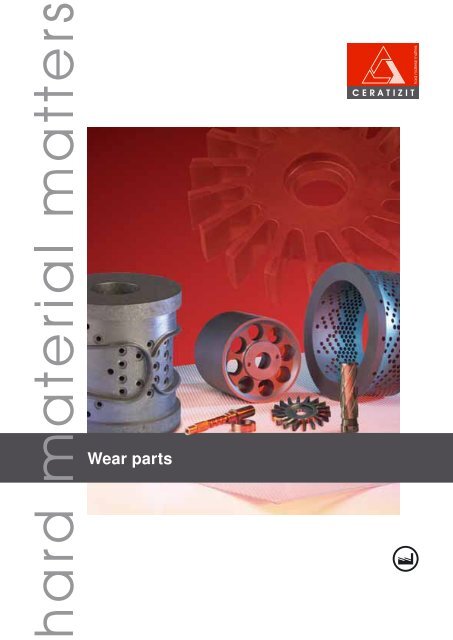

Wear parts

Wear parts

Wear parts

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Wear</strong> <strong>parts</strong>

2<br />

CERATIZIT – the parent companies<br />

Headquarters and parent company in<br />

MAMER / Luxembourg<br />

Hard material matters – it is the<br />

core of our business. Through<br />

in-depth knowledge and highly<br />

flexible production facilities we<br />

strive to provide our business<br />

partners with direct competitive<br />

advantages in the field of hard<br />

materials for tooling solutions<br />

and wear <strong>parts</strong>. Our dedication<br />

to hard material matters creates<br />

intelligent solutions for tomorrow<br />

and time to come.<br />

North America<br />

• USA<br />

South America<br />

• Brasil<br />

Direct sales and distribution partners<br />

Production plants in the three<br />

main economic areas and a<br />

worldwide sales network of<br />

subsidiaries and distribution<br />

partners ensure a quick response<br />

to customer needs. In-house<br />

training courses and seminars<br />

guarantee that both business<br />

partners and employees share<br />

the latest information on our product<br />

range.<br />

Europe<br />

• Austria<br />

• Bulgaria<br />

• Czech Republic<br />

• France<br />

• Germany<br />

• Hungary<br />

• Italy<br />

• Luxembourg<br />

• Netherlands<br />

• Poland<br />

• Switzerland<br />

• Spain<br />

• United Kingdom<br />

Parent company in REUTTE / Austria<br />

We promote intensive dialogue<br />

with our customers and strive for<br />

long-term business relations on<br />

a partnership basis.<br />

The CERATIZIT corporate value<br />

‘The focus and point of view of<br />

our business partners matters’<br />

is a guiding principle for all<br />

CERATIZIT employees worldwide.<br />

Asia<br />

• China<br />

• India<br />

• Japan

CERATIZIT – other production sites for wear <strong>parts</strong><br />

CERATIZIT Hitzacker, Germany<br />

Production site for:<br />

• blanks for metal forming<br />

CERATIZIT Horb, Germany<br />

Production site for:<br />

• general wear <strong>parts</strong> and preforms<br />

CERATIZIT Schweiz AG<br />

Production site for:<br />

• blanks and finished <strong>parts</strong> for<br />

various segments<br />

CERATIZIT Columbia South Carolina, USA<br />

Production site for:<br />

• balls and products for the wood industry<br />

CERATIZIT Warren Michigan,<br />

USA<br />

Production site for:<br />

• carbide formed <strong>parts</strong> for<br />

the American market<br />

3

4<br />

Blanks for<br />

metal forming<br />

Sealing rings<br />

Automotive industry<br />

Food industry<br />

Wire industry<br />

<strong>Wear</strong> <strong>parts</strong> for<br />

industrial applications<br />

Oil industry<br />

Brick industry<br />

Chemical industry<br />

Electronics/electrical engineering<br />

Nozzles

<strong>Wear</strong> <strong>parts</strong> for<br />

industrial applications<br />

Glass industry<br />

Coating technology<br />

Rotary cutters<br />

CERATIZIT is the world market<br />

leader in selected industry sectors<br />

for unique and consistently<br />

innovative hard material products.<br />

General<br />

wear <strong>parts</strong><br />

Lock industry<br />

Crushing/recycling<br />

Stone working<br />

High-pressure tools<br />

Parts for high-speed<br />

machines<br />

5

6<br />

Hard materials for wear <strong>parts</strong><br />

Hard materials in general and hard metals in particular offer a series of interesting properties for all<br />

applications where maximum wear resistance is required. In practical applications, wear <strong>parts</strong> are<br />

usually influenced by various interdependent factors: high pressure, high temperature, use of abrasive<br />

or aggressive media, machining of hard materials. These are only some examples of criteria causing<br />

wear, which hard materials or hard metals have to be resistant to. The powder-metallurgical production<br />

of CERATIZIT wear <strong>parts</strong> enables tailor-made wear resistance of the material.<br />

This is what makes CERATIZIT hard materials and hard metals indispensable when it comes to<br />

decisively increasing the service life of highly stressed components. Ever more powerful machines,<br />

facilities and machining methods create daily new challenges for the CERATIZIT development<br />

engineers. Our development projects are characterised by close cooperation with customers as well as<br />

a joint search for solutions to application problems.<br />

Causes of wear<br />

Abrasion<br />

Cutting with water-jet and abrasive<br />

additives at a pressure of<br />

4000 bar (approx. 500g sand/min.)<br />

Temperature<br />

Cutting of molten glass.<br />

Temperature 1,250°C<br />

Pressure/mechanical<br />

stress<br />

Tool for the synthesis<br />

of CBN and PCD<br />

pressure during operation:<br />

72,000 bar

Competence and know-how<br />

At CERATIZIT we consider the carbide<br />

business to be a matter of confidence.<br />

Decades of experience in carbide<br />

development and production enable us<br />

to offer you this confidence. Our quality<br />

management systems meet the highest<br />

standards. This is documented by the<br />

ISO9001:2000 quality certificate.<br />

Our facilities and production methods<br />

represent state-of-the-art technology<br />

because only modern and innovative<br />

production procedures offer the possibility<br />

to fulfil complex tasks economically.<br />

Engineering know-how and competent<br />

on site application advice, as well<br />

as intensive cooperation with our<br />

customers make the difference.<br />

Make use of our professional service.<br />

Our dedication to hard material matters<br />

creates intelligent solutions for<br />

tomorrow and time to come.<br />

7

8<br />

Tungsten oxide<br />

Reduction<br />

Tungsten<br />

Carburising<br />

Tungsten<br />

carbide<br />

Carbide production / blanks<br />

Carbide is a composite material consisting of particles mainly with tungsten carbide as hard material<br />

and a metallic binder. For this reason, with carbide it is possible to achieve hardness and toughness<br />

combinations which cannot be obtained with other materials. The graphic illustration below shows the<br />

basic steps for producing carbide blanks in the metal forming sector.<br />

Powder preparation<br />

Due to its high melting point tungsten carbide (WC) can only be produced through sintering when needed<br />

for technically sophisticated applications. For this purpose, the powder consisting of the tungsten carbide,<br />

the cobalt binder (Co) and sometimes additional alloys, is mixed, milled and spray-dried.<br />

This process results in a spray-dried granulate which can easily be used for production, since its chemical<br />

and physical properties have already been adapted to the final carbide specification (e.g. WC grain<br />

size).<br />

Co (NI,Fe)<br />

Mixing<br />

Milling<br />

TiC, TaC, NbC<br />

Cr3C2 , VC, MoC<br />

Granulation<br />

Carbide powder<br />

granulate

Manufacture and machining of blanks<br />

Carbide production<br />

By applying pressure the carbide powder is converted into a blank. The material will receive its near net<br />

shape through the application of traditional machining methods (sawing, drilling, milling, turning), so that<br />

extended machining of the sintered carbide blank is no longer necessary. The density of the blank is<br />

approx. 50% of the sintered carbide‘s density which leads to an approx. 20% shrinkage in length.<br />

Sintering<br />

Die<br />

pressing<br />

Sintering<br />

Blanks<br />

Isostatic<br />

pressing (cold)<br />

Optional:<br />

machining of blanks<br />

The sintering process converts the blank into a homogeneous piece of carbide with a high degree of<br />

hardness. When sintering hard metal (usually at a temperature of approx. 1400°C), this process is called<br />

liquid phase sintering. In this case, the binder (e.g. cobalt) melts and wets the WC hard material particles.<br />

After sintering, the density of the carbide is almost, or even precisely, the same as the theoretical density.<br />

Any residual porosity which occurs after the sintering procedure may be removed through an ensuing<br />

HIP process.<br />

Further processing<br />

9

10<br />

Grinding<br />

Carbide manufacturing / finishing<br />

CNC external and<br />

internal cylindrical<br />

grinding<br />

CNC surface and<br />

profile grinding<br />

Coatings / surface treatment<br />

Precision centreless grinding<br />

<strong>Wear</strong> <strong>parts</strong> with<br />

PVD or CVD coatings<br />

Face and parallel<br />

lapping<br />

CNC 5-axesgrinding<br />

Our machines and plants meet highest demands with regard to standards and functionality,<br />

precision and reliability.<br />

Our coating competence covers classic hard material coatings and functional tailor-made coatings<br />

for specific customer applications. For the production of coatings we apply CVD, PVD and galvanic<br />

processes. Special surface treatments are mainly applied to improve brazing properties.<br />

Parts with cobalt coating

Composite <strong>parts</strong><br />

For several applications it does not make sense to manufacture the entire component in hard metal.<br />

The use of hard metal is limited to the area in which wear occurs. Materials with suitable wearresistance<br />

are used for the carrier tool; they are easier to machine than carbide. For the combination of<br />

carbide with other materials, numerous tried and tested technologies are applied.<br />

Examples: brazing, gluing, clamping, connections with screws and shrinking.<br />

Erosion<br />

Control<br />

Chamfering insert<br />

brazed on steel part<br />

Cavity sinking of a<br />

coining die<br />

3D measurement of an<br />

extrusion pressing die<br />

Carbide ring glued on<br />

steel core<br />

Carbide treatment by means of spark erosion meets the highest technological standards. Wire erosion<br />

and cavity sinking by EDM additionally guarantee high precision. Long-standing experience combined<br />

with carbide grades that are specially adapted for erosion guarantee optimum machining results.<br />

Wire erosion of a<br />

formed part<br />

The control of finished components is part of our certified quality management system. This control is<br />

carried out by qualified staff, mainly on computer-controlled measuring machines. Control records are<br />

archived for 10 years. Upon request the customer can view the quality management records which are<br />

relevant for him.<br />

11

12<br />

<strong>Wear</strong> resistance<br />

Cermet<br />

Natural diamond<br />

Hard materials / carbide<br />

PCD<br />

Diamond coated<br />

CBN<br />

Ceramic (O)<br />

Ceramic (N)<br />

What is carbide?<br />

Cemented carbide<br />

HSS<br />

Toughness<br />

Carbide is a brittle, hard material<br />

with mechanical properties that<br />

can be adjusted within a very wide<br />

range, given its composition and<br />

microstructure. The hardness and<br />

toughness range of the CERATIZIT<br />

grades includes everything from<br />

wear resistant tool steel to super-hard<br />

ceramic materials.<br />

Carbide is a powder metallurgically produced composite material consisting of a hard material<br />

(e.g. tungsten carbide, WC) and a metallic binder (e.g. cobalt, Co)<br />

The hard material provides the necessary<br />

→ hardness<br />

→ wear resistance<br />

The metallic binder provides<br />

→ toughness<br />

Carbide properties depending on the Co contents<br />

and WC grain size<br />

Cobalt content ↑↑<br />

Grain size ↓↓<br />

T.R.S.<br />

High hardness<br />

(= wear resistance)<br />

WC<br />

Co<br />

WC<br />

Micrograph of WC-Co carbide<br />

Cobalt content ↓↓<br />

Grain size ↓↓<br />

Fracture<br />

toughness<br />

Cobalt content ↑↑<br />

Grain size ↑↑

The basis for optimum quality<br />

The graphic illustrations below show that the mechanical properties of the carbide mainly depend on the binder<br />

content (Co) and the TC grain size. Hardness, i.e. wear resistance, increases inversely/reciprocally proportional<br />

to the fracture toughness. This means that the harder the material the more it reacts to notch tensions and impact<br />

stress (the ‘impact resistance’ parameter, which cannot be precisely defined, correlates to a high degree with the<br />

fracture toughness of the material).<br />

On the other hand, the transverse rupture strength does not directly depend on the hardness but rather on the TC<br />

grain size and the cobalt content. The adhesive wear (tendency to stick), however, decreases with the grain size and<br />

the cobalt content of the carbide used. The list of the mentioned interdependencies, which could be extended at will<br />

for other wear and failure mechanisms, show that it is only possible to choose the correct carbide grade following a<br />

systematic procedure and/or based on experience with similar forming processes.<br />

Submicron grain<br />

Fine / medium grain<br />

Coarse grain<br />

Hardness [HV30]<br />

Transverse rupture strength [MPa]<br />

Toughness K IC-value [MPa*m 1/2 ]<br />

Submicron grain<br />

Fine / medium grain<br />

Coarse grain<br />

Submicron grain<br />

Fine / medium grain<br />

Coarse grain<br />

Submicron grain<br />

Fine / medium grain<br />

Coarse grain<br />

13

14<br />

CT<br />

grade<br />

code<br />

Grades ISO K Application<br />

range<br />

WC/Co grain size coarse/medium<br />

Grade characteristics<br />

Binder Hardness T.R.S. Grain<br />

size<br />

[%] HV10 HV30 HRA [MPa] [P.S.I.]<br />

CTM12 B10T K20 G10 6 1520 1500 91,1 2200 319.000<br />

CTM14 GC12 K25 G10 7 1550 1530 91,4 2600 377.000<br />

CTM17 GC15 K30-K40 G15 8,5 1420 1400 90,4 2800 406.000<br />

CTC12 GC17 K30 G10-G20 6 1350 1340 89,9 2800 406.000<br />

CTC20 B30T/GC32 K40 G20-G30 10 1170 1160 88,2 3000 435.000<br />

CTC25 B40T/CE65 >K40 G20-G30 12,5 1080 1070 87,2 3100 450.000<br />

CTC30 B50T/GC40 - G30-G40 15 1020 1010 86,5 3150 457.000<br />

CTC35 GC50 - G40-G50 17,5 950 940 85,6 3200 464.000<br />

CTC40 B60T/GC60 - G40-G50 20 900 890 84,9 3200 464.000<br />

CTC50 B70T/GC65 - >G50 25 810 800 83,5 3200 464.000<br />

CTC60 GC70 - >G50 30 730 720 82,2 3200 464.000<br />

WC/Co grain size fine<br />

CTF08 GC01 K05-K10 G01 4 1850 1820 93,2 2100 305.000<br />

CTF11 GC05/H10T K10 G05 5,5 1760 1730 92,7 2300 334.000<br />

CTF12 GC10/H20T/AG06 K20 G10 6 1630 1610 91,9 2300 334.000<br />

CTF18 H30T/AG09 K30 G15 9 1490 1470 91,1 2800 406.000<br />

CTF24 GC20/H40T/AG12 K40 G20 12 1350 1340 89,8 3000 435.000<br />

CTF30 GC30/H50T >K40 G30 15 1240 1230 88,8 3100 450.000<br />

CTF40 GC37/H60T - G40 20 1050 1040 86,7 3400 493.000<br />

CTF50 GC55/H70T - G50 25 950 940 85,4 3400 493.000<br />

CTF54 GC62 - >G50 27 920 910 85,0 3200 464.000<br />

WC/Co grain size submicron<br />

CTS06 MG06/TSM01 K01 - 3,3 2020 1980 93,9 3300 479.000<br />

CTS10 TSM05 K05 - 4,8 1980 1940 93,8 3300 479.000<br />

CTS12 MG12/TSM10 K05-K10 - 6 1850 1820 93,3 3500 508.000<br />

CTS15 MG15/TSM20 K10-K30 - 7,5 1740 1710 92,6 3600 522.000<br />

CTS20 MG18/TSM33 K20-K40 - 10 1650 1630 92,1 3700 537.000<br />

CTS24 MG24/TSM40 K40 - 12 1490 1470 90,9 4000 580.000<br />

CTS30 MG30 >K40 - 15 1330 1320 89,7 3800 551.000<br />

WC/Co grain size ultrafine<br />

CTU05 SMG02

CT<br />

grade<br />

code<br />

Grade characteristics<br />

CTU05R CTU05R 2,5 (NiCr) 2350 2250 95,0 2000 290.000<br />

CTU06M KCR05 - - 2,8 (CoNiCr) 2150 2110 94,5 2500 363.000<br />

CTS06M KCR06 - - 3 (CoNiCr) 1950 1910 93,6 2300 334.000<br />

CTU12R CTU12R - - 6 (NiCr) 1750 1720 92,6 2600 377.000<br />

CTU17R KR15 - - 8,5 (NiCr) 1760 1730 92,7 2500 363.000<br />

CTS17R KR16/V714 - - 8,5 (NiCr) 1600 1580 91,7 2800 406.000<br />

CTF16R KR17/TNI25 - - 8 (NiCr) 1480 1460 90,8 2900 421.000<br />

CTM16N K16 - - 8 (Ni) 1300 1290 89,4 2400 348.000<br />

CTC20M CTC20M - - 10 (CoNiCr) 1100 1090 87,3 2600 377.000<br />

CTC40M CTC40M - - 20 (CoNiCr) 850 840 84,0 2800 406.000<br />

CTC60M CTC60M - - 30 (CoNiCr) 650 640 80,9 2700 392.000<br />

When referring to carbide, ‘corrosion’ means the detachment of the binder caused by corrosive<br />

materials. This can cause early breakage (notching!) or notably increased wear. In this context<br />

carbides containing Co/Ni or Ni or a chromium-doped binder represent an advantage.<br />

The ferromagnetic properties of cobalt and nickel make it possible to magnetise carbides which have<br />

a suitable binder. Upon request some of the nickel-bound carbide grades can also be delivered as non<br />

magnetic grades.<br />

CT<br />

grade<br />

code<br />

Grades Density Binder Hardness T.R.S. Grain<br />

size<br />

[g/cm 3 ] [%] HV10 HV30 HRA [MPa] [P.S.I.]<br />

Cermets (TiC basis carbides)<br />

CTF28T TCN541 6,4 14 (CoNi) 1550 1530 91,4 2400 348.000<br />

CTF36T TWF18 5,9 18 (Ni) 1470 1450 90,8 1800 261.000<br />

Silicon nitride (Si3N4)<br />

Grades ISO K Application<br />

range<br />

Corrosion resistant grades<br />

SNC1 SNC1 3,25 9 1550 1530 91,4 1100 160.000<br />

Classification of the WC grain size<br />

WC grain size [µm] Classification<br />

< 0,2<br />

nano<br />

0,2 - 0,5<br />

ultrafine<br />

0,5 - 0,8<br />

submicron<br />

0,8 - 1,3<br />

fine<br />

1,3 - 2,5<br />

medium<br />

2,5 - 6,0<br />

coarse<br />

> 6,0<br />

extra-coarse<br />

Binder Hardness T.R.S. Grain<br />

size<br />

[%] HV10 HV30 HRA [MPa] [P.S.I.]<br />

ultrafine<br />

submicron<br />

ultrafine<br />

ultrafine<br />

submicron<br />

submicron<br />

medium<br />

coarse<br />

coarse<br />

coarse<br />

fine<br />

fine<br />

ultrafine<br />

Comments:<br />

1. The data in this table<br />

represents typical material<br />

parameters. We reserve the<br />

right to modify the data due to<br />

technical progress or due to<br />

further development within our<br />

company.<br />

15

16<br />

Modulus of elasticity [GPa]<br />

Grain size Impact stress<br />

700<br />

0,245<br />

600<br />

0,240<br />

500<br />

0,235<br />

400<br />

0,230<br />

300<br />

0,225<br />

200<br />

0,220<br />

100<br />

0,215<br />

0<br />

0,210<br />

2 6 10 14 18 22 26<br />

Co content<br />

Modulus of elasticiy [GPa]<br />

Poisson‘s ratio [-]<br />

Grade characteristics<br />

Basic guidelines for the selection of carbide grades:<br />

Poisson‘s ratio [-]<br />

Stress caused<br />

by notching<br />

Density [GPa]<br />

15,5<br />

15,0<br />

14,5<br />

14,0<br />

13,5<br />

13,0<br />

Tension and<br />

compression<br />

(with good surface<br />

quality!)<br />

Resistance<br />

to adhesion<br />

(against metal)<br />

Coarse/medium ++ + o o<br />

Fine + o o +<br />

Submicron o - + ++<br />

Ultrafine - -- ++ ++<br />

Within the various classes of grain sizes the following applies: the lower the Co content (=increased hardness), the higher the<br />

wear resistance and compressive strength, but toughness decreases notably.<br />

Modulus of elasticity, Poisson‘s ratio, density<br />

and thermal expansion coefficient<br />

4<br />

2 6 10 14 18 22 26<br />

Co content<br />

Modulus of elasticity<br />

Thermal expansion<br />

Co content<br />

[GPa] Poisson‘s ratio [-] Density [g/cm³] coefficient [10-6 1/K]<br />

4 648 0,21 15,2 4,6<br />

6 623 0,22 15,0 4,8<br />

8 598 0,22 14,8 5<br />

10 574 0,22 14,6 5,2<br />

12 549 0,24 14,4 5,4<br />

14 524 0,23 14,2 5,6<br />

16 499 0,23 14,0 5,8<br />

18 474 0,23 13,8 6<br />

20 449 0,24 13,6 6,2<br />

22 424 0,24 13,4 6,4<br />

24 399 0,24 13,2 6,6<br />

Grinding micrographs 1500 x<br />

7<br />

6,5<br />

6<br />

5,5<br />

5<br />

4,5<br />

Density [GPa]<br />

Thermal expansion coefficient [10-6 1/K]<br />

WC-Co carbide Cermets Silicon nitride<br />

Thermal expansion<br />

coefficient [10-6 1/K ]

Si 3 N 4 for cutting tools<br />

Si 3 N 4 for wear <strong>parts</strong><br />

Range for wear applications<br />

Silicon nitride<br />

Ceramic hard materials and particularly silicon nitride have several characteristics which compared to<br />

metallic hard materials are advantageous for numerous applications. This is not only true for cutting<br />

tool applications but also for certain fields in wear protection. Silicon nitride is mainly used where the<br />

following properties are required:<br />

● Low weight<br />

● Good mechanical properties up to 1200°C<br />

● Good reliability<br />

● High resistance to thermal shock<br />

● Good corrosion resistance<br />

● High wear resistance<br />

● Low thermal expansion<br />

● Low conductivity<br />

● Good anti-friction properties<br />

Application examples:<br />

– <strong>parts</strong> in grey cast iron<br />

– rolls in chilled casting<br />

Sinicut grades<br />

CTN3110, CTM3110 for rough machining of rolls in cast<br />

iron and the new CTN3105 for the machining of cast iron<br />

<strong>parts</strong> in high volume production<br />

Application examples:<br />

– bearing rings and roller bearings<br />

– guide rolls<br />

– rods<br />

Our grade SNCB5 is certified at<br />

leading companies in the sector.<br />

Properties Unit SNC1 SNC20 SNCB5<br />

Colour grey black black<br />

Binder (Al2O3 / Y2O3 ) % 9 11 12.5<br />

Grain size ultrafine ultrafine ultrafine<br />

Density (ISO3369) g/cm 3<br />

3.25 3.25 3.25<br />

Hardness (ISO3878) HV10 1550 1430 1500<br />

Hardness (ISO3738) HRA 91.5 90.8 91.1<br />

Transverse rupture strength<br />

(ISO3327 – 3 point)<br />

MPa 1100 850 900<br />

Compressive strength MPa 3000 3000 3000<br />

Modulus of elasticity GPa 300 290 300<br />

Toughness (SEVNB) MPa.m -1/2<br />

6.5 6.0 6.0<br />

Thermal conductivity Wm -1 K -1<br />

30 30 30<br />

Expansion coefficient 10 -6 K -1<br />

3.3 3.5 3.4<br />

17

18<br />

Tolerance table<br />

Blank tolerances<br />

Compact formed <strong>parts</strong> are manufactured through pressing and subsequent sintering which implies a<br />

volume shrinkage of around 20%. It is therefore a special challenge for the production specialists to<br />

obtain tight blank tolerances.<br />

Apart from the composition and the geometrical shape the type of machining operation is mainly decisive<br />

for the result achieved.<br />

For standard <strong>parts</strong>, tolerances are also specified in the ISO standards (e.g.: ISO 2768).<br />

Examples for blank tolerances depending on the manufacturing method:<br />

Manufacturing method<br />

Directly pressed <strong>parts</strong><br />

Extrusion pressed <strong>parts</strong><br />

Formed <strong>parts</strong><br />

Preform<br />

Dimensions<br />

(example)<br />

[mm]<br />

d s<br />

12,7 x 12,7 x 4,76<br />

15,88 x 15,88 x 6,35<br />

19,05 x 11,05 x 7,15<br />

d L<br />

3,25 330<br />

6,2 330<br />

16,2 330<br />

L B<br />

40–50 50–50<br />

100–120 80–120<br />

200–225 > 120<br />

Tolerances<br />

[mm]<br />

d s<br />

± 0,10 ± 0,05<br />

± 0,12 ± 0,06<br />

± 0,15 ± 0,07<br />

d<br />

+ 0,1 0,25<br />

+ 0,25 0,25<br />

+ 0,3 0,25<br />

± 0,45<br />

± 1,1<br />

± 1,25<br />

Sintered part<br />

Grinding<br />

allowance<br />

[mm]<br />

0,2 – 0,5/page<br />

+ 50% of the sintering<br />

tolerance<br />

0,25<br />

0,20<br />

0,20<br />

0,4<br />

0,5<br />

0,5

Roughness and surface<br />

Table for the comparison of measuring systems<br />

(metric vs. inch) of surface roughness<br />

R tmax<br />

[µm]<br />

CLA/R a<br />

[µm]<br />

CLA<br />

[µ"]<br />

RMS<br />

[µm]<br />

RMS<br />

[µ"]<br />

0,06 0,02 0,75 0,02 0,8<br />

0,1 0,03 1,2 0,04 13<br />

0,2 0,06 2,5 0,08 2,8<br />

0,3 0,09 3,7 0,1 4,2<br />

0,4 0,13 5,0 0,14 5,6<br />

0,5 0,16 6,7 0,18 6,9<br />

0,6 0,19 7,5 0,21 8,3<br />

0,7 0,22 8,7 0,25 9,7<br />

0,8 0,25 10,0 0,28 11,1<br />

0,9 0,28 11,2 0,32 12,5<br />

1,0 0,31 12,5 0,35 14,0<br />

1,2 0,38 15,8 0,42 16,7<br />

1,5 0,47 18,8 0,53 20,9<br />

1,8 0,57 22,6 0,64 25,5<br />

2,0 0,64 25,1 0,78 27,9<br />

CLA (centre line average)<br />

RMS (root mean square)<br />

Surface quality according to manufacturer<br />

Surface symbol<br />

according to ISO 1302<br />

Surface symbol<br />

according to ISO 3141<br />

Roughness index<br />

Arithmetic<br />

mean value<br />

Surface roughness<br />

Longitudinal grinding<br />

Surface grinding<br />

Peripheral grinding<br />

Face grinding<br />

Grinding of hole<br />

Polish grinding<br />

Long stroke honing<br />

Short stroke honing<br />

Cylindrical lapping<br />

Flat lapping<br />

Ultrasonic lapping<br />

Polish lapping<br />

Surface roughness (produced<br />

through special methods)<br />

new<br />

until now<br />

Surface quality<br />

R tmax<br />

[µm]<br />

CLA/R a<br />

[µm]<br />

1 µm = 0,001 mm = 39,37 µ″<br />

1 µ″ = 0,000001″ = 0,0000254 mm<br />

CLA<br />

[µ"]<br />

RMS<br />

[µm]<br />

RMS<br />

[µ"]<br />

2,4 0,73 30,1 0,85 33,4<br />

2,8 0,89 35,2 0,99 39,0<br />

3,0 0,95 37,6 1,06 41,9<br />

3,5 1,11 43,9 1,24 48,8<br />

4,0 1,27 50,2 1,41 55,8<br />

5,0 1,59 62,7 1,77 69,7<br />

6,0 1,91 75,5 2,12 83,6<br />

7,0 2,22 87,5 2,48 92,6<br />

8,0 2,54 100,0 2,83 111,7<br />

10,0 3,18 125,5 3,54 140,0<br />

20,0 6,64 251,5 7,8 279,0<br />

40,0 12,7 502,0 14,1 558,0<br />

60,0 19,1 755,0 21,2 836,0<br />

125,0 39,5 1560,0 43,5 1750,0<br />

200,0 64,0 2510,0 78,0 2790,0<br />

0,025 0,05 0,1 0,2 0,4 0,8 1,6 3,2 6,3 12,5 25 50<br />

N 1 N 2 N 3 N 4 N 5 N 6 N 7 N 8 N 9 N 10 N 11 N 12<br />

R a [µm] 0,025 0,05 0,1 0,2 0,4 0,8 1,6 3,2 6,3 12,5 25 50<br />

R z [µm] 0,25 0,63 1 1,6 2,5 4-6,3 10 16-25 40 63 100 160<br />

Surface roughness (produced through<br />

normal workshop methods)<br />

Surface roughness (produced through<br />

rough machining methods)<br />

19

20<br />

CERATIZIT corporate values<br />

1 3<br />

The views and focus of our<br />

business partners matters<br />

2 4<br />

Innovative and flexible<br />

thinking matters<br />

CERATIZIT consulting<br />

Our external service staff elaborate<br />

individual carbide solutions on site. In this<br />

manner you will benefit from our longstanding<br />

and worldwide know-how already<br />

in the product development phase. You<br />

will be continuously informed on new<br />

tendencies in the carbide sector, new<br />

grades or standard products from our<br />

CERATIZIT plants throughout the world.<br />

CERATIZIT<br />

Carbide injection moulding<br />

technology<br />

Carbide <strong>parts</strong> with a complex geometry<br />

can virtually be injection moulded at will,<br />

just like plastic <strong>parts</strong>. This creates new<br />

possibilities for:<br />

• filigree constructions<br />

• thin walls<br />

• undercuts, transverse holes, etc.<br />

Injection moulding of carbide is<br />

particularly suitable for large volume<br />

production.<br />

Communication matters<br />

Employee development<br />

matters<br />

CERATIZIT<br />

feasibility studies<br />

5<br />

Professionalism<br />

matters<br />

6<br />

Our environment<br />

matters<br />

Every request is discussed by our<br />

specialist teams: carbide grades are<br />

defined, mass, tolerances, forming<br />

and surface quality are controlled, the<br />

production process is optimised for the<br />

respective batch size and manufacturing<br />

costs are analysed.<br />

CERATIZIT<br />

alternative solutions<br />

Our team elaborates optimised<br />

alternative solutions for you in order<br />

to ensure low-cost manufacturing.<br />

In this way solutions, tailor-made to<br />

your needs, are created.<br />

The views and focus<br />

of our business partners<br />

matters<br />

– Instead of talking product with<br />

customers, we work on real solutions<br />

for business partners.

September<br />

M D M D F S S<br />

29 30 31 1 2 3 4<br />

5 6 7 8 9 10 11<br />

12 13 14 15 16 17 18<br />

19 20 21 22 23 24 25<br />

26 27 28 29 30 1 2<br />

CERATIZIT preparation of work<br />

Precise manufacturing dimensions and<br />

optimal operation plans are our strength.<br />

This requires drawings of blanks and<br />

finished <strong>parts</strong> where the shrinkage<br />

(around 20%) is taken into account. Also<br />

pressing tools, devices for working blanks<br />

and diamond grinding disks for finishing<br />

operations have to be included in the<br />

planning. Programs have to be written for<br />

CNC machining of blanks and finished<br />

<strong>parts</strong>.<br />

CERATIZIT construction of<br />

tools and fixtures<br />

Our in-house tool and fixture department<br />

allows us to quickly respond to your<br />

requirements as well as to maintain tools<br />

and repair them if necessary.<br />

CERATIZIT prototype <strong>parts</strong><br />

Prototype <strong>parts</strong> make quick<br />

implementation of your product<br />

ideas possible. In this context you<br />

will continuously be advised by our<br />

specialists. In this way volume batches<br />

suitable for the market are manufactured:<br />

both material and geometry are optimised<br />

and can be manufactured economically.<br />

CERATIZIT SAP network<br />

All processes, from order acceptance<br />

via production and quality control, stock<br />

management, dispatch and invoicing of<br />

the products are memorised in the SAP.<br />

The manufacturing state of the orders is<br />

continuously monitored so that delivery<br />

deadlines can be met.<br />

For contract orders the SAP system<br />

automatically checks the minimum<br />

quantities and production is planned<br />

dynamically<br />

All CERATIZIT production sites are<br />

connected online via the SAP.<br />

21

22<br />

Extract of our print media for wear <strong>parts</strong><br />

Circuit boards,<br />

disks and hobs<br />

Forming<br />

technology<br />

Knives<br />

Tool and die<br />

industry<br />

Gen. industry<br />

cutting tools<br />

No. 332 ‘Carbide blanks for hobs, slitting<br />

knives and circular shear knives’<br />

No. 339 ‘Blanks for printed circuit boards’<br />

No. 322 ‘Carbide drawing tools’<br />

No. 323 Carbide tools for cold<br />

forming’<br />

No. 304 ‘Cemented carbide cold<br />

heading die nibs‘<br />

No. 176 ‘Paper cutting<br />

systems’<br />

No. 285 ‘Carbide for the tool<br />

and die industry’<br />

No. 311 ‘Silicon nitride’<br />

Glass<br />

Nozzles<br />

Hot rolls<br />

General<br />

industry I<br />

General<br />

industry II<br />

Nr. 288<br />

‘Tungsten carbide for the<br />

glass industry‘<br />

No. 257<br />

‘Water jet nozzles’<br />

No. 275 ‘Carbide rolls’<br />

No. 298 ‘High pressure<br />

tools’<br />

No. 277 ‘Carbide formed<br />

<strong>parts</strong> - tailor-made’

Headquarters: CERATIZIT S.A.<br />

Main site Luxembourg<br />

CERATIZIT Luxembourg Sarl<br />

Route de Holzem, B.P. 51<br />

L-8201 Mamer<br />

Tel.: +352 312 085-1<br />

Fax: +352 311 911<br />

E-Mail: info@ceratizit.com<br />

www.ceratizit.com<br />

Sales Companies<br />

Austria<br />

CERATIZIT Austria Gesellschaft m.b.H.<br />

A-6600 Reutte/Tyrol<br />

Tel.: +43 (5672) 200-0<br />

Fax: +43 (5672) 200-502<br />

E-Mail: info.austria@ceratizit.com<br />

Bulgaria<br />

CERATIZIT Bulgaria AG<br />

Boulevard Stoletov 157<br />

BG-5301 Gabrovo<br />

Tel: +359 (66) 812 207<br />

Fax: +359 (66) 801 608<br />

E-Mail: info.bulgaria@ceratizit.com<br />

China<br />

CERATIZIT China Ltd.<br />

Room 1201-1204<br />

Hollywood Centre<br />

233 Hollywood Rd., Sheung Wan<br />

Hong Kong<br />

Tel.: +852 (2542)-1838<br />

Fax: +852 (2854) 3777<br />

E-Mail: info.china@ceratizit.com.hk<br />

Czech Republic<br />

CERATIZIT<br />

Kancelar Ceska Republika<br />

Pod Hradbami 2002/1<br />

CZ-59401 Velke Mezirici<br />

Tel.: +420 (566) 520-341<br />

Fax: +420 (566) 521-340<br />

E-Mail: info.cz@ceratizit.com<br />

France<br />

CERATIZIT France Sarl<br />

Offi ce Pontoise<br />

20, Rue Lavoisier<br />

F-95300 Pontoise<br />

Tel.: +33 (1) 3433-3180<br />

Fax: +33 (1) 3030-9339<br />

E-Mail: info.france@ceratizit.com<br />

Germany<br />

CERATIZIT Deutschland GmbH<br />

Offi ce Langenfeld<br />

Hans-Böckler-Straße 10<br />

D-40764 Langenfeld<br />

Tel.: +49 (2173) 97 25-0<br />

Fax: +49 (2173) 97 25-25<br />

E-Mail: info.deutschland@ceratizit.com<br />

CERATIZIT Deutschland GmbH<br />

Büro Dettingen<br />

Karlstraße 80<br />

D-72581 Dettingen<br />

Tel.: +49 (7123) 9201-0<br />

Fax: +49 (7123) 9201-210<br />

E-Mail: info.dettingen@ceratizit.com<br />

Main site Austria<br />

CERATIZIT Austria Gesellschaft m.b.H.<br />

A-6600 Reutte/Tyrol<br />

Tel.: +43 (5672) 200-0<br />

Fax: +43 (5672) 200-502<br />

E-Mail: info.austria@ceratizit.com<br />

CERATIZIT Horb GmbH<br />

Stadionstraße<br />

D-72160 Horb<br />

Tel.: +49 (7451) 522 0<br />

Fax: +49 (7451) 522 288<br />

E-Mail: info.horb@ceratizit.com<br />

CERATIZIT Hitzacker GmbH<br />

Am Räsenberg 3<br />

D-29456 Hitzacker<br />

Tel.: +49 (5862) 969 10-0<br />

Fax: +49 (5862) 9696 10-70<br />

E-Mail: info.hitzacker@ceratizit.com<br />

CERATIZIT Logistik GmbH<br />

Daimlerstraße 70<br />

D-87437 Kempten<br />

Tel.: +49 (831) 570 11-0<br />

Fax: +49 (831) 570 11-3811<br />

E-Mail: info.logistik@ceratizit.com<br />

Great Britain<br />

CERATIZIT UK Ltd.<br />

Cliff Lane<br />

Grappenhall<br />

Warrington WA4 3JX<br />

Tel.: +44 (1925) 261-161<br />

Fax: +44 (1925) 267-933<br />

E-Mail: info.uk@ceratizit.com<br />

Hungary<br />

CERATIZIT<br />

Iroda Magyarorszag<br />

Kórház u 6-12<br />

HU-1033 Budapest<br />

Tel.: +36 1 43709-30<br />

Fax: +36 1 43709-31<br />

E-Mail: info.hu@ceratizit.com<br />

India<br />

CERATIZIT India Pvt. Ltd.<br />

58, Motilal Gupta Road<br />

Barisha<br />

IN-700 008 Kolkata<br />

Tel.: +91 (33) 2494-5435<br />

Fax: +91 (33) 2494-1472<br />

Telex: 021 8142 ihm in<br />

E-Mail: info.india@ceratizit.com<br />

Italy<br />

CERATIZIT Italia SpA<br />

Piazza F. Martelli, 7<br />

I-20162 Milano<br />

Tel.: +39 (02) 6441-111<br />

Fax: +39 (02) 6611-6040<br />

E-Mail: info.italia@ceratizit.com<br />

Japan<br />

CERATIZIT Japan Ltd.<br />

3-13-9, Mizuho<br />

Shizuoka 421 – 0115<br />

Tel.: +81 (54) 268 1060<br />

Fax: +81 (54) 257 8181<br />

E-Mail: info.japan@ceratizit.com<br />

Luxembourg<br />

CERATIZIT Luxembourg Sarl<br />

Route de Holzem, B.P. 51<br />

L-8201 Mamer<br />

Tel.: +352 312 085-1<br />

Fax: +352 311 911<br />

E-Mail: info@ceratizit.com<br />

Netherlands<br />

CERATIZIT Nederland B.V.<br />

Bergrand 224<br />

NL-4707 AT Roosendaal<br />

Tel.: +31 (165) 55 08 00<br />

Fax: +31 (165) 55 61 76<br />

E-Mail: info.nederland@ceratizit.com<br />

Spain<br />

CERATIZIT Ibérica SL<br />

Offi ce Pozuelo<br />

Vía de las Dos Castillas, 9c<br />

Portal 2, Bajo B<br />

E-28224 Pozuelo (Madrid)<br />

Tel.: +34 (91) 351-0609<br />

Fax: +34 (91) 351-2813<br />

E-Mail: info.iberica@ceratizit.com<br />

CERATIZIT Ibérica SL<br />

Offi ce Bilbao<br />

Avda. Mazarredo 41 1 Izqda.<br />

E-48009 Bilbao<br />

Tel.: +34 (944) 23 71 18<br />

Fax: +34 (944) 23 97 18<br />

E-Mail: info.bilbao@ceratizit.com<br />

Poland<br />

CERATIZIT<br />

Biuro Polska<br />

U. Lagiewnicka 33a<br />

PL-30-417 Kraków<br />

Tel.: +48 12 252 85-91<br />

Fax: +48 12 252 85-93<br />

E-Mail: info.pl@ceratizit.com<br />

Switzerland<br />

CERATIZIT Schweiz AG<br />

Solothurnstrasse 68<br />

CH-2504 Biel<br />

Tel.: +41 (32) 344 93 93<br />

Fax: +41 (32) 344 93 94<br />

E-Mail: info.schweiz@ceratizit.com<br />

USA<br />

CERATIZIT USA Inc.<br />

777 Old Clemson Road<br />

Columbia<br />

South Carolina 29229<br />

Toll free: +1 (800) 334 1165<br />

Tel.: +1 (803) 736 1900<br />

Fax: +1 (803) 736 1902<br />

E-Mail: info.usa@ceratizit.com

272/ 0<br />

272 EN 03.06<br />

7001071<br />

We reserve the right to make technical changes for<br />

improvement of the product.