ECHONews - SOCON Sonar Control Kavernenvermessung GmbH

ECHONews - SOCON Sonar Control Kavernenvermessung GmbH

ECHONews - SOCON Sonar Control Kavernenvermessung GmbH

Erfolgreiche ePaper selbst erstellen

Machen Sie aus Ihren PDF Publikationen ein blätterbares Flipbook mit unserer einzigartigen Google optimierten e-Paper Software.

The gas drying unit (GDU)<br />

When gas flows through the GDU the<br />

pressure and temperature is reduced.<br />

The pressure drop depends upon the volumetric<br />

flow and real values are used for<br />

the calibration. For a given rate the pressure<br />

drop can be interpolated by a spline.<br />

A „good“ approximation is yielded from<br />

a large number of accurate measured values<br />

and provides a „reasonable“ assessment<br />

of the pressure drop. When multiple<br />

GDU‘s are working in parallel the gas<br />

stream is split in line with the number of<br />

used GDU’s. The volumetric flow leads to<br />

a smaller pressure drop.<br />

The pressure reduction stream and<br />

heat exchanger<br />

If the combined cavern pressure compared<br />

to the transmission pipeline (national<br />

grid) pressure is very high, then<br />

the pressure is reduced to the pressure<br />

which is necessary to transfer the gas<br />

into the transmission pipeline plus pressure<br />

losses in the station piping and the<br />

meter streams. The heat exchanger has<br />

the job of raising the gas temperature to<br />

achieve a minimum temperature of 18°C<br />

downstream the pressure reduction station.<br />

Temperatures are generally calculated<br />

using the Joule-Thomson algorithm.<br />

The calculations have been taken from<br />

the worksheet G499 published by the<br />

German Technical Association for Gas<br />

and Water (DVGW) [5].<br />

Possible scenarios during injection /<br />

withdrawal<br />

Essentially four cases can be differentiated<br />

in the calculations for the above<br />

ground procedures:<br />

1. Withdrawal without compression<br />

2. Withdrawal with compression<br />

3. Injection without compression<br />

4. Injection with compression<br />

By way of example case 1 is described<br />

in more detail. The procedures and cal-<br />

10<br />

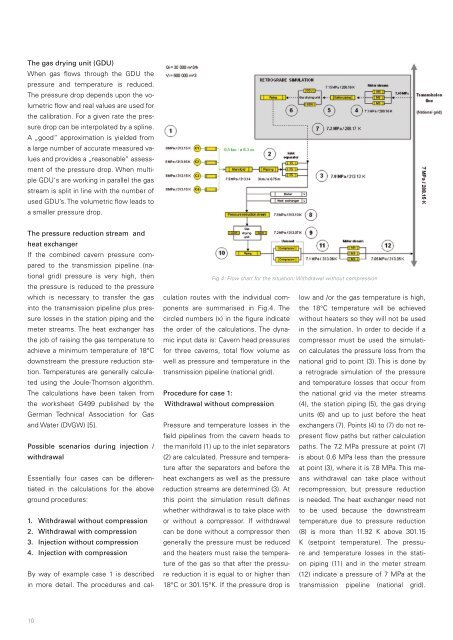

Fig.4: Flow chart for the situation: Withdrawal without compression<br />

culation routes with the individual components<br />

are summarised in Fig.4. The<br />

circled numbers (x) in the figure indicate<br />

the order of the calculations. The dynamic<br />

input data is: Cavern head pressures<br />

for three caverns, total flow volume as<br />

well as pressure and temperature in the<br />

transmission pipeline (national grid).<br />

Procedure for case 1:<br />

Withdrawal without compression<br />

Pressure and temperature losses in the<br />

field pipelines from the cavern heads to<br />

the manifold (1) up to the inlet separators<br />

(2) are calculated. Pressure and temperature<br />

after the separators and before the<br />

heat exchangers as well as the pressure<br />

reduction streams are determined (3). At<br />

this point the simulation result defines<br />

whether withdrawal is to take place with<br />

or without a compressor. If withdrawal<br />

can be done without a compressor then<br />

generally the pressure must be reduced<br />

and the heaters must raise the temperature<br />

of the gas so that after the pressure<br />

reduction it is equal to or higher than<br />

18°C or 301.15°K. If the pressure drop is<br />

low and /or the gas temperature is high,<br />

the 18°C temperature will be achieved<br />

without heaters so they will not be used<br />

in the simulation. In order to decide if a<br />

compressor must be used the simulation<br />

calculates the pressure loss from the<br />

national grid to point (3). This is done by<br />

a retrograde simulation of the pressure<br />

and temperature losses that occur from<br />

the national grid via the meter streams<br />

(4), the station piping (5), the gas drying<br />

units (6) and up to just before the heat<br />

exchangers (7). Points (4) to (7) do not represent<br />

flow paths but rather calculation<br />

paths. The 7.2 MPa pressure at point (7)<br />

is about 0.6 MPa less than the pressure<br />

at point (3), where it is 7.8 MPa. This means<br />

withdrawal can take place without<br />

recompression, but pressure reduction<br />

is needed. The heat exchanger need not<br />

to be used because the downstream<br />

temperature due to pressure reduction<br />

(8) is more than 11.92 K above 301.15<br />

K (setpoint temperature). The pressure<br />

and temperature losses in the station<br />

piping (11) and in the meter stream<br />

(12) indicate a pressure of 7 MPa at the<br />

transmission pipeline (national grid).