Profilemaster -;

Profilemaster -;

Profilemaster -;

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

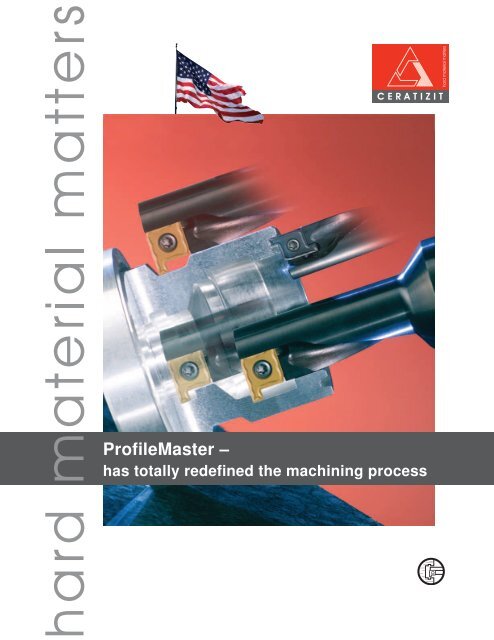

Profi leMaster –<br />

has totally redefi ned the machining process

2<br />

Headquarters and main site<br />

Mamer / Luxembourg<br />

With expertise and highly flexible<br />

production facilities we<br />

strive to provide our business<br />

partners with direct<br />

competitive advantages in<br />

the field of hard materials for<br />

tooling solutions and wear parts.<br />

Our dedication to hard material<br />

matters creates intelligent solutions<br />

for tomorrow and time to<br />

come. With 13 production plants<br />

North America<br />

• USA<br />

CERATIZIT – a global partner<br />

for advanced hard material<br />

South America<br />

• Brasil<br />

Direct sales and distribution partners<br />

Europe<br />

• Austria<br />

• Bulgaria<br />

• Czech Republic<br />

• France<br />

• Germany<br />

• Hungary<br />

• Italy<br />

• Luxembourg<br />

• Netherlands<br />

• Poland<br />

• Switzerland<br />

• Spain<br />

• United Kingdom<br />

Main site Reutte / Austria<br />

in the three main economic<br />

areas and a worldwide sales<br />

network of over 30 subsidiaries<br />

and distribution partners ensure<br />

a quick response to customer<br />

needs. In-house trainings and<br />

seminars guarantee that both<br />

business partners and employees<br />

share the latest information<br />

on our product range.<br />

The demand to improve the rela-<br />

tionship with our business partners<br />

results furthermore in long-term<br />

investments to strengthen<br />

the sales organisations in the<br />

various countries.<br />

The CERATIZIT corporate value<br />

‘The views and focus of our<br />

business partners matters’ is<br />

a guiding principle for all 3,500<br />

CERATIZIT employees worldwide.<br />

Asia<br />

• China<br />

• India<br />

• Japan

Machining of complex turned parts<br />

Which tools would you use to machine<br />

these workpieces?<br />

3

Machining with ProfileMaster<br />

ProfileMaster from CERATIZIT provides the comprehensive solution<br />

Right-hand tool<br />

Right-hand tool<br />

Right-hand insert<br />

Left-hand insert Right-hand insert<br />

Left-hand tool Right-hand tool<br />

Right-hand insert<br />

5

6<br />

ProfileMaster<br />

Machining methods<br />

Machining methods – radial application<br />

1<br />

2<br />

Machining methods – axial application<br />

3<br />

4<br />

5<br />

6<br />

7<br />

1<br />

2<br />

3<br />

4<br />

5<br />

Drilling into solid material with flat bottom holes<br />

Boring applications<br />

External turning applications<br />

Internal turning applications<br />

Turning of face profiles<br />

External radial grooving<br />

Internal radial grooving<br />

External turning applications<br />

Internal turning applications<br />

Turning of face profiles<br />

External axial grooving<br />

Internal axial grooving<br />

When changing from internal to external<br />

machining, reverse direction of rotation

“Masterfi nish”<br />

wiper effect<br />

– Excellent surface quality<br />

– Shorter machining times<br />

Considerable tool<br />

acquisition cost<br />

savings<br />

ProfileMaster<br />

Benefits<br />

Reduction of<br />

– Tool changing times<br />

– Reduced pre-setting and set-up times<br />

– Less programming effort<br />

Problem solver for<br />

insuffi cient tool<br />

storage capacity<br />

Reduced<br />

stock-keeping<br />

costs<br />

Variable<br />

drilling diameter<br />

Produces a fl at<br />

bottom hole<br />

7

8<br />

+30%<br />

-1%<br />

ProfileMaster<br />

Productivity<br />

Turn the cost screw together with CERATIZIT<br />

Tooling costs<br />

2 - 6 %<br />

Material costs<br />

14 - 18 %<br />

Increase in productivity:<br />

(parts produced<br />

per time unit)<br />

Due to improved utilization of the available<br />

machine capacity considerable cost reduction<br />

per workpiece becomes possible.<br />

In this context ProfileMaster from CERATIZIT<br />

makes a decisive contribution through:<br />

- fewer tool changes<br />

- increase of cutting speed<br />

- increase of feed rate<br />

- increase of depth of cut<br />

Break-down of workpiece costs<br />

Increase of<br />

tool life by<br />

+30%<br />

results in<br />

reduction of<br />

workpiece costs by<br />

-1%<br />

Increase in<br />

productivity by<br />

+30%<br />

results in<br />

reduction of<br />

workpiece costs by<br />

-19%<br />

Increase of tool life:<br />

Manufacturing costs<br />

(machine / manpower)<br />

78 - 82 %<br />

+30%<br />

-19%<br />

As the average tool costs amount to only<br />

2–6 % of the workpiece costs, prolonging<br />

tool life typically can only reduce total<br />

costs minimally.

Tools<br />

Inserts<br />

ProfileMaster<br />

Nominal diameter [mm]<br />

Cutting direction<br />

ProfileMaster<br />

ProfileMaster<br />

Designation systems<br />

Nominal diameter [mm]<br />

Cutting direction<br />

PM 25 R - 2.25D - E<br />

Version<br />

Cutting width [ mm / 10]<br />

Cutting depth [ mm / 10]<br />

PM 25 R G 35 30 04 - M20 CTC1435<br />

Corner radius<br />

Max. drilling depth<br />

Chip groove<br />

Carbide grade<br />

9

10<br />

1.5D (=l 2 )<br />

2.25D (=l 2 )<br />

Type,<br />

description<br />

ProfileMaster Ø .394-.630 inch<br />

L<br />

Tools / radial application<br />

inch<br />

D<br />

(mm) d 1 d 2 l 1 l 2 l 3 f A<br />

PM 10R-1.5D-E<br />

PM 10R-2.25D-E<br />

R<br />

(10)<br />

.394<br />

.500<br />

-<br />

.630<br />

3.150<br />

2.821<br />

.590<br />

.886<br />

-<br />

1.197<br />

PM 10L-1.5D-E<br />

PM 10L-2.25D-E<br />

L<br />

(10)<br />

.394<br />

.500<br />

-<br />

.630<br />

3.150<br />

2.821<br />

.590<br />

.886<br />

-<br />

1.197<br />

PM 12R-1.5D-E<br />

PM 12R-2.25D-E<br />

R<br />

(12)<br />

.472<br />

.625<br />

-<br />

.787<br />

3.543<br />

3.049<br />

.709<br />

1.063<br />

-<br />

1.299<br />

PM 12L-1.5D-E<br />

PM 12L-2.25D-E<br />

L<br />

(12)<br />

.472<br />

.625<br />

-<br />

.787<br />

3.543<br />

3.049<br />

.709<br />

1.063<br />

-<br />

1.299<br />

PM 16R-1.5D-E<br />

PM 16R-2.25D-E<br />

R<br />

(16)<br />

.630<br />

.750<br />

-<br />

.984<br />

4.921<br />

3.832<br />

.945<br />

1.417<br />

-<br />

1.831<br />

PM 16L-1.5D-E<br />

PM 16L-2.25D-E<br />

L<br />

(16)<br />

.630<br />

.750<br />

-<br />

.984<br />

4.921<br />

3.832<br />

.945<br />

1.417<br />

-<br />

1.831<br />

Supply details: Basic body fitted with 1 piece of clamping screw, without inserts<br />

Ordering example: 3 pieces PM 16R-2.25D<br />

.197<br />

1/16“-27<br />

PM 10R..<br />

.197 PM 10L..<br />

.236<br />

1/8“-27<br />

PM 12R..<br />

.236 PM 12L..<br />

.315<br />

1/8“-27<br />

PM 16R..<br />

.315 PM 16L..<br />

Spare parts /<br />

D<br />

accessories (mm) inch<br />

1 piece 1 piece<br />

PM 10 ... (10) .394 10001230/M1,8X3,8/T06 7883305/TORX/T06<br />

PM 12 ... (12) .472 7883215/M2,2X4,0/T07 7724105/TORX/T07<br />

PM 16 ... (16) .630 7883214/M3,0X5,7/ T08 7724106/TORX/T08<br />

Page<br />

PM 10.. PM 12.. PM 16..<br />

14 14 14<br />

A<br />

Drawing shows right-hand tool

1.5D (=l 2 )<br />

2.25D (=l 2 )<br />

ProfileMaster Ø .787-1.260 inch<br />

Tools / radial application<br />

Type,<br />

description<br />

L D<br />

(mm) d1 d2 l1 l2 l3 f A<br />

PM 20R-1.5D-E<br />

PM 20R-2.25D-E<br />

PM 20L-1.5D-E<br />

PM 20L-2.25D-E<br />

R<br />

L<br />

(20)<br />

.787<br />

(20)<br />

.787<br />

1.000<br />

1.000<br />

-<br />

1.260<br />

-<br />

1.260<br />

5.906<br />

4.415<br />

5.906<br />

4.415<br />

1.181<br />

1.772<br />

1.181<br />

1.772<br />

-<br />

2.165<br />

-<br />

2.165<br />

.394<br />

.394<br />

1/4“-18<br />

PM 20R..<br />

PM 20L..<br />

PM 25R-1.5D-E<br />

PM 25R-2.25D-E<br />

PM 25L-1.5D-E<br />

PM 25L-2.25D-E<br />

R<br />

L<br />

(25)<br />

.984<br />

(25)<br />

.984<br />

1.250<br />

1.250<br />

-<br />

1.575<br />

-<br />

1.575<br />

7.087<br />

5.233<br />

7.087<br />

5.233<br />

1.476<br />

2.217<br />

1.476<br />

2.217<br />

-<br />

2.858<br />

-<br />

2.858<br />

.492<br />

.492<br />

1/4“-18<br />

PM 25R..<br />

PM 25L..<br />

PM 32R-1.5D-E<br />

PM 32R-2.25D-E<br />

PM 32L-1.5D-E<br />

PM 32L-2.25D-E<br />

R<br />

L<br />

(32)<br />

1.260<br />

(32)<br />

1.260<br />

1.500<br />

1.500<br />

-<br />

1.969<br />

-<br />

1.969<br />

7.874<br />

6.215<br />

7.874<br />

6.215<br />

1.890<br />

2.835<br />

1.890<br />

2.835<br />

-<br />

3.465<br />

-<br />

3.465<br />

.630<br />

.630<br />

1/4“-18<br />

PM 32R..<br />

PM 32L..<br />

Spare parts /<br />

D<br />

accessories (mm) inch<br />

1 piece 1 piece<br />

PM 20 ... (20) .787 7722111/M3,5X7,2/T15 7724103/TORX/T15<br />

PM 25 ... (25) .984 7783209/M3,5X8,6/T15 7724103/TORX/T15<br />

PM 32 ... (32) 1.260 10001785/M5,0X10,8/T20 7724104/TORX/T20<br />

inch<br />

Supply details: Basic body fitted with 1 piece of clamping screw, without inserts<br />

Ordering example: 3 pieces PM 20L-1.5D<br />

Page<br />

PM 20.. PM 25.. PM 32..<br />

14 14 14<br />

A<br />

Drawing shows right-hand tool<br />

11

12<br />

1.5D (=l 2 )<br />

2.25D (=l 2 )<br />

ProfileMaster Ø .630-.787 inch<br />

Type,<br />

description<br />

L DNOM (mm) DAX d1 d2 l1 l2 l3 f A<br />

PM 16R-1.5D-E<br />

PM 16R-2.25D-E<br />

PM 16L-1.5D-E<br />

PM 16L-2.25D-E<br />

R<br />

L<br />

(16)<br />

.630<br />

(16)<br />

.630<br />

.630-∞<br />

.630-∞<br />

.750<br />

.750<br />

-<br />

.984<br />

-<br />

.984<br />

5.012<br />

3.890<br />

5.012<br />

3.890<br />

1.035<br />

1.508<br />

1.035<br />

1.508<br />

-<br />

1.921<br />

-<br />

1.921<br />

.224<br />

.224<br />

1/8“-27<br />

PM 16L..<br />

PM 16R..<br />

PM 20R-1.5D-E<br />

PM 20R-2.25D-E<br />

PM 20L-1.5D-E<br />

PM 20L-2.25D-E<br />

R<br />

L<br />

(20)<br />

.787<br />

(20)<br />

.787<br />

.787-∞<br />

.787-∞<br />

1.000<br />

1.000<br />

-<br />

1.260<br />

-<br />

1.260<br />

6.016<br />

4.590<br />

6.016<br />

4.590<br />

1.291<br />

1.882<br />

1.291<br />

1.882<br />

-<br />

2.276<br />

-<br />

2.276<br />

.283<br />

.283<br />

1/4“-18<br />

PM 20L..<br />

PM 20R..<br />

Spare parts /<br />

D<br />

accessories (mm) inch<br />

1 piece 1 piece<br />

PM 16 ... (16) .630 7883214/M3,0X5,7/T08 7724106/TORX/T08<br />

PM 20 ... (20) .787 7722111/M3,5X7,2/T15 7724103/TORX/T15<br />

PM 16.. PM 20..<br />

14 14<br />

Tools / axial application<br />

inch<br />

Supply details: Basic body fitted with 1 piece of clamping screw, without inserts<br />

Ordering example: 3 pieces PM 16R-2.25D<br />

Page<br />

Details see<br />

page 32<br />

= D NOM<br />

D AXmin<br />

A<br />

Drawing shows right-hand tool

1.5D (=l 2 )<br />

2.25D (=l 2 )<br />

ProfileMaster Ø .984-1.260 inch<br />

Type,<br />

description<br />

L DNOM (mm) DAX d1 d2 l1 l2 l3 f A<br />

PM 25R-1.5D-E<br />

PM 25R-2.25D-E<br />

PM 25L-1.5D-E<br />

PM 25L-2.25D-E<br />

R<br />

L<br />

(25)<br />

.984<br />

(25)<br />

.984<br />

.984-∞<br />

.984-∞<br />

1.250<br />

1.250<br />

-<br />

1.575<br />

-<br />

1.575<br />

7.217<br />

5.363<br />

7.217<br />

5.363<br />

1.606<br />

2.346<br />

1.606<br />

2.346<br />

-<br />

2.988<br />

-<br />

2.988<br />

.362<br />

.362<br />

1/4“-18<br />

PM 25L..<br />

PM 25R..<br />

PM 32R-1.5D-E<br />

PM 32R-2.25D-E<br />

PM 32L-1.5D-E<br />

PM 32L-2.25D-E<br />

R<br />

L<br />

(32)<br />

1.260<br />

(32)<br />

1.260<br />

1.260-∞<br />

1.260-∞<br />

1.500<br />

1.500<br />

-<br />

1.969<br />

-<br />

1.969<br />

8.043<br />

6.384<br />

8.043<br />

6.384<br />

2.059<br />

3.004<br />

2.059<br />

3.004<br />

-<br />

3.634<br />

-<br />

3.634<br />

.461<br />

.461<br />

1/4“-18<br />

PM 32L..<br />

PM 32R..<br />

Spare parts /<br />

D<br />

accessories (mm) inch<br />

1 piece 1 piece<br />

PM 25 ... (25) .984 7883209/M3,5X8,6/T15 7724103/TORX/T15<br />

PM 32 ... (32) 1.260 10001785/M5,0X10,8/T20 7724104/TORX/T20<br />

PM 25.. PM 32..<br />

14 14<br />

Tools / axial application<br />

inch<br />

Supply details: Basic body fitted with 1 piece of clamping screw, without inserts<br />

Ordering example: 3 pieces PM 25R-2.25D<br />

Page<br />

Details see<br />

page 32<br />

= D NOM<br />

D AXmin<br />

A<br />

Drawing shows right-hand tool<br />

13

14<br />

Size<br />

-M20<br />

PM -1.5D PM -2.25D<br />

10-13 10-13<br />

ProfileMaster<br />

Inserts<br />

Uncoated Coated<br />

groove<br />

Chip<br />

Type,<br />

description<br />

x<br />

(mm)<br />

y<br />

(mm)<br />

inch<br />

l s d1 r<br />

10 PM 10LG 201504-M20 M20 (2,0) .079 (1,5) .059 .197 .083 .083 .016<br />

10 PM 10RG 201504-M20 M20 (2,0) .079 (1,5) .059 .197 .083 .083 .016<br />

12 PM 12LG 201804-M20 M20 (2,0) .079 (1,8) .071 .236 .091 .098 .016<br />

12 PM 12RG 201804-M20 M20 (2,0) .079 (1,8) .071 .236 .091 .098 .016<br />

16 PM 16LG 252004-M20 M20 (2,5) .098 (2,0) .079 .315 .110 .134 .016<br />

16 PM 16RG 252004-M20 M20 (2,5) .098 (2,0) .079 .315 .110 .134 .016<br />

20 PM 20LG 302504-M20 M20 (3,0) .118 (2,5) .098 .394 .146 .157 .016<br />

20 PM 20RG 302504-M20 M20 (3,0) .118 (2,5) .098 .394 .146 .157 .016<br />

25 PM 25LG 353004-M20 M20 (3,5) .138 (3,0) .118 .492 .177 .173 .016<br />

25 PM 25RG 353004-M20 M20 (3,5) .138 (3,0) .118 .492 .177 .173 .016<br />

32 PM 32LG 404004-M20 M20 (4,0) .157 (4,0) .157 .630 .220 .236 .016<br />

32 PM 32RG 404004-M20 M20<br />

Steel<br />

Stainless<br />

Cast iron<br />

(4,0) .157 (4,0) .157 .630 .220 .236 0,4<br />

Non ferrous metals<br />

Heat resistant<br />

Hard materials<br />

= Main application<br />

= Extended application<br />

= International CERATIZIT range, for present availability see price list<br />

Ordering example: 20 pieces PM 10LG 201504-M20 CTC1435<br />

Page<br />

CTC1435<br />

CTP2440

Drilling<br />

feed (ipr)<br />

.0063<br />

.0055<br />

.0047<br />

.0039<br />

.0031<br />

.0024<br />

.0016<br />

.0008<br />

Face turning<br />

ap (inch)<br />

.236<br />

.197<br />

.157<br />

.118<br />

.079<br />

.039<br />

ProfileMaster<br />

Cutting depth / feed rate<br />

.0020 .0039 .0059 .0087 .0098 .0118 .0138 .0157<br />

feed (ipr)<br />

15

16<br />

Longitudinal turning<br />

ap (inch)<br />

.394<br />

.354<br />

.319<br />

.276<br />

.236<br />

.197<br />

.157<br />

.118<br />

.079<br />

.039<br />

ap (inch)<br />

.319<br />

.276<br />

.236<br />

.197<br />

.157<br />

.118<br />

.079<br />

.039<br />

ProfileMaster<br />

Cutting depth / feed rate<br />

.0020 .0039 .0059 .0087 .0098 .0118 .0138 .0157<br />

.0020 .0039 .0059 .0087 .0098 .0118 .0138 .0157<br />

feed (ipr)<br />

feed (ipr)

Radial grooving - internal + external<br />

feed (ipr)<br />

.0102<br />

.0094<br />

.0087<br />

.0079<br />

.0070<br />

.0063<br />

.0055<br />

.0047<br />

.0039<br />

.0031<br />

.0024<br />

.0016<br />

.0008<br />

ProfileMaster<br />

Feed rate<br />

17

18<br />

Longitudinal turning<br />

ap (inch)<br />

.236<br />

.197<br />

.157<br />

.118<br />

.079<br />

.039<br />

Face turning<br />

ap (inch)<br />

.236<br />

.197<br />

.157<br />

.118<br />

.079<br />

.039<br />

ProfileMaster<br />

Depth of cut / feed rate<br />

.0020 .0039 .0059 .0087 .0098 .0118 .0138 .0157<br />

.0020 .0039 .0059 .0087 .0098 .0118 .0138 .0157<br />

feed (ipr)<br />

feed (ipr)

Axial grooving - internal + external<br />

feed (ipr)<br />

.0102<br />

.0094<br />

.0087<br />

.0079<br />

.0070<br />

.0063<br />

.0055<br />

.0047<br />

.0039<br />

.0031<br />

.0024<br />

.0016<br />

.0008<br />

ProfileMaster<br />

Feed rate<br />

With PM 10 and PM 12 axial grooving is not possible.<br />

19

20<br />

A<br />

R<br />

F<br />

N<br />

S<br />

H<br />

Workpiece<br />

material Type of treatment / alloy VDI 3323<br />

Non alloyed steel<br />

Low alloyed steel<br />

High alloyed steel<br />

Corrosion resistant steel<br />

Stainless steel<br />

Grey cast iron<br />

Grey cast iron with<br />

spheroidal graphite<br />

Tempered iron<br />

Aluminium<br />

wrought alloys<br />

Aluminium<br />

cast alloys<br />

Copper and<br />

copper alloys (bronze,<br />

brass)<br />

Non metal<br />

materials<br />

Heat resistant<br />

alloys<br />

Titanium alloys<br />

annealed ≤ 0,15% C<br />

annealed 0,15% - 0,45% C<br />

tempered ≥ 0,45% C<br />

annealed<br />

tempered<br />

tempered<br />

annealed<br />

tempered<br />

annealed ferritic<br />

tempered martensitic<br />

annealed ferritic / martensitic<br />

quenched austenitic<br />

quenched duplex<br />

hardened martensitic / austenitic<br />

non hardened<br />

hardened<br />

perlitic / ferritic<br />

perlitic / martensitic<br />

ferritic<br />

perlitic<br />

ferritic<br />

perlitic<br />

non hardened < 12% Si<br />

hardened < 12% Si<br />

non hardened > 12% Si<br />

hardened and tempered<br />

Tempered steel<br />

hardened and tempered<br />

Chilled castings cast<br />

Tempered cast iron hardened and tempered<br />

* Rm = maximum strength, measured in MPa<br />

Cutting data<br />

Grades / material<br />

machining alloy stock (1% Pb)<br />

brass, red bronze<br />

bronze<br />

lead-free copper and electrolytic copper<br />

thermosetting plastics<br />

fi bre-reinforced plastics<br />

hard rubber<br />

annealed Fe-base<br />

hardened Fe-Fe-base<br />

annealed Ni- or Co-base<br />

hardened Ni- or Co-base 30 - 58 HRC<br />

cast Ni- oder Co-base 1500 - 2200 Nmm2 pure titanium<br />

alpha + beta alloys<br />

group<br />

Hardness<br />

CTC<br />

1435<br />

v c<br />

HB [sfm]<br />

1 125 459 - 918<br />

2 150 - 250 328 - 656<br />

3 300 262 - 590<br />

6 180 328 - 656<br />

7 / 8 250 - 300 262 - 525<br />

9 350 230 - 459<br />

10 200 328 - 590<br />

11 350 197 - 459<br />

12 200 328 - 656<br />

13 325 262 - 492<br />

14 200 328 - 656<br />

14 180 328 - 590<br />

14 230 - 260 –<br />

14 330 –<br />

15 180 394 - 820<br />

16 260 394 - 820<br />

17 160 361 - 820<br />

18 – 361 - 820<br />

19 130 328 - 820<br />

20 230 328 - 820<br />

21 60 –<br />

22 100 –<br />

23 80 –<br />

24 90 –<br />

25 130 –<br />

26 – –<br />

27 – –<br />

28 90 –<br />

29 100 –<br />

29 100 –<br />

29 – –<br />

30 – –<br />

31 200 –<br />

32 280 –<br />

33 250 –<br />

34 – –<br />

35 – –<br />

36 R 440* m –<br />

37 R 1050* m –<br />

38 55 HRC –<br />

39 60 HRC –<br />

40 400 –<br />

40 55 HRC –

CTP<br />

2440<br />

vc [sfm]<br />

394 - 820<br />

262 - 590<br />

197 - 492<br />

262 - 590<br />

197 - 492<br />

197 - 394<br />

262 - 525<br />

164 - 394<br />

164 - 656<br />

164 - 492<br />

164 - 656<br />

164 - 590<br />

164 - 328<br />

164 - 262<br />

–<br />

–<br />

–<br />

–<br />

–<br />

–<br />

328 - 1640<br />

328 - 984<br />

328 - 1640<br />

328 - 984<br />

328 - 656<br />

328 - 1640<br />

328 - 1640<br />

328 - 984<br />

328- 984<br />

262 - 590<br />

197 - 492<br />

328 - 820<br />

66 - 164<br />

66 - 131<br />

49 - 82<br />

33 - 66<br />

33 - 66<br />

164 - 394<br />

98 - 164<br />

–<br />

–<br />

–<br />

–<br />

Cutting data<br />

Grades / material<br />

21

22<br />

Material<br />

Blue: steel<br />

machining, cementation,<br />

tempered and constructional<br />

steels<br />

Green: non ferrous metals<br />

and non metals<br />

Al wrought and Al cast alloys,<br />

copper, copper alloys, non<br />

metal materials<br />

Machining application type<br />

MasterGuide<br />

Based on VDI 3323 CERATIZIT‘s MasterGuide divides<br />

materials into six main groups.<br />

Each is given a colour, according to the system partly<br />

adopted in ISO 513.<br />

Yellow: stainless steel<br />

ferritic Cr-steels, austenitic<br />

CrNi-steels, martensitic Crsteels,<br />

duplex steels<br />

Orange: heat resistant<br />

alloys / titanium<br />

Ni-/Co-base-alloys,<br />

Ti-alloys<br />

Red: cast iron<br />

grey cast iron, tempered iron,<br />

spheroidal cast iron, sintered<br />

iron<br />

White: hard materials<br />

hardened steels (≥45 HRC),<br />

chilled castings, hard cast<br />

irons<br />

Each coloured segment is divided into three sections, and<br />

each section indicates the relevant machining application<br />

type:<br />

R = Rough machining M = Medium machining F = Fine machining

Application<br />

MasterGuide<br />

The ideal application area for each insert is indicated by a<br />

black circle. Extended applications are indicated by an open<br />

circle. The CERATIZIT MasterGuide provides you with an easily<br />

understandable structure for choosing a product and enables<br />

you to reduce grade and geometry stocks.<br />

● Main application<br />

○ Extended application<br />

The right indexable insert at a glance<br />

Main application:<br />

Medium machining of steel and cast iron<br />

Extended application:<br />

Medium machining of stainless steels<br />

23

24<br />

CTC1435<br />

(P35, M30, K20)<br />

CTP2440<br />

(P40, M35, K25)<br />

Toughness:<br />

Wear resistance:<br />

Toughness:<br />

Wear resistance:<br />

Grade description<br />

Steel<br />

Composition:<br />

Co 9.5%; composite carbides 6.5%; WC rest<br />

Grain size: 1 - 2 μm<br />

Hardness: HV 1400<br />

Coating specification: CVD, TiN + Ti (C,N) + Ti (N,B)<br />

+ Al 2 O 3 + Ti (C,N,B); 6 μm<br />

0<br />

0<br />

2 4 6<br />

2 4 6<br />

8 10<br />

Composition:<br />

Co 9.5%; composite carbides 6.5%; WC rest<br />

Grain size: 1 - 2 μm<br />

Hardness: HV 1400<br />

Coating specification: PVD, TiAIN, 3 - 5 μm<br />

8 10

CTC1435<br />

(P35, M30, K20)<br />

CTP2440<br />

(P40, M35, K25)<br />

Toughness:<br />

Wear resistance:<br />

Toughness:<br />

Wear resistance:<br />

Grade description<br />

Stainless steel<br />

Composition:<br />

Co 9.5%; composite carbides 6.5%; WC rest<br />

Grain size: 1 - 2 μm<br />

Hardness: HV 1400<br />

Coating specification: CVD, TiN + Ti (C,N) + Ti (N,B)<br />

+ Al 2 O 3 + Ti (C,N,B); 6 μm<br />

0<br />

0<br />

2 4 6<br />

2 4 6<br />

8 10<br />

Composition:<br />

Co 9.5%; composite carbides 6.5%; WC rest<br />

Grain size: 1 - 2 μm<br />

Hardness: HV 1400<br />

Coating specification: PVD, TiAIN, 3 - 5 μm<br />

8 10<br />

25

26<br />

CTC1435<br />

(P35, M30, K20)<br />

CTP2440<br />

(P40, M35, K25)<br />

Toughness:<br />

Wear resistance:<br />

Toughness:<br />

Grade description<br />

Cast iron<br />

Composition:<br />

Co 9.5%; composite carbides 6.5%; WC rest<br />

Grain size: 1 - 2 μm<br />

Hardness: HV 1400<br />

Coating specification: CVD, TiN + Ti (C,N) + Ti (N,B)<br />

+ Al 2 O 3 + Ti (C,N,B); 6 μm<br />

0<br />

0<br />

2 4 6<br />

Heat resistant alloys / titanium<br />

Wear resistance:<br />

2 4 6<br />

8 10<br />

Composition:<br />

Co 9.5%; composite carbides 6.5%; WC rest<br />

Grain size: 1 - 2 μm<br />

Hardness: HV 1400<br />

Coating specification: PVD, TiAIN, 3 - 5 μm<br />

8 10

Grade<br />

description<br />

CTC1435<br />

CTP2440<br />

Standard<br />

designation<br />

HC-P35<br />

HC-M30<br />

HC-K20<br />

HC-P40<br />

HC-M35<br />

HC-K25<br />

Grade overview<br />

Application range Material group<br />

05 15 25 35 45<br />

01 10 20 30 40 50<br />

01 10 20 30 40 50<br />

05 15 25 35 45<br />

A R F N S H<br />

Steel<br />

Stainless<br />

Cast iron<br />

Non ferrous<br />

metals<br />

Heat<br />

resistant<br />

materials<br />

Main application range<br />

Extended application<br />

Hard<br />

materials<br />

27

28<br />

Edge chipping<br />

Type of wear Workpiece<br />

problems<br />

Chip control<br />

Built-up edges<br />

Flank wear<br />

raise, increase<br />

large influence<br />

raise, increase<br />

small influence<br />

Plastic deformation<br />

ProfileMaster<br />

Problems / corrective measures<br />

Type of problem<br />

Vibrations<br />

Surface quality<br />

Chip too long (snarl chip)<br />

Chip too short (fragmented chip)<br />

avoid, reduce<br />

large influence<br />

Cutting speed<br />

Feed rate<br />

avoid, reduce<br />

small influence<br />

Corrective<br />

measures<br />

Cutting material<br />

Clamping of tool<br />

Clamping of workpiece<br />

Overhang<br />

Tip height<br />

Cooling lubricant<br />

Wear resistance<br />

Toughness<br />

control,<br />

optimize<br />

use<br />

Cutting values<br />

Selection of inserts<br />

General criteria

Mounting of the insert<br />

Axial displacement of the machine<br />

Displacement in x-direction<br />

Through hole<br />

ProfileMaster<br />

Application recommendations<br />

Angular error Turret position error<br />

With through holes a sharp-edged disk is<br />

created as tool break-out occurs.<br />

Safety measures are necessary.<br />

29

30<br />

Off-centre drilling<br />

ProfileMaster<br />

Application recommendations<br />

Due to the special construction of Profi leMaster tools and inserts off-centre drilling is possible. Thus desired devations<br />

from the tool‘s nominal diameter can be obtained (see table below).<br />

Tool type<br />

D (mm) inch D (inch) min D (inch)<br />

max<br />

PM 10R/L ... (10) .394 .388 .472<br />

PM 12R/L ... (12) .472 .467 .591<br />

PM 16R/L ... (16) .630 .624 .748<br />

PM 20R/L ... (20) .787 .780 .945<br />

PM 25R/L ... (25) .984 .976 1.142<br />

PM 32R/L ... (32) 1.260 1.252 1.496<br />

Machining across centre line<br />

Situation:<br />

In case of insuffi cient movement of the machine across the<br />

centre line the external diameter can not be machined with<br />

the same tool.<br />

Nominal tool ∅ Drilling ∅<br />

Maximum movement<br />

across centre line<br />

Solution:<br />

Use a right-hand<br />

Profi leMaster tool

Coolant supply<br />

2<br />

1<br />

v c = 492 sfm a p = .0394 inch<br />

ProfileMaster<br />

Coolant supply / “Masterfinish” effect<br />

ProfileMaster is equipped with a unique coolant and<br />

chip removal system.<br />

3<br />

In order to guarantee efficient chip evacuation from a hole,<br />

a minimum coolant pressure of<br />

3 – 6 bar (optimum 7 – 10 bar) is required.<br />

“Masterfinish” effect<br />

Surface test on material Ck60 (1.1221)<br />

with a standard boring bar and ProfileMaster<br />

.0039 .0059 .0087 .0098 .0118 .0138 .0157 .0177<br />

1<br />

2<br />

3<br />

Cooling of the insert cutting edge<br />

General coolant stream<br />

“Chipbooster“ prevents chips<br />

from getting stuck between tool<br />

and workpiece<br />

feed (ipr)<br />

31

32<br />

Axial grooving - axial application<br />

D Nom<br />

(mm) inch<br />

D AXmin<br />

inch<br />

D AXmin = D Nom<br />

D AXmax = ∞<br />

D AXmax<br />

inch<br />

(16) .630 .630 ∞<br />

(20) .787 .787 ∞<br />

(25) .984 .984 ∞<br />

(32) 1.260 1.260 ∞<br />

Situation<br />

D AX >= D Nom<br />

ProfileMaster<br />

Application recommendations<br />

= D NOM<br />

D AXmin<br />

Situation<br />

D AX < D Nom<br />

If the first cut is carried out with a diameter<br />

which is smaller than the nominal tool<br />

diameter D Nom (90° application), collision<br />

will result.

Technical data:<br />

Workpiece: HSK100 adapter<br />

Material: 1.2343 / X38 CrMoV 5 1<br />

Strength: approx. 1100 N/mm 2<br />

Tool: PM 16R-1.5D<br />

Insert: PM 16RG 252004-M20 CTP2440<br />

Competitor: 2 tools<br />

Technical data:<br />

Workpiece: Piston<br />

Material: 1.0756 / 35SPb20+C<br />

Tool: PM 16R-1.5D<br />

Insert: PM 16RG 252004-M20 CTC1435<br />

Competitor: 2 tools<br />

ProfileMaster<br />

Machining examples 1 + 2<br />

Criteria:<br />

> Problems due to lack of turret positions<br />

> Optimisation of machining time<br />

Cutting data:<br />

v c [sfm] 492<br />

a p [inch] .0394<br />

f [inch/rev.] .0059<br />

Result:<br />

> Only 1 tool instead of 2<br />

> 1 free turret position<br />

Criteria:<br />

> Increase in productivity<br />

> Insuffi cient quality of groove surface<br />

Cutting data: CERATIZIT WB<br />

v c [sfm] 344<br />

a p [inch] .0118 – .197<br />

f [inch/rev.] Turning .0059 .0039<br />

Grooving .0024<br />

Result:<br />

> Machining time reduced by 50%<br />

> Enhanced groove quality<br />

33

Headquarters: CERATIZIT S.A.<br />

Main site Luxembourg<br />

CERATIZIT Luxembourg Sarl<br />

Route de Holzem, B.P. 51<br />

L-8201 Mamer<br />

Tel.: +352 312 085-1<br />

Fax: +352 311 911<br />

E-Mail: info@ceratizit.com<br />

www.ceratizit.com<br />

Sales Companies<br />

Austria<br />

CERATIZIT Austria Gesellschaft m.b.H.<br />

A-6600 Reutte/Tyrol<br />

Tel.: +43 (5672) 200-0<br />

Fax: +43 (5672) 200-502<br />

E-Mail: info.austria@ceratizit.com<br />

Bulgaria<br />

CERATIZIT Bulgaria AG<br />

Boulevard Stoletov 157<br />

BG-5301 Gabrovo<br />

Tel: +359 (66) 803 811<br />

Fax: +359 (66) 801 608<br />

E-Mail: info.bulgaria@ceratizit.com<br />

China<br />

CERATIZIT China Ltd.<br />

Room 1201-1204<br />

Hollywood Centre<br />

233 Hollywood Rd., Sheung Wan<br />

Hong Kong<br />

Tel.: +852 (2542)-1838<br />

Fax: +852 (2854) 3777<br />

E-Mail: info.china@ceratizit.com.hk<br />

France<br />

CERATIZIT France Sarl<br />

Pontoise<br />

20, Rue Lavoisier<br />

F-95300 Pontoise<br />

Tel.: +33 (1) 3433-3180<br />

Fax: +33 (1) 3030-9339<br />

E-Mail: info.france@ceratizit.com<br />

Germany<br />

CERATIZIT Deutschland GmbH<br />

Offi ce Langenfeld<br />

Hans-Böckler-Straße 10<br />

D-40764 Langenfeld<br />

Tel.: +49 (2173) 97 25-0<br />

Fax: +49 (2173) 97 25-25<br />

E-Mail: info.deutschland@ceratizit.com<br />

CERATIZIT Deutschland GmbH<br />

Offi ce Dettingen<br />

Karlstraße 80<br />

D-72581 Dettingen<br />

Tel.: +49 (7123) 9201-0<br />

Fax: +49 (7123) 9201-210<br />

E-Mail: info.dettingen@ceratizit.com<br />

Main site Austria<br />

CERATIZIT Austria Gesellschaft m.b.H.<br />

A-6600 Reutte/Tyrol<br />

Tel.: +43 (5672) 200-0<br />

Fax: +43 (5672) 200-502<br />

E-Mail: info.austria@ceratizit.com<br />

Great Britain<br />

CERATIZIT UK Ltd.<br />

Cliff Lane<br />

Grappenhall<br />

Warrington WA4 3JX<br />

Tel.: +44 (1925) 261-161<br />

Fax: +44 (1925) 267-933<br />

E-Mail: info.uk@ceratizit.com<br />

India<br />

CERATIZIT India Pvt. Ltd.<br />

58, Motilal Gupta Road<br />

Barisha<br />

IN-700 008 Kolkata<br />

Tel.: +91 (33) 2494-5435<br />

Fax: +91 (33) 2494-1472<br />

Telex: 021 8142 ihm in<br />

E-Mail: info.india@ceratizit.com<br />

Italy<br />

CERATIZIT Italia SpA<br />

Piazza F. Martelli, 7<br />

I-20162 Milano<br />

Tel.: +39 (02) 6441-111<br />

Fax: +39 (02) 6611-6040<br />

E-Mail: info.italia@ceratizit.com<br />

Japan<br />

CERATIZIT Japan Ltd.<br />

3-13-9, Mizuho<br />

Shizuoka 421 - 0115<br />

Tel.: +81 (54) 268 1060<br />

Fax: +81 (54) 257 8181<br />

E-Mail: info.japan@ceratizit.com<br />

Luxembourg<br />

CERATIZIT Luxembourg Sarl<br />

Route de Holzem, B.P. 51<br />

L-8201 Mamer<br />

Tel.: +352 312 085-1<br />

Fax: +352 311 911<br />

E-Mail: info@ceratizit.com<br />

Netherlands<br />

CERATIZIT Nederland B.V.<br />

Bergrand 224<br />

NL-4707 AT Roosendaal<br />

Tel.: +31 (165) 55 08 00<br />

Fax: +31 (165) 55 61 76<br />

E-Mail: info.nederland@ceratizit.com<br />

Spain<br />

CERATIZIT Ibérica SL<br />

Offi ce Pozuelo<br />

Vía de las Dos Castillas, 9c<br />

Portal 2, Bajo B<br />

E-28224 Pozuelo (Madrid)<br />

Tel.: +34 (91) 351-0609<br />

Fax: +34 (91) 351-2813<br />

E-Mail: info.iberica@ceratizit.com<br />

CERATIZIT Ibérica SL<br />

Offi ce Bilbao<br />

Avda. Mazarredo 41 1 Izqda.<br />

E-48009 Bilbao<br />

Tel.: +34 (944) 23 71 18<br />

Fax: +34 (944) 23 97 18<br />

E-Mail: info.bilbao@ceratizit.com<br />

USA<br />

CERATIZIT USA Inc.<br />

777 Old Clemson Road<br />

Columbia<br />

South Carolina 29229<br />

Toll free: +1 (800) 334 1165<br />

Tel.: +1 (803) 736 1900<br />

Fax: +1 (803) 736 1902<br />

E-Mail: info.usa@ceratizit.com

293/ 0<br />

7000626<br />

293 USA 06.05<br />

We reserve the right to make technical changes<br />

for improvement of the product.