ECHONews - SOCON Sonar Control Kavernenvermessung GmbH

ECHONews - SOCON Sonar Control Kavernenvermessung GmbH

ECHONews - SOCON Sonar Control Kavernenvermessung GmbH

Erfolgreiche ePaper selbst erstellen

Machen Sie aus Ihren PDF Publikationen ein blätterbares Flipbook mit unserer einzigartigen Google optimierten e-Paper Software.

Operations were started in the Holford<br />

gas storage in November 2011. It was<br />

possible from the end of June 2012 to implement<br />

and test the NomiX system together<br />

with the surface and underground<br />

components of the CavBase Gas Storage<br />

software. The first comparisons between<br />

the measured values and the simulation<br />

results have already been made and are<br />

presented here. As cavern simulation<br />

using CavBase Gas Storage has already<br />

been described in detail at previous<br />

SMRI meetings [2], [3], we have in this<br />

paper restricted ourselves to a presentation<br />

of the results of the surface calculations<br />

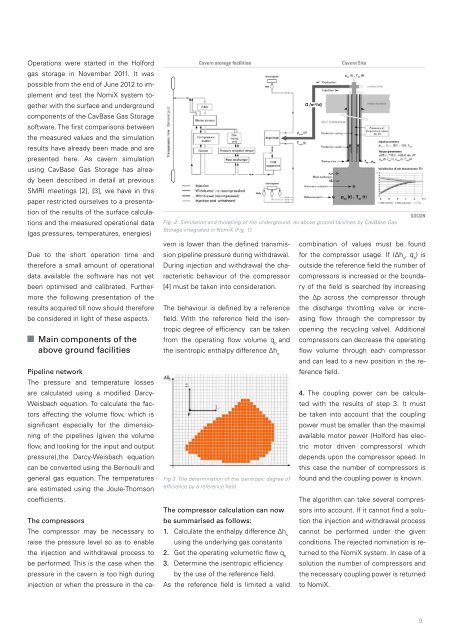

and the measured operational data Fig. 2: Simulation and modeling of the underground an above ground facilities by CavBase Gas<br />

Fig. 2: Simulation and modeling of the underground and above ground facilities by CavBase Gas Storage<br />

Storage integrated in NomiX (Fig. 1)<br />

(gas pressures, temperatures, energies) integrated in NomiX (Fig. 1).<br />

vern is lower than the defined transmis- combination of values must be found<br />

Operations were started in the Holford gas storage in November 2011. It was possible from the end of<br />

Due to the short operation time and sion pipeline pressure during withdrawal. for the compressor usage. If (Δh , q ) is<br />

June 2012 to implement and test the NomiX system together with the surface and underground<br />

s b<br />

therefore a small amount of operational components During injection of the CavBase and withdrawal Gas Storage the software. cha- The outside first comparisons the reference between field the measured number values of<br />

and the simulation results have already been made and are presented here. As cavern simulation using<br />

data available the software has not yet<br />

CavBase<br />

racteristic<br />

Gas Storage<br />

behaviour<br />

has already<br />

of the<br />

been<br />

compressor<br />

described in<br />

compressors<br />

detail at previous<br />

is<br />

SMRI<br />

increased<br />

meetings<br />

or the<br />

[2],<br />

bounda-<br />

[3], we have<br />

been optimised and calibrated. Further- in this [4] must paper be restricted taken ourselves into consideration. to a presentation of ry the of the results field of is the searched surface calculations (by increasing and the<br />

measured operational data (gas pressures, temperatures, energies)<br />

more the following presentation of the<br />

the Δp across the compressor through<br />

results acquired till now should therefore Due The to the behaviour short operation is defined time and by therefore a reference a small the amount discharge of operational throttling data available valve or the incre- software<br />

has not During yet been injection optimised and calibrated. withdrawal Furthermore the characteristic the following presentation behaviour of the of results the acquired compresso<br />

be considered in light of these aspects. till now field. should With therefore the reference be considered field in the light isen- of these asing aspects. flow through the compressor by<br />

consideration.<br />

tropic degree of efficiency can be taken opening the recycling valve). Additional<br />

Main components of the above ground facilities<br />

Main components of the from The the behaviour operating is flow defined volume by a q reference and compressors field. With can the decrease reference the operating field the isentrop<br />

b<br />

above ground facilities Pipeline the can isentropic network be taken enthalpy from difference the operating Δh flow flow volume volume q b and through the isentropic each compressor enthalpy differ<br />

s<br />

The pressure and temperature losses are calculated using a modified Darcy-Weisbach equation. To<br />

calculate the factors affecting the volume flow, which and is significant can lead especially to a new for position the dimensioning in the reof<br />

the<br />

Pipeline network<br />

pipelines (given the volume flow, and looking for the<br />

ference<br />

input and<br />

field.<br />

output pressure),the Darcy-Weisbach<br />

equation can be converted using the Bernoulli and general gas equation. The temperatures are estimated<br />

The pressure and temperature losses using the Joule-Thomson coefficients.<br />

are calculated using a modified Darcy-<br />

4. The coupling power can be calcula-<br />

The compressors<br />

Weisbach equation. To calculate the fac- The compressor may be necessary to raise the pressure ted with level the so results as to enable of step the 3. injection It must and<br />

withdrawal process to be performed. This is the case when the pressure in the cavern is too high during<br />

tors affecting the volume flow, which is<br />

be taken into account that the coupling<br />

injection or when the pressure in the cavern is lower than the defined transmission pipeline pressure<br />

significant especially for the dimensio- during withdrawal.<br />

power must be smaller than the maximal<br />

ning of the pipelines (given the volume<br />

available motor power (Holford has elec-<br />

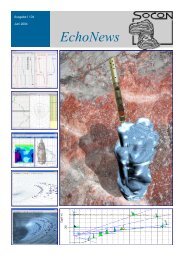

Fig 3. The determination of the isentropic<br />

flow, and looking for the input and output<br />

tric motor driven compressors) which<br />

reference field<br />

pressure),the Darcy-Weisbach equation<br />

3 depends upon the compressor speed. In<br />

can be converted using the Bernoulli and<br />

this case the number of compressors is<br />

general gas equation. The temperatures Fig 3. The determination of the isentropic degree of found and the coupling power is known.<br />

efficience by a reference field<br />

are estimated using the Joule-Thomson<br />

The compressor calculation can now be summarised as follows:<br />

coefficients.<br />

The algorithm can take several compres-<br />

The<br />

1.<br />

compressor<br />

Calculate the<br />

calculation<br />

enthalpy<br />

can<br />

difference hs now sors<br />

using<br />

into account.<br />

the underlying<br />

If it cannot<br />

gas<br />

find<br />

constants<br />

a solu-<br />

2. Get the operating volumetric flow qb<br />

The compressors<br />

be summarised as follows:<br />

tion the injection and withdrawal process<br />

3. Determine the isentropic efficiency by the use of the reference field.<br />

The compressor may be necessary to 1. Calculate the enthalpy difference Δh cannot be performed under the given<br />

s<br />

raise the pressure level so as to enable As using the the reference underlying field gas is constants limited a valid conditions. combination The rejected of values nomination must be is re- found for<br />

the injection and withdrawal process to 2. ( Get hs, the qb) operating is outside volumetric the reference flow q turned to the NomiX system. In case of a<br />

bfield<br />

the number of compressors is increased or<br />

be performed. This is the case when the 3. is Determine searched the (by isentropic increasing efficiency the p solution across the the number compressor of compressors through and the disch<br />

pressure in the cavern is too high during increasing by the use of flow the reference through the field. compressor the necessary by opening coupling the power recycling is returned valve). Add<br />

injection or when the pressure in the ca- As<br />

decrease<br />

the reference<br />

the<br />

field<br />

operating<br />

is limited<br />

flow<br />

a valid<br />

volume through each compressor and can lead<br />

to NomiX.<br />

reference field.<br />

4. The coupling power can be calculated with the results of step 3. It must be ta<br />

coupling power must be smaller than the maximal available motor power (Ho<br />

driven compressors) which depends upon the compressor speed. In this 9<br />

case the<br />

is found and the coupling power is known.