ECHONews - SOCON Sonar Control Kavernenvermessung GmbH

ECHONews - SOCON Sonar Control Kavernenvermessung GmbH

ECHONews - SOCON Sonar Control Kavernenvermessung GmbH

Sie wollen auch ein ePaper? Erhöhen Sie die Reichweite Ihrer Titel.

YUMPU macht aus Druck-PDFs automatisch weboptimierte ePaper, die Google liebt.

Tying in the Underground Thermodynamic Simulation of Gas<br />

Storage Caverns with the Surface Process Engineering<br />

Paper presented at the SMRI fall meeting 2012 in Bremen, Germany. Authors: Dr Michael Krieter, Stefan Wieber-<br />

Klocke, André Stille (<strong>SOCON</strong> <strong>Sonar</strong> <strong>Control</strong> <strong>Kavernenvermessung</strong> <strong>GmbH</strong>), Jochen Kemper (OGE, Open Grid<br />

Europe <strong>GmbH</strong>, Essen), Dr Katrin Vosbeck (EGS, E.ON Gas Storage <strong>GmbH</strong>, Essen)<br />

Abstract<br />

Commissioned by EGS and in cooperation<br />

with EGS and OGE, <strong>SOCON</strong> has developed<br />

a software package that extends<br />

the CavBase Gas Storage software by<br />

including features for the above ground<br />

facilities. This software, which can also<br />

be used independently of the cavern<br />

software, enables pressure and temperature<br />

calculations to be made from the<br />

cavern head all the way to gas transport<br />

pipelines. In doing this the various individual<br />

components are considered, for<br />

instance the station piping, separators,<br />

boilers, heat exchangers, pressure reduction<br />

streams , compressors, coolers,<br />

gas drying units and meter streams. Heat<br />

exchanger, boiler and compressor capacities<br />

are likewise indicated. In addition<br />

the calculations reveal how many heat<br />

exchanger and compressor components<br />

are needed for a planned gas nomination.<br />

Nominations are made on an hourly basis<br />

and assimilated by the NomiX software<br />

created by GreyLogix <strong>GmbH</strong>. The data<br />

is then made available to CavBase. The<br />

entire CavBase system is embedded in<br />

NomiX and its purpose is to provide a rapid<br />

thermodynamic and rock mechanics<br />

check of the gas nominations to enable<br />

permanent online access to the information<br />

on capacity and availability of the<br />

cavern storage. The system has been implemented<br />

in the EGS’s Holford gas storage.<br />

Installation and initial tests of the<br />

software were carried out and assessed<br />

in May/June 2012.<br />

Introduction<br />

On the basis of the know-how within<br />

the companies <strong>SOCON</strong>, OGE, EGS and<br />

GreyLogix, the software – entitled NomiX<br />

[1] – can precisely predict the feasibility<br />

of gas quantity nominations with regards<br />

to the rock mechanics, thermodynamics<br />

8<br />

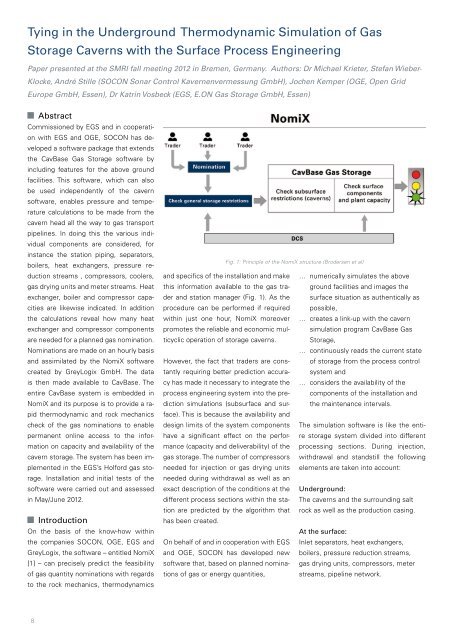

Fig. 1: Principle of the NomiX structure (Brodersen et al)<br />

and specifics of the installation and make<br />

this information available to the gas trader<br />

and station manager (Fig. 1). As the<br />

procedure can be performed if required<br />

within just one hour, NomiX moreover<br />

promotes the reliable and economic multicyclic<br />

operation of storage caverns.<br />

However, the fact that traders are cons-<br />

tantly requiring better prediction accura-<br />

cy has made it necessary to integrate the<br />

process engineering system into the prediction<br />

simulations (subsurface and surface).<br />

This is because the availability and<br />

design limits of the system components<br />

have a significant effect on the performance<br />

(capacity and deliverability) of the<br />

gas storage. The number of compressors<br />

needed for injection or gas drying units<br />

needed during withdrawal as well as an<br />

exact description of the conditions at the<br />

different process sections within the station<br />

are predicted by the algorithm that<br />

has been created.<br />

On behalf of and in cooperation with EGS<br />

and OGE, <strong>SOCON</strong> has developed new<br />

software that, based on planned nominations<br />

of gas or energy quantities,<br />

… numerically simulates the above<br />

ground facilities and images the<br />

surface situation as authentically as<br />

possible,<br />

… creates a link-up with the cavern<br />

simulation program CavBase Gas<br />

Storage,<br />

… continuously reads the current state<br />

of storage from the process control<br />

system and<br />

… considers the availability of the<br />

components of the installation and<br />

the maintenance intervals.<br />

The simulation software is like the entire<br />

storage system divided into different<br />

processing sections. During injection,<br />

withdrawal and standstill the following<br />

elements are taken into account:<br />

Underground:<br />

The caverns and the surrounding salt<br />

rock as well as the production casing.<br />

At the surface:<br />

Inlet separators, heat exchangers,<br />

boilers, pressure reduction streams,<br />

gas drying units, compressors, meter<br />

streams, pipeline network.