PRINTED CIRCUIT BOARDS LAYOUT SPECIFICATION - Read

PRINTED CIRCUIT BOARDS LAYOUT SPECIFICATION - Read

PRINTED CIRCUIT BOARDS LAYOUT SPECIFICATION - Read

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

MITAC <strong>SPECIFICATION</strong> SC830215321021 R07C<br />

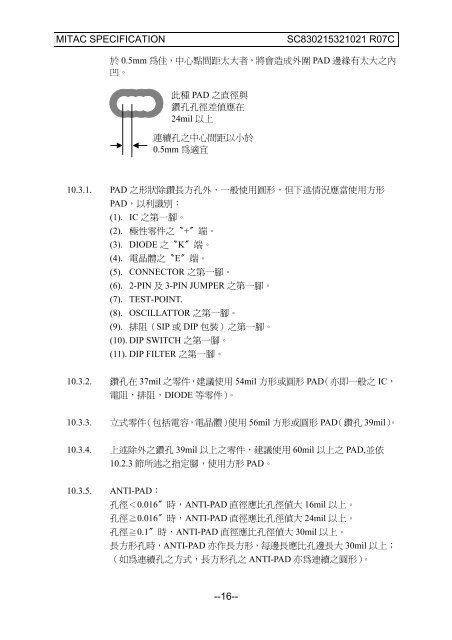

於 0.5mm 為佳,㆗心點間距太大者,將會造成外圍 PAD 邊緣有太大之內<br />

凹。<br />

此種 PAD 之直徑與<br />

鑽孔孔徑差值應在<br />

24mil 以㆖<br />

連續孔之㆗心間距以小於<br />

0.5mm 為適宜<br />

10.3.1. PAD 之形狀除鑽長方孔外,㆒般使用圓形,但㆘述情況應當使用方形<br />

PAD,以利識別:<br />

(1). IC 之第㆒腳。<br />

(2). 極性零件之〝+〞端。<br />

(3). DIODE 之〝K〞端。<br />

(4). 電晶體之〝E〞端。<br />

(5). CONNECTOR 之第㆒腳。<br />

(6). 2-PIN 及 3-PIN JUMPER 之第㆒腳。<br />

(7). TEST-POINT.<br />

(8). OSCILLATTOR 之第㆒腳。<br />

(9). 排阻(SIP 或 DIP 包裝)之第㆒腳。<br />

(10). DIP SWITCH 之第㆒腳。<br />

(11). DIP FILTER 之第㆒腳。<br />

10.3.2. 鑽孔在 37mil 之零件,建議使用 54mil 方形或圓形 PAD(亦即㆒般之 IC,<br />

電阻,排阻,DIODE 等零件)。<br />

10.3.3. 立式零件(包括電容,電晶體)使用 56mil 方形或圓形 PAD(鑽孔 39mil)。<br />

10.3.4. ㆖述除外之鑽孔 39mil 以㆖之零件,建議使用 60mil 以㆖之 PAD,並依<br />

10.2.3 節所述之指定腳,使用方形 PAD。<br />

10.3.5. ANTI-PAD:<br />

孔徑