Wear parts

Wear parts

Wear parts

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

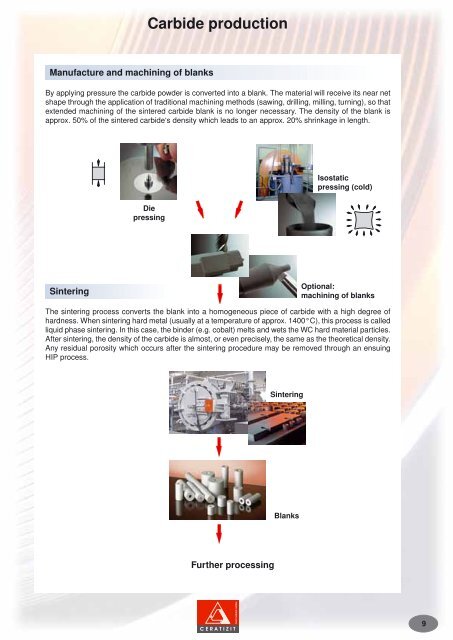

Manufacture and machining of blanks<br />

Carbide production<br />

By applying pressure the carbide powder is converted into a blank. The material will receive its near net<br />

shape through the application of traditional machining methods (sawing, drilling, milling, turning), so that<br />

extended machining of the sintered carbide blank is no longer necessary. The density of the blank is<br />

approx. 50% of the sintered carbide‘s density which leads to an approx. 20% shrinkage in length.<br />

Sintering<br />

Die<br />

pressing<br />

Sintering<br />

Blanks<br />

Isostatic<br />

pressing (cold)<br />

Optional:<br />

machining of blanks<br />

The sintering process converts the blank into a homogeneous piece of carbide with a high degree of<br />

hardness. When sintering hard metal (usually at a temperature of approx. 1400°C), this process is called<br />

liquid phase sintering. In this case, the binder (e.g. cobalt) melts and wets the WC hard material particles.<br />

After sintering, the density of the carbide is almost, or even precisely, the same as the theoretical density.<br />

Any residual porosity which occurs after the sintering procedure may be removed through an ensuing<br />

HIP process.<br />

Further processing<br />

9