<strong>2017</strong><br />

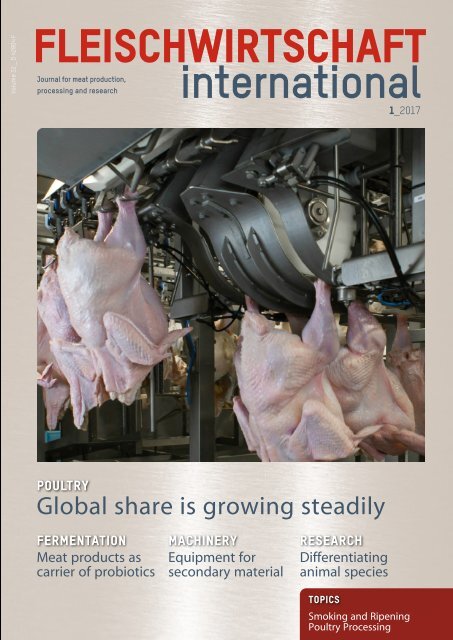

Poultry<br />

Global share is growing steadily<br />

Fermentation<br />

Meat products as<br />

carrier of probiotics<br />

Machinery<br />

Equipment for<br />

secondary material<br />

Research<br />

Differentiating<br />

animal species<br />

Topics<br />

Smoking and Ripening<br />

Poultry Processing

Fleischwirtschaft <strong>international</strong> 1_<strong>2017</strong><br />

3<br />

Editorial<br />

RenateKühlcke -kck Gerd Abeln -abe YvonneBuch -yb MichaelWeisenfels -mw<br />

KathrinGrünewald -gru<br />

Focus on quality<br />

<strong>2017</strong> presents anew <strong>FLEISCHWIRTSCHAFT</strong> <strong>international</strong><br />

Over the years poultry has become extremely<br />

appreciated by consumers worldwide. An<br />

ever-growing share in the global meat consumption<br />

is the mirror of this development.This<br />

means that poultry is the focus of both the consumers<br />

and the industry -and of this issue of<br />

<strong>FLEISCHWIRTSCHAFT</strong> <strong>international</strong>.<br />

Likethe title story and our readers, we editors<br />

focus on the quality of our product–the bimonthly<br />

magazine for the entire meat sector.<br />

Over the past few months, we have sharpened the<br />

profile of <strong>FLEISCHWIRTSCHAFT</strong> <strong>international</strong><br />

and given it amodern look. At thefirst glance, the<br />

clear,straightforward logo and the new cover<br />

layout,based on hygienic design optics, come into<br />

view.The content is noticeably different and yet<br />

familiar.New fonts, arevised picture and graphic<br />

language, clear tables and agreater diversity of<br />

articles makethe reading experience more distinctive<br />

and make<strong>FLEISCHWIRTSCHAFT</strong><br />

<strong>international</strong> non-interchangeable.<br />

Thetried-and-tested structure of the journal<br />

remains unchanged. Thepractical-oriented<br />

front part of each issue shows the "meat chain"<br />

from agricultural generation to harvesting,<br />

processing and marketing. Apart of the DNA<br />

of our <strong>FLEISCHWIRTSCHAFT</strong> <strong>international</strong><br />

is also the peer-reviewed “Research and Development”section.<br />

Our diversity and depth of<br />

topics are consistently aligned with the needs<br />

of our target group with atechnological and<br />

scientific focus. In terms of content,wecontinue<br />

to rely on the expertise of the specialist<br />

authors, which has carried us intothe 32nd<br />

year of our <strong>international</strong> issue in English and<br />

the 97th of our German one. Our claim remains<br />

to be areliable navigator.Here we use<br />

the columns "News", "Business News"and<br />

"Foreign Markets", which arelocated on the<br />

first pages of each issue. In this section information<br />

about meat-relevant events and topics,<br />

the initiation and accompaniment of debates<br />

are central concerns.<br />

It is atricky thing to revise awell-tried print<br />

journal, which is anchored in the industry.Finding<br />

the right measure was our goal. Please let us<br />

know if we have succeeded. r red-flw@dfv.de

.....................................................<br />

4<br />

Fleischwirtschaft <strong>international</strong> 1_<strong>2017</strong><br />

Content<br />

14 44<br />

Poultry<br />

In recent years consumers have<br />

more and more appreciated all<br />

kinds of poultry as an important<br />

source of protein. In addition they<br />

like the low fat content and the<br />

good digestibility. 14 Photo: Marel<br />

Columns<br />

3 Editorial<br />

6 News<br />

8 Business News<br />

11 Foreign Markets<br />

18 Industry News<br />

47 Calendar<br />

48 Advertisers, Credits, Subscriptions<br />

55 Research News<br />

Meat chain<br />

14 Poultry<br />

Use of antibiotics in the Chinese poultry<br />

industry and alternative solutions development<br />

of antibiotic-free breeding<br />

24 Machinery<br />

Multi-purpose equipment allows the<br />

processing of secondary meat raw<br />

materials<br />

36 Food Waste<br />

Active and intelligent packagings can<br />

reduce wastes in meat-producing<br />

chains<br />

44 Testing Methods<br />

Duplex PCR opens new possibilities for<br />

the detection of GM soya in chicken<br />

sausages<br />

Research &Development<br />

50 Methods of differentiating animal species in foods –<br />

Status quo<br />

56 Storage stability of chicken meat incorporated noodles<br />

at ambient temperature under aerobic condition<br />

62 Thermoresistance and regeneration<br />

of heat-damaged E. faecium PCM 1859<br />

in amedium with reduced ph value<br />

66 Guidelines for authors<br />

of <strong>FLEISCHWIRTSCHAFT</strong> <strong>international</strong>

Fleischwirtschaft <strong>international</strong> 1_<strong>2017</strong><br />

20<br />

Topics<br />

20 Consumer Research<br />

Dutch per capita consumption of poultry<br />

meat remains constant at ahigh level<br />

22 Packaging<br />

Modern technologies and materials lead<br />

to high quality and product safety<br />

28 Ingredients<br />

Fermented meat products are suitable<br />

carriers of probiotics<br />

56

................................................<br />

6<br />

Fleischwirtschaft <strong>international</strong> 1_<strong>2017</strong><br />

News<br />

Rabobank<br />

Pork Quarterly Q1published<br />

The level to which China imports pork<br />

after Chinese New Year will determine<br />

the start of the seasonal increase of<br />

the Rabobank Five-Nation Hog Price<br />

Index, according to the latest<br />

Rabobank Pork Quarterlyreport.<br />

Chinese pork prices will remain<br />

elevated, but likelyslightlyless so<br />

after Chinese New Year.The stabilising<br />

sow herd and rapidlyrising productivity<br />

will not affect the market<br />

before summer, while the continuing<br />

impact of environmental policies on<br />

industry restructuring will limit expansion.<br />

Pressured supplyand<br />

continuing exports will support<br />

prices and margins in the EU. However,<br />

rising export dependency as a<br />

result of ongoing pressured domestic<br />

France<br />

Ban for beef lifted<br />

U.S. authorities have lifted an<br />

embargo on French beef imports<br />

after 19 years, the French agriculture<br />

ministry said. This was<br />

reported by CTV News.<br />

France is the fourth EU country<br />

to have its beef re-admitted to<br />

the US market after a1998 ban<br />

consumption increases the importance<br />

of afavourable exchange rate,<br />

given rising competition from the<br />

Americas. The margin split in the US<br />

industry will continue in 1H <strong>2017</strong>.<br />

Rising production will continue to<br />

pressure farmers’ margins, while<br />

demand will support packers’ margins.<br />

However, trade developments<br />

and the impact of exchange rates will<br />

be the wildcards.<br />

//www.rabobank.com<br />

imposed because of fears over<br />

bovine spongiform encephalopathy<br />

(BSE), also known as mad<br />

cow disease. The others are<br />

Ireland, Lithuania and the<br />

Netherlands.<br />

//www.ctvnews.ca<br />

Advertisement<br />

Partner country was Hungary<br />

Once again the International Green Week Berlin <strong>2017</strong> emphasised<br />

its function as aleading trade fair for national and <strong>international</strong><br />

agribusiness. From 20 to 29 January atotal of 1,650 exhibitors<br />

from 66 countries provided acomprehensive review of<br />

the food industry’s global market and of the achievements of<br />

agriculture and horticulture.<br />

Messe Berlin registered at the trade fair and conferences of the<br />

Green Week <strong>2017</strong> total almost 400,000. In addition to visitors<br />

attending this event daily the halls were filled each day with some<br />

10,000 personnel such as exhibitors and stand staff,service<br />

operatives and media representatives. Percapita expenditure by<br />

visitors to the fair remained at last year’s level, exceeding of 120€<br />

and providing exhibitors with sales worth more than 48 mill. €.<br />

Dates of the next event:19to28January 2018.<br />

//www.gruenewoche.de/en<br />

Photo: Messe Berlin<br />

DMRI<br />

Danish Institute opened modern slaughterhouse in South Korea<br />

Daejeon Chungnam Pig-Farmer Cooperative<br />

(DC) plans to establish a40,000 m 2 new<br />

slaughterhouse for 3,000 pigs and 300 cattle<br />

per day near Cheonan, South Korea. It will<br />

become the workplace of 400 employees. DC<br />

is amajor pig producer and the owner of<br />

butcher shops and restaurants in South<br />

Korea.<br />

The facility is planned to start operating at<br />

the end of 2018,meeting all modern demands<br />

and standards. DC has engaged the Danish<br />

Meat Research Institute and Haenglim Architecture<br />

&Engineering to facilitate the<br />

project.<br />

The capacity of the plant is planned to<br />

process 3,000 pigs and 300 cattle per day<br />

with the possibility of expanding with aprocessing<br />

department. The site will offer space<br />

of around 85,000 m 2 ;the buildings will take<br />

around 40,000 m 2 .The construction works are<br />

The Danish Meat<br />

Research Institute<br />

designed the<br />

state-of-the-art plant for<br />

the Daejeon Chungnam<br />

Pig-Farmer Cooperative.<br />

planned to start in the earlyspring of <strong>2017</strong><br />

and by the end of 2018 the production will<br />

start up. The slaughterhouse will complywith<br />

the standards of the European Union and the<br />

United States of America for slaughtering,<br />

cutting, de-boning and hygiene for producing<br />

quality meat products for Korea. Facilities will<br />

be made for the collection and separation of<br />

animal by-products according to the EU<br />

by-product regulation “Health rules concerning<br />

animal by-products not intended for<br />

human consumption” EU 1774/2002.<br />

Equipment and processes will be chosen<br />

according to the EU environmental standards<br />

for slaughterhouses, BREF (11.03) "Best Available<br />

Techniques in the Slaughterhouses and<br />

Animal By-Product Industries". Media consumption<br />

and emission will be within the<br />

ranges stated in the EU BREF. Transport of<br />

products to and from the slaughterhouse will<br />

be made from the main roads east and south<br />

of the site.<br />

//www.dti.dk

Fleischwirtschaft <strong>international</strong> 1_<strong>2017</strong><br />

7<br />

News<br />

WPF<br />

Gates Foundation grants<br />

poultry project in Africa<br />

The World Poultry Foundation<br />

(WPF) has received afour year<br />

$21.4mill. grant from the Bill &<br />

Melinda Gates Foundation to<br />

enhance poultry production in<br />

Tanzania and Nigeria.<br />

Working closelywith government<br />

and in-country private sector<br />

partners, the WPF will lead a<br />

project that will catalyze atransformation<br />

of rural poultry production<br />

in these two countries. This<br />

initiative will increase poultry<br />

production and productivity<br />

through the access of low-input<br />

dual purpose birds, increase rural<br />

household income, improve household<br />

nutrition and empower<br />

women.<br />

The grant provides WPF with an<br />

opportunity to implement astrategy<br />

that creates access of improved<br />

genetics to the rural<br />

famers, provides technical assistance<br />

and training, and offers<br />

access to markets that may not<br />

have been possible before. The<br />

goal is to impact 2.5 mill. households<br />

across Tanzania and Nigeria<br />

by the end of this four-year initiative.<br />

The project will focus on training<br />

and extension support to build a<br />

sustainable value chain. Another<br />

key component of the project is<br />

the establishment of over 1,500<br />

entrepreneurial enterprises –<br />

primarilyowned and managed by<br />

women –that will supplyhealthy<br />

brooded and vaccinated chicks to<br />

the rural smallholder farmers.<br />

//worldpoultryfoundation.org<br />

EFSA<br />

Chronic wasting disease implies risks for EU<br />

Chronic wasting disease (CWD) is<br />

most likelytoenter the European<br />

Union through the movement of live<br />

cervids that are transported or roam<br />

freelyfrom Norway to Sweden and<br />

Finland.<br />

EFSA’sPanel on Biological Hazards<br />

has identified monitoring activities<br />

and measures to prevent the introduction<br />

and spread of the disease<br />

into and within the EU. The experts<br />

also assessed new evidence on<br />

possible public health risks. CWD is a<br />

highlycontagious and deadlyanimal<br />

brain disease belonging to the group<br />

of diseases known as Transmissible<br />

Spongiform Encephalopathies (TSE).<br />

It was thought to be restricted to<br />

deer, elk and moose in North America<br />

and South Korea, but in April and<br />

May 2016 it was discovered in one<br />

wild reindeer and one wild moose in<br />

Norway.Itwas the first time that the<br />

disease has been detected in Europe<br />

and in reindeer in the wild. EFSA<br />

Reindeer and Moose take CWD into Europe.<br />

Photo: Dieter Schütz/pixelio.de<br />

scientists note that humans may<br />

consume infected meat in areas<br />

where the disease is present.<br />

However, they conclude that there<br />

is no current scientific evidence<br />

that humans can get the disease<br />

through eating meat from infected<br />

animals. EFSA’sopinion proposes a<br />

three-year monitoring system<br />

across eight countries to detect if<br />

US President Donald J. Trump<br />

signed an executive order withdrawing<br />

the United States from the<br />

Trans-Pacific Partnership (TPP)<br />

agreement, which was signed by<br />

President Obama as well as the<br />

leaders of eleven other Pacific Rim<br />

nations.<br />

The aim of the agreement was to<br />

lower tariff and other barriers to<br />

trade. President Trump said he<br />

would withdraw from the agreement<br />

altogether, and his executive<br />

order to that effect made good on<br />

that pledge. The order was met<br />

with consternation in most of the<br />

agriculture community, which had<br />

been broadlysupportive of the TPP,<br />

extolling its potential benefits for<br />

US agricultural exports. It was<br />

expected the Trump administration<br />

also may seek changes to the<br />

22-year-old North American Free<br />

Trade Agreement (NAFTA) with<br />

the disease is present. It also provides<br />

risk managers with aset of<br />

possible measures for prevention<br />

and control which aim at reducing<br />

contact between animals, lowering<br />

cervid population densities, and<br />

increasing awareness of the disease.<br />

//www.efsa.europe.eu/en<br />

TPP<br />

Trade agreement canceled by US President<br />

Canada and Mexico. Indications<br />

were the Trump administration was<br />

seeking meetings with the leaders<br />

of those two nations.<br />

The US Meat Export Federation<br />

(USMEF) said the organization<br />

would remain committed to trading<br />

partners in the TPP and NAFTA,<br />

which account for more than 60%<br />

of US red meat exports.<br />

//www.meatinstitute.org

8<br />

Fleischwirtschaft <strong>international</strong> 1_<strong>2017</strong><br />

Business News<br />

CP Foods<br />

Takeover of Bellisio completed<br />

Thailand’sCharoen Pokphand<br />

Foods (CP Foods) has taken over<br />

frozen specialist Bellisio Foods<br />

with a$1.075 bn. deal. CP Foods’<br />

huge deal to take over Bellisio<br />

Foods marks its first acquisition of<br />

aUSfirm.<br />

The transaction brings together<br />

one of America’smost dynamic<br />

frozen food firms with the might of<br />

Thailand’sdominant verticallyintegrated<br />

meat business. Bellisio<br />

manufactures and distributes<br />

single-serve frozen entrées under<br />

anumber of brands, such as Michelina’s,<br />

Atkins, Boston Market,<br />

Chili’s, EatWell and Eat. Bellisio also<br />

produces arange of private-label<br />

and foodservice items. In business<br />

for over 25 years, Minneapolis-based Bellisio<br />

Foods manufactures more than 400 frozen food<br />

items and CP Foods said the well-known brands<br />

would enhance its US operation. CP Foods<br />

acquired all outstanding interest in Bellisio<br />

Financial expert called Charoen Pokphand Foods (CP Foods) the<br />

ideal partner for Bellisio Foods. Photo: Bellisio Foods<br />

from US-based private equity firm Centre Partners.<br />

Bruce Pollack, managing partner at the<br />

investment firm, described CP Foods as the<br />

ideal partner for Bellisio.<br />

//www.cpfworldwide.com<br />

Atria<br />

Company’s pork exports to China will start<br />

Atria Finland Ltd has signed the contract of the<br />

first pork delivery to China. Atria supplies frozen<br />

pork products to its Chinese customers around<br />

3mill. kg during the year <strong>2017</strong>.<br />

The delivery includes all types of products<br />

derived from apig carcass. The first delivery to<br />

the customer will be realized in earlyMay.The<br />

company has reached an agreement with their<br />

Danish Crown<br />

Acquiring Teterower Fleisch<br />

Danish Crown is acquiring the German cattle<br />

slaughterhouse Teterower Fleisch to become the<br />

fifth-largest cattle slaughterhouse in Germany.<br />

The purchase price will not be disclosed.<br />

Teterower Fleisch in Mecklenburg-Vorpommern,<br />

afederal state in Germany, has an annual turnover<br />

of 150mill. €, slaughters 110000 cattle annually,<br />

has 187employees and is privatelyowned. Close to<br />

20% of the cattle slaughtered by Teterower Fleisch<br />

are organic. The company also slaughters pigs and<br />

lambs, but mainlycattle. Danish Crown’sbeef<br />

division also has significant slaughtering activities<br />

in the north German city of Husum, where almost<br />

90000 animals are slaughtered annually. Following<br />

the takeover of Teterower Fleisch, the plan is to<br />

run Danish Crown Beefs existing slaughterhouse<br />

activities in Husum and the newlyacquired business<br />

as an integrated unit, focusing on specialization<br />

and on utilizing synergies in the <strong>international</strong><br />

Chinese customers of the first deliveries of<br />

meat to China. Negotiations with customers are<br />

progressing well and the first large-scale<br />

delivery is evaluated as apromising start to<br />

long-term cooperation, said Juha Gröhn Atria<br />

Group's CEO.<br />

//www.atria.com<br />

markets that both companies serve. The agreement<br />

on the acquisition of Teterower Fleisch has<br />

been reported to the German federal cartel office<br />

(the Bundeskartellamt), which must approve the<br />

takeover.<br />

//www.danishcrown.com<br />

The Danish company will become the<br />

fifth-largest cattle slaughterhouse in<br />

Germany.<br />

Viskase<br />

Company acquires<br />

Walsroder Casings Group<br />

Viskase Companies, Inc., announced that it has<br />

signed adefinitive agreement to acquire 100% of<br />

the equity interests in Walsroder Casings Group<br />

(including its subsidiaries Walsroder Casings<br />

GmbH and Walsroder Casings Polska Sp. zo.o.),<br />

headquartered in Bomlitz, Germany, from Quota<br />

International GmbH and CT Holding GmbH. The<br />

acquisition also includes the casing business<br />

assets of Poly-clip System, LLC, Walsroder’s US<br />

distributor and an affiliate of Quota, located in<br />

Mundelein, Illinois.<br />

After several decades, Walsroder is widely<br />

recognized by the processed meat industry for<br />

its high quality product line of fibrous and plastic<br />

casings and innovative manufacturing technology.The<br />

company’sproducts are distributed<br />

throughout the world. There are manufacturing<br />

and distribution facilities in Germany and Poland,<br />

and distribution in the US through Poly-clip.<br />

For the year ending 2016,Walsroder’s total<br />

turnover is approximately$60 mill. This acquisition<br />

will strengthen and complement Viskase’s<br />

broad product line of fibrous and plastic casings<br />

and provide additional production capacity for all<br />

of Viskase’skey markets. Final closing of the<br />

acquisition is expected by mid-January, once<br />

regulatory requirements are completed. Transition<br />

of the Poly-clip casings finishing and distribution<br />

business in the US to Viskase will occur<br />

over the next few months to ensure that all<br />

customer needs will continue to be satisfied.<br />

//Viskase.com<br />

Miratorg<br />

Increases in food<br />

production recorded<br />

Miratorg Zapad, Russia’slargest producer of<br />

frozen semi-finished meat products and readyto-eat<br />

meals reports a27% increase in production<br />

to over 43000 tin2016.<br />

The plant with atotal capacity of 80000 tof<br />

products per year produces more than 150<br />

different types of products and is akey supplier<br />

for <strong>international</strong> restaurant chains in Russia.<br />

The enterprise is also certified for supplyinto<br />

foreign markets.<br />

The company’sstrategy focuses on consistent<br />

growth of production volumes and expansion<br />

of product lines to satisfy the demand for<br />

high-quality meat semi-finished products and<br />

ready-to-eat meals both for Horeca sector and<br />

the retail market. Miratorg additionallyinvested<br />

more than 1bnrubles in increase of the enterprise<br />

capacity and the installation of new hightech<br />

lines that allow manufacturing of products<br />

unique for the Russian market. In <strong>2017</strong> the<br />

enterprise will continue to increase production<br />

and start new types of semi-finished products.<br />

//www.miratorg.ru/en

Fleischwirtschaft <strong>international</strong> 1_<strong>2017</strong><br />

9<br />

Frontmatec<br />

Five specialists joined their forces<br />

Business News<br />

During the fall of 2016 and beginning<br />

of <strong>2017</strong>,the Danish private<br />

equity company Axcel acquired<br />

five companies –all regarded as<br />

leaders within their respective<br />

fields: Attec, Itec, Carometec, SFK<br />

Leblanc and Frontmatec. As from<br />

31 January <strong>2017</strong>,the Group and<br />

the various entities will conduct<br />

their business under the name<br />

Frontmatec.<br />

The goal is to create aleading<br />

global supplier of equipment,<br />

solutions and software for <strong>international</strong><br />

food companies. The integration<br />

of the companies is well<br />

under way the companies are<br />

united under the name Frontmatec,<br />

under the leadership of a<br />

newlyappointed Executive Team.<br />

The new team of Executive<br />

Directors to head the Frontmatec<br />

Group is: Henrik Andersen as CEO,<br />

Lars Hansen as COO and Henrik<br />

Alifas Nielsen as CFO. He has<br />

been heading the European<br />

organization of the<br />

combined Frontmatec<br />

Group for the<br />

past three. Prior to<br />

this, he has been CEO<br />

of Carometec, a<br />

company with an<br />

enviable development,<br />

and considered<br />

as atrue innovator<br />

in its field. He<br />

has extensive experience<br />

in the food<br />

industry and is highly<br />

respected for his<br />

commitment. He also<br />

has astrong commercial<br />

and technical background.<br />

Starting in June <strong>2017</strong>,Lars<br />

Hansen will join the team as Chief<br />

Operating Officer.Heiscurrently<br />

VP SupplyChain/Operations at<br />

Assa Abloy Entrance Systems and<br />

is highlyexperienced in aglobal<br />

manufacturing footprint.<br />

Frontmatec is the name for the new Group after Attec, Itec, Carometec, Frontmatec and SFK<br />

Leblanc have joined forces.<br />

Henrik Alifas Nielsen, currently<br />

CFO at SFK Leblanc, will continue<br />

as CFO for the new Group.<br />

The implementation of the<br />

Frontmatec name as the new<br />

corporate brand starts as of 31<br />

January <strong>2017</strong>.The transition from<br />

current brands to Frontmatec will<br />

happen graduallyduring <strong>2017</strong>,with<br />

no immediate changes affecting<br />

existing business relationships.<br />

Though changing the company<br />

names to one united corporate<br />

brand, ITEC will remain as acategory<br />

brand under Frontmatec for<br />

hygiene equipment and solutions.<br />

//www.merger.frontmatec.com<br />

Smithfield<br />

Progress in sow keeping<br />

Smithfield Foods, Inc. reported that<br />

87% of pregnant sows on companyowned<br />

farms have been transitioned<br />

to group housing systems, a<br />

6% increase over 2015.Asplanned,<br />

all company-owned farms in the<br />

U.S. are expected to be fullyconverted<br />

by <strong>2017</strong>.Actuallynearlynine<br />

out of every ten of their pregnant<br />

sows are living in group housing.<br />

The change has cost several hundred<br />

mill. dollars, and on many of<br />

the farms, the transition process<br />

led to additional construction work,<br />

equipment and system upgrades<br />

and the development of new feeding<br />

and watering systems. Beyond<br />

efforts at company-owned farms,<br />

the company previouslyannounced<br />

it expects all U.S. contract growers<br />

to transition to group housing by<br />

2022. It's hog production operations<br />

in Poland (AgriPlus) and Romania<br />

(Smithfield Ferme) fullyconverted to<br />

group housing facilities years ago.<br />

Other <strong>international</strong> hog operations,are<br />

expected to convert to<br />

group housing by 2022.<br />

//www.smithfieldfoods.com<br />

Sanderson Farms<br />

New facility opened<br />

Sanderson Farms opened anew<br />

$155mill. processing plant and<br />

wastewater treatment facility in<br />

St. Pauls, N.C. This new 180,000-<br />

square-foot plant will accompany<br />

the existing 65,000-square-foot<br />

hatchery located in Lumberton,<br />

N.C., as well as afeed mill in<br />

Kinston, N.C. The facility features<br />

the latest technology in the poultry<br />

industry, including food safety,<br />

employee welfare and environmental<br />

conservation. The stateof-the-art<br />

poultry complex will be<br />

able to process 1.25 mill. birds per<br />

week and will sell approximately<br />

500 mill. pounds of dressed poultry<br />

meat annually.<br />

//www.sandersonfarms.com

10<br />

Fleischwirtschaft <strong>international</strong> 1_<strong>2017</strong><br />

Business News<br />

Allen Harim<br />

Two personal changes announced<br />

MRI<br />

Institute appointed<br />

new leader<br />

Simmons<br />

Jackson becomes president<br />

and chief operating officer<br />

Photos: Allen Harim<br />

Photo: MRI<br />

Photo: Simmons<br />

Allen Harim, aleading producer and<br />

processor of chicken on Delmarva,<br />

has named veteran communications<br />

expert Catherine M. Bassett<br />

as the new Director of Public Relations<br />

to help share positive news<br />

about the company and oversee<br />

community relations. Also they<br />

hired Harry L. Tillman as afood<br />

industry sales management professional<br />

to oversee business development<br />

for the company.<br />

Bassett began her career in Salisbury<br />

as anewspaper reporter for<br />

The DailyTimes in 1989. She started<br />

her own public relations company in<br />

2009, and has worked with arange<br />

of clients including Delmarva<br />

Power, the Ocean City Air Show,<br />

Maryland Capital Enterprises and<br />

the Delmarva Zoological Society.<br />

Tillman joined Allen Harim in mid-<br />

January as Senior Manager of Business<br />

Development. He has spent<br />

the past 20 years as asales operations<br />

and strategy executive with a<br />

deep background in high quality<br />

value added and retail businesses.<br />

//www.allenharimllc.com<br />

Hormel Foods<br />

Leadership hire announced<br />

Hormel Foods Corporation announced<br />

the appointment of Janet Hogan as<br />

vice president, human resources,<br />

effective 17 January <strong>2017</strong>.<br />

Hogan assumes responsibility for<br />

leading the global HR function at the<br />

company.Her responsibilities will<br />

include building and executing<br />

world-class strategies for talent<br />

development, employee engagement,<br />

total rewards and labor relations.<br />

Most recently, she has led<br />

global human resource organizations<br />

including ProQuest and OshKosh<br />

Corporation. Prior to her work at<br />

these companies, Hogan served as<br />

the vice president of human resources<br />

for five years at Harsco<br />

Corporation and spent almost 20<br />

years at Monsanto Company.<br />

//www.hormelfoods.com<br />

Professor Dr.Pablo Steinberg,<br />

Director of the Institute for Food<br />

Toxicology and Analytical Chemistry<br />

at the University of Veterinary<br />

Medicine Hannover, has been appointed<br />

President of the Max Rubner<br />

Institute by the Federal Ministry<br />

of Food and Agriculture.<br />

Professor Steinberg studied biochemistry,<br />

taking his doctorate in<br />

this field at the University of Buenos<br />

Aires. He has aHabilitation in toxicology<br />

from Johannes Gutenberg<br />

University Mainz and held various<br />

positions there. In 1998, he was<br />

appointed to the Chair of Food<br />

Toxicology in the Institute of Nutritional<br />

Science at the University of<br />

Potsdam, becoming Executive<br />

Director of the Institute of Nutritional<br />

Science in 2002. This was<br />

followed in 2008 by the Professorship<br />

in Food Toxicology and Replacement/Complementary<br />

Methods<br />

to Animal Testing at the University<br />

of Veterinary Medicine Hannover.Concurrently,<br />

Professor<br />

Steinberg became the university’s<br />

Director of the Institute for Food<br />

Toxicology and Analytical Chemistry.<br />

//www.mri.bund.de<br />

Simmons Prepared Foods, Inc.,<br />

announced that David Jackson will<br />

succeed Gary Murphy as President<br />

and Chief Operating Officer of Simmons<br />

Prepared Foods, reporting<br />

directlytoToddSimmons, Chief<br />

Executive Officer of Simmons Foods,<br />

Inc. &Affiliates.<br />

David was succeeded as President<br />

and Chief Operating Officer of Simmons<br />

Pet Food by Jason Godsey in<br />

October.Murphy recentlycelebrated<br />

25 years with Simmons, after almost<br />

two decades with ConAgra Foods.<br />

As President and COO of Simmons<br />

Prepared Foods, he led consistent<br />

growth, including multiple recordsetting<br />

years of performance.<br />

Jackson earned aBachelor of Science<br />

degree in Administrative<br />

Management from the University of<br />

Arkansas and aMaster of Business<br />

Administration degree from the<br />

University of Texas at Austin. He<br />

recentlycelebrated 25 years at<br />

Simmons. Jackson spent most of his<br />

earlycareer in the poultry business<br />

before leading Simmons Pet Food as<br />

President and Chief Operating<br />

Officer for the last four years.<br />

//www.simmonsfoods.com<br />

BRF<br />

Enterprise reached Tier 2onfarm animal welfare<br />

BRF, one of the largest food companies in the<br />

world, has advanced to Tier 2from Tier 3inthe<br />

annual report of the Business Benchmark on<br />

Farm Animal Welfare (BBFAW). This improvement<br />

recognises BRF’scommitment to animal welfare,<br />

as reflected in the company’spolicies and<br />

practices.<br />

BRF’sclimb in the BBFAWranking follows<br />

years of continuous investment in animal welfare,<br />

during which appropriate systems were<br />

adopted and relevant actions intensified.<br />

Alongside this, data and information concerning<br />

animal welfare on BRF’swebsite have been<br />

broadened and made easier to access.<br />

In its report, BBFAWacknowledges the established<br />

internal processes BRF has put in<br />

place to manage compliance and best practices<br />

concerning animal welfare commitments.<br />

It also draws attention to BRF’spartnership with<br />

World Animal Protection (WAP), which is working<br />

to better animal welfare practices in the supply<br />

and production chains. One goal towards which<br />

BRF is working, with the assistance of WAP, is<br />

the transitioning of 100% of sows to group<br />

gestation systems by 2026.<br />

Amongst the examples of BRF’sanimal welfare<br />

engagement in 2016 was the implementation<br />

of environmental enrichment instruments<br />

in more than 200 aviaries, which encourage<br />

natural animal behaviour and lead to stress<br />

reduction. With animal welfare being acore<br />

value at BRF, ongoing investment is being<br />

made in environmental enrichment studies,<br />

with aview to improving conditions for animal<br />

breeding.<br />

Now in its fifth year, the BBFAWpublishes an<br />

annual review of 99 global food companies,<br />

assessing their quality of animal welfare management,<br />

as well as their disclosure of animal<br />

welfare policies and practice.<br />

//www.brf-global.com

Fleischwirtschaft <strong>international</strong> 1_<strong>2017</strong><br />

11<br />

Foreign Markets<br />

France<br />

Welfare monitoring in<br />

slaughterhouses<br />

China<br />

Buffalo meat from India finally accepted<br />

France's national assembly<br />

adopted draft legislation that could<br />

see all livestock slaughtering<br />

recorded on video from next year to<br />

enforce animal welfare regulations.<br />

This was reported by Irish Farmers<br />

Journal. “From 1January 2018,<br />

pending trials to evaluate feasibility<br />

and implementation conditions,<br />

cameras will be installed in all<br />

lairage, housing, restraining, stunning,<br />

slaughtering and killing areas,”<br />

the bill adopted by French<br />

deputies. It adds that footage will<br />

be kept for up to one month for<br />

inspection and may be used for<br />

staff training. The legislation also<br />

asks the government to produce<br />

reports regarding potential bans on<br />

the slaughter of female livestock in<br />

the last third of pregnancy and the<br />

use of CO2 asphyxiation to slaughter<br />

pigs. The bill must now go to the<br />

senate before final adoption.<br />

//www.farmersjournal.ie<br />

China has finallyagreed to remove<br />

restrictions on beef export<br />

from India. Atop official in the<br />

Commerce ministry said Beijing,<br />

which has sent quality inspection<br />

team to India earlier to examine<br />

buffalo meat facilities, has<br />

cleared 14 abattoirs for importing<br />

meat from here. Making China<br />

agree for direct import of bovine<br />

meat from India has been atop<br />

priority for Indian government<br />

since Narendra Modi government<br />

took over in May 2014.This was<br />

reported by the Indian Express.<br />

Officials said China has been<br />

buying Indian beef from Vietnam<br />

in the last few years and New<br />

Delhi was not getting any advantages<br />

in terms of changing the<br />

bilateral trade. Sources said<br />

Ministry hopes that the export of<br />

beef would make aconsiderable<br />

change in the bilateral trade<br />

deficit. India’strade deficit with<br />

China increased to $52.69 bn. in<br />

With the world’slargest population, China’sconsumption of meat has been<br />

rising. Photo: Janine Grab-Bollinger<br />

2015-16 from $48.48 bn. in the<br />

previous financial year.<br />

China signed an MoU for importing<br />

bovine meat from India in<br />

2013 during Premier Li Keqiang’s<br />

visit, but has not lifted the restrictions<br />

yet. The country has<br />

exported 13,14,158.05 MT of<br />

buffalo meat products to the<br />

world for the worth of<br />

Rs 2,6681.56 crore and the main<br />

export destinations are Malaysia,<br />

Egypt, Saudi Arabia and Iraq<br />

apart from Vietnam.<br />

//Indianexpress.com

12<br />

Fleischwirtschaft <strong>international</strong> 1_<strong>2017</strong><br />

Foreign Markets<br />

Hong Kong<br />

Country bans imports<br />

Singapore<br />

Trade potential discussed<br />

Regarding to the News Agency<br />

Xinhua, Hong Kong authorities<br />

announced that they have banned<br />

the import of poultry meat and<br />

products from Chile's Quilpue and<br />

Romania. This was reported by<br />

Global Times.<br />

The Center for Food Safety (CFS)<br />

of Hong Kong's Food and Environmental<br />

Hygiene Department said<br />

that in view of anotification from<br />

the Chilean authorities about an<br />

Highlypathogenic H5N8 avian<br />

influenzainRomania was one<br />

reason for the ban. Photo: Peter<br />

Smola /pixelio.de<br />

outbreak of low pathogenic avian<br />

influenzaH7inQuilpue, Chile, it<br />

has banned the import of poultry<br />

meat and products (including<br />

poultry eggs) from the above area<br />

with immediate effect. In addition,<br />

in view of anotification from the<br />

World Organization for Animal<br />

Health (OIE) about an outbreak of<br />

highlypathogenic H5N8 avian<br />

influenzainRomania, the CFS has<br />

banned the import of poultry meat<br />

and products (including poultry<br />

eggs) from Romania with immediate<br />

effect to protect public health<br />

in Hong Kong.<br />

ACFS spokesman said that in<br />

the first eleven months of last<br />

year, Hong Kong imported about<br />

750 toffrozen poultry meat from<br />

Chile. Since Hong Kong has not<br />

established any protocol with<br />

Romania for imports of poultry<br />

meat and eggs, there is no import<br />

of such commodities from Romania.<br />

//www.globaltimes.cn<br />

Leaders from Russia and Singapore<br />

are examining ways the two<br />

countries can develop import<br />

and export relations between<br />

the two countries concerning<br />

the trade of poultry and pork<br />

products.<br />

The Agri-food and Veterinary<br />

Authority (AVA)ofthe Republic of<br />

Singapore recentlyaddressed<br />

Rosselkhoznadzor, Russia’s<br />

Federal Service for Veterinary<br />

and Phytosanitary Surveillance in<br />

aletter stating its commitment<br />

to start targeted activities aimed<br />

at the development of trade<br />

relations between Singapore and<br />

Russia.<br />

Specifically, AVA was referring<br />

to the implementation of mutual<br />

inspections of the Russian and<br />

Singaporean animal product<br />

manufacturing establishments<br />

that were scheduled during the<br />

negotiations between the<br />

Rosselkhoznadzor and AVA held<br />

late in November 2016.Thus the<br />

Singaporean party expressed<br />

intention to hold a10-day inspection<br />

of four Russian pork<br />

and poultry plants. In order to<br />

optimize the Singaporean experts’<br />

activities the AVA requested<br />

the Russian agency to<br />

provide supplementary data on<br />

measures taken to control diseases<br />

such as African swine<br />

fever (ASF), foot-and-mouth<br />

disease (FMD) and avian influenzainRussia.<br />

The Singaporean party also<br />

invited the Russian inspectors to<br />

visit animal product manufacturing<br />

establishments interested in<br />

exports to Russia in February<br />

2016,and asked the agency to<br />

provide veterinary and sanitary<br />

requirements for imported meat<br />

and meat products.<br />

The Rosselkhoznadzor stated<br />

it will further take all necessary<br />

measures to start exports of the<br />

Russian animal products to<br />

Singapore.<br />

//www.ava.gov.sg<br />

IPPE<br />

More than 31,000 attendees visited the fair<br />

The <strong>2017</strong> International Production<br />

&Processing Expo (IPPE), taken<br />

place from 31 January to 2February,<br />

had more than 31,000 poultry,<br />

meat and feed industry leader<br />

attendees from all over the world.<br />

In addition, the show had more<br />

than 533,000 of net square feet of<br />

exhibit space and 1,275 exhibitors.<br />

Sponsored by the U.S.<br />

Poultry &Egg Association, American<br />

Feed Industry Association<br />

and North American Meat Institute,<br />

IPPE is the world's largest<br />

annual feed, meat and poultry<br />

industry event of its kind. This<br />

year’s tremendous exhibit floor<br />

and attendee and exhibitor numbers<br />

are acompliment to IPPE’s<br />

unmatched education programs,<br />

ample networking opportunities<br />

and diverse exhibits.<br />

The excitement and energy<br />

displayed by this year’s attendees<br />

and exhibitors will continue<br />

to safeguard the success and<br />

growth of future IPPEs, the three<br />

organizations said. The central<br />

attraction is the large exhibit<br />

floor.Exhibitors demonstrated<br />

the most current innovations in<br />

equipment, supplies and services<br />

used by industry firms in the<br />

production and processing of<br />

meat, poultry, eggs and feed<br />

products. Numerous companies<br />

highlighted their new products at<br />

the trade show, with all phases<br />

of the feed, meat and poultry<br />

industry represented, from live<br />

production and processing to<br />

further processing and packaging.<br />

The wide variety of educational<br />

programs complemented the<br />

exhibits by keeping industry<br />

management informed on the<br />

latest issues and events. This<br />

year’s educational line-up featured<br />

25 programs, ranging from a<br />

conference on Listeria monocytogenes<br />

prevention and control, to<br />

aprogram on FSMA hazard analysis<br />

training, to aprogram on<br />

whole genome sequencing and<br />

food safety implications.<br />

The wide variety of educational programs completed the exhibitor range.<br />

Photo: IPPE<br />

Other featured events included<br />

the International Poultry Scientific<br />

Forum, Beef 101 Workshop, Pet<br />

Food Conference, TECHTalks<br />

program, Event Zone activities<br />

and publisher-sponsored pro-<br />

grams, all of which have made the<br />

<strong>2017</strong> IPPE the foremost annual<br />

protein and feed event in the<br />

world.<br />

//www.ippexpo.com

14<br />

Fleischwirtschaft <strong>international</strong> 1_<strong>2017</strong><br />

Poultry<br />

Stricter standards and controls<br />

Use of antibiotics in the Chinese poultry industry and alternative solutions<br />

In China the significance of the<br />

production and the consumption of<br />

poultry meat is very high. The total<br />

output of poultry meat was more<br />

than 14 mill. tin2013; the percapita<br />

consumption was more than 10 kg.<br />

In this way poultry meat is the<br />

second biggest consumer good after<br />

pork (LI WENRUI,2014). This is<br />

associated with apoultry production<br />

becoming more and more intensive.<br />

Particularly with regard to the<br />

preservation of animal health during<br />

the production time the use of<br />

antibiotics seems to be unavoidable.<br />

By Wang Wei, FriedhelmJaeger,<br />

Catharina Hölscher,<br />

HouBoand Ji Lili<br />

According to the official Chinese<br />

statistics the consumption rate<br />

of antibiotics is about 200,000 t.<br />

This is nearly the half amount wold<br />

wide. Theamount of 97,000 tof<br />

them are used in animal farming<br />

systems. This is about 48.5% of the<br />

total amount (LI ZHEN,2009). But<br />

anyimproper practice, especially an<br />

excessive practice in poultry farming,<br />

must appreciated as critically.<br />

Also the importance of the influence<br />

on human health is increasing<br />

today.This item considers the use<br />

of antibiotics in poultry farming<br />

and the correlated problems in<br />

China. Thepossibility and chance<br />

for poultry farming without the use<br />

of antibiotics are discussed.<br />

Use of antibiotics in poultry<br />

production in the past<br />

Since in 1929 the English scholar<br />

Fleming found the Penicillin,<br />

antibiotics are actually the most<br />

used and most important<br />

medicines against infectious diseases.<br />

So theyare regarded as the<br />

biggest discovery in the 20th century.Thus<br />

manyinfectious diseases<br />

could be cured andthe expectancy<br />

of human life could be increased<br />

(HUANG FUBING,2012). Also for<br />

animal farming systems the use of<br />

antibiotics has been amain factor<br />

to prevent and cure epidemic diseases.<br />

In 1946 MOORE et al. reported<br />

already about the performanceenhancing<br />

effectofantibiotics.<br />

They verified, that adaily dose of<br />

antibiotics increases the weight gain<br />

notable (MOORE,P., A. EVENSION,T.<br />

LUCKEY,etal., 1946). Other studies<br />

showed, that as aresult of atargeted<br />

and efficient use of antibiotics<br />

chicklets grow faster,hens lay more<br />

eggs and the loss ratedecrease. In<br />

the development of the last 60 years<br />

over 20 different antibiotics are<br />

used in poultry farming. In 2005 a<br />

market report of the International<br />

Society for Animal Hygiene suggested,<br />

that with an abandonment<br />

of antibiotics in the same time the<br />

In recent years, poultry<br />

farming in China was<br />

intensified significantly.<br />

production of poultry has to increase<br />

about 25% to cover the requirement<br />

(LU XIN,2008).<br />

Butalready since the use of<br />

antibiotics has been started the<br />

apprehension about negative consequences<br />

has been present.BARNES<br />

(1958) and ELLIOTT (1959) reported<br />

about bacterial resistances related<br />

to Tetracycline. In 2002 LI KAINAN<br />

showed that already in the 80’s<br />

pathogenic bacteria have been<br />

resistant to manyantibiotics.In<br />

1997 the world health organisation<br />

requested the governments of all<br />

countries to reduce the amount of<br />

antibiotics. As areaction the regulations<br />

and the supervision of the use<br />

of antibiotics has been intensified<br />

(LI KAINIAN,2005).<br />

Current situation<br />

Theuse of antibiotics in countries<br />

of Europeand North America has<br />

along history and is widely used.<br />

Because of the developing research<br />

and the awkward growth of<br />

bacterial resistances the common<br />

use of antibiotics is decreasing. In<br />

the EU-Countries several antibiotics<br />

are prohibited because of<br />

their growth-enhancing influence.<br />

In 2011 the European Commission<br />

pronounced afive year action plan<br />

for defending bacterial resistances.<br />

Thetarget of this plan where the<br />

appropriated and restricteduse of<br />

antibiotics in human and animal<br />

medicine, and also the optimised<br />

supervision of animal used antibiotics.<br />

In the USA the FDAin1977<br />

allowed the use of Penicillin, Aureomycin<br />

and Oxytetracyclin in animal<br />

feeding systems. In 1996 a<br />

supervision and audit system for<br />

bacterial resistances was established<br />

by the government.This was<br />

the basis to reacttothe appearance<br />

of bacterial resistances by prohibiting<br />

targeted antibiotics. On this way<br />

in October2000 twoquinolone<br />

antibiotics were prohibited for<br />

using in animal feed. In 2014 the<br />

FDAprohibited the use of antibiotics<br />

as preventive agents. In this<br />

way the health of human and animals<br />

should be savedsustainable.<br />

Also in Japan and Australia antibiotics<br />

are often used in animal

Fleischwirtschaft <strong>international</strong> 1_<strong>2017</strong><br />

15<br />

Poultry<br />

farming systems. Although in this<br />

countries the use of antibiotics has<br />

begun lately,the supervision by the<br />

authority is much stricter. Australia<br />

also has established an entire systemtodetectand<br />

control potential<br />

residues in foodstuff.<br />

In Japan the central government<br />

has founded 12 commissions and<br />

several other entities to approve and<br />

supervise the use of medicines. In<br />

2002 the Japanese government<br />

prohibited the use of Penicillin,<br />

Streptomycin, Salinomycin and<br />

Monensin in animal feeds.<br />

In the 70’softhe 20th century<br />

the use of antibiotics in China has<br />

begun step by step. Butthe quantity<br />

has increased immediately.<br />

According to several studies the<br />

cumulative production of antibiotics<br />

is about 200,000 t. This is<br />

nearly the half amount wold wide.<br />

97,000 tofthem are used in<br />

animal farming systems (ZHANG<br />

XIAOYING,2015).<br />

To ensure the consumers highest<br />

defence, in 1999 the Chinese<br />

government pronounced standards<br />

for residue levels in animal<br />

source foods. These included 109<br />

medicines. Thestandards are<br />

revised in 2001and 2002. Several<br />

antibiotics were prohibited to use<br />

in feeding systems. In 2001withdrawal-periods<br />

for 20 antibiotics<br />

were defined. Alist with 57 antibiotics<br />

was created. This list<br />

animal species, contained indication,<br />

withdrawal-periodand advises<br />

for each medicine. In 2005<br />

Especiallyinrural areas measures to ensure food safety differ by far from <strong>international</strong> standards.<br />

the further use of antibiotics were<br />

prohibited.<br />

TheChinese government improves<br />

permanent the legislation<br />

and standards about use of<br />

medicine, especially antibiotics.<br />

Butthere is an increasing demand<br />

for poultry products. As a<br />

consequence the improper use of<br />

antibiotics is still an existing<br />

problem.<br />

Abundant appearing problems<br />

In the Chinese industrial poultry<br />

farming the standard of the stockman’s<br />

education is in general low.<br />

There is insufficient knowledge<br />

about breeding, improper use of<br />

antibiotics and the official rules.<br />

That is the reason whyantibiotics<br />

are often used inefficiently.Breeders<br />

couldn’t recognise the right<br />

medical indication for using

16<br />

Fleischwirtschaft <strong>international</strong> 1_<strong>2017</strong><br />

Poultry<br />

Stricter standards and controls<br />

Some time ago Chinese<br />

researchers have started<br />

to provide the scientific<br />

basis for reducing the<br />

use of antibiotics in<br />

poultry production.<br />

medicine. Also reports about use<br />

of illegal antibiotics and the abusive<br />

use of antibiotics are existing<br />

(ZHOU MINGLI,2013).<br />

Inthe year 2004 China pronounced<br />

aregulation about the<br />

administration of medicines. This<br />

includes several reserve antibiotics<br />

for human medicine. So the<br />

use of these antibiotics is prohibited<br />

in animals. Aproblem for<br />

stockmen are the insufficient<br />

broad spectrum efficacyofthe<br />

most antibiotics with are allowed<br />

to use for animals. Thus many<br />

stockmen use the prohibited<br />

antibiotics despiteoftheir deficient<br />

knowledge. In this way they<br />

are impairing the common problems<br />

(YAN KEMIN, REN YINXIAO,<br />

2008).<br />

Theduration of the withdrawal<br />

periodafter use of antibiotic is<br />

one of the main factors for elimination<br />

of residues. Forseveral<br />

medicine the withdrawal period<br />

is clearly defined. Butthere are<br />

still pig fattening systems which<br />

are breaking the official withdrawal<br />

period. According to an<br />

American study 76% of antibiotic<br />

residues are resulting from unregarded<br />

withdrawal periods, 18%<br />

from feed contamination and 6%<br />

from an improper use of antibiotics<br />

(XI HUIPING,2007).<br />

Hazard by an improper<br />

use of antibiotics<br />

According to different studies<br />

bacterial resistances could be<br />

grafted from animals trough the<br />

environment and the food chain<br />

to human. In this way the bacterial<br />

resistances in human organisms<br />

are increasing. Theresult of<br />

an improper use of antibiotics<br />

could be consumption residues in<br />

poultry meat.These residues<br />

could be directly or indirectly<br />

perniciously for the human organism.<br />

Each year there are thousands<br />

of lives claimed by infectious<br />

diseases with resistant<br />

microorganisms. Other risks<br />

could be genomic mutations,<br />

malformations, cancer.Chloramphenicol<br />

and Streptomycin could<br />

be causes for these dangerous<br />

effects (ZHOU SHUPING,2012).<br />

After the application to poultry,<br />

some antibiotics could be excreted<br />

unalterably.Some antibiotics like<br />

Steptomycin have aresilient<br />

structure. So theycouldn’t be<br />

biodegraded easily. Astudy by<br />

ZHANG HUIMIN et al. (2008) about<br />

residues of antibiotic in the north<br />

territory of the province Zhejiang<br />

showed that on the residues of<br />

Terramycin, Tetracyclin and Aureomycin<br />

were 5.172, 0.553 and<br />

0.588 mg/kg among the limit<br />

value after liquid manure had<br />

applied (ZHANG HUIMING, ZHANG<br />

MINGKUI, GU GUOPING,2008).<br />

Every improper use of antibiotics<br />

is also ahigh risk for poultry<br />

farming itself.Because of the<br />

abundant use of several antibiotics,<br />

bacterial resistances increase.<br />

In this way some infectious<br />

diseases couldn’t be cured<br />

anymore. Therelevance Escherichia<br />

coli, Staphylococcus ,<br />

Salmonella ssp. as disease agents<br />

could increase again. In August<br />

1996 the European Union had<br />

stopped all imports of Chinese<br />

farm products from poultry and<br />

other animals, because the value<br />

limits of antibiotic residues had<br />

been exceeded. In 1997 and 1998<br />

experts were sent to Chinato<br />

control the poultry farming systems.<br />

Points of criticism had been<br />

the management of control and<br />

therapy of diseases and the detection<br />

of antibiotic residues. As a<br />

reaction the embargo has been<br />

continued (FU MINGCHUN, XI<br />

HUIPING, LIU YANZHAO,2008).<br />

Poultry farming<br />

without antibiotics<br />

Because of all the aspects about<br />

the use of antibiotics the effort to a<br />

poultry farming without use of<br />

antibiotics becomes more and<br />

more important.The first efforts<br />

were observed in Europe. Today<br />

there are main strategies for a<br />

poultry farming systems without<br />

use of antibiotics in the USA,<br />

Germanyand Japan. Forexample<br />

the “Kikok”-Production in Germanyisone<br />

of these strategies<br />

with ahigh hygienically standard.<br />

In Japan broiler farming systems<br />

use Chinese healing plants instead<br />

of antibiotics. These chicks<br />

are also mentioned as “Hanfang<br />

Chicks”(DONG SHANGYUN,2004).<br />

At the moment also in China<br />

there is ahigh progress in alternative<br />

methods and technologies.<br />

Themain focus is on probiotics,<br />

antimicrobial peptides, healing<br />

plants and enzyme compounds.<br />

Themethodwithhigh hygienic<br />

standards is based on astrictly<br />

controlled environment.This<br />

begins already with the chicklets.<br />

They are selectedand reared also<br />

with ahigh hygienic standard. In<br />

this way the infiltration with<br />

pathogens and their distribution<br />

should be prevented. Thetemperature,<br />

feed and drinking water are<br />

strictly controlled. DONG<br />

SHANGYUN et al. (2004) made a<br />

comparative study about models<br />

of poultry farming without antibiotics<br />

(WANGWEI, JI LILI,2016). The<br />

results showed, that with ahigh

Fleischwirtschaft <strong>international</strong> 1_<strong>2017</strong><br />

17<br />

Poultry<br />

quality of chicklets, feed and with a<br />

good husbandry system poultry<br />

farming without antibiotics is<br />

possible. Unfortunately this systemisstill<br />

very expensive and is<br />

currently reserved for only some<br />

biological working farms with<br />

enough funding. At least the high<br />

prevalence of pathogens is another<br />

problem regarding to theimplementation<br />

of this method. Although<br />

in China the interest in<br />

this methodisincreasing.<br />

Chinese healing plants are one<br />

of the important ingredients of the<br />

traditional Chinese medicine.<br />

Added to feed they are able to<br />

replace antibiotics under special<br />

requirements .WANG CHANGKANG<br />

et al. (2008) tried to describe the<br />

influence of the traditional Chinese<br />

medicine to chicken rearing<br />

and carcass quality.The results<br />

showed, that the use of Chinese<br />

healing plants could decrease the<br />

influence of pathogens and increase<br />

and the quality of poultry<br />

meat.WANG JINPING,LIYUQING et<br />

al. (2010,2013) breeded ducks with<br />

asupplement of Garlicin. The<br />

study showed, that Garlicin suppressed<br />

the growth of Escherichia<br />

col in the jejunum and caecum<br />

significantly.Also the loss rate<br />

decreased and the daily gain increased.<br />

Thestudy of SHENG<br />

WEIWU et al. (2012)equally<br />

showed abetter growth of fattening<br />

poultry (Ross-308) with a<br />

supplement of Saccharicterpenin.<br />

YU LIANHONG et al. (2013)used<br />

traditional medicine likeGlauber<br />

salt,Zeolith, Astragalus mongholicus<br />

und garlic together and discovered<br />

how far antibiotics could be<br />

replaced. Anumber of studies<br />

from Chinese scientist clarify,that<br />

antibiotics can be replaced by<br />

Chinese healing plants. Actually<br />

there are some problems. For<br />

example today it isn’t possible to<br />

identify the agent from ahealing<br />

plant which has the main effect<br />

against pathogens. And also there<br />

is not enough data about toxicological<br />

effects. So it’s necessary to<br />

explore these methodmuch more.<br />

Probiotics are also termed as<br />

living microbiological and microeconomical<br />

compounds. They are<br />

applied by drinking water.Important<br />

are also their microbial metabolic<br />

products. They cansuppress<br />

pathogens in the gastro-intestinal<br />

system, produce main organic<br />

acids, decrease the pH-value,<br />

encourage hydrogen peroxide and<br />

encourage antimicrobial effective<br />

agents as Acidophillin. In this way<br />

theyare able to stabilize the enteric<br />

flora (LI DEFA,2009). HE<br />

MINGQING et al. (2002) replaced<br />

antibiotics by microeconomical<br />

compounds like Bacillus 8901for<br />

fattening poultry systems. The<br />

results showed, that the appearance<br />

of diseases decreased about<br />

20%. At the same time the daily<br />

gain increased. Other studies<br />

described similar results. Butin<br />

contrast some studies expounded,<br />

that probiotics actually can’t replaceantibiotics<br />

totally.Although<br />

theywere able to stabilize the<br />

enteric flora, the effectagainst<br />

diseases couldn’t be proven yet<br />

(BALISH,E., R.D.WAGNER,1998).<br />

CHENG ANCHUN et al. (2008)<br />

concluded all the studies about the<br />

use of probiotics. They underlined<br />

apart from the opportunity to<br />

replace antibiotics, the positive<br />

effectofprobiotics for the environment,animal<br />

products and the<br />

reduction of bacterial resistances.<br />

They advised to push the development<br />

of probiotics forward.<br />

Theantimicrobial peptide is a<br />

small molecular peptide, which is<br />

also named Bacteriozin. It is<br />

actual mainly used as asupplement<br />

to feed. Thedifferent peptides<br />

can be graduated in peptides<br />

with origin from mammalians,<br />

amphibians, insects, plants,<br />

viruses and bacteria. They have a

18<br />

Fleischwirtschaft <strong>international</strong> 1_<strong>2017</strong><br />

Poultry<br />

Stricter standards and controls<br />

In the traditional Chinese medicine several plants play an<br />

important role; under certain conditions their effect can<br />

substitute oral antibiotics. Photo: Archive<br />

wide action spectrum against<br />

tumor cells, viruses, protozoa and<br />

bacteria (LEONARD,B.C., V.K.<br />

AFFOLTER,C.L. BEVINS,2012). The<br />

first antimicrobial peptide was<br />

found in 1972. Studies showed the<br />

good inhibition effecttoviruses,<br />

mushrooms, protozoa and a<br />

killing effectagainst microbials,<br />

without genesis of resistances<br />

(ANDRE,2003). CHEN XIAOSHENG<br />

(2005) and HUANG ZIRAN (2006)<br />

replaced antibiotics by antimicrobial<br />

peptides from the silkworm.<br />

Theresults were adecrease of<br />

diseases and an increase of the<br />

poultry’s growth.<br />

Today twelve enzyme compounds<br />

be used in feeds. Their<br />

whole production is approaches<br />

100,000 t. Mainly the enzyme<br />

Phytase is used, because the other<br />

products aren’t readyfor practice<br />

yet.One of the negative factors is<br />

the high price and the low effective<br />

range. Theage of the animals, the<br />

kind of enzymes and the method<br />

of application are influencing<br />

factors for the effect(CHENG<br />

GUYUE,HAO HAIHONG,XIE<br />

SHUYU,WANG XU and YUAN<br />

ZONGHUI,2014). Thechief virtue<br />

is the increase of digestibility.In<br />

this way the multiplying of<br />

pathogens is inhibited indirectly<br />

(RAVINDRAN V. and J.H. SON, 2011).<br />

GU XIANHONG et al. (2000) were<br />

able to verify,that the daily gain of<br />

fattening poultry in the age of 0to<br />

3weeks increased about 25.41%<br />

when theyadded enzyme compounds<br />

to the feed. Thedaily gain<br />

of fattening poultry in the age of 4<br />

to 6weeks increased about 8.34%.<br />

In both groups the feed conversion<br />

ratio could also be increased.<br />

Although these effects are identified,<br />

the action of enzyme compounds<br />

against pathogens isn’t<br />

known as far.The approval is very<br />

low at the moment.Thus also for<br />

this methodit’snecessary to continue<br />

investigation and proving.<br />

Conclusion<br />

Antibiotics are actually one of the<br />

most important medicines to save<br />

the health in animal farming systems<br />

and to content the demand for<br />

poultry meat and other animal<br />

source foods. Butany improper<br />

practice, especially an excessively<br />

practice in poultry farming, must<br />

appreciated as critically.Currently no<br />

alternatives for the use of antibiotics,<br />

especially to replace the antibiotics,<br />

are found. Butthe development in<br />

the modern animal farming systems<br />

and the requirement of the consumer<br />

are looking forward to abandonment<br />

of antibiotics in poultry<br />

farming. Based on this alternative<br />

solutions for the use of antibiotics<br />

are intensively researched in China.<br />

Thereby hygienic conditions, healing<br />

plants, probiotics, antimicrobial<br />

peptides and enzyme agents are the<br />

focus of several studies. In future at<br />

first the official norms and legislation<br />

considering the use of antibiotics<br />

will be toughened and as well<br />

as environmental pollution and the<br />

developing of resistance will be<br />

stopped. Thetarget is the continuously<br />

decrease of the use of antibiotics<br />

in the farming systems.<br />

References<br />

The entire bibliography can be requested<br />

either from the corresponding<br />

authors or the editors office.<br />

Author`s addresses<br />

Prof. Dr.Wang Wei, Professsor and Director<br />

(corresponding author for inquiries in<br />

Chinese: wangwei8619@163.com), Hou Bo<br />

and Ji Lili, Central Laboratory for Meat<br />

Processing of the Province Sichuan,<br />

Chengdu University, 610106Chengdu,<br />

Sichuan, China; Prof. Dr.Friedhelm Jaeger<br />

(corresponding author for inquiries in<br />

German: friedhelm.jaeger@mkulnv.nrw.de)<br />

and Catharina Hölscher, Ministry of the<br />

Climate Protection, Environment, Agriculture,<br />

Conservation and Consumer Protection<br />

of the State of North-Rhine Westphalia<br />

(Animal Welfare, Animal Health, Veterinary<br />

Medicines), Schwannstr.3,40476 Düsseldorf,<br />

Germany<br />

Food safety<br />

China: bird flu situation is stable<br />

Bird flu<br />

Disease reached Belgium<br />

China's Ministry of Agriculture said<br />

the recent outbreaks of bird flu<br />

have been handled in atimelyand<br />

effective manner without spreading<br />

and have not affected chicken<br />

products or prices.<br />

In an emailed statement to<br />

Reuters, the government department<br />

said the situation in the<br />

world's second-largest poultry<br />

consumer was stable. The comments<br />

come as South Korea and<br />

In China bird flu shows no impact<br />

on the poultry market. Photo:<br />

Nico Lubaczowski /pixelio.de<br />

neighbouring countries battle<br />

outbreaks of various strains of the<br />

highlyvirulent flu.<br />

China has culled more than<br />

170,000 birds in four provinces<br />

since October and closed some<br />

live poultry markets after people<br />

and birds were infected by strains<br />

of the avian flu. The Chinese government<br />

said it has recorded ten<br />

cases of poultry being infected<br />

with the H5N6 strain this year<br />

compared with eleven last year.<br />

The ministry, together with<br />

local agriculture agencies, have<br />

monitored and investigated poultry<br />

markets and farms where<br />

infected people live, it said. It has<br />

also searched for the source of<br />

the virus and conducted emergency<br />

handling for infected poultry,<br />

as well as urged farmers,<br />

butchers and traders to step up<br />

sterilization programmes.<br />

//www.reuters.com<br />

Ahighlycontagious strain of bird<br />

flu that has affected poultry<br />

farmers in France and Germany<br />

has now spread to Belgium. This<br />

was reported by News 24.<br />

The H5N8 avian virus was identified<br />

among birds at ahome in<br />

the Dutch-speaking region of<br />

Flanders between the cities of<br />

Brussels and Ghent. "The virus<br />

that has hit our neighbours in the<br />

past months has now reached<br />

Belgium," said Belgian Agriculture<br />

Minister WillyBorsus. "Professional<br />

farmers have not been<br />

affected, but we must be vigilant,"<br />

he added.<br />

Belgium in November preventivelyimplemented<br />

confinement<br />

measures in order to stop an<br />

epidemic during the bird migratory<br />

season. Authorities expanded<br />

them to include private owners of<br />

poultry and other birds.<br />

The H5N8 strain can spread<br />

quicklyinaffected farms, often<br />

Migrating birds are able to spread<br />

bird flu. Photo: uschi dreiucker /<br />

pixelio.de<br />

leading to the culling of thousands<br />

of birds. Since October, the<br />

strain has been detected in<br />

15 other European countries<br />

including Britain, France and<br />

Germany.Hungary has had the<br />

highest number of outbreaks in<br />

the past three months, with<br />

201cases reported in farms and<br />

four in wild birds.<br />

//www.news24.com

Fleischwirtschaft <strong>international</strong> 1_<strong>2017</strong><br />

19<br />

Nutriad<br />

Situation of the US poultry industry<br />

Industry News<br />

As the US is moving from aturbulent<br />

2016 into anew year with an<br />

uncertain political outlook, it is<br />

important for the poultry industry<br />

to understand the various scenarios<br />

that may unfoldinthe near future<br />

and possiblechanges in global trade<br />

agreements, currencyexchange<br />

rates, regulations and overall cost of<br />

production. Using insights from<br />

industry experts within the Nutriad<br />

group and input from external<br />

consultants, the companyreviews<br />

several possiblescenarios and<br />

shares its vision to theyearahead.<br />

Influenzaoutbreaks throughout the<br />

Asian countries and the EU will play<br />

an important role.<br />

Forecast of the market<br />

Both broiler and turkey production<br />

was short in the last quarter of<br />

2016.Broiler production is expected<br />

to increase in the first<br />

quarter of <strong>2017</strong>.The forecasts for<br />

<strong>2017</strong> prices were increased slightly<br />