Wear parts

Wear parts

Wear parts

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

CT<br />

grade<br />

code<br />

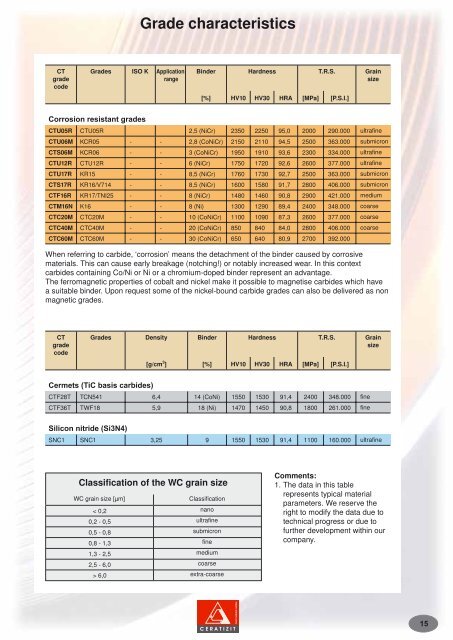

Grade characteristics<br />

CTU05R CTU05R 2,5 (NiCr) 2350 2250 95,0 2000 290.000<br />

CTU06M KCR05 - - 2,8 (CoNiCr) 2150 2110 94,5 2500 363.000<br />

CTS06M KCR06 - - 3 (CoNiCr) 1950 1910 93,6 2300 334.000<br />

CTU12R CTU12R - - 6 (NiCr) 1750 1720 92,6 2600 377.000<br />

CTU17R KR15 - - 8,5 (NiCr) 1760 1730 92,7 2500 363.000<br />

CTS17R KR16/V714 - - 8,5 (NiCr) 1600 1580 91,7 2800 406.000<br />

CTF16R KR17/TNI25 - - 8 (NiCr) 1480 1460 90,8 2900 421.000<br />

CTM16N K16 - - 8 (Ni) 1300 1290 89,4 2400 348.000<br />

CTC20M CTC20M - - 10 (CoNiCr) 1100 1090 87,3 2600 377.000<br />

CTC40M CTC40M - - 20 (CoNiCr) 850 840 84,0 2800 406.000<br />

CTC60M CTC60M - - 30 (CoNiCr) 650 640 80,9 2700 392.000<br />

When referring to carbide, ‘corrosion’ means the detachment of the binder caused by corrosive<br />

materials. This can cause early breakage (notching!) or notably increased wear. In this context<br />

carbides containing Co/Ni or Ni or a chromium-doped binder represent an advantage.<br />

The ferromagnetic properties of cobalt and nickel make it possible to magnetise carbides which have<br />

a suitable binder. Upon request some of the nickel-bound carbide grades can also be delivered as non<br />

magnetic grades.<br />

CT<br />

grade<br />

code<br />

Grades Density Binder Hardness T.R.S. Grain<br />

size<br />

[g/cm 3 ] [%] HV10 HV30 HRA [MPa] [P.S.I.]<br />

Cermets (TiC basis carbides)<br />

CTF28T TCN541 6,4 14 (CoNi) 1550 1530 91,4 2400 348.000<br />

CTF36T TWF18 5,9 18 (Ni) 1470 1450 90,8 1800 261.000<br />

Silicon nitride (Si3N4)<br />

Grades ISO K Application<br />

range<br />

Corrosion resistant grades<br />

SNC1 SNC1 3,25 9 1550 1530 91,4 1100 160.000<br />

Classification of the WC grain size<br />

WC grain size [µm] Classification<br />

< 0,2<br />

nano<br />

0,2 - 0,5<br />

ultrafine<br />

0,5 - 0,8<br />

submicron<br />

0,8 - 1,3<br />

fine<br />

1,3 - 2,5<br />

medium<br />

2,5 - 6,0<br />

coarse<br />

> 6,0<br />

extra-coarse<br />

Binder Hardness T.R.S. Grain<br />

size<br />

[%] HV10 HV30 HRA [MPa] [P.S.I.]<br />

ultrafine<br />

submicron<br />

ultrafine<br />

ultrafine<br />

submicron<br />

submicron<br />

medium<br />

coarse<br />

coarse<br />

coarse<br />

fine<br />

fine<br />

ultrafine<br />

Comments:<br />

1. The data in this table<br />

represents typical material<br />

parameters. We reserve the<br />

right to modify the data due to<br />

technical progress or due to<br />

further development within our<br />

company.<br />

15