- Page 1: ACME 2011 Proceedings of the 19 th

- Page 4 and 5: First published 2011 by Heriot-Watt

- Page 7 and 8: CONTENTS Invited Lectures CHALLENGE

- Page 9 and 10: A DAMAGE-MECHANICS-BASED RATE-DEPEN

- Page 11: A PROJECTED QUASI-NEWTON METHOD FOR

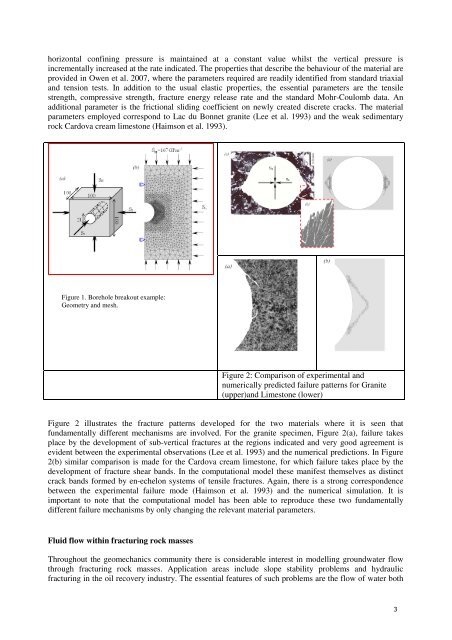

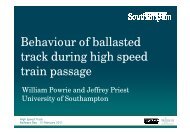

- Page 16 and 17: through individual rock blocks and

- Page 18 and 19: (a) Finite element mesh (b) Gas mes

- Page 21 and 22: Proceedings of the 19 th UK Confere

- Page 23 and 24: T E −1 ( ) ( ) T ∂s ∂T − du

- Page 25 and 26: Proceedings of the 19 th UK Confere

- Page 27 and 28: nondimensional tangential velocity

- Page 29 and 30: Proceedings of the 19 th UK Confere

- Page 31 and 32: Figure 2: Results for an open arter

- Page 33 and 34: Proceedings of the 19 th UK Confere

- Page 35 and 36: (a) Abaqus model von Mises stress (

- Page 37 and 38: Proceedings of the 19 th UK Confere

- Page 39 and 40: Vle Vli De Di k1 (MPa) 8.34 2.11 1.

- Page 41 and 42: Proceedings of the 19 th UK Confere

- Page 43 and 44: 3 RESULTS AND DISCUSSIONS In this p

- Page 45 and 46: Proceedings of the 19 th UK Confere

- Page 47 and 48: The potential energy U of the tunne

- Page 49 and 50: Proceedings of the 19 th UK Confere

- Page 51 and 52: where the problem is formulated in

- Page 53 and 54: Proceedings of the 19 th UK Confere

- Page 55 and 56: Figure 1: 2D slope model geometry (

- Page 57 and 58: Proceedings of the 19 th UK Confere

- Page 59 and 60: Figure 1. Comparison between the pr

- Page 61 and 62: Proceedings of the 19 th UK Confere

- Page 63 and 64: following anisotropic hardening rel

- Page 65 and 66:

Proceedings of the 19 th UK Confere

- Page 67 and 68:

that R Γ Spin[N]XdΓ = 0, the func

- Page 69 and 70:

Proceedings of the 19 th UK Confere

- Page 71 and 72:

4 INCORPORATING EPRCM IN FEA The de

- Page 73 and 74:

Proceedings of the 19 th UK Confere

- Page 75 and 76:

No distinct yield point is observed

- Page 77 and 78:

Proceedings of the 19 th UK Confere

- Page 79 and 80:

stress [MPa] 1 0 -1 -2 -3 -2.5 -2 -

- Page 81 and 82:

Proceedings of the 19 th UK Confere

- Page 83 and 84:

ecomes available, the material mode

- Page 85 and 86:

Proceedings of the 19 th UK Confere

- Page 87 and 88:

where ∂fin ∂UM force 2.5 2 1.5

- Page 89 and 90:

Proceedings of the 19 th UK Confere

- Page 91 and 92:

Practicallly, the perturbation fiel

- Page 93 and 94:

Proceedings of the 19 th UK Confere

- Page 95 and 96:

3 SIMULATING CONCRETE MESO-STRUCTUR

- Page 97 and 98:

Proceedings of the 19 th UK Confere

- Page 99 and 100:

Proceedings of the 19 th UK Confere

- Page 101 and 102:

Proceedings of the 19 th UK Confere

- Page 103 and 104:

¯K i is an approximation of the co

- Page 105 and 106:

Proceedings of the 19 th UK Confere

- Page 107 and 108:

h = 5.36 matrix 4.3 z P E f νf 0.9

- Page 109 and 110:

Proceedings of the 19 th UK Confere

- Page 111 and 112:

From the total hoop strainε θ , t

- Page 113 and 114:

Proceedings of the 19 th UK Confere

- Page 115 and 116:

3 EXTERIOR POINT ESHELBY BASED CRAC

- Page 117 and 118:

Proceedings of the 19 th UK Confere

- Page 119 and 120:

is applied uniformly on the edge to

- Page 121 and 122:

Proceedings of the 19 th UK Confere

- Page 123 and 124:

(a) (b) (c) (d) Figure 1: Influence

- Page 125 and 126:

Proceedings of the 19 th UK Confere

- Page 127 and 128:

On each subdomain, we then have to

- Page 129 and 130:

Proceedings of the 19 th UK Confere

- Page 131 and 132:

( i�1) ( i�1) �Un�1 � ε

- Page 133 and 134:

Proceedings of the 19 th UK Confere

- Page 135 and 136:

� ~ � 1 ψ ~ � � ~ (2) �

- Page 137 and 138:

Proceedings of the 19 th UK Confere

- Page 139 and 140:

For the case of uni-axial tension,

- Page 141 and 142:

Proceedings of the 19 th UK Confere

- Page 143 and 144:

3 Numerical results Preliminary num

- Page 145 and 146:

Proceedings of the 19 th UK Confere

- Page 147 and 148:

The coefficients An cannot be deriv

- Page 149 and 150:

Proceedings of the 19 th UK Confere

- Page 151 and 152:

The spatial semi-discretisation is

- Page 153 and 154:

Proceedings of the 19 th UK Confere

- Page 155 and 156:

3 CRITICAL TIME STEP INCREASED WITH

- Page 157 and 158:

Proceedings of the 19 th UK Confere

- Page 159 and 160:

v/vo 2E-05 1.5E-05 1E-05 5E-06 0 -3

- Page 161 and 162:

Proceedings of the 19 th UK Confere

- Page 163 and 164:

3 RESULTS AND DISCUSSION Fig. 1a sh

- Page 165 and 166:

Proceedings of the 19 th UK Confere

- Page 167 and 168:

Model updating from eigenvalue and

- Page 169 and 170:

Proceedings of the 19 th UK Confere

- Page 171 and 172:

1. If R = ω 2 n, there is no eigen

- Page 173 and 174:

Proceedings of the 19 th UK Confere

- Page 175 and 176:

F = ´ Ω STv CSv dΩ A = ´ Γ U

- Page 177 and 178:

Proceedings of the 19 th UK Confere

- Page 179 and 180:

Fig. 3 Wall normal pressure in the

- Page 181 and 182:

Proceedings of the 19 th UK Confere

- Page 183 and 184:

contact contact (ii). f ≈ f ( d,

- Page 185 and 186:

Proceedings of the 19 th UK Confere

- Page 187 and 188:

In the analysis of the incident P-w

- Page 189 and 190:

Proceedings of the 19 th UK Confere

- Page 191 and 192:

elow a certain threshold. In both t

- Page 193 and 194:

Proceedings of the 19 th UK Confere

- Page 195 and 196:

K/d 2 Effective Permeability 0.0032

- Page 197 and 198:

Proceedings of the 19 th UK Confere

- Page 199 and 200:

METHOD 2 (Mellor and Herring Type)

- Page 201:

Proceedings of the 19 th UK Confere

- Page 204 and 205:

(a) Free Surface Profile from Janos

- Page 206 and 207:

2 IMMERSED FLUID SOLVER Consider th

- Page 208 and 209:

References [1] R. Mittal and G. Iac

- Page 210 and 211:

a second impact on the forward fuse

- Page 212 and 213:

Acknowledgement L. Papagiannis is f

- Page 214 and 215:

acceptable probability throughout t

- Page 216 and 217:

algorithm was then responsible for

- Page 218 and 219:

strategy of saving the computationa

- Page 220 and 221:

(a) (b) Figure 5. Comparison of (a)

- Page 222 and 223:

Thermal load step i i i i Update ,

- Page 224 and 225:

Displacement (mm) Conclusions 45 40

- Page 226 and 227:

load carrying of the structure to b

- Page 228 and 229:

compressive stress field between co

- Page 230 and 231:

Unbonded flexible pipes and risers

- Page 232 and 233:

Figure 2: (a) Riser configuration (

- Page 234 and 235:

Furthermore the total strain varies

- Page 236 and 237:

Displacement 14 12 10 8 6 4 2 0 Mem

- Page 238 and 239:

As this project was in the conceptu

- Page 240 and 241:

kg and additional mass to represent

- Page 242 and 243:

1 Step make box 2 Step make cylinde

- Page 244 and 245:

element method. The solid model is

- Page 246 and 247:

just new element classes) without t

- Page 248 and 249:

Fig.4. Frame model and the displace

- Page 250 and 251:

capacities to meet with such demand

- Page 252 and 253:

esponses. Severe cases are to be co

- Page 254 and 255:

2 Numerical results In this section

- Page 256 and 257:

the frequency intially increases un

- Page 258 and 259:

and F (R) = ⎡ ⎢ ⎣ ... UαT (R

- Page 260 and 261:

Merit function g 10 1 10 0 10 -1 10

- Page 262 and 263:

2 STRUCTURAL CHARACTERISTICS OF PTM

- Page 264 and 265:

Fig. 5. Simplified FE model of a PT

- Page 266 and 267:

general the computational results o

- Page 268 and 269:

References [1] Ainsworth M, Oden JT

- Page 270 and 271:

Error Cause Interpolation Error Ele

- Page 272 and 273:

(a) Before Improvement (b) After Im

- Page 274 and 275:

een applied to FE fluid flow proble

- Page 276 and 277:

Acknowledgements Figure 2: Flowchar

- Page 278 and 279:

1 1 ′′ 1 ′′′ 3 ′′ 2

- Page 280 and 281:

3 COMBINING SHAPE FUNCTIONS The exp

- Page 282 and 283:

electron current). For the case of

- Page 284 and 285:

electron concentration (1/cm 3 ) x

- Page 286 and 287:

2 CONSERVATION LAW FOR A MOVING CV

- Page 288 and 289:

5 NUMERICAL RESULTS A 1-D cellular

- Page 290 and 291:

FEM can be found in [3]. In this pa

- Page 292 and 293:

h Y 1 0 −1 −2 −3 −4 −5

- Page 294 and 295:

applications. The partition of unit

- Page 296 and 297:

1.1 1.05 1 0.95 0.9 0.85 0.8 0.75 2

- Page 298 and 299:

2 NURBS BASIS FUNCTIONS NURBS are a

- Page 300 and 301:

4 RESULTS To illustrate the isoBEM

- Page 302 and 303:

290

- Page 304 and 305:

1 1 2 { σ ( ξ, s) } = [ D] { ε (

- Page 306:

4.4 Example 4 - A single edge crack