Wear parts

Wear parts

Wear parts

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

18<br />

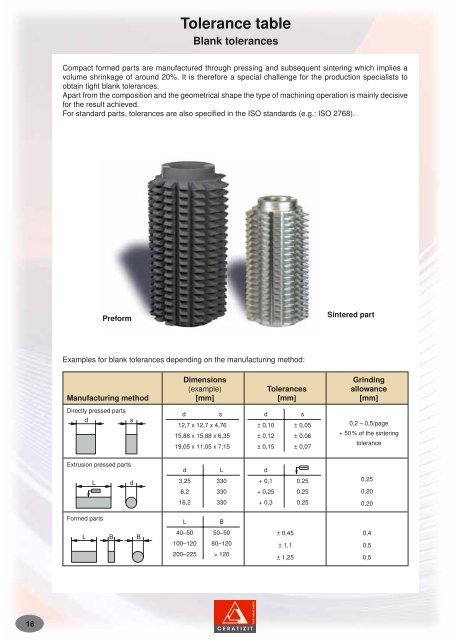

Tolerance table<br />

Blank tolerances<br />

Compact formed <strong>parts</strong> are manufactured through pressing and subsequent sintering which implies a<br />

volume shrinkage of around 20%. It is therefore a special challenge for the production specialists to<br />

obtain tight blank tolerances.<br />

Apart from the composition and the geometrical shape the type of machining operation is mainly decisive<br />

for the result achieved.<br />

For standard <strong>parts</strong>, tolerances are also specified in the ISO standards (e.g.: ISO 2768).<br />

Examples for blank tolerances depending on the manufacturing method:<br />

Manufacturing method<br />

Directly pressed <strong>parts</strong><br />

Extrusion pressed <strong>parts</strong><br />

Formed <strong>parts</strong><br />

Preform<br />

Dimensions<br />

(example)<br />

[mm]<br />

d s<br />

12,7 x 12,7 x 4,76<br />

15,88 x 15,88 x 6,35<br />

19,05 x 11,05 x 7,15<br />

d L<br />

3,25 330<br />

6,2 330<br />

16,2 330<br />

L B<br />

40–50 50–50<br />

100–120 80–120<br />

200–225 > 120<br />

Tolerances<br />

[mm]<br />

d s<br />

± 0,10 ± 0,05<br />

± 0,12 ± 0,06<br />

± 0,15 ± 0,07<br />

d<br />

+ 0,1 0,25<br />

+ 0,25 0,25<br />

+ 0,3 0,25<br />

± 0,45<br />

± 1,1<br />

± 1,25<br />

Sintered part<br />

Grinding<br />

allowance<br />

[mm]<br />

0,2 – 0,5/page<br />

+ 50% of the sintering<br />

tolerance<br />

0,25<br />

0,20<br />

0,20<br />

0,4<br />

0,5<br />

0,5