Wear parts

Wear parts

Wear parts

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

6<br />

Hard materials for wear <strong>parts</strong><br />

Hard materials in general and hard metals in particular offer a series of interesting properties for all<br />

applications where maximum wear resistance is required. In practical applications, wear <strong>parts</strong> are<br />

usually influenced by various interdependent factors: high pressure, high temperature, use of abrasive<br />

or aggressive media, machining of hard materials. These are only some examples of criteria causing<br />

wear, which hard materials or hard metals have to be resistant to. The powder-metallurgical production<br />

of CERATIZIT wear <strong>parts</strong> enables tailor-made wear resistance of the material.<br />

This is what makes CERATIZIT hard materials and hard metals indispensable when it comes to<br />

decisively increasing the service life of highly stressed components. Ever more powerful machines,<br />

facilities and machining methods create daily new challenges for the CERATIZIT development<br />

engineers. Our development projects are characterised by close cooperation with customers as well as<br />

a joint search for solutions to application problems.<br />

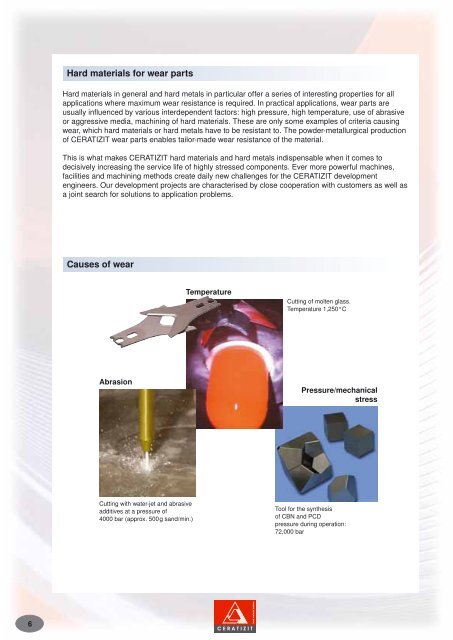

Causes of wear<br />

Abrasion<br />

Cutting with water-jet and abrasive<br />

additives at a pressure of<br />

4000 bar (approx. 500g sand/min.)<br />

Temperature<br />

Cutting of molten glass.<br />

Temperature 1,250°C<br />

Pressure/mechanical<br />

stress<br />

Tool for the synthesis<br />

of CBN and PCD<br />

pressure during operation:<br />

72,000 bar