HYDRAULIKPRESSE 2/2013 - einseitig - Hansa Flex

HYDRAULIKPRESSE 2/2013 - einseitig - Hansa Flex

HYDRAULIKPRESSE 2/2013 - einseitig - Hansa Flex

Erfolgreiche ePaper selbst erstellen

Machen Sie aus Ihren PDF Publikationen ein blätterbares Flipbook mit unserer einzigartigen Google optimierten e-Paper Software.

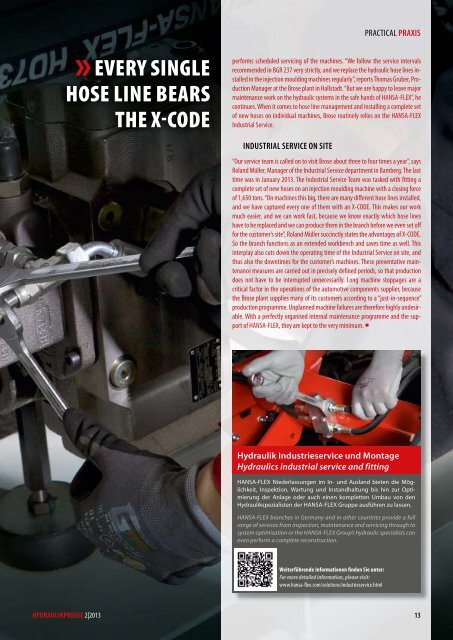

PraCtICal praxis<br />

every Single<br />

hoSe line BearS<br />

the X-code<br />

performs scheduled servicing of the machines. “we follow the service intervals<br />

recommended in BGr 237 very strictly, and we replace the hydraulic hose lines installed<br />

in the injection moulding machines regularly”, reports thomas Gruber, Production<br />

Manager at the Brose plant in hallstadt. “But we are happy to leave major<br />

maintenance work on the hydraulic systems in the safe hands of hanSa-FleX”, he<br />

continues. when it comes to hose line management and installing a complete set<br />

of new hoses on individual machines, Brose routinely relies on the hanSa-FleX<br />

Industrial Service.<br />

indusTrial serVice On siTe<br />

“our service team is called on to visit Brose about three to four times a year”, says<br />

roland Müller, Manager of the Industrial Service department in Bamberg. the last<br />

time was in January <strong>2013</strong>. the Industrial Service team was tasked with fitting a<br />

complete set of new hoses on an injection moulding machine with a closing force<br />

of 1,650 tons. “on machines this big, there are many different hose lines installed,<br />

and we have captured every one of them with an X-CoDe. this makes our work<br />

much easier, and we can work fast, because we know exactly which hose lines<br />

have to be replaced and we can produce them in the branch before we even set off<br />

for the customer’s site”, roland Müller succinctly states the advantages of X-CoDe.<br />

So the branch functions as an extended workbench and saves time as well. this<br />

interplay also cuts down the operating time of the Industrial Service on site, and<br />

thus also the downtimes for the customer’s machines. these preventative maintenance<br />

measures are carried out in precisely defined periods, so that production<br />

does not have to be interrupted unnecessarily. long machine stoppages are a<br />

critical factor in the operations of the automotive components supplier, because<br />

the Brose plant supplies many of its customers according to a “just-in-sequence”<br />

production programme. Unplanned machine failures are therefore highly undesirable.<br />

with a perfectly organised internal maintenance programme and the support<br />

of hanSa-FleX, they are kept to the very minimum. •<br />

Hydraulik Industrieservice und Montage<br />

Hydraulics industrial service and fitting<br />

HANSA-FLEX Niederlassungen im In- und Ausland bieten die Möglichkeit,<br />

Inspektion, Wartung und Instandhaltung bis hin zur Optimierung<br />

der Anlage oder auch einen kompletten Umbau von den<br />

Hydraulikspezialisten der HANSA-FLEX Gruppe ausführen zu lassen.<br />

HANSA-FLEX branches in Germany and in other countries provide a full<br />

range of services from inspection, maintenance and servicing through to<br />

system optimisation or the HANSA-FLEX Group’s hydraulic specialists can<br />

even perform a complete reconstruction.<br />

Weiterführende Informationen finden Sie unter:<br />

For more detailed information, please visit:<br />

www.hansa-flex.com/solutions/industrieservice.html<br />

<strong>HYDRAULIKPRESSE</strong> 2|<strong>2013</strong><br />

13