Oerlikon Schlafhorst Express - Oerlikon Schlafhorst - Oerlikon Textile

Oerlikon Schlafhorst Express - Oerlikon Schlafhorst - Oerlikon Textile

Oerlikon Schlafhorst Express - Oerlikon Schlafhorst - Oerlikon Textile

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

12<br />

<strong>Oerlikon</strong> <strong>Schlafhorst</strong> <strong>Express</strong> Technology<br />

A neat job thanks to PreciFX<br />

New design for dye packages for yarn-protecting,<br />

reliable downstream processing<br />

For the package dyeing plant in particular,<br />

optimally constructed and prepared packages<br />

are the key to success where top quality and<br />

efficiency are concerned. The highest level<br />

of technological know-how and process<br />

expertise is required – after all, it’s a question<br />

of converting the individual dyeing process<br />

requirements into a package design that<br />

meets these requirements.<br />

Key requirements and parameters for<br />

dye packages<br />

The most important criterion is maximum<br />

uniformity in the package structure and density,<br />

both within a package and reproducibly<br />

from package to package. Often-described<br />

factors that influence the winding process<br />

include the yarn tension, package flank<br />

formation, the cradle pressure, ordered<br />

laying of the yarn and pattern-free package<br />

build. The choice of winding technology is a<br />

“question of philosophy and faith”: "random<br />

winding", precision winding or step precision<br />

winding. With the Autoconer 338 and the<br />

Autoconer 5 and the systems Autotense FX<br />

und Propack FX, central setting of the winding<br />

parameters, mechanical lateral displacement<br />

of the yarn layers and gentle placing of<br />

the yarn, <strong>Oerlikon</strong> <strong>Schlafhorst</strong> has already<br />

made a substantial contribution to optimi-<br />

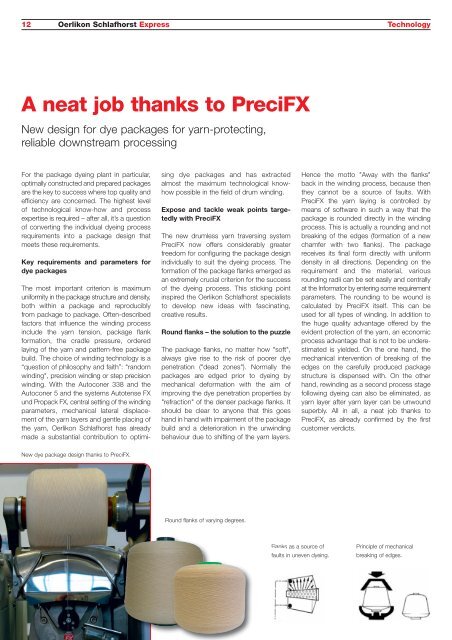

New dye package design thanks to PreciFX.<br />

sing dye packages and has extracted<br />

almost the maximum technological knowhow<br />

possible in the field of drum winding.<br />

Expose and tackle weak points targetedly<br />

with PreciFX<br />

The new drumless yarn traversing system<br />

PreciFX now offers considerably greater<br />

freedom for configuring the package design<br />

individually to suit the dyeing process. The<br />

formation of the package flanks emerged as<br />

an extremely crucial criterion for the success<br />

of the dyeing process. This sticking point<br />

inspired the <strong>Oerlikon</strong> <strong>Schlafhorst</strong> specialists<br />

to develop new ideas with fascinating,<br />

creative results.<br />

Round flanks – the solution to the puzzle<br />

The package flanks, no matter how "soft",<br />

always give rise to the risk of poorer dye<br />

penetration ("dead zones"). Normally the<br />

packages are edged prior to dyeing by<br />

mechanical deformation with the aim of<br />

improving the dye penetration properties by<br />

"refraction" of the denser package flanks. It<br />

should be clear to anyone that this goes<br />

hand in hand with impairment of the package<br />

build and a deterioration in the unwinding<br />

behaviour due to shifting of the yarn layers.<br />

Round flanks of varying degrees.<br />

Hence the motto "Away with the flanks"<br />

back in the winding process, because then<br />

they cannot be a source of faults. With<br />

PreciFX the yarn laying is controlled by<br />

means of software in such a way that the<br />

package is rounded directly in the winding<br />

process. This is actually a rounding and not<br />

breaking of the edges (formation of a new<br />

chamfer with two flanks). The package<br />

receives its final form directly with uniform<br />

density in all directions. Depending on the<br />

requirement and the material, various<br />

rounding radii can be set easily and centrally<br />

at the Informator by entering some requirement<br />

parameters. The rounding to be wound is<br />

calculated by PreciFX itself. This can be<br />

used for all types of winding. In addition to<br />

the huge quality advantage offered by the<br />

evident protection of the yarn, an economic<br />

process advantage that is not to be underestimated<br />

is yielded. On the one hand, the<br />

mechanical intervention of breaking of the<br />

edges on the carefully produced package<br />

structure is dispensed with. On the other<br />

hand, rewinding as a second process stage<br />

following dyeing can also be eliminated, as<br />

yarn layer after yarn layer can be unwound<br />

superbly. All in all, a neat job thanks to<br />

PreciFX, as already confirmed by the first<br />

customer verdicts.<br />

Flanks as a source of<br />

faults in uneven dyeing.<br />

Principle of mechanical<br />

breaking of edges.