Wear parts

Wear parts

Wear parts

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

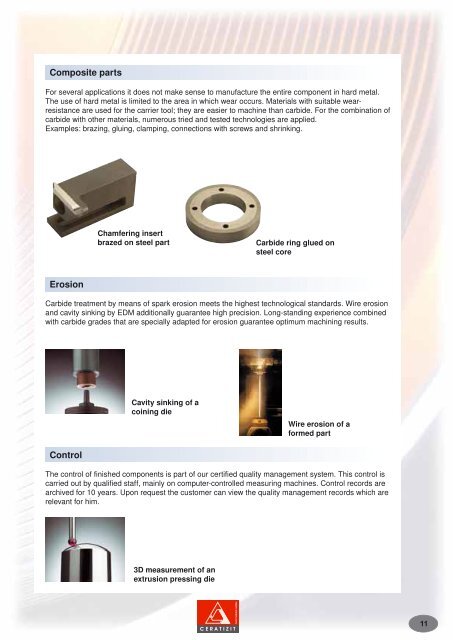

Composite <strong>parts</strong><br />

For several applications it does not make sense to manufacture the entire component in hard metal.<br />

The use of hard metal is limited to the area in which wear occurs. Materials with suitable wearresistance<br />

are used for the carrier tool; they are easier to machine than carbide. For the combination of<br />

carbide with other materials, numerous tried and tested technologies are applied.<br />

Examples: brazing, gluing, clamping, connections with screws and shrinking.<br />

Erosion<br />

Control<br />

Chamfering insert<br />

brazed on steel part<br />

Cavity sinking of a<br />

coining die<br />

3D measurement of an<br />

extrusion pressing die<br />

Carbide ring glued on<br />

steel core<br />

Carbide treatment by means of spark erosion meets the highest technological standards. Wire erosion<br />

and cavity sinking by EDM additionally guarantee high precision. Long-standing experience combined<br />

with carbide grades that are specially adapted for erosion guarantee optimum machining results.<br />

Wire erosion of a<br />

formed part<br />

The control of finished components is part of our certified quality management system. This control is<br />

carried out by qualified staff, mainly on computer-controlled measuring machines. Control records are<br />

archived for 10 years. Upon request the customer can view the quality management records which are<br />

relevant for him.<br />

11