Click here for PDF - Society of Manufacturing Engineers

Click here for PDF - Society of Manufacturing Engineers

Click here for PDF - Society of Manufacturing Engineers

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Tooling & Workholding<br />

are available in a wide range <strong>of</strong> sizes<br />

from a miniature #8-32 thread size to<br />

a 1"-8 thread with 2500 lb (1134-kg)<br />

clamping <strong>for</strong>ce. A compact clamp with<br />

a metallic wiper edge is especially well<br />

suited <strong>for</strong> applications w<strong>here</strong> space is<br />

limited. Two different clamping levers<br />

are available, which can be machined<br />

to fit the workpiece. Four different sizes<br />

are available, each with a short or long<br />

clamping arm.<br />

Carr Lane Roemheld Mfg Co.<br />

Ph: 800-827-2526<br />

Web site: www.clrh.com<br />

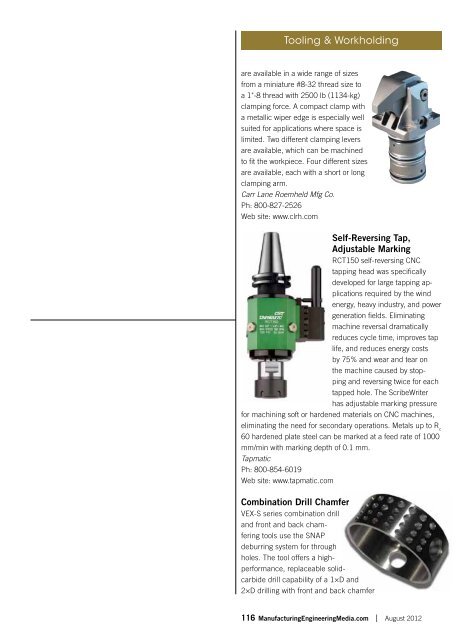

Self-Reversing Tap,<br />

Adjustable Marking<br />

RCT150 self-reversing CNC<br />

tapping head was specifically<br />

developed <strong>for</strong> large tapping applications<br />

required by the wind<br />

energy, heavy industry, and power<br />

generation fields. Eliminating<br />

machine reversal dramatically<br />

reduces cycle time, improves tap<br />

life, and reduces energy costs<br />

by 75% and wear and tear on<br />

the machine caused by stopping<br />

and reversing twice <strong>for</strong> each<br />

tapped hole. The ScribeWriter<br />

has adjustable marking pressure<br />

<strong>for</strong> machining s<strong>of</strong>t or hardened materials on CNC machines,<br />

eliminating the need <strong>for</strong> secondary operations. Metals up to R c<br />

60 hardened plate steel can be marked at a feed rate <strong>of</strong> 1000<br />

mm/min with marking depth <strong>of</strong> 0.1 mm.<br />

Tapmatic<br />

Ph: 800-854-6019<br />

Web site: www.tapmatic.com<br />

Combination Drill Chamfer<br />

VEX-S series combination drill<br />

and front and back chamfering<br />

tools use the SNAP<br />

deburring system <strong>for</strong> through<br />

holes. The tool <strong>of</strong>fers a highper<strong>for</strong>mance,<br />

replaceable solidcarbide<br />

drill capability <strong>of</strong> a 1×D and<br />

2×D drilling with front and back chamfer<br />

116 <strong>Manufacturing</strong>EngineeringMedia.com | August 2012