Wear parts

Wear parts

Wear parts

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

16<br />

Modulus of elasticity [GPa]<br />

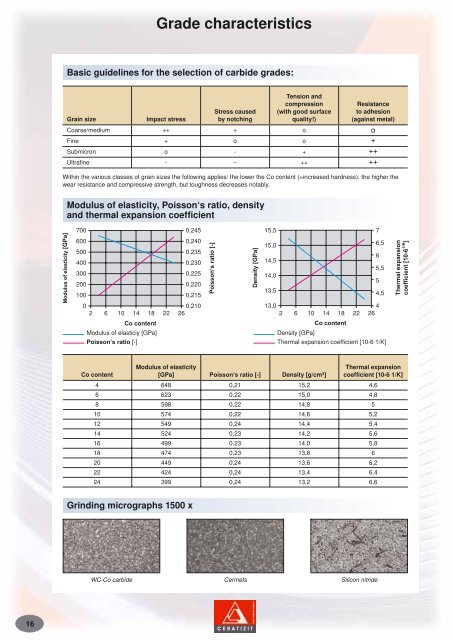

Grain size Impact stress<br />

700<br />

0,245<br />

600<br />

0,240<br />

500<br />

0,235<br />

400<br />

0,230<br />

300<br />

0,225<br />

200<br />

0,220<br />

100<br />

0,215<br />

0<br />

0,210<br />

2 6 10 14 18 22 26<br />

Co content<br />

Modulus of elasticiy [GPa]<br />

Poisson‘s ratio [-]<br />

Grade characteristics<br />

Basic guidelines for the selection of carbide grades:<br />

Poisson‘s ratio [-]<br />

Stress caused<br />

by notching<br />

Density [GPa]<br />

15,5<br />

15,0<br />

14,5<br />

14,0<br />

13,5<br />

13,0<br />

Tension and<br />

compression<br />

(with good surface<br />

quality!)<br />

Resistance<br />

to adhesion<br />

(against metal)<br />

Coarse/medium ++ + o o<br />

Fine + o o +<br />

Submicron o - + ++<br />

Ultrafine - -- ++ ++<br />

Within the various classes of grain sizes the following applies: the lower the Co content (=increased hardness), the higher the<br />

wear resistance and compressive strength, but toughness decreases notably.<br />

Modulus of elasticity, Poisson‘s ratio, density<br />

and thermal expansion coefficient<br />

4<br />

2 6 10 14 18 22 26<br />

Co content<br />

Modulus of elasticity<br />

Thermal expansion<br />

Co content<br />

[GPa] Poisson‘s ratio [-] Density [g/cm³] coefficient [10-6 1/K]<br />

4 648 0,21 15,2 4,6<br />

6 623 0,22 15,0 4,8<br />

8 598 0,22 14,8 5<br />

10 574 0,22 14,6 5,2<br />

12 549 0,24 14,4 5,4<br />

14 524 0,23 14,2 5,6<br />

16 499 0,23 14,0 5,8<br />

18 474 0,23 13,8 6<br />

20 449 0,24 13,6 6,2<br />

22 424 0,24 13,4 6,4<br />

24 399 0,24 13,2 6,6<br />

Grinding micrographs 1500 x<br />

7<br />

6,5<br />

6<br />

5,5<br />

5<br />

4,5<br />

Density [GPa]<br />

Thermal expansion coefficient [10-6 1/K]<br />

WC-Co carbide Cermets Silicon nitride<br />

Thermal expansion<br />

coefficient [10-6 1/K ]