Wear parts

Wear parts

Wear parts

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

8<br />

Tungsten oxide<br />

Reduction<br />

Tungsten<br />

Carburising<br />

Tungsten<br />

carbide<br />

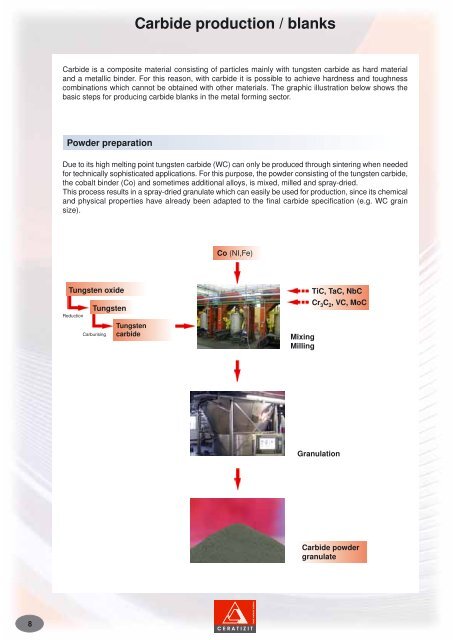

Carbide production / blanks<br />

Carbide is a composite material consisting of particles mainly with tungsten carbide as hard material<br />

and a metallic binder. For this reason, with carbide it is possible to achieve hardness and toughness<br />

combinations which cannot be obtained with other materials. The graphic illustration below shows the<br />

basic steps for producing carbide blanks in the metal forming sector.<br />

Powder preparation<br />

Due to its high melting point tungsten carbide (WC) can only be produced through sintering when needed<br />

for technically sophisticated applications. For this purpose, the powder consisting of the tungsten carbide,<br />

the cobalt binder (Co) and sometimes additional alloys, is mixed, milled and spray-dried.<br />

This process results in a spray-dried granulate which can easily be used for production, since its chemical<br />

and physical properties have already been adapted to the final carbide specification (e.g. WC grain<br />

size).<br />

Co (NI,Fe)<br />

Mixing<br />

Milling<br />

TiC, TaC, NbC<br />

Cr3C2 , VC, MoC<br />

Granulation<br />

Carbide powder<br />

granulate