Download - VACUUMSCHMELZE GmbH & Co. KG

Download - VACUUMSCHMELZE GmbH & Co. KG

Download - VACUUMSCHMELZE GmbH & Co. KG

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

submitted as paper BE 01 to the Intermag 2002 <strong>Co</strong>nference, Amsterdam, April 2002<<br />

Top Nd-Fe-B Magnets: >56 MGOe, Energy<br />

Density, 9.8 kOe <strong>Co</strong>ercivity<br />

W. RODEWALD, B. WALL, M. KATTER, and K. UESTUENER<br />

Abstract—Sintered Nd-Fe-B magnets are prepared by powder<br />

metallurgy. Besides the composition of the alloy, the alignment of<br />

the powder particles is decisive for achieving high remanent<br />

polarizations. The alignment of the powder particles can be<br />

improved by applying field pulses in addition to an alignment in<br />

a constant magnetic field. Alternating field pulses parallel and<br />

antiparallel to the easy axis proved to be more efficient than<br />

unidirectional field pulses. By such a refined processing route<br />

sintered Nd-Fe-B magnets with a remanent polarization of<br />

1.519 T, a coercivity H cJ of 7.8 kA/cm (9.8 kOe) and a maximum<br />

energy density of 451 kJ/m³ (56.7 MGOe) could be prepared.<br />

Index Terms—Alignment coefficient, energy density, magnets,<br />

temperature measurement.<br />

M<br />

I. INTRODUCTION<br />

ODERN permanent magnets enable the design of strong<br />

motors, disk drives for data storage in computers or<br />

various accessories for automobiles. In most applications the<br />

magnets should be as powerful as possible in order to<br />

optimize the efficiency of a magnet assembly and to save<br />

weight or volume, respectively. Up to now sintered Nd-Fe-B<br />

magnets achieve the highest energy densities.<br />

The maximum energy density is mainly determined by the<br />

remanent polarization and the reversible permeability. The<br />

J<br />

remanent polarization at 20 °C can be calculated from:<br />

r<br />

J r ( 20°<br />

C)<br />

= J S ( 20°<br />

C)<br />

⋅ ⋅ ( 1−<br />

Vnonmag<br />

ρ0<br />

⋅ fϕ<br />

J s ( 20 ° C)<br />

, ρ0<br />

Vnonmag fϕ<br />

ρ<br />

)<br />

(1)<br />

ρ , and denote the saturation<br />

polarization of the Nd2Fe14B<br />

compound at 20 °C, the density<br />

related to the theoretical density of the alloy, the fraction of<br />

nonmagnetic constituents and the alignment coefficient,<br />

respectively. The alignment coefficient is defined by:<br />

Manuscript received February 10, 2002.<br />

W. Rodewald is with Vacuumschmelze <strong>GmbH</strong> & <strong>Co</strong> <strong>KG</strong>, P. O. Box 2253,<br />

D 63412 Hanau, Germany (telephone: + 49 6181 38-2482, e-mail:<br />

werner.rodewald@vacuumschmelze.com).<br />

B. Wall is with Vacuumschmelze <strong>GmbH</strong> & <strong>Co</strong> <strong>KG</strong>, P. O. Box 2253,<br />

D 63412 Hanau, Germany (e-mail: boris.wall@vacuumschmelze.com).<br />

M. Katter is with Vacuumschmelze <strong>GmbH</strong> & <strong>Co</strong> <strong>KG</strong>, P. O. Box 2253,<br />

D 63412 Hanau, Germany (e-mail: matthias.katter @vacuumschmelze.com).<br />

K. Uestuener is with Vacuumschmelze <strong>GmbH</strong> & <strong>Co</strong> <strong>KG</strong>, P. O. Box 2253,<br />

D 63412 Hanau, Germany (e-mail: kaan.uestuener@vacuumschmelze.com).<br />

f = cosϕ<br />

with<br />

ϕ<br />

⎛<br />

⎜ J<br />

= arctan 2<br />

⎜ J<br />

⎝<br />

⎞<br />

⎟<br />

⎟<br />

⎠<br />

r⊥<br />

ϕ (2)<br />

and represents the average misalignment angle ϕ of the<br />

grains with respect to the easy axis [1]. The precondition is a<br />

homogeneous and cylindrical symmetrical distribution of the<br />

misaligned grains. Isostatically pressed magnets meet these<br />

preconditions fairly well and achieve alignment coefficients<br />

up to 98 %. For magnets pressed in a transverse magnetic<br />

field, however, the perpendicular components of the remanent<br />

J<br />

polarization parallel or transverse to the pressing<br />

r⊥<br />

direction are different. Hence for transverse pressed magnets<br />

two alignment coefficients have to be distinguished.<br />

The alignment coefficient can be easily determined from the<br />

remanent polarization measured parallel J r and<br />

J<br />

perpendicular with respect to the easy axis of an<br />

r⊥<br />

anisotropic magnet. The impact of different powder alignment<br />

procedures on the alignment coefficient and hence on the<br />

remanent polarization or maximum energy density,<br />

respectively, are reported.<br />

II. EXPERIMENTAL<br />

Anisotropic magnets were prepared by blending<br />

Nd12.7Dy0.03Fe80.7TM0.8B5.8 and Nd13.7Dy0.03Fe79.8TM0.8B5.7<br />

alloy-powders, TM: Al, Ga, <strong>Co</strong>, Cu, in different ratios in order<br />

to optimize the RE-concentration in sintered magnets. The<br />

alloy-powders were milled in inert atmosphere to an average<br />

particle size in the range between 3 and 5 µm. The blends<br />

were aligned in a magnetic field of 13 kA/cm and compacted<br />

to about 29 % of the theoretical density. In order to improve<br />

the alignment of the powder particles, magnetic field pulses<br />

with a peak field strength of about 64 kA/cm, t ≈ 10 ms, were<br />

applied parallel to the easy axis of the powder compacts<br />

repeatedly. For comparison another set of powder compacts<br />

got an additional alignment by similar field pulses which were<br />

directed at first antiparallel and afterwards parallel to the easy<br />

axis of the powder compacts. The number of the field pulses<br />

has been varied. All powder compacts are pressed<br />

isostatically.<br />

The green compacts were sintered at temperatures between<br />

1050 and 1100 °C for 4 h and annealed at temperatures<br />

between 500 and 600 °C for 1 h.<br />

r<br />

1

submitted as paper BE 01 to the Intermag 2002 <strong>Co</strong>nference, Amsterdam, April 2002<<br />

The magnetic properties were deduced from<br />

demagnetization curves J(H), recorded in a hysteresisgraph on<br />

test samples 9 mm in diameter, 6 mm in thickness at<br />

temperatures between 20 and 80 °C. The alignment<br />

coefficients have been determined from the remanent<br />

polarizations measured parallel J and perpendicular<br />

r<br />

with respect to the easy axis of the anisotropic magnets.<br />

III. RESULTS<br />

Due to liquid phase sintering, the Nd-Fe-B magnets achieve<br />

easily densities between 7.55 and 7.6 g/cm³ or ρ ρ0<br />

> 99 %,<br />

respectively. The fraction of impurities, for instance Ndoxides<br />

or - nitrides, could be decreased to

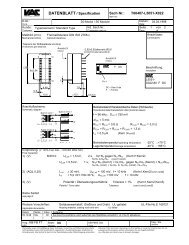

submitted as paper BE 01 to the Intermag 2002 <strong>Co</strong>nference, Amsterdam, April 2002<<br />

20 °C 80 °C<br />

-12 -10 -8 -6 -4 -2 0<br />

Fig. 3. Demagnetization curves J(H) and B(H) of a sintered Nd-Fe-B magnet<br />

with a remanent polarization of 1.519 T, a coercivity of 7.8 kA/cm and a<br />

maximum energy density of 451 kJ/m³.<br />

D. Microstructure<br />

magnetic field strength in kOe<br />

Prerequisite for a strong coercivity of a magnet is a<br />

homogeneous fine grained mircostructure. The enhancement<br />

of the coercivity by additions of heavy RE-metals like Dy or<br />

Tb, is not appropriate, since they decrease the saturation<br />

polarization of the Nd2Fe14B compound. Hence the content of<br />

heavy RE additions must be minimized. The average grain<br />

size must be controlled by the sintering conditions in order to<br />

achieve a small grain size. Fig. 4 reveals the microstructure of<br />

a magnet with an energy density of 451 kJ/m³. The average<br />

grain size amounts to 4.6 µm. Only a few grains have<br />

dimensions up to 25 µm. The RE-rich constituents are<br />

homogeneously distributed.<br />

Fig. 4 Microstructure of a sintered Nd-Fe-B magnet with a maximum energy<br />

density of 451 kJ/m³ with an average grains size of 4.6 µm and a few grains<br />

with dimensions up to 25 µm.<br />

However, if the amount of RE-rich constituents is<br />

1,6<br />

1,4<br />

1,2<br />

1,0<br />

0,8<br />

0,6<br />

0,4<br />

0,2<br />

0,0<br />

increased, the grain growth is enforced. That results in an<br />

average grains size of 4.9 µm, see Fig. 5. In addition there are<br />

some large grains with dimensions up to 330 µm, what<br />

increases the reversible permeability and hence decreases the<br />

maximum energy density.<br />

Fig. 5 Microstructure of a sintered Nd-Fe-B magnet with a maximum energy<br />

density of 440 kJ/m³ with an average grains size of 4.9 µm and some large<br />

grains with dimensions up to 330 µm.<br />

IV. CONCLUSIONS<br />

The manufacture of sintered Nd-Fe-B magnets with high<br />

energy densities requires almost ternary Nd-Fe-B alloys with a<br />

negligible amount of impurities. During powder metallurgical<br />

processing the optimum alignment of the powder particles<br />

could be achieved by the application of additional field pulses<br />

with alternating polarity. Probably the powder particles<br />

experience a torque in the direction of the magnetic field and<br />

an impact by magnetic field gradients, so that they can<br />

overcome the friction between the particles and agglomerates<br />

are disintegrated simultaneously.<br />

The minimization of the RE-rich constituents enlarges the<br />

fraction of the hardmagnetic compound, but also promotes a<br />

fine grained mircostructure.<br />

ACKNOWLEDGMENT<br />

The authors are grateful to M. Lemcke for the<br />

metallographic analysis and acknowledge the technical<br />

assistance of R. Langer, S. Stein and J. P. Jacquet.<br />

REFERENCES<br />

[1] W. Fernengel, A. Lehnert, M. Katter, W. Rodewald, B. Wall,<br />

“Examination of the degree of alignment in sintered Nd-Fe-B magnets<br />

by measurements of the remanent polarizations,” J. Magn. Magn. Mat.<br />

vol. 157, pp. 19-20, 1996.<br />

[2] Y. Kaneko, “Highest performance of Nd-Fe-B magnet over 55 MGOe,”<br />

IEEE Trans. Mag. vol. 36, pp. 3275 – 3278, 2000.<br />

[3] M. Sagawa, H. Nagata, “Novel processing technology for permanent<br />

magnets”, IEEE Trans. Mag. vo. 29, pp. 2747 – 2751, 1993.<br />

[4] W. Rodewald, M. Katter, B. Wall, R. Blank, G. W. Reppel, H. D. Zilg,<br />

“Dependence of the coercivity HcJ of heigh energy Nd-Fe-B magnets on<br />

the alignment coefficient”, IEEE Trans. Mag. vol 36, pp. 3279 – 3281,<br />

2000.<br />

3