stories on hard material matters - Ceratizit S.A.

stories on hard material matters - Ceratizit S.A.

stories on hard material matters - Ceratizit S.A.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

01/08<br />

<str<strong>on</strong>g>stories</str<strong>on</strong>g> <strong>on</strong> <strong>hard</strong> <strong>material</strong> <strong>matters</strong><br />

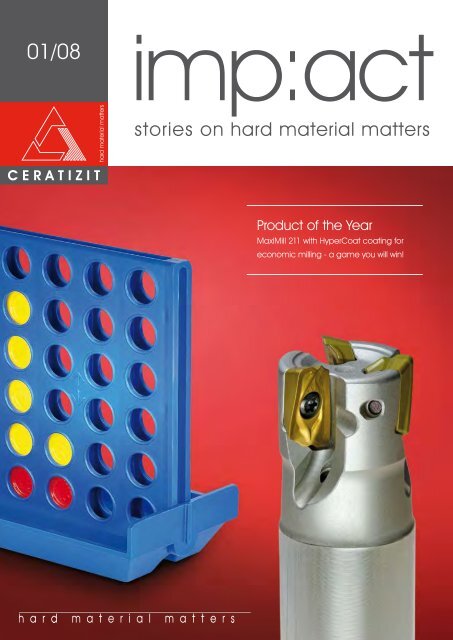

Product of the Year<br />

MaxiMill 211 with HyperCoat coating for<br />

ec<strong>on</strong>omic milling - a game you will win!

Titanium machining with CERATIZIT<br />

CERATIZIT engineers thoroughly studied the characteristics of titanium<br />

and designed a machining soluti<strong>on</strong> for this <strong>material</strong> <strong>on</strong>ly.<br />

The result is a perfect symbiosis of tungsten carbide, geometry and<br />

coating expertise - a symbiosis titanium cannot resist.<br />

www.ceratizit.com

Today, CERATIZIT is already the world-market leader<br />

for carbide products in wood and st<strong>on</strong>e machining<br />

as well as Europe‘s largest supplier for industrial<br />

wear parts. The group is also gaining strength in<br />

the USA where we are catching up in the ranking.<br />

Furthermore, CERATIZIT counts <strong>on</strong> the segments where -<br />

thanks to our expertise – we can achieve the best<br />

customer benefit and growth opportunities. In the<br />

coming years CERATIZIT will focus <strong>on</strong> Cutting Tools and<br />

c<strong>on</strong>sistently implement their multi-channel strategy.<br />

They will c<strong>on</strong>centrate <strong>on</strong> niches and develop exclu-<br />

sive soluti<strong>on</strong>s for the automotive, engineering,<br />

aerospace and oilfield sectors. We want to strive for<br />

c<strong>on</strong>tinuous organic growth above average worldwide.<br />

Ever since its foundati<strong>on</strong> CERATIZIT has grown notably<br />

quicker than the market. This is how we wantto c<strong>on</strong>tinue,<br />

am<strong>on</strong>gst others through targeted acquisiti<strong>on</strong>s. In this<br />

c<strong>on</strong>text new companies have to adapt to the CERATIZIT<br />

group strategically, culturally and also financially. With a<br />

turnover of approx. 600 milli<strong>on</strong> euros the carbide producer<br />

ranks am<strong>on</strong>g the TOP 5 worldwide. We are now striving for<br />

a turnover of <strong>on</strong>e billi<strong>on</strong> euros by 2012. In order to reach<br />

this ambitious goal we have several levers that we can<br />

activate efficiently.<br />

Pressing ahead with internati<strong>on</strong>alizati<strong>on</strong><br />

CERATIZIT has a str<strong>on</strong>g positi<strong>on</strong> in Central and Eastern<br />

Europe, thus we were able to benefit extraordinarily from<br />

the ec<strong>on</strong>omic growth in Eastern Europe and will be further<br />

extending our success.<br />

CERATIZIT is excellently positi<strong>on</strong>ed in the NAFTA area, which is<br />

still the strategically most important market in the world. We<br />

have companies in the USA and in Mexico where we have<br />

been gaining market shares for years. After the acquisiti<strong>on</strong><br />

of Newcomer Products last year CERATIZIT has become a<br />

‘household name’ also in the American Cutting Tool sector.<br />

Latin America for us is an independent market with high<br />

potential. For years the company has achieved doubledigit<br />

growth rates, and after Eastern Europe and East Asia,<br />

Latin America will remain the growth regi<strong>on</strong> where we will be<br />

investing most intensively. East Asia is at the top of our<br />

A WORD<br />

FROM THE BOARD<br />

A WORD FROM THE BOARD<br />

agenda, as we have companies in the three most important<br />

markets, China, Japan and India which c<strong>on</strong>tribute in a<br />

higher-than-average way to the group’s growth. We will<br />

certainly press ahead with our efforts in the Asian markets.<br />

“We c<strong>on</strong>sistently optimize our processes”<br />

Rati<strong>on</strong>alizati<strong>on</strong> is always a topic as the cost pressure from<br />

competitors never ceases. This does not however mean<br />

that we are trying to attain the cost structure of our Asian<br />

- namely our Chinese - competitors. And we will also not be<br />

moving our entire producti<strong>on</strong> to low-wage countries as we<br />

obviously want to maintain our high standard with regard to<br />

quality, products and services and above all our customer<br />

proximity. This however does not rule out producti<strong>on</strong> being<br />

transferred in single cases.<br />

In the framework of our current project, FOCUS FUTURE, our<br />

aim is to interlock producti<strong>on</strong> and sales, also geographically,<br />

in such a way that the customer‘s requests are fulfilled as<br />

quickly and efficiently as possible. At the moment this project<br />

“We prefer to be the number 1 in selected segments than the<br />

number 3 overall”, says Board member Wolter.<br />

basically c<strong>on</strong>cerns the West European producti<strong>on</strong> sites.<br />

But the more we grow in Asia and Latin America, the more<br />

we will extend our producti<strong>on</strong> in these regi<strong>on</strong>s to maintain<br />

customer proximity.<br />

We want to optimize all the processes which are necessary<br />

to fulfil the customer’s requests. For this purpose we have to<br />

c<strong>on</strong>tinuously increase efficiency in all areas, i.e. research &<br />

development, acquisiti<strong>on</strong>, sales, producti<strong>on</strong> and logistics.<br />

CERATIZIT and our employees have already attained a lead<br />

over competitors.<br />

Thierry Wolter<br />

Member of the Executive Board<br />

thierry.wolter@ceratizit.com<br />

03

04<br />

CONTENTS<br />

03<br />

06<br />

07<br />

08/09<br />

10/11<br />

12/13<br />

15<br />

16/17<br />

18/21<br />

22/23<br />

24/25<br />

26<br />

27<br />

28/29<br />

30<br />

31<br />

32/33<br />

34/35<br />

36/37<br />

38/41<br />

42/43<br />

A word from the Board<br />

Thierry Wolter<br />

Presentati<strong>on</strong><br />

High Speed Machining<br />

Plansee Seminar 2009<br />

- from 25 to 29 May in Reutte, Austria<br />

Trilogy <strong>on</strong> ship building<br />

Aerodyn - machining of propelling screws<br />

Trilogy <strong>on</strong> ship building<br />

SCANA - machining of motor shafts<br />

Trilogy <strong>on</strong> ship building<br />

Outokumpu - machining of<br />

stainless steel<br />

MAC coolant set<br />

Dry aluminium machining<br />

Metaldyne India<br />

Automotive machining<br />

Audi Hungaria<br />

Crankshaft machining<br />

Leicht + Müller<br />

Stamping technology<br />

Hilti<br />

Drill manufacturer<br />

MaxiMill HEC<br />

High Efficiency Cutting<br />

Change in leadership<br />

CERATIZIT Germany<br />

MSS-SX<br />

Blade system for parting and grooving<br />

Coated CBN<br />

World innovati<strong>on</strong> from CERATIZIT<br />

MaxiMill HFC<br />

High Feed Cutting<br />

Rado<br />

Carbide watch cases<br />

Zrinski Tehnologia<br />

- has found the right tooling partner<br />

Titanium machining of<br />

the future - CTC5240<br />

VM Motori, Italy<br />

Manufacturer of Diesel engines<br />

HPC 12<br />

High Performance Cutting<br />

1<br />

2<br />

3<br />

1<br />

2<br />

imp:act 01/08

3<br />

IMP:ACT 01/08<br />

imp:act, <str<strong>on</strong>g>stories</str<strong>on</strong>g> <strong>on</strong> <strong>hard</strong> <strong>material</strong> <strong>matters</strong><br />

Customer magazine from the CERATIZIT<br />

Group<br />

Published twice a year<br />

Publisher:<br />

CERATIZIT S.A.<br />

Route de Holzem, B.P. 51<br />

L-8201 Mamer<br />

Tel.: +352 312 085-1<br />

Fax: +352 311 911<br />

E-mail: info@ceratizit.com<br />

www.ceratizit.com<br />

Resp<strong>on</strong>sible editor:<br />

Filip Miermans<br />

PR and group communicati<strong>on</strong><br />

Tel: +43 (5672) 200-2127<br />

Fax: +43 (5672) 200-526<br />

E-mail: fi lip.miermans@ceratizit.com<br />

Design development:<br />

Agentur Singer, Lechaschau,<br />

Austria (www.agentur-singer.at)<br />

Printed by:<br />

RWF Frömelt-Hechenleitner<br />

Werbegesellschaft m.b.H.<br />

Volders, Austria<br />

We reserve the right to make technical<br />

changes for improvement of the product.

06<br />

7 TH INTERNATIONAL CONFERENCE ON HIGH SPEED MACHINING<br />

CERATIZIT at the 7 th Internati<strong>on</strong>al<br />

C<strong>on</strong>ference <strong>on</strong> High Speed<br />

Machining<br />

From 28 to 29 May 2008 in Darmstadt the renowned<br />

internati<strong>on</strong>al c<strong>on</strong>ference <strong>on</strong> the topic of high speed<br />

machining took place at the brand new c<strong>on</strong>ference<br />

centre ’Darmstadtium’. The impetus for the idea of<br />

the main topic of this c<strong>on</strong>ference <strong>on</strong> high speed<br />

machining (which is held every two years) came from<br />

the American aerospace industry in 1975.<br />

It was the first time then that significantly higher<br />

cutting speeds were proposed for industrial applica-<br />

ti<strong>on</strong>s in aluminium comp<strong>on</strong>ent machining. In this<br />

c<strong>on</strong>text the following advantages were shown during<br />

the first tests: improved surface qualities combined<br />

with notably increased machining efficiency, reduced<br />

cutting forces combined with a higher metal removal<br />

rate, and enhanced precisi<strong>on</strong> of the comp<strong>on</strong>ents<br />

thanks to better heat transfer into the swarf. In order<br />

to achieve this, new machines had to be designed<br />

which were able to operate with high-performance<br />

spindles and high machine dynamics. Today such<br />

high-speed processes enable five to ten times higher<br />

cutting speeds than c<strong>on</strong>venti<strong>on</strong>al processes in the<br />

aerospace industry, are applied in the field of mould<br />

and die c<strong>on</strong>structi<strong>on</strong> and in the automotive industry.<br />

The resulting demands <strong>on</strong> comp<strong>on</strong>ent geometry,<br />

machine c<strong>on</strong>cept, machining strategy and tools have<br />

been presented to and discussed by a large audience<br />

in the framework of this internati<strong>on</strong>al c<strong>on</strong>ference since<br />

the 1990’s. In two days over 120 participants listened to<br />

up-do-date presentati<strong>on</strong>s of the topics of process stabi-<br />

lity, dry machining, machines and tools, simulati<strong>on</strong>,<br />

imp:act 01/08<br />

modelling, spindle systems and <strong>hard</strong> machining, while<br />

visiting the various booths. Obviously CERATIZIT could<br />

not miss this occasi<strong>on</strong>. Dr. Schleinkofer gave a presentati<strong>on</strong><br />

<strong>on</strong> high-speed machining when using ceramic<br />

<strong>material</strong>s, and in the exhibiti<strong>on</strong> area close by the visitors<br />

could inform themselves about the competences<br />

of the CERATIZIT group.<br />

“A large expert audience c<strong>on</strong>sisting of machine<br />

manufacturers, tool producers and operators were<br />

provided with up-to-date informati<strong>on</strong> <strong>on</strong> all aspects of<br />

high-speed machining. In particular the new methods<br />

of machining process analysis (based <strong>on</strong> the machine,<br />

the work piece and the tool) were extremely interesting.”<br />

Dr. Uwe Schleinkofer<br />

Dr. Uwe Schleinkofer, head of the cutting tool development department. CERATIZIT tools for high-speed machining.

PLANSEE organises the<br />

17 th PLANSEE Seminar<br />

from 25 to 29 May 2009 in Reutte, Austria<br />

Scope of the Seminar<br />

The presentati<strong>on</strong>s at the 17 th Plansee Seminar will<br />

cover all market segments where products made from<br />

high performance P/M <strong>material</strong>s (metals, composites<br />

and <strong>hard</strong> <strong>material</strong>s) are currently playing an important<br />

role, or where they offer promising alternatives to<br />

current <strong>material</strong> soluti<strong>on</strong>s.<br />

Message from the Secretary<br />

The 17 th Plansee Seminar <strong>on</strong> Powder Metallurgical High<br />

Performance Materials will take place at the head-<br />

quarters of the Plansee Group in Reutte, Austria from<br />

May 25 – 29, 2009. It is my pleasure to invite the worldwide<br />

community involved with powder metals and <strong>hard</strong> mate-<br />

rials to participate in this event. A special invitati<strong>on</strong> is<br />

extended to students and young scientists engaged in<br />

the field of powder metallurgy. Since we gathered at<br />

the previous Plansee Seminar, the ec<strong>on</strong>omic growth<br />

particularly in Asia has str<strong>on</strong>gly increased the global<br />

demand for raw <strong>material</strong>s and hence the costs for<br />

metal powders. At the same time, resp<strong>on</strong>sibility for our<br />

PLANSEE SEMINAR 2009<br />

envir<strong>on</strong>ment impels us to critically review the amount of<br />

energy c<strong>on</strong>sumed in the manufacture of P/M products.<br />

This poses the challenge of further optimizing the overall<br />

<strong>material</strong> efficiency, e.g. by near-net-shape forming<br />

and by recycling, and of introducing novel, more<br />

energy-efficient processes, in particular for sintering.<br />

On the other hand, innovative P/M <strong>material</strong>s will c<strong>on</strong>ti-<br />

nue to play a key role in increasing the efficiency of<br />

all kinds of machinery, for energy c<strong>on</strong>versi<strong>on</strong>, for transportati<strong>on</strong><br />

etc. Developments in all these directi<strong>on</strong>s are<br />

well <strong>on</strong> the way.<br />

In this c<strong>on</strong>text the Plansee Seminar will <strong>on</strong>ce<br />

again serve as a global forum to define the current<br />

status of the science and technology of powder<br />

metals and <strong>hard</strong> <strong>material</strong>s. It will also provide a guideline<br />

for the directi<strong>on</strong> of the developments that we should<br />

embark <strong>on</strong>.<br />

Peter Rödhammer<br />

Secretary of the Plansee Seminar<br />

07

08<br />

SHIP BUILDING TRILOGY 1/3 - AERODYN<br />

Full speed ahead with cutting<br />

inserts from CERATIZIT!<br />

The Swedish shipbuilding company Aerodyn increases depth of cut<br />

by 50 %, thus doubling tool life<br />

From the left: Hans Axelss<strong>on</strong> (CERATIZIT sales manager Lars Anderss<strong>on</strong><br />

(Aerodyn managing director), Petri Piippo and Chung To (both of them<br />

Aerodyn employees) find the increase in productivity gratifying which<br />

they have achieved together.<br />

The Swedish company Aerodyn specialises in the<br />

machining of blades for propelling screws. The cast skin is<br />

eliminated and the profile finished through milling. After<br />

milling the surfaces are carefully polished. In this way,<br />

since the year 2000, several projects have been realized<br />

in close cooperati<strong>on</strong> with the carbide expert<br />

CERATIZIT and productivity increased.<br />

Propelling screw in applicati<strong>on</strong><br />

The propelling screw c<strong>on</strong>verts the<br />

energy produced by the motor<br />

into moti<strong>on</strong>. The propeller blades<br />

are characterised by a hydrodynamic<br />

wing profile. The blades<br />

are designed in such a way that<br />

the water streams around them<br />

asymmetrically when they rotate. A<br />

difference of pressure is caused in or<br />

c<strong>on</strong>trary to the directi<strong>on</strong> of movement.<br />

A current called `thrust´ is generated<br />

and drives the vessel.<br />

5-axis milling centres for propelling blades<br />

Aerodyn was founded in 1989 and first produced<br />

imp:act 01/08<br />

Laser-aided: an Aerodyn employee measures the cast blade, and<br />

determines the milling procedure.<br />

comp<strong>on</strong>ents for the aerospace industry: this is where<br />

the company name comes from. The company is<br />

based in the Swedish Karlskoga and has 40 employees<br />

who now specialise in the machining of propelling<br />

screws. In this special field Aerodyn is <strong>on</strong>e step ahead.<br />

The secret: Aerodyn was <strong>on</strong>e of the first companies to<br />

utilize 5-axis machining centres for the machining of<br />

this kind of blade. Previously, they used to be ground,<br />

not milled.<br />

Per year the Aerodyn employees machine between<br />

500 and 700 blades and numerous other comp<strong>on</strong>ents<br />

for propulsi<strong>on</strong> systems of super oil tankers, freight<br />

vessels and cruise liners. The blades, cast in br<strong>on</strong>ze or<br />

stainless steel, weigh between 80 kilos and 5 t<strong>on</strong>s and<br />

are shipped directly to the company which equips<br />

the vessels with them. There they are assembled as<br />

propelling screws. The cycle time of <strong>on</strong>e blade at<br />

Aerodyn ranges from two to three weeks or three<br />

m<strong>on</strong>ths, depending <strong>on</strong> its complexity and size. The<br />

propelling screw has two to seven blades. Propelling<br />

screws for ice-breaking vessels are normally made of<br />

stainless steel. 75 % of Aerodyn’s blades are made of<br />

br<strong>on</strong>ze, the others of stainless steel.

Maximum quality requirements – surface quality is<br />

decisive<br />

Aerodyn’s quality requirements are extremely high. The<br />

customers’ specificati<strong>on</strong>s c<strong>on</strong>cerning both strength<br />

and form are very precise, in fact a surface roughness<br />

of R a 1.6 is often demanded. Furthermore the weight<br />

of the single propeller blades should not differ from<br />

each other. With a given weight of the blades of 3.8<br />

t<strong>on</strong>s the tolerance is <strong>on</strong>ly 6 kilos, in a very fast vessel<br />

the difference in weight must not exceed <strong>on</strong>e kilo. For<br />

every order independent audits are carried out before<br />

the products are released.<br />

Productivity increase with CERATIZIT tools<br />

In recent years several projects in the field of cutting<br />

tools have been realized in close cooperati<strong>on</strong> between<br />

SHIP BUILDING TRILOGY 1/3 - AERODYN<br />

the Swedish Aerodyn sales and the CERATIZIT Energy<br />

& Transport segment. The CERATIZIT inserts -M31 CTC<br />

5235 with HyperCoat-coating have, for instance,<br />

been applied now for several m<strong>on</strong>ths. And the results<br />

are stunning. “Applying the CTC5235 inserts we have<br />

been able to increase the cutting depth by 50% and<br />

simultaneously double tool life. I d<strong>on</strong>’t think we need to<br />

go into more detail here“, says a satisfied Petri Piippo,<br />

producti<strong>on</strong> manager at Aerodyn.<br />

Lars Anderss<strong>on</strong>, Aerodyn managing director, <strong>on</strong> the<br />

questi<strong>on</strong> about the particular advantages of working<br />

together with CERATIZIT states: “Quality, service and<br />

market-adapted prices are the characteristics of<br />

CERATIZIT. We also appreciate the possibility to be able<br />

to order <strong>on</strong>line via the E-TechStore at CERATIZIT.”<br />

The propeller blades are characterised by a hydrodynamic wing profile: blades weigh between 80 kilo and 5 t<strong>on</strong>s. Propelling screws for ice-breaking<br />

vessels are normally made of stainless steel.<br />

09

SHIP BUILDING TRILOGY 2/3 - SCANA<br />

Motor shafts <strong>on</strong> the high seas –<br />

customer story from CERATIZIT<br />

Scana relies <strong>on</strong> CERATIZIT’s competence in ship building<br />

2No matter whether it is a tanker or a luxury cruise liner,<br />

a motor yacht or a passenger ferry - all these vessels<br />

have <strong>on</strong>e thing in comm<strong>on</strong>: shafts transmit the force<br />

from the engine to the propeller. The producti<strong>on</strong><br />

of such shafts is a speciality of the<br />

Scana company. For turning ope-<br />

rati<strong>on</strong>s, Scana relies <strong>on</strong> inserts and<br />

tools from CERATIZIT.<br />

10<br />

Scana Björneborg in Sweden is<br />

part of the Norwegian Scana<br />

Industrier ASA, which manufactures<br />

steel products for the<br />

following five industry sectors:<br />

energy (comp<strong>on</strong>ents for generators<br />

and turbines), ship building<br />

(propeller shafts and hubs),<br />

machines and transport (axles,<br />

clutches and forks for fork lifts), steel<br />

(rolls, forged comp<strong>on</strong>ents and profiles)<br />

and offshore products (valves and joints for drilling<br />

platforms). The entire group has 1,850 employees, 320<br />

at the Björneborg site.<br />

Inserts for internati<strong>on</strong>al customers<br />

The Björneborg site looks back <strong>on</strong> a l<strong>on</strong>g forging<br />

traditi<strong>on</strong>: the first forge was built as far back as 1656.<br />

Scana Björneborg has its own steelwork, its own forge<br />

with a 3600/4500 t<strong>on</strong> press, a facility for heat treatment<br />

and a machine hall for finishing. Per year about 2,500<br />

For the turning of shafts (this <strong>on</strong>e here is 25 metres l<strong>on</strong>g) Scana relies <strong>on</strong><br />

inserts and tools from CERATIZIT.<br />

imp:act 01/08<br />

products are manufactured for ABB, Siemens, Rolls<br />

Royce, DEW, Wärtsilä, Metso and Shell. In the field of<br />

turning Scana applies inserts and tools from CERATIZIT.<br />

The roughing of a propeller shaft takes between 15 and 30 hours.

Interview with Magnus Dåverhög, producti<strong>on</strong><br />

and process engineer at Scana:<br />

Which <strong>material</strong> are the shafts made of?<br />

Dåverhög: “The shafts are made of steel. The alloy is<br />

adapted to the applicati<strong>on</strong> and requirements. Every<br />

product we manufacture is therefore unique.”<br />

Where do you buy the steel?<br />

Dåverhög: “We buy steel scrap within a radius of 150<br />

km and melt it ourselves. The waste produced at our<br />

company during machining is also recycled. The raw<br />

<strong>material</strong> department machines about 80,000 t<strong>on</strong>s of<br />

steel per year. We use 100 different steel grades.”<br />

How much swarf is produced per m<strong>on</strong>th?<br />

Dåverhög: “That depends <strong>on</strong> the parts we machine. On<br />

average these are around 1000 t<strong>on</strong>s per m<strong>on</strong>th.”<br />

How l<strong>on</strong>g does it take <strong>on</strong> average to machine a shaft?<br />

Dåverhög: “After forging the shafts are subject to heat<br />

treatment and are then transported to the machine hall.<br />

Most of the time the parts are <strong>on</strong>ly rough machined,<br />

which takes between 15 and 30 hours. If the shaft has to<br />

be finish-machined (as in the case of naval shafts) we<br />

are talking about several hundred hours.”<br />

What is so special about this kind of machining?<br />

Dåverhög: “We produce shafts with a length up to 25<br />

metres and a diameter of up to two metres. All shafts<br />

are produced through open-die forging. As every shaft<br />

is unique, their manufacture can be c<strong>on</strong>sidered as a<br />

SHIP BUILDING TRILOGY 2/3 - SCANA<br />

Magnus Dåverhög, producti<strong>on</strong> and process engineer at Scana.<br />

special art. It takes many years to train a good machine<br />

operator so that he is able to carry out turning and<br />

milling operati<strong>on</strong>s reliably. We are therefore very happy<br />

to have more than 350 years of experience at the<br />

Björneborg site!”<br />

How do you assess the relati<strong>on</strong>ship of Scana and<br />

CERATIZIT?<br />

Dåverhög: “We strive c<strong>on</strong>tinuously to optimize our<br />

processes. In this respect the tools in the workshop are<br />

an important element. We work together very closely<br />

with some companies, and CERATIZIT is <strong>on</strong>e of them.<br />

CERATIZIT always provides tools which corresp<strong>on</strong>d to the<br />

state of the art of carbide technology.”<br />

Scana Björneborg has wide experience in the manufacture of l<strong>on</strong>g products. The first forge was built as far back as 1656.<br />

11

12<br />

SHIP BUILDING TRILOGY 3/3 - OUTOKUMPU<br />

Building bridges in the world with<br />

CERATIZIT<br />

Carbide expert CERATIZIT helps with the machining of stainless steel<br />

for giant tankers and bridges<br />

Stainless steel is a <strong>material</strong> which is difficult to machine.<br />

It is characterized by low thermal c<strong>on</strong>ductivity and a<br />

relatively high tendency to cold <strong>hard</strong>ening; it is tough<br />

and tends to adhesi<strong>on</strong>. The c<strong>on</strong>sequence: its machinability<br />

is four times worse than the <strong>on</strong>e of machining<br />

steel. A big challenge, as shown by the example of the<br />

CERATIZIT customer Outokumpu in Degerfors in Sweden.<br />

Stainless steels are very popular thanks to their particular<br />

properties. The <strong>material</strong> has an aesthetic appearance,<br />

is resistant to corrosi<strong>on</strong> and can be recycled completely.<br />

It is mainly applied in the fields of catering and<br />

household (33%), c<strong>on</strong>structi<strong>on</strong> of industrial plants (26%)<br />

and transport (16%). Stainless steel c<strong>on</strong>sists of at least<br />

10.5% to 13 % of chrome. Thanks to this high chrome<br />

c<strong>on</strong>tent, a protective passive layer of chrome oxide<br />

is created <strong>on</strong> the work piece surface. Stainless steel is<br />

mainly used in sectors where cleanliness and hygiene<br />

are of utmost importance. In fact this steel is resistant to<br />

water, vapour, humidity, salt, acids in food and weak<br />

organic or inorganic acids.<br />

Know-how for high-tech bridge c<strong>on</strong>structi<strong>on</strong><br />

The Outokumpu group achieves a turnover of six billi<strong>on</strong><br />

euros with 8,000 employees worldwide. The visi<strong>on</strong> of the<br />

group is to become the unc<strong>on</strong>tested number 1 in the<br />

stainless steel sector.<br />

3<br />

The Outokumpu plant in Degerfors mainly<br />

manufactures stainless steel flat and<br />

l<strong>on</strong>g products. “We have a very<br />

wide product range and countless<br />

applicati<strong>on</strong>s are possible”, says<br />

Business Development Manager<br />

Anders Finnås. One of our<br />

speciality fields is ship and bridge<br />

building. The company produces<br />

sheet metal for the internal<br />

panelling of tankers which transport<br />

chemical products. In the field<br />

of high-tech bridge c<strong>on</strong>structi<strong>on</strong> the<br />

company‘s know-how lies primarily in<br />

the producti<strong>on</strong> of sheet metal and structural<br />

parts made of stainless steel. “Both appearance<br />

and corrosi<strong>on</strong> resistance play a very important<br />

role. A bridge in stainless steel is not <strong>on</strong>ly technically<br />

interesting but also has a l<strong>on</strong>ger service life, and is also<br />

visually appealing thanks to the <strong>material</strong>,“ says Finnås.<br />

A prestige project in H<strong>on</strong>g K<strong>on</strong>g: St<strong>on</strong>ecutters Bridge.<br />

An Outokumpu employee checks the milling cutters.<br />

imp:act 01/08<br />

St<strong>on</strong>ecutters Bridge in the H<strong>on</strong>g K<strong>on</strong>g harbour: a<br />

prestige project<br />

In H<strong>on</strong>g K<strong>on</strong>g at the moment <strong>on</strong>e of the l<strong>on</strong>gest cablestayed<br />

bridges in the world is being built: St<strong>on</strong>ecutters<br />

Bridge. From 2009 <strong>on</strong>wards this highway bridge will relieve<br />

the city centre of c<strong>on</strong>tainer trucks and serve as a prominent<br />

gateway to the harbour of the city. The bridge’s<br />

structural system will have a width of 51 m and will be<br />

provided with 4 lanes in every directi<strong>on</strong> plus a breakdown<br />

lane. The total length of the bridge will amount to<br />

1596 metres with a span of 1018 metres.

Due to the saline air and the str<strong>on</strong>g gale-force winds in<br />

H<strong>on</strong>g K<strong>on</strong>g the upper 120 metres of the 300 metres high<br />

bridge pyl<strong>on</strong>s were cladded with high-tensile stainless<br />

steel (duplex) by Outokumpu. The company produced<br />

both the cladding elements made of stainless steel (all<br />

in all 2,000 t<strong>on</strong>s) and the anchoring of the main bearer<br />

cables. What is so special about it? The duplex stainless<br />

steel will need no maintenance work for the entire<br />

service life of the bridge.<br />

More than <strong>on</strong>ly stainless steel sheets<br />

Outokumpu however does not <strong>on</strong>ly supply stainless steel<br />

sheets. The company supports customers with regard to<br />

<strong>material</strong> selecti<strong>on</strong>, planning and c<strong>on</strong>structi<strong>on</strong> during the<br />

entire project and optimally prepares the sheet metal<br />

with perfect surface treatment, precise form and joints<br />

tailored to the welders’ needs.<br />

High demands with regard to the CERATIZIT inserts<br />

The CERATIZIT cutting inserts are used at Outokumpu<br />

for the preparati<strong>on</strong> of joints. With the HyperCoat grade<br />

CTP2235 Outokumpu mills the most varied joint profiles.<br />

Stainless steel is a <strong>material</strong> which is difficult to machine.<br />

Internal cladding in stainless steel in a tanker that transports chemical <strong>material</strong>s.<br />

SHIP BUILDING TRILOGY 3/3 - OUTOKUMPU<br />

For example, its thermal c<strong>on</strong>ductivity is <strong>on</strong>ly a third of the<br />

thermal c<strong>on</strong>ductivity of machining steel. For this reas<strong>on</strong><br />

the heat that is produced during machining can <strong>on</strong>ly be<br />

evacuated insufficiently through the swarf. The tendency<br />

towards work <strong>hard</strong>ening is relatively high. This means<br />

that after a first machining step the <strong>material</strong> <strong>on</strong> the<br />

surface becomes <strong>hard</strong>er than before, so the cutting edge<br />

needs to perform even better in the sec<strong>on</strong>d operati<strong>on</strong>.<br />

Furthermore, stainless steel is particularly tough, has a<br />

relatively high tendency to adhesi<strong>on</strong> and bad chip<br />

formati<strong>on</strong>. This is why its machinability is four times<br />

worse than the <strong>on</strong>e of machining steel. Especially for<br />

Outokumpu CERATIZIT has developed the cutting<br />

insert SEAN250161 and offers a tailored soluti<strong>on</strong> for the<br />

machining of stainless steel. The inserts are used in a strip<br />

edge milling cutter by Outokumpu. In this way the ideal<br />

tool is created for the machining of difficult <strong>material</strong>s<br />

such as stainless steel. Good clamping, small tool overhang<br />

and small corner radius or radius of the cutting<br />

edge are decisive to avoid vibrati<strong>on</strong> and cutting forces.<br />

Sufficient cutting depth should be applied so that the<br />

cutting edges in the following operati<strong>on</strong> interact as little as<br />

possible with the cold formed layer.<br />

13

MaxiMill 211 – make the c<strong>on</strong>necti<strong>on</strong>!<br />

1: Win with performance, 2: Win <strong>on</strong> quality,<br />

3: Win time savings, 4: Win tool life.<br />

MaxiMill 211 with HyperCoat coating for ec<strong>on</strong>omic milling -<br />

a game you will win!

World innovati<strong>on</strong>: machining of<br />

aluminium wheels now<br />

without coolant<br />

Benefit from savings with the new MAC tool from CERATIZIT<br />

One of the special fields of the carbide expert CERATIZIT<br />

is aluminium wheel machining. The recently developed<br />

MAC system now allows the complete dry machining of<br />

wheels without refitting machines. In this way CERATIZIT<br />

<strong>on</strong>ce again is able to support their customers in the<br />

automotive industry when it comes to the decisive topic<br />

of cost reducti<strong>on</strong>.<br />

C<strong>on</strong>venti<strong>on</strong>al cooling in the field of aluminium wheel<br />

machining through cooling lubricants is cost intensive.<br />

Both the recycling of the chips and the coolant causes<br />

c<strong>on</strong>siderable costs. While machining a wheel between<br />

four and six kilos of swarf are produced. The recycling<br />

costs are about 20 cent per kilo or approximately <strong>on</strong>e<br />

euro per wheel. For tens of thousands of aluminium rims<br />

where dry machining is applied instead of wet machining<br />

attractive saving is realized very quickly. With the latest<br />

world innovati<strong>on</strong> MAC from CERATIZIT, aluminium rim<br />

producers can save m<strong>on</strong>ey, optimize their profit and<br />

distinguish themselves from competitors.<br />

Ingenious: MAC cools utilizing the Joule-Thoms<strong>on</strong> effect<br />

“There were already various external air cooling<br />

systems available in the market, however, their effect was<br />

satisfactory to a limited degree. The nozzle was too far<br />

away from the tool, too much cold air was lost,” explains<br />

Michael Steiner in charge of the development of<br />

the new MAC tool at the CERATIZIT development<br />

department.<br />

With MAC the CERATIZIT research department has<br />

solved this problem. The cooling unit is directly integrated<br />

into the CERATIZIT tool. The compressed air from the<br />

machine goes through the tool into the MAC unit and is<br />

then cooled to minus temperatures through a physical<br />

effect known as Joule-Thoms<strong>on</strong> effect. Then it imme-<br />

diately hits the insert and the work piece.<br />

This causes the air to be divided into a warm and a cold<br />

stream (depending <strong>on</strong> the setting). The cold air exits <strong>on</strong><br />

the fr<strong>on</strong>t of the insert through the lateral holes <strong>on</strong> the<br />

tool. The air temperature <strong>on</strong> the cutting edge is then in<br />

sub-zero range and efficiently cools both work piece<br />

and tool. About 6 bar and 400 l/min capacity are the<br />

prerequisite<br />

MAC<br />

The cold air reduces the temperature of the swarf and<br />

enabling the tool to decrease and in a lot of cases<br />

ideally avoids the tendency of adhesi<strong>on</strong> of aluminium.<br />

The cooling intensity depends <strong>on</strong> the quantity of air<br />

supplied, its entrance temperature, the quality of the air<br />

and the tool settings of MAC.<br />

The CERATIZIT programme for dry machining<br />

Currently the following grades are available for dry<br />

machining of aluminium wheels:<br />

• CTP4115 (PVD –TiAlN lubricating layer; K10)<br />

• CTD4110 (medium fine diam<strong>on</strong>d grains; DP-K01)<br />

CTP4115 is a tried and tested PVD coating with good<br />

low-fricti<strong>on</strong> properties. Its advantages can mainly be<br />

seen when machining aluminium alloys with low silic<strong>on</strong><br />

c<strong>on</strong>tent (Si ≤ 3 %) in combinati<strong>on</strong> with str<strong>on</strong>g built-up<br />

edge.<br />

In grade CTD4110, PCD (polycrystalline diam<strong>on</strong>d) being<br />

an extremely <strong>hard</strong> cutting <strong>material</strong> is characterised<br />

by high abrasi<strong>on</strong> resistance and l<strong>on</strong>g service life. This<br />

grade is particularly suitable for aluminium alloys with<br />

increased silic<strong>on</strong> c<strong>on</strong>tent (Si ≥ 12 %), for polish turning of<br />

mirror faces and the machining of high-quality wheels<br />

and comp<strong>on</strong>ents in aluminium.<br />

The newly developed MAC system from CERATIZIT now allows the<br />

complete dry machining of wheels without refitting machines.<br />

15

16<br />

METALDYNE, INDIA<br />

CERATIZIT customer<br />

report at subc<strong>on</strong>tractor<br />

Metaldyne in India<br />

Metaldyne Managing Director Sabherwal:<br />

“CERATIZIT does not sell bulk products, but engineering”<br />

“Metaldyne believes in the strength of people and<br />

ideas”, Tim Leuliette, chairman of the Metaldyne Board<br />

describes the mainspring that drives the company.<br />

Metaldyne is a leading global designer and supplier<br />

of power train and chassis products for the automotive<br />

industry. Metaldyne has been a CERATIZIT India<br />

customer since 2003.<br />

Metaldyne supplies brands such as Ford, H<strong>on</strong>da, Renault,<br />

Nissan, Toyota and Daimler-Chrysler with high-quality<br />

products. The company has 6500 employees worldwide<br />

and achieves a turnover exceeding 2 billi<strong>on</strong> dollars. The<br />

products range from dampers, exhaust parts, pumps<br />

and assemblies for clutches and differential gears to<br />

suspensi<strong>on</strong> comp<strong>on</strong>ents.<br />

Flywheels for trucks and dampers for cars<br />

The Metaldyne site in Jamshedpur, India, employs 330<br />

people. Here flywheels for trucks and dampers for cars<br />

are produced. The products arrive as cast ir<strong>on</strong> compo-<br />

nents and are then machined with CERATIZIT tools. Per<br />

m<strong>on</strong>th around 4,500 flywheels are manufactured by<br />

Metaldyne. It takes 13 minutes to machine a flywheel.<br />

With a cutting edge of the CERATIZIT turning insert<br />

CNMG120408/12EN TFQ in the grade CTC1110,<br />

Metaldyne machines up to 30 flywheels.<br />

Metaldyne Jamshedpur produces about 25,000 ’dampo-<br />

lators’. A ‘dampolator’ is a ring which reduces vibrati<strong>on</strong><br />

of the crankshaft when machining at high or also low<br />

RPM. Six machining operati<strong>on</strong>s are necessary until a<br />

blank is finished. For this purpose the CERATIZIT inserts<br />

CTC11353 and CTC1125 are applied. A damper is<br />

completely machined within <strong>on</strong>ly four minutes. This short<br />

machining time can <strong>on</strong>ly be achieved because tool life<br />

is relatively l<strong>on</strong>g. One cutting edge (CTC1125) can be<br />

used to face turn up to 270 parts and a cutting edge of<br />

CTC1135 does the finish turning for 90 comp<strong>on</strong>ents until<br />

it has to be reversed.<br />

Metaldyne employee balancing a flywheel.<br />

imp:act 01/08<br />

After the flywheel has been machined the external ring is mounted.

Interview with<br />

Sanjay Sabherwal,<br />

Managing Director<br />

Metaldyne India<br />

Mr. Sabherwal, what is most typical of the Indian<br />

industry?<br />

Sabherwal: “I would say the speed, definitely. In 1991<br />

it took about three weeks to get a teleph<strong>on</strong>e installed,<br />

now there are approximately six milli<strong>on</strong> new teleph<strong>on</strong>e<br />

c<strong>on</strong>tracts per m<strong>on</strong>th. This is why India has a telecommunicati<strong>on</strong>s<br />

system which is far more modern than, for<br />

example, the American system. Mobility is also increasing<br />

rapidly: We have so many airline flights now that<br />

we cannot train enough pilots – we employ them from<br />

other countries.”<br />

The automotive industry is booming in India. An example<br />

is Tata presenting its new small-sized and low-budget<br />

car called the `Nano´. What does this mean for the<br />

suppliers to the automotive industry such as Metaldyne?<br />

Sabherwal: “For us this means an incredible price pressure.<br />

Cost reducti<strong>on</strong> is an <strong>on</strong>going process in this industry,<br />

translated into as many parts per minute as possible.<br />

Today the producti<strong>on</strong> volumes are about 1.4 milli<strong>on</strong> cars<br />

and 500,000 trucks per year. These numbers require a<br />

different approach in producti<strong>on</strong>.”<br />

Damper parts for automobile motors before machining.<br />

Sanjay Sabherwal, Managing Director.<br />

METALDYNE, INDIA<br />

What about quality?<br />

Sabherwal: “Quality is taken for granted. Customers are<br />

more interested in process stability and reliability.”<br />

CERATIZIT is your preferred partner for cutting tool<br />

soluti<strong>on</strong>s. Why is CERATIZIT different?<br />

Sabherwal: “CERATIZIT does not sell a commodity, it sells<br />

engineering, and this is what we need. Our customers pay<br />

for designed products with added value, so we design<br />

for our customers. CERATIZIT offers great soluti<strong>on</strong>s which<br />

enable the highest speeds with the best feeds at the<br />

lowest prices! Another plus for CERATIZIT is the enormous<br />

commitment to our company, which is the basis of a<br />

healthy relati<strong>on</strong>ship.”<br />

17

18<br />

CRANKSHAFT MACHINING AT AUDI HUNGARIA<br />

Crankshaft machining<br />

with tailor-made inserts<br />

from CERATIZIT<br />

Report from the CERATIZIT customer Audi Hungaria<br />

AUDI HUNGARIA MOTOR Kft. in Györ, Hungary, has 5,500<br />

employees. Here the engines for the brands of the Volkswagen<br />

group, Audi, VW, Skoda and Seat are manufactured.<br />

In Györ the Audi TT Coupé and Roadster is built,<br />

and the Audi A3 Cabriolets will be built there in the future.<br />

In 2006 more than 23,500 vehicles and close to two<br />

milli<strong>on</strong> engines left the plant. This makes Audi Hungaria the<br />

sec<strong>on</strong>d biggest exporter in Hungary. For the machining<br />

of crankshafts Audi Hungaria counts <strong>on</strong> the technology<br />

and experience of the carbide expert CERATIZIT.<br />

Audi is syn<strong>on</strong>ymous with optimum technical performance<br />

and the logo with the four rings. In a few words: Audi ranks<br />

as <strong>on</strong>e of the top firms in the automotive world. It therefore<br />

makes sense to purchase products at CERATIZIT, the<br />

technological leader in the field of carbide for wear parts<br />

and cutting tools.<br />

Crankshaft machining at Audi<br />

Györ is situated 45 km from the Austrian border, in Hungary,<br />

and numbers 130,000 inhabitants. Since 1994 Audi<br />

Hungaria Motor Kft has been located at the periphery of<br />

the town. Audi selected this site for various reas<strong>on</strong>s: the<br />

logistic c<strong>on</strong>necti<strong>on</strong> is very good, within a radius of 50 km<br />

there are competitive subc<strong>on</strong>tractors, a hall with a<br />

surface of 100,000 sq.m. already existed, and a lot of<br />

people in this area speak German very well. Furthermore<br />

the technical University of Györ ensures that well-trained<br />

engineers and experts are available.<br />

Crankshafts are exposed to enormous forces; their<br />

producti<strong>on</strong> requires maximum precisi<strong>on</strong><br />

Zoltán Szathmári is in charge of producti<strong>on</strong> planning and<br />

tool technology in engine producti<strong>on</strong> at Audi Hungaria<br />

Motor Kft. He works closely together with the CERATIZIT<br />

representatives and development specialists. His most<br />

important c<strong>on</strong>tact <strong>on</strong> site is Barnabás Deri, the sales<br />

manager of CERATIZIT Hungaria.<br />

Szathmári leads us through the impressive producti<strong>on</strong><br />

department: high, luminous halls with three extremely<br />

l<strong>on</strong>g and up-to-the-minute producti<strong>on</strong> lines, which are<br />

in additi<strong>on</strong> fully automated. At Audi in Hungary it is very<br />

clean and <strong>on</strong>e is immediately aware that the employees<br />

are proud to work here.<br />

imp:act 01/08<br />

In crankshaft machining Audi Hungaria relies <strong>on</strong> seven<br />

different types of inserts from CERATIZIT: special soluti<strong>on</strong>s<br />

CERATIZIT developed together with the machine manufacturer<br />

GFM. Maximum precisi<strong>on</strong> is required. Zoltán<br />

Szathmári explains: “The crankshaft is an essential comp<strong>on</strong>ent<br />

of the engine. It c<strong>on</strong>verts the linear movement into<br />

a rotati<strong>on</strong>al movement. The comp<strong>on</strong>ent is exposed to<br />

enormous forces. We manufacture six different crankshafts.<br />

The crankshafts are supplied in forged c<strong>on</strong>diti<strong>on</strong>. Before<br />

machining, a crankshaft for the 3.0 TDI engine weighs 26<br />

kg, after machining it still weighs as much as 18 kg.“<br />

An Audi employee dismantling a planetary milling cutter. After around<br />

250 crankshafts the inserts in the milling cutter have to be indexed.<br />

Before machining a crankshaft for the 3.0 TDI engine weighs 26 kg, after<br />

machining it still weighs as much as 18 kg.

Three highly modern complete automated producti<strong>on</strong> lines in the huge 100,000 sq.m. hall.<br />

Mr Szathmári, what is important in the machining of<br />

crankshafts?<br />

Szathmári: “Two thirds of producti<strong>on</strong> relate to the 3.0<br />

TDI engine. The crankshafts for this engine are made of<br />

42CrMoS4. Rough machining of this crankshaft represents<br />

a difficult task as it c<strong>on</strong>sists of a high-tensile <strong>material</strong><br />

at the limit to soft machining. The <strong>hard</strong> forging skin<br />

virtually ‘eats away’ the tool.”<br />

What does that mean for the tools?<br />

Szathmári: “The blank crankshaft is irregular and shows<br />

varying properties and the surface is not homogeneous.<br />

This means <strong>hard</strong> and irregular strain <strong>on</strong> the insert.”<br />

How l<strong>on</strong>g does an insert last?<br />

Szathmári: “When rough machining (rough milling of<br />

main bearing and webs) the inserts are mounted <strong>on</strong> a<br />

KURBELWELLENBEARBEITUNG BEI AUDI UNGARN<br />

Interview with Zoltán Szathmári, producti<strong>on</strong> planning<br />

and tooling technology at Audi Hungaria<br />

planetary milling cutter or side and face milling cutter.<br />

After around 250 crankshafts the inserts in the milling<br />

cutter have to be indexed.”<br />

How do you assess the relati<strong>on</strong>ship with CERATIZIT?<br />

Szathmári: “We have been working together with<br />

CERATIZIT for four years and maintain a very open<br />

relati<strong>on</strong>ship, there are no secrets. For every new<br />

development we are informed precisely about what<br />

has been improved. CERATIZIT is in a c<strong>on</strong>tinuous<br />

optimizati<strong>on</strong> process and is aware that coming to a<br />

standstill is dangerous, because the pressure is high:<br />

every year we invite tenders for the inserts, every year<br />

there are new test procedures and CERATIZIT has to<br />

assert itself. We have been very successful for four<br />

years.”<br />

19

20<br />

CRANKSHAFT MACHINING AT AUDI HUNGARIA<br />

Interview with László Janó,<br />

product segment V6,<br />

mechanical producti<strong>on</strong><br />

department at<br />

Audi Hungaria<br />

Mr Janó, how l<strong>on</strong>g does the machining of a crankshaft<br />

take?<br />

Janó: “There are several ways of looking at this. You<br />

could say that at the end of the producti<strong>on</strong> line a<br />

finished crankshaft comes out every 49 sec<strong>on</strong>ds. This is<br />

the cycle time of the line. Including the buffers (per line<br />

there are 5,700 cranks in the buffers) the flow time for<br />

1,400 parts per day amounts to around six days.”<br />

How important is the role of the tools in this producti<strong>on</strong><br />

line?<br />

Janó: “Extremely important. This line is very complex and<br />

flexible. The investment for such a line, for instance, is<br />

three times as high as for a line for the producti<strong>on</strong> of<br />

cylinder heads. For such a complex machining method<br />

process security has to be very good. In the automated<br />

machining chain tool life has to be c<strong>on</strong>sistently high.<br />

65% of the costs are tooling costs. The tools also play a<br />

very important role.“<br />

What is the proporti<strong>on</strong> of n<strong>on</strong> c<strong>on</strong>forming <strong>material</strong>?<br />

Janó: “The tolerances for a crankshaft are very close.<br />

The entire line is designed for this and is c<strong>on</strong>tinuously opti-<br />

mized. Quality c<strong>on</strong>trol is also very intensive. For the 3.0<br />

TDI engine a 100% rupture test is carried out. For me the<br />

quality of the final product is important, not so much the<br />

share of n<strong>on</strong> c<strong>on</strong>forming <strong>material</strong>. In the last four years<br />

Patrick Zobl, product manager at CERATIZIT,<br />

describes crankshaft machining in detail<br />

Technique for crankshaft machining<br />

• High cutting speeds (up to 260 m/min)<br />

• Planetary milling cutters with diameters ranging from<br />

350mm to 750mm<br />

• Dry machining leading to high temperature stress <strong>on</strong><br />

the cutting <strong>material</strong><br />

• High number of teeth of the planetary milling cutters<br />

(40 up to 200 teeth)<br />

• Main bearing and webs are machined at the same<br />

time with two planetary milling cutters<br />

• Due to the length and the relatively small diameter of<br />

the crankshaft machining stability is low<br />

imp:act 01/08<br />

László Janó, product segment V6 with a finished Audi crankshaft.<br />

<strong>on</strong>ly two crankshafts have been returned to us; this was<br />

due to faulty <strong>material</strong>, not to faulty machining.“<br />

What can a crankshaft withstand?<br />

Janó: “I d<strong>on</strong>‘t want to give numbers, but the basic rule<br />

is that the crankshaft has to withstand three times as<br />

much as the engine.“<br />

Requirements with regard to the CERATIZIT inserts<br />

• High resistance to thermal shock<br />

• C<strong>on</strong>sistent quality of the cutting <strong>material</strong> providing<br />

process security at the customer<br />

• L<strong>on</strong>g tool life, therefore low tool changing costs<br />

• Smooth surface thanks to lower fricti<strong>on</strong>al heat<br />

and wear<br />

Materials used in crankshafts<br />

• Cast ir<strong>on</strong> <strong>material</strong>s for engines when subject to<br />

reduced stress in the engine<br />

• Alloyed steel (Cr, Ni, Mo) with high fatigue strength in<br />

engines which are subject to higher stress or to<br />

reduce weight

CRANKSHAFT MACHINING AT AUDI HUNGARIA<br />

AUDI HUNGARIA MOTOR in Györ, Hungary: in 2006 al<strong>on</strong>e more than 23,500 vehicles and close to two milli<strong>on</strong> engines left the plant.<br />

Basic characteristics of CERATIZIT inserts<br />

• Geometry of the insert is mainly defined by the<br />

profile of the crankshaft<br />

• CERATIZIT chooses the insert to be applied as well as<br />

the geometry of the cutting edge<br />

Steps in the producti<strong>on</strong> of a crankshaft<br />

a. Preparati<strong>on</strong><br />

1. Cutting and centring<br />

2. Internal and external profile milling of the pin of the<br />

bearing and c<strong>on</strong>necti<strong>on</strong> rod bearing pin<br />

3. Turning of the main bearing pins and the end parts<br />

4. Deburring<br />

5. Solid carbide deep hole drilling<br />

b. Hardening (inducti<strong>on</strong> <strong>hard</strong>ening)<br />

c. Finishing<br />

1. Hard turning<br />

2. Threading<br />

3. Chain wheel broaching<br />

4. CBN grinding<br />

5. Fluorescent rupture test<br />

6. Dynamic balancing<br />

7. Finishing (polishing and lapping)<br />

d. Quality test<br />

21

22<br />

LEICHT + MÜLLER, STAMPING INDUSTRY<br />

High pressure, high speed<br />

and precisi<strong>on</strong><br />

imp:act 01/08<br />

CERATIZIT is the technological leader worldwide in the field of the die industry<br />

Every day we deal with stamped parts. No matter<br />

whether it is furniture metal fittings or motor saws, small<br />

plug-in c<strong>on</strong>tacts in computers, mobile ph<strong>on</strong>es or electric<br />

household appliances – we can find stamped parts<br />

practically everywhere. At the Reutte site CERATIZIT<br />

produces carbide erosi<strong>on</strong> blocks and formed parts for<br />

the die industry according to customer drawings. One<br />

of the CERATIZIT customers who has been trusting the<br />

carbide expert for many years already is the<br />

Leicht + Müller Stanztechnik company.<br />

Stamping is the manufacture of flat or bent parts made<br />

of sheet metal or foil strips using a stamping press and<br />

a stamping tool. CERATIZIT produces carbide erosi<strong>on</strong><br />

blocks and formed parts from which the customer makes<br />

die inserts and punches through spark erosi<strong>on</strong> (EDM and<br />

wire erosi<strong>on</strong>) or grinding. In fact the business segment<br />

‘tool and die industry’ has gained the world leadership<br />

in the past few years.<br />

The Leicht + Müller success story<br />

The Leicht + Müller Stanztechnik company produces<br />

stamped parts and tools for automotive electrics, telecommunicati<strong>on</strong>,<br />

household appliances and many other<br />

industry sectors. The company was founded in November<br />

1984 by Heinz Leicht, expert toolmaker, and Klaus<br />

Müller, tool c<strong>on</strong>structor, in Remchingen near Pforzheim<br />

(Germany). Their priority was to enter the internati<strong>on</strong>al<br />

vanguard of tooling manufacturers.<br />

Some of the Leicht + Müller products: around a billi<strong>on</strong><br />

of such parts are produced per year.<br />

As far back as 1985 Leicht + Müller also started their<br />

producti<strong>on</strong> of stamped parts. This sec<strong>on</strong>d string to their<br />

bow not <strong>on</strong>ly provided synergy effects but also decisive<br />

growth impulses for the company. Today Leicht + Müller<br />

has 60 employees, who <strong>on</strong> a surface of 5,500 sq.m.<br />

produce approx. 1.3 billi<strong>on</strong> stamped parts (20-80 t<strong>on</strong>s)<br />

per year <strong>on</strong> 10 Bruderer stamping machines.<br />

Up-to-date stamping machines for razor blades<br />

The company is particularly proud of the project for<br />

Gillette (Procter & Gamble Group): together with other<br />

companies Leicht + Müller developed a complex, fully<br />

automatic stamping line for the further processing of<br />

razor blades which are applied in the latest product<br />

‘FUSION’. The Americans requested a higher output from<br />

Leicht + Müller as compared to the previous technology<br />

applied. In the meantime three complete stamping lines<br />

have been built at L+M which are suitable for batch<br />

producti<strong>on</strong> and have been delivered to Gillette (two<br />

of them in Bost<strong>on</strong>/USA and <strong>on</strong>e in Berlin/Germany).<br />

The most important parameters of the currently most<br />

modern stamping machines worldwide is the notably<br />

higher output, 500 strokes per minute, two blades with 13<br />

laser points per stroke respectively, a cleaning module,<br />

laser measuring device and a camera in the stamping<br />

tool. Furthermore robotics and c<strong>on</strong>veyor belts to<br />

guarantee full automati<strong>on</strong> of the process are also utilized.

Interview with the leading<br />

management quartet of Leicht + Müller<br />

At Leicht + Müller the young generati<strong>on</strong> is already<br />

straining at the leash. The s<strong>on</strong>s Timo Leicht and Marco<br />

Müller have both completed a profound educati<strong>on</strong>.<br />

Currently they are working in Sales, Marketing, project<br />

management and in the company management, and<br />

later <strong>on</strong> they will entirely take <strong>on</strong> the resp<strong>on</strong>sibilities of<br />

their fathers, Heinz Leicht and Klaus Müller.<br />

What is important in stamping technology and what<br />

does that mean with reference to the carbide?<br />

Marco Müller: “High precisi<strong>on</strong>, l<strong>on</strong>g tool life and profitability.<br />

Carbide applied in high-performance stamping<br />

technology has to be adapted c<strong>on</strong>tinuously to the high<br />

demands regarding tool life and will always be under<br />

scrutiny when compared to ceramics.”<br />

Is there a ceramic soluti<strong>on</strong> which can keep the pace?<br />

Marco Müller: “This discussi<strong>on</strong> has been going <strong>on</strong> for a<br />

while. Of course we have already tested special ceramic<br />

grades and the results in terms of wear and tool life were<br />

sometimes even better than with carbide. However,<br />

the applicati<strong>on</strong> of ceramic is not worthwhile c<strong>on</strong>sidering<br />

the high acquisiti<strong>on</strong> costs and the extraordinary<br />

complexity of machining operati<strong>on</strong>s compared to<br />

carbide. Up to now ceramic has not caught <strong>on</strong> in our<br />

sector for ec<strong>on</strong>omic reas<strong>on</strong>s, and this is also not to be<br />

expected in the near future.”<br />

What are the trends in the stamping sector?<br />

Timo Leicht: “Target prices <strong>on</strong> a globally minimum level,<br />

but products of the customary best German quality. The<br />

market is becoming more and more difficult and <strong>on</strong>e<br />

has to orient <strong>on</strong>eself based <strong>on</strong> low-wage countries. For<br />

cost reas<strong>on</strong>s <strong>on</strong>e should actually buy comp<strong>on</strong>ents for<br />

stamping tools there in order to remain competitive.<br />

The quality however up to now does not meet the<br />

standards of Leicht + Müller. So we have to c<strong>on</strong>centrate<br />

<strong>on</strong> cost reducti<strong>on</strong> in our company, e.g. automati<strong>on</strong> of the<br />

processes. Another tendency is towards hybrid compo-<br />

nents (plastic-metal composite <strong>material</strong>).<br />

Visi<strong>on</strong> C<strong>on</strong>trol for <strong>on</strong>e hundred per cent process security<br />

Leicht + Müller offers an extensive service range. The<br />

company’s designers work <strong>on</strong> 2-D (Cadda) and 3-D<br />

(Solid Works) CAD work places from Daveg. The<br />

Pforzheim based company is also able to offer prototyping<br />

and pilot producti<strong>on</strong>. Last but not least it is involved<br />

in batch producti<strong>on</strong> of stamped parts with Visi<strong>on</strong><br />

C<strong>on</strong>trol for guaranteed product quality and ‘laser<br />

marking <strong>on</strong> the fly’ for 100 per cent traceability (every<br />

single part is provided with a marking without slowing<br />

down the process).<br />

LEICHT + MÜLLER, STAMPING INDUSTRY<br />

A family-owned company – two generati<strong>on</strong>s manage the high-tech<br />

company Leicht + Müller. (From left: Marco Müller, Klaus Müller, Heinz<br />

Leicht and Timo Leicht).<br />

An ever increasing number of customers requests<br />

complete assemblies from <strong>on</strong>e source, that means<br />

stamped parts are covered with plastic and provided<br />

with additi<strong>on</strong>al comp<strong>on</strong>ents such as e.g. Reed sensors<br />

or resistances. Since 2004 we have been able to offer<br />

this through Leicht + Müller SYSCOTEC.”<br />

How did the partnership with CERATIZIT start?<br />

Heinz Leicht: “That was at the beginning of the 80’s. At<br />

that time Josef Lämmle was the segment manager. He<br />

visited us frequently and asked if we were ready to test<br />

his products, and he was successful.”<br />

How do you assess the relati<strong>on</strong>ship with CERATIZIT?<br />

Klaus Müller: “We are delighted with the carbide from<br />

CERATIZIT! We appreciate speed, the large assortment<br />

and above all c<strong>on</strong>sistent quality. In a business where<br />

time pressure is enormous the business partners have to<br />

be absolutely reliable. And we fully trust the CERATIZIT<br />

team which has been serving us professi<strong>on</strong>ally for many<br />

years. Carbide is really a matter of c<strong>on</strong>fidence!”<br />

Combinati<strong>on</strong>s of metal and plastic<br />

Leicht + Müller SYSCOTEC (Systems, Comp<strong>on</strong>ents,<br />

Technologies) was founded in 2004 and specializes<br />

in the development and producti<strong>on</strong> of complete<br />

assemblies, i.e. combinati<strong>on</strong>s of metal stamping<br />

products and plastic parts. The new products from<br />

Leicht + Müller SYSCOTEC have brought customers such<br />

as Mercedes, BMW, TRW and C<strong>on</strong>tinental Teves <strong>on</strong>to<br />

the scene. The first batch producti<strong>on</strong> for level sensors in<br />

automotive windscreen washing fluid started in 2005.<br />

23

24<br />

HILTI, DRILL MANUFACTURER<br />

CERATIZIT produces carbide<br />

bits for HILTI drills<br />

Customer story for the development of tailored carbide bits<br />

The demands <strong>on</strong> the carbide follow from the practical requirements at<br />

the c<strong>on</strong>structi<strong>on</strong> sites, which according to up-to-date market analyses<br />

are steadily increasing.<br />

HILTI, the CERATIZIT key-account customer in the field<br />

of st<strong>on</strong>e working is based in the Principality of Liechten-<br />

stein. HILTI has been buying all carbide bits from the<br />

carbide expert CERATIZIT since 1985. As: <strong>on</strong> the interface<br />

between the drill and the base <strong>material</strong> the carbide<br />

from CERATIZIT shows its strength, thus ensuring l<strong>on</strong>g tool<br />

life. Jan Do<strong>on</strong>gaji, Senior Vice President Business Unit<br />

Drilling & Demoliti<strong>on</strong> at HILTI states: “It is exactly the<br />

products made of carbide from CERATIZIT that customers<br />

perceive as distinctive.”<br />

“In the 1990’s HILTI, the worldwide market and technology<br />

leader in the professi<strong>on</strong>al drill business, together with<br />

CERATIZIT developed the idea of launching a welded<br />

solid head drill. That was the hour of birth of an intensive<br />

development cooperati<strong>on</strong>”, remembers Dr. Wolfgang<br />

Böhlke, Head of the Wear Part Development at<br />

2<br />

1<br />

imp:act 01/08<br />

On the interface between the drill and the base <strong>material</strong> the carbide<br />

from CERATIZIT shows its strength, ensuring l<strong>on</strong>g tool life.<br />

CERATIZIT Luxembourg. The solid head soluti<strong>on</strong> of the<br />

HILTI drill is still unique today. There are no single carbide<br />

pins and tips which are inserted into the steel body, but<br />

<strong>on</strong>ly <strong>on</strong>e head which is brazed or welded <strong>on</strong>to the steel<br />

body.<br />

Georg Schmid, Business Unit Manager of the tool produc-<br />

ti<strong>on</strong> at HILTI explains: “As the drill head c<strong>on</strong>sists entirely<br />

of <strong>on</strong>e carbide <strong>on</strong>ly, there is more freedom in terms of<br />

cutting edge geometry which subsequently results in<br />

better drilling performance.”<br />

Unique solid head soluti<strong>on</strong> wins EPMA Award<br />

The joining process is regarded as the most delicate<br />

step in drill producti<strong>on</strong>. Schmid: “Carbide and steel are<br />

rather unequal partners when it comes to properties<br />

like brittleness and thermal expansi<strong>on</strong>. The critical area<br />

with regard to fractures is undoubtedly where the steel<br />

and the carbide are c<strong>on</strong>nected.” In order to avoid this<br />

problem HILTI and CERATIZIT developed a solid carbide<br />

drill with gradient structure. This means that the carbide<br />

Solid head drill with gradient z<strong>on</strong>es in C3X geometry, 4-16 mm – the best<br />

powder-metallurgical development at the EPMA c<strong>on</strong>ference.<br />

Carbide with a gradient structure: 1 Wear resistant <strong>on</strong> the<br />

drill tip, 2 Stable welded c<strong>on</strong>necti<strong>on</strong> with the steel shank

is extremely <strong>hard</strong> <strong>on</strong> the tip but rather tough <strong>on</strong> the<br />

steel side. The gradient in the carbide combines two<br />

characteristics: good wear resistance <strong>on</strong> the tip and a<br />

stable welded c<strong>on</strong>necti<strong>on</strong> with the steel shank. The solid<br />

head drill with gradient z<strong>on</strong>es which was developed by<br />

HILTI and CERATIZIT together with the geometry C3X was<br />

even awarded a prize at the EPMA c<strong>on</strong>ference 2006 in<br />

Gent (EPMA = European Powder Metallurgy Associati<strong>on</strong>).<br />

“The cooperati<strong>on</strong> between HILTI and CERATIZIT also<br />

includes basic elements such as the development of new<br />

cutting <strong>material</strong>s“, says Dr. Till Cramer, Head of the C<strong>on</strong>sum-<br />

ables Development BU Drilling and Demoliti<strong>on</strong> at HILTI:<br />

“HILTI strives for c<strong>on</strong>sistent differentiati<strong>on</strong> in the market.<br />

The cutting <strong>material</strong> represents the key technology<br />

for the differentiati<strong>on</strong> of a drill,“ says the drill expert. “We<br />

really appreciate CERATIZIT’s extraordinary willingness to<br />

implement such developments with us.” Vice President<br />

Do<strong>on</strong>gaji adds: “It has also to do with trust and traditi<strong>on</strong>.<br />

We have already developed several generati<strong>on</strong>s<br />

of drills together, which enables us to move <strong>on</strong> to the<br />

next level of competency together.”<br />

HILTI, DRILL MANUFACTURER<br />

focuses <strong>on</strong> high quality. Dr. Cramer says: “In additi<strong>on</strong><br />

to drills HILTI also develops heavy duty hammers and<br />

combi-hammers. In this way the two comp<strong>on</strong>ents, tool<br />

and carbide bit, can be perfectly adapted to each<br />

other. Those who drill several hundred holes a day realize<br />

the difference.”<br />

Drill producti<strong>on</strong> in Kaufering<br />

The drills are actually not produced in Liechtenstein but<br />

in Kaufering in Bavaria. HILTI’s drills range from diameter<br />

5 mm (length 120 mm) up to diameter 40 mm (length<br />

920 mm).<br />

HILTI relies <strong>on</strong> innovative soluti<strong>on</strong>s for c<strong>on</strong>structi<strong>on</strong> sites<br />

HILTI as a brand name l<strong>on</strong>g ago became syn<strong>on</strong>ymous<br />

with heavy duty drills and other tooling systems am<strong>on</strong>gst<br />

professi<strong>on</strong>als; the company employs 20,000 people<br />

and stands for innovative soluti<strong>on</strong>s for professi<strong>on</strong>als at<br />

c<strong>on</strong>structi<strong>on</strong> sites. And the results are stunning. In 2007<br />

the HILTI group showed a double-digit growth for the<br />

fourth time in a row, launching more than 30 new<br />

products <strong>on</strong> the market every year.<br />

Demands <strong>on</strong> the carbide in the drilling industry<br />

The demands <strong>on</strong> the carbide result from the drill itself,<br />

and these demands are steadily increasing. The <strong>material</strong><br />

to be machined is becoming ever <strong>hard</strong>er, and the<br />

carbide bits are characterized by ever higher<br />

performance capacity. CERATIZIT head of development<br />

Böhlke says: „The demands <strong>on</strong> the carbide are basically<br />

maximum wear resistance when drilling very abrasive<br />

c<strong>on</strong>crete and sufficient toughness when encountering<br />

reinforcements in the c<strong>on</strong>crete. This also requires a stable<br />

welded c<strong>on</strong>necti<strong>on</strong> with the steel shank of the drill.“ And<br />

these capabilities are tested at HILTI in an exceedingly<br />

demanding laboratory for new developments that HILTI drills with CERATIZIT carbide bits are supplied throughout the world.<br />

25

26<br />

MaxiMill HEC<br />

CERATIZIT‘s MaxiMill HEC offers<br />

clear performance advantages:<br />

High Efficiency Cutting<br />

The new MaxiMill HEC cutters from CERATIZIT will reduce tooling costs when machining Cast Ir<strong>on</strong> comp<strong>on</strong>ents and maximise productivity.<br />

The launch of CERATIZIT’s MaxiMill HEC face milling<br />

system at EMO 2007 is further proof of the high levels of<br />

research and development taking place at its Reutte,<br />

Austria manufacturing facility.<br />

The MaxiMill HEC accepts CERATIZIT precisi<strong>on</strong>-<br />

manufactured inserts of either carbide, ceramic or CBN<br />

<strong>material</strong>, which provide up to eight useable edges. These<br />

tangentially-mounted inserts are mounted in such a way<br />

as to ensure maximum cutting performance and cutter<br />

stability, while at the same time reducing the power<br />

required to operate them at their optimum, making<br />

them suitable to a much wider range of machine tools.<br />

The result is a face milling cutter that will generate high<br />

table feeds, l<strong>on</strong>g and c<strong>on</strong>sistent tool life, ec<strong>on</strong>omic<br />

applicati<strong>on</strong> and process security. While MaxiMill HEC<br />

can be used in virtually any C.I. face milling applicati<strong>on</strong><br />

it will be of real interest to those companies supplying the<br />

automotive sector where the volumes and comp<strong>on</strong>ent<br />

types will suit its particular characteristics and generate<br />

the maximum productivity and cost savings for the enduser.<br />

Typical applicati<strong>on</strong> areas for MaxiMill HEC would<br />

be cast ir<strong>on</strong> comp<strong>on</strong>ents such as c<strong>on</strong>tact faces of<br />

crank cases, cylinder heads, turbochargers and pump<br />

cases, etc.<br />

imp:act 01/08<br />

“MaxiMill HEC is the result of an <strong>on</strong>going and extensive<br />

development programme at CERATIZIT”, says C<strong>on</strong>an<br />

Jacks<strong>on</strong>, CERATIZIT UK’s Sales Manager. “HEC is a<br />

welcome extensi<strong>on</strong> to the existing MaxiMill range and<br />

will provide many of our automotive customers with the<br />

opportunity to maximise their machine capacity while<br />

reducing tooling costs.”<br />

With the LNHX 1106PNER inserts available in grades<br />

CTC3215 (carbide), CTN3105 Si3N4 (ceramic) and<br />

segmented CBN, the cutting data achieved is impressive.<br />

For example, machining GG25 <strong>material</strong> at a <strong>hard</strong>ness<br />

of HB 180-220 is achieved at 200m/min, 0.25 mm/tooth<br />

feed rate with up to 5 mm depth of cut and 79 mm<br />

width of cut. Similarly, GGG 70 <strong>material</strong> at a <strong>hard</strong>ness<br />

of HB 240-300 can be cut at 180 m/min at a feed<br />

of 0.2 mm/tooth.

Change in leadership at<br />

CERATIZIT Germany<br />