Information for the certification of weld shops in rail ... - SLV Halle

Information for the certification of weld shops in rail ... - SLV Halle

Information for the certification of weld shops in rail ... - SLV Halle

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

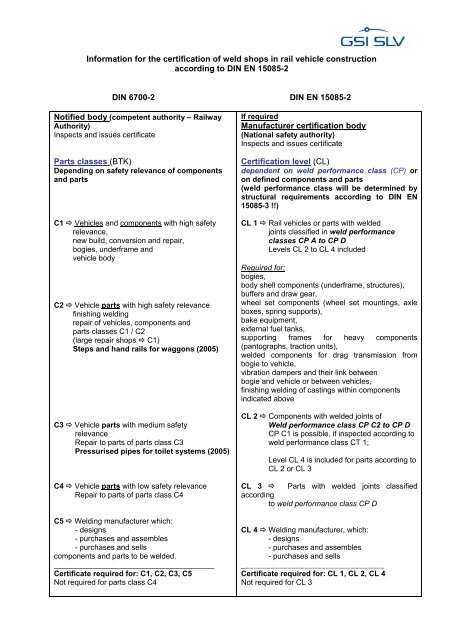

<strong>In<strong>for</strong>mation</strong> <strong>for</strong> <strong>the</strong> <strong>certification</strong> <strong>of</strong> <strong>weld</strong> <strong>shops</strong> <strong>in</strong> <strong>rail</strong> vehicle construction<br />

accord<strong>in</strong>g to DIN EN 15085-2<br />

DIN 6700-2 DIN EN 15085-2<br />

Notified body (competent authority – Railway<br />

Authority)<br />

Inspects and issues certificate<br />

Parts classes (BTK)<br />

Depend<strong>in</strong>g on safety relevance <strong>of</strong> components<br />

and parts<br />

C1 Vehicles and components with high safety<br />

relevance,<br />

new build, conversion and repair,<br />

bogies, underframe and<br />

vehicle body<br />

C2 Vehicle parts with high safety relevance<br />

f<strong>in</strong>ish<strong>in</strong>g <strong>weld</strong><strong>in</strong>g<br />

repair <strong>of</strong> vehicles, components and<br />

parts classes C1 / C2<br />

(large repair <strong>shops</strong> C1)<br />

Steps and hand <strong>rail</strong>s <strong>for</strong> waggons (2005)<br />

C3 Vehicle parts with medium safety<br />

relevance<br />

Repair to parts <strong>of</strong> parts class C3<br />

Pressurised pipes <strong>for</strong> toilet systems (2005)<br />

C4 Vehicle parts with low safety relevance<br />

Repair to parts <strong>of</strong> parts class C4<br />

C5 Weld<strong>in</strong>g manufacturer which:<br />

- designs<br />

- purchases and assembles<br />

- purchases and sells<br />

components and parts to be <strong>weld</strong>ed.<br />

______________________________________<br />

Certificate required <strong>for</strong>: C1, C2, C3, C5<br />

Not required <strong>for</strong> parts class C4<br />

If required<br />

Manufacturer <strong>certification</strong> body<br />

(National safety authority)<br />

Inspects and issues certificate<br />

Certification level (CL)<br />

dependent on <strong>weld</strong> per<strong>for</strong>mance class (CP) or<br />

on def<strong>in</strong>ed components and parts<br />

(<strong>weld</strong> per<strong>for</strong>mance class will be determ<strong>in</strong>ed by<br />

structural requirements accord<strong>in</strong>g to DIN EN<br />

15085-3 !!)<br />

CL 1 Rail vehicles or parts with <strong>weld</strong>ed<br />

jo<strong>in</strong>ts classified <strong>in</strong> <strong>weld</strong> per<strong>for</strong>mance<br />

classes CP A to CP D<br />

Levels CL 2 to CL 4 <strong>in</strong>cluded<br />

Required <strong>for</strong>:<br />

bogies,<br />

body shell components (underframe, structures),<br />

buffers and draw gear,<br />

wheel set components (wheel set mount<strong>in</strong>gs, axle<br />

boxes, spr<strong>in</strong>g supports),<br />

bake equipment,<br />

external fuel tanks,<br />

support<strong>in</strong>g frames <strong>for</strong> heavy components<br />

(pantographs, traction units),<br />

<strong>weld</strong>ed components <strong>for</strong> drag transmission from<br />

bogie to vehicle,<br />

vibration dampers and <strong>the</strong>ir l<strong>in</strong>k between<br />

bogie and vehicle or between vehicles,<br />

f<strong>in</strong>ish<strong>in</strong>g <strong>weld</strong><strong>in</strong>g <strong>of</strong> cast<strong>in</strong>gs with<strong>in</strong> components<br />

<strong>in</strong>dicated above<br />

CL 2 Components with <strong>weld</strong>ed jo<strong>in</strong>ts <strong>of</strong><br />

Weld per<strong>for</strong>mance class CP C2 to CP D<br />

CP C1 is possible, if <strong>in</strong>spected accord<strong>in</strong>g to<br />

<strong>weld</strong> per<strong>for</strong>mance class CT 1;<br />

Level CL 4 is <strong>in</strong>cluded <strong>for</strong> parts accord<strong>in</strong>g to<br />

CL 2 or CL 3<br />

CL 3 Parts with <strong>weld</strong>ed jo<strong>in</strong>ts classified<br />

accord<strong>in</strong>g<br />

to <strong>weld</strong> per<strong>for</strong>mance class CP D<br />

CL 4 Weld<strong>in</strong>g manufacturer, which:<br />

- designs<br />

- purchases and assembles<br />

- purchases and sells<br />

__________________________________<br />

Certificate required <strong>for</strong>: CL 1, CL 2, CL 4<br />

Not required <strong>for</strong> CL 3

Quality requirements to <strong>weld</strong><strong>in</strong>g<br />

manufacturer<br />

Parts class C1 to C3: accord<strong>in</strong>g to DIN EN ISO<br />

3834-3<br />

Parts class C4: accord<strong>in</strong>g to DIN EN ISO 3834-4<br />

Parts class C5: accord<strong>in</strong>g to DIN EN ISO 3834-3<br />

(if QMS accord<strong>in</strong>g to DIN EN ISO 9001 required:<br />

DIN EN ISO 3834-2)<br />

Weld<strong>in</strong>g coord<strong>in</strong>ators<br />

Parts class C1 responsible <strong>weld</strong><strong>in</strong>g coord<strong>in</strong>ator,<br />

level 1<br />

deputy , level 1<br />

(not <strong>for</strong> smaller <strong>weld</strong><strong>in</strong>g shop)<br />

<strong>in</strong> addition to each <strong>weld</strong><strong>in</strong>g shop,<br />

level 3 or 4<br />

Parts class C2 responsible <strong>weld</strong><strong>in</strong>g coord<strong>in</strong>ator,<br />

level 1<br />

deputy, level 2 or 3<br />

<strong>in</strong> addition per <strong>weld</strong><strong>in</strong>g shop,<br />

level 3 or 4<br />

(with several manufactur<strong>in</strong>g <strong>shops</strong>)<br />

Parts class C3 responsible <strong>weld</strong><strong>in</strong>g coord<strong>in</strong>ator,<br />

level 2 or 3<br />

deputy, level 4<br />

Parts class C4 no requirements<br />

Parts class C5 <strong>for</strong> parts class C1 one <strong>weld</strong><strong>in</strong>g<br />

coord<strong>in</strong>ator <strong>for</strong> level 1<br />

<strong>for</strong> parts class C2 one <strong>weld</strong><strong>in</strong>g<br />

coord<strong>in</strong>ator, level 1<br />

(construction only: DVS-<strong>weld</strong><strong>in</strong>g<br />

designer<br />

<strong>for</strong> parts class C3 one <strong>weld</strong><strong>in</strong>g<br />

coord<strong>in</strong>ator 2 or 3<br />

(construction only: like parts class<br />

C2)<br />

Involvement <strong>in</strong> organization<br />

Also see DVS-leaflet 1617<br />

Description <strong>of</strong> <strong>the</strong> job: DIN EN ISO 14731<br />

tasks, responsibilities and areas <strong>of</strong> competence<br />

rules <strong>for</strong> <strong>the</strong> areas <strong>of</strong> competence<br />

when must a responsible <strong>weld</strong><strong>in</strong>g coord<strong>in</strong>ator be<br />

present<br />

measures <strong>in</strong> case <strong>of</strong> absence <strong>of</strong> a responsible<br />

<strong>weld</strong><strong>in</strong>g coord<strong>in</strong>ator<br />

authority to issue <strong>in</strong>structions<br />

Quality requirements to <strong>weld</strong><strong>in</strong>g<br />

manufacturer<br />

CL 1: accord<strong>in</strong>g to DIN EN ISO 3834-2<br />

CL 2: accord<strong>in</strong>g to DIN EN ISO 3834-3<br />

CL 3: accord<strong>in</strong>g to DIN EN ISO 3834-4<br />

CL 4: accord<strong>in</strong>g to DIN EN ISO 3834-3<br />

Weld<strong>in</strong>g coord<strong>in</strong>ators<br />

CL 1 responsible , level A<br />

deputy, level A<br />

(not <strong>for</strong> smaller <strong>weld</strong><strong>in</strong>g <strong>shops</strong>)<br />

fur<strong>the</strong>r deputies, level B or C / with<br />

fur<strong>the</strong>r <strong>weld</strong><strong>in</strong>g <strong>shops</strong> fur<strong>the</strong>r<br />

deputy, level C<br />

CL 2 responsible <strong>weld</strong><strong>in</strong>g coord<strong>in</strong>ator, level B<br />

or C<br />

deputy, level C<br />

CL 3 No requirements<br />

CL 4 For CL 1: level A<br />

For CL 2: level B or C<br />

See annex B<br />

Tasks and areas <strong>of</strong> competence <strong>of</strong> <strong>weld</strong><strong>in</strong>g<br />

coord<strong>in</strong>ator<br />

Weld<strong>in</strong>g coord<strong>in</strong>ation organization<br />

Description <strong>of</strong> <strong>the</strong> job: DIN EN ISO 14731<br />

Tasks, responsibilities and areas <strong>of</strong> competence<br />

Rules <strong>for</strong> <strong>the</strong> areas <strong>of</strong> competence<br />

when must a responsible <strong>weld</strong><strong>in</strong>g coord<strong>in</strong>ator be<br />

present<br />

measures <strong>in</strong> case <strong>of</strong> absence <strong>of</strong> a responsible<br />

<strong>weld</strong><strong>in</strong>g coord<strong>in</strong>ator<br />

Authority to issue <strong>in</strong>structions<br />

Decision mak<strong>in</strong>g <strong>in</strong>dependent <strong>of</strong> manufactur<strong>in</strong>g<br />

pressures<br />

CL 1: Owners, manag<strong>in</strong>g directors,<br />

works manager, manufactur<strong>in</strong>g manager

decision mak<strong>in</strong>g <strong>in</strong>dependent <strong>of</strong> manufactur<strong>in</strong>g<br />

pressures<br />

Parts class C1: Owners, manag<strong>in</strong>g directors,<br />

works manager, manufactur<strong>in</strong>g manager<br />

are not approved as <strong>weld</strong><strong>in</strong>g coord<strong>in</strong>ator,<br />

deputy may be approved<br />

External <strong>weld</strong><strong>in</strong>g coord<strong>in</strong>ator<br />

(<strong>in</strong> special cases)<br />

see also DVS-guidel<strong>in</strong>e 1619 and<br />

A-Z-collection <strong>of</strong> KoA<br />

<strong>for</strong> parts classes C2, C3 and C5 possible<br />

also valid <strong>for</strong> <strong>weld</strong><strong>in</strong>g coord<strong>in</strong>ators who are<br />

employed by ano<strong>the</strong>r part <strong>of</strong> <strong>the</strong> same manufacturer<br />

(hold<strong>in</strong>g, head <strong>of</strong>fice, adm<strong>in</strong>istration)<br />

work contract and work<strong>in</strong>g time ruled<br />

description <strong>of</strong> <strong>the</strong> job<br />

(when must a <strong>weld</strong><strong>in</strong>g coord<strong>in</strong>ator be present)<br />

runn<strong>in</strong>g <strong>of</strong> a work book<br />

ma<strong>in</strong>tenance: Weld<strong>in</strong>g coord<strong>in</strong>ator <strong>of</strong> level 1 <strong>of</strong> a<br />

ma<strong>in</strong>tenance works can be approved <strong>for</strong> 2 fur<strong>the</strong>r<br />

smaller works <strong>of</strong> <strong>the</strong> same owner as <strong>the</strong> responsible<br />

<strong>weld</strong><strong>in</strong>g coord<strong>in</strong>ator (<strong>for</strong> parts class C2)<br />

Welders, operators, setters<br />

DIN EN 287-1, DIN EN ISO 9606-2,<br />

DIN EN ISO 9606-3, DIN EN 1418<br />

per <strong>weld</strong><strong>in</strong>g process, material group (and<br />

dimension) m<strong>in</strong>. 2 accord<strong>in</strong>g to <strong>the</strong> applicable<br />

standards<br />

<strong>for</strong> fillet <strong>weld</strong> separated evidence required<br />

(butt <strong>weld</strong> does not <strong>in</strong>clude fillet <strong>weld</strong>)<br />

Alum<strong>in</strong>ium-material groups 21 to 23:<br />

with TIG and MIG pr<strong>in</strong>cipally radiography <strong>of</strong> <strong>the</strong><br />

butt <strong>weld</strong>;<br />

<strong>for</strong> fillet <strong>weld</strong> additional macro-section<br />

Weld<strong>in</strong>g coord<strong>in</strong>ator level 1 is allowed to take<br />

exam<strong>in</strong>ations<br />

(if approved by <strong>the</strong> notified body)<br />

Inspection personnel<br />

quality <strong>in</strong>spections with<strong>in</strong> <strong>weld</strong><strong>in</strong>g manufacture:<br />

Inspection personnel must be <strong>in</strong>structed by<br />

<strong>weld</strong><strong>in</strong>g coord<strong>in</strong>ator<br />

if required: ndt (VT, PT, MT, ET, UT, RT)<br />

accord<strong>in</strong>g to DIN EN 473<br />

are not admitted as <strong>weld</strong><strong>in</strong>g coord<strong>in</strong>ator<br />

no approval possible,<br />

(Yes, <strong>in</strong> case <strong>of</strong> smaller <strong>shops</strong>, if <strong>weld</strong><strong>in</strong>g<br />

coord<strong>in</strong>ator has level A and deputy has<br />

level C)<br />

Deputy may be approved<br />

Subcontracted <strong>weld</strong><strong>in</strong>g coord<strong>in</strong>ator<br />

(special cases)<br />

Weld<strong>in</strong>g coord<strong>in</strong>ators who are not employed<br />

Only valid <strong>for</strong> responsible <strong>weld</strong><strong>in</strong>g coord<strong>in</strong>ator<br />

<strong>for</strong> CL 1 to CL 4 possible<br />

only one subcontract per manufactur<strong>in</strong>g plant<br />

deputy must be employed with manufacturer<br />

work contract and work<strong>in</strong>g time ruled,<br />

runn<strong>in</strong>g <strong>of</strong> a work book / record<br />

if subcontracted <strong>weld</strong><strong>in</strong>g coord<strong>in</strong>ator is to be<br />

active <strong>in</strong> more than two plants, approval <strong>of</strong> customer<br />

is required,<br />

<strong>for</strong> CL 4 exceptions <strong>in</strong> accordance with<br />

manufacturer <strong>certification</strong> body<br />

also valid <strong>for</strong> <strong>weld</strong><strong>in</strong>g coord<strong>in</strong>ator who is<br />

employed with ano<strong>the</strong>r plant than that <strong>of</strong> <strong>the</strong><br />

manufacturer (hold<strong>in</strong>g, head <strong>of</strong>fice, adm<strong>in</strong>istration)<br />

Welders, operators, setters<br />

DIN EN 287-1, DIN EN ISO 9606-2,<br />

DIN EN ISO 9606-3, DIN EN 1418<br />

<strong>for</strong> all <strong>weld</strong><strong>in</strong>g processes, types <strong>of</strong> material, types<br />

<strong>of</strong> seams and <strong>weld</strong><strong>in</strong>g positions <strong>in</strong> manufacture<br />

<strong>for</strong> fillet <strong>weld</strong> separated evidence required<br />

(butt <strong>weld</strong> does not <strong>in</strong>clude fillet <strong>weld</strong>)<br />

responsible Weld<strong>in</strong>g coord<strong>in</strong>ator level 1 is<br />

allowed to take exam<strong>in</strong>ations<br />

(if approved by <strong>the</strong> notified body)<br />

M<strong>in</strong>imum number not stated!!<br />

Inspection personnel<br />

quality <strong>in</strong>spections with<strong>in</strong> <strong>weld</strong><strong>in</strong>g manufacture:<br />

Inspection personnel must be <strong>in</strong>structed by<br />

<strong>weld</strong><strong>in</strong>g coord<strong>in</strong>ator<br />

e.g. <strong>for</strong> visual test<strong>in</strong>g <strong>for</strong> external evaluation <strong>of</strong> <strong>the</strong><br />

<strong>weld</strong>s<br />

if required: PT, MT, ET, UT, RT accord<strong>in</strong>g to<br />

DIN EN 473 with <strong>in</strong>struction by <strong>weld</strong><strong>in</strong>g<br />

coord<strong>in</strong>ator,<br />

Inspector with level 1 / <strong>in</strong>spection coord<strong>in</strong>ator with<br />

level 2;

<strong>in</strong>spectors with level 1 / <strong>in</strong>spection coord<strong>in</strong>ator<br />

with level 2;<br />

subcontracted <strong>in</strong>spection personnel possible<br />

All <strong>in</strong>spections <strong>of</strong> <strong>the</strong> <strong>weld</strong>ed jo<strong>in</strong>ts are to be<br />

carried out and evaluated under <strong>the</strong><br />

responsibility <strong>of</strong> <strong>the</strong> responsible <strong>weld</strong><strong>in</strong>g<br />

coord<strong>in</strong>ator !!<br />

Weld<strong>in</strong>g Procedure Specifications (WPS)<br />

<strong>for</strong> parts class C1 to C3 required<br />

<strong>for</strong> parts class C4 only if required by <strong>the</strong> customer<br />

Evidence <strong>of</strong> <strong>the</strong> WPS:<br />

manual / partly automated processes <strong>in</strong><br />

materials groups 1.1, 1.2, 8, 9, 21-26 accord<strong>in</strong>g to<br />

DIN EN ISO 15614-1 and -2 or<br />

DIN EN ISO 15611 or DIN EN ISO 15613;<br />

repair accord<strong>in</strong>g to DIN EN ISO 15613<br />

directly be<strong>for</strong>e start <strong>of</strong> production<br />

fully automated processes or material groups<br />

1.3-7 and 31-36<br />

accord<strong>in</strong>g to DIN EN ISO 15614-1 and -2<br />

Approval <strong>of</strong> <strong>the</strong> WPS us<strong>in</strong>g WPQR by:<br />

Inspection report <strong>of</strong> an <strong>in</strong>spection board (not<br />

necessarily <strong>the</strong> notified body accord<strong>in</strong>g to DIN<br />

6700) or<br />

<strong>the</strong> approved <strong>weld</strong><strong>in</strong>g coord<strong>in</strong>ator, level 1 if <strong>the</strong><br />

shop has an accredited test<strong>in</strong>g laboratory<br />

Supplementary area <strong>of</strong> validity <strong>of</strong> <strong>the</strong> WPS:<br />

Materials groups see A-Z collection<br />

Test piece thickness t ≤ 3 mm:<br />

manufactur<strong>in</strong>g range 1.0 mm to 2t is valid<br />

Fillet <strong>weld</strong> thickness <strong>of</strong> <strong>the</strong> work piece a

Suitable tools and similar correspond<strong>in</strong>g to <strong>the</strong><br />

materials worked (alum<strong>in</strong>ium, sta<strong>in</strong>less steels)<br />

Weld<strong>in</strong>g equipment<br />

<strong>for</strong> parts class C1 and C2:<br />

Rotat<strong>in</strong>g fixtures / clamp<strong>in</strong>g devices<br />

Work<strong>in</strong>g plat<strong>for</strong>ms / lift<strong>in</strong>g devices<br />

Straighten<strong>in</strong>g equipment<br />

Special areas <strong>for</strong> work<strong>in</strong>g with alum<strong>in</strong>ium and<br />

sta<strong>in</strong>less steels<br />

Approval <strong>of</strong> <strong>the</strong> <strong>weld</strong> <strong>shops</strong><br />

See also DVS-guidel<strong>in</strong>e 1619<br />

Audit<br />

Evidence <strong>of</strong> WPS<br />

Expert discussion (Weld<strong>in</strong>g coord<strong>in</strong>ators)<br />

Certificate <strong>of</strong> <strong>weld</strong><strong>in</strong>g:<br />

bound to <strong>the</strong> location <strong>of</strong> <strong>the</strong> <strong>weld</strong> shop and its<br />

<strong>weld</strong><strong>in</strong>g coord<strong>in</strong>ators<br />

Validity<br />

Maximum 3 years<br />

Surveillance by notified body<br />

(see DVS-guidel<strong>in</strong>e 1619),<br />

Modifications are to be disclosed,<br />

Extension must be applied <strong>for</strong> <strong>in</strong> time<br />

Withdrawal <strong>of</strong> <strong>the</strong> certificate<br />

Repair<br />

se DIN 27201-6<br />

Verification <strong>of</strong> con<strong>for</strong>mity<br />

accord<strong>in</strong>g to order:<br />

to be declared by <strong>the</strong> body agreed upon<br />

by <strong>the</strong> manufacturer:<br />

Work<strong>in</strong>g plat<strong>for</strong>ms / lift<strong>in</strong>g devices<br />

Straighten<strong>in</strong>g equipment<br />

Special areas <strong>for</strong> work<strong>in</strong>g with alum<strong>in</strong>ium and<br />

sta<strong>in</strong>less steels<br />

Certification procedure<br />

Audit<br />

Evidence <strong>of</strong> WPS<br />

Evidence <strong>of</strong> work specimens accord<strong>in</strong>g to EN<br />

15085-4<br />

Expert discussion (<strong>weld</strong><strong>in</strong>g coord<strong>in</strong>ators)<br />

Weld<strong>in</strong>g quality assurance accord<strong>in</strong>g to<br />

<strong>the</strong> applicable part <strong>of</strong> EN ISO 3834<br />

Issu<strong>in</strong>g <strong>of</strong> a certificate<br />

bound to <strong>the</strong> location <strong>of</strong> <strong>the</strong> <strong>weld</strong> shop and its<br />

<strong>weld</strong><strong>in</strong>g coord<strong>in</strong>ators<br />

Validity<br />

Maximum 3 years<br />

Valid only <strong>for</strong> <strong>the</strong> location <strong>the</strong> shop stated <strong>in</strong> <strong>the</strong><br />

certificate,<br />

Annual surveillance by manufacturer <strong>certification</strong><br />

body (it is permitted to take <strong>in</strong>to account reports<br />

on <strong>in</strong>ternal audits, too)<br />

Modifications are to be disclosed,<br />

Extension must be applied <strong>for</strong> <strong>in</strong> time<br />

Repair<br />

out <strong>of</strong> <strong>the</strong> certified shop <strong>for</strong> production<br />

<strong>of</strong> workability (transfer)<br />

<strong>in</strong> case <strong>of</strong> warranty or ma<strong>in</strong>tenance <strong>of</strong> its own<br />

vehicles <strong>weld</strong><strong>in</strong>g works are admissible under <strong>the</strong><br />

same conditions regard<strong>in</strong>g personnel, technical<br />

and qualitative requirements<br />

(<strong>the</strong> o<strong>the</strong>r shop need not be stated <strong>in</strong> <strong>the</strong><br />

certificate)<br />

certified body is permitted to carry out <strong>weld</strong><strong>in</strong>g<br />

works <strong>in</strong> ano<strong>the</strong>r workshop if <strong>the</strong> workshop is<br />

<strong>in</strong>spected <strong>in</strong> a verification procedure and <strong>the</strong><br />

workshop is <strong>in</strong>dicated <strong>in</strong> <strong>the</strong> certificate<br />

Verification <strong>of</strong> con<strong>for</strong>mity<br />

No requirements <strong>in</strong>cluded <strong>in</strong> DIN EN 15085

Inspections and documentation accord<strong>in</strong>g to <strong>the</strong><br />

specified <strong>weld</strong> per<strong>for</strong>mance class accord<strong>in</strong>g to<br />

DIN 6700-5<br />

by body agreed upon:<br />

Inspections and documentation accord<strong>in</strong>g to<br />

specified <strong>weld</strong> per<strong>for</strong>mance class accord<strong>in</strong>g to<br />

DIN 6700-5 and attestation <strong>of</strong> con<strong>for</strong>mity<br />

or<br />

<strong>in</strong>stead <strong>of</strong> <strong>in</strong>spections, <strong>the</strong> body agreed upon<br />

per<strong>for</strong>ms surveillance <strong>of</strong> <strong>the</strong> QMS<br />

(certificate will not be issued)<br />

But:<br />

DIN EN 15085-5,<br />

Chapter 9 Declaration <strong>of</strong> con<strong>for</strong>mity<br />

Manufacturer must submit certificate <strong>of</strong> compliance<br />

with <strong>the</strong> determ<strong>in</strong>ed contract requirements;<br />

Guidel<strong>in</strong>es <strong>for</strong> issu<strong>in</strong>g:<br />

see EN ISO/IEC 17050-1 and -2<br />

Evidence <strong>of</strong> <strong>weld</strong><strong>in</strong>g procedure specifications – DIN EN 15085-4<br />

Chapter 4.1.4<br />

Weld per<strong>for</strong>mance class CP A:<br />

Certificate accord<strong>in</strong>g to EN 10204 shall be agreed<br />

between customer and manufacturer<br />

WPQR accord<strong>in</strong>g to EN ISO 15614 or EN ISO 15620;<br />

Accord<strong>in</strong>g to EN ISO 15613 only if a WPQR accord<strong>in</strong>g to EN ISO 15614 is present;<br />

For materials with Reh > 500 MPa or <strong>for</strong> fully automated <strong>weld</strong><strong>in</strong>g only<br />

EN ISO 15614 is possible<br />

Test pieces must fulfill <strong>the</strong> requirements <strong>of</strong> <strong>weld</strong> per<strong>for</strong>mance class CP A (EN 15085-3,<br />

tables 5 and 6)<br />

<strong>for</strong> <strong>weld</strong> per<strong>for</strong>mance class CP B, CP C1, CP C2:<br />

WPQR accord<strong>in</strong>g to EN ISO 15613, EN ISO 14555, EN ISO 15620;<br />

If required by component or material: accord<strong>in</strong>g to EN ISO 15614<br />

Note: EN ISO 15610, EN ISO 15611, EN ISO 15612 not possible<br />

<strong>for</strong> <strong>weld</strong> per<strong>for</strong>mance class CP C3:<br />

WPQR accord<strong>in</strong>g to EN ISO 15610, 15611, 15612, 15613, 14555, 15620<br />

If required by component or material: accord<strong>in</strong>g to EN ISO 15614<br />

<strong>for</strong> <strong>weld</strong> per<strong>for</strong>mance class CP D: only if requested by customer