Welding Fabrication Standards - EWF

Welding Fabrication Standards - EWF

Welding Fabrication Standards - EWF

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Welding</strong> <strong>Fabrication</strong> <strong>Standards</strong> Page 26<br />

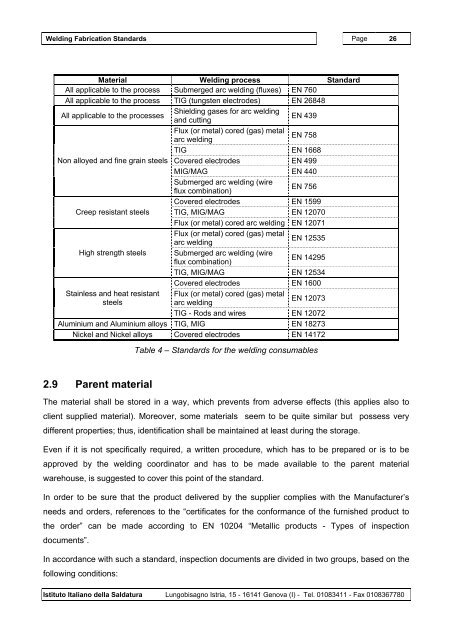

Material <strong>Welding</strong> process Standard<br />

All applicable to the process Submerged arc welding (fluxes) EN 760<br />

All applicable to the process TIG (tungsten electrodes) EN 26848<br />

All applicable to the processes<br />

Shielding gases for arc welding<br />

and cutting<br />

EN 439<br />

Flux (or metal) cored (gas) metal<br />

arc welding<br />

EN 758<br />

TIG EN 1668<br />

Non alloyed and fine grain steels Covered electrodes EN 499<br />

MIG/MAG EN 440<br />

Submerged arc welding (wire<br />

flux combination)<br />

EN 756<br />

Covered electrodes EN 1599<br />

Creep resistant steels TIG, MIG/MAG EN 12070<br />

Flux (or metal) cored arc welding EN 12071<br />

Flux (or metal) cored (gas) metal<br />

arc welding<br />

EN 12535<br />

High strength steels Submerged arc welding (wire<br />

flux combination)<br />

EN 14295<br />

TIG, MIG/MAG EN 12534<br />

Covered electrodes EN 1600<br />

Stainless and heat resistant<br />

steels<br />

Flux (or metal) cored (gas) metal<br />

arc welding<br />

EN 12073<br />

TIG - Rods and wires EN 12072<br />

Aluminium and Aluminium alloys TIG, MIG EN 18273<br />

Nickel and Nickel alloys Covered electrodes EN 14172<br />

2.9 Parent material<br />

Table 4 – <strong>Standards</strong> for the welding consumables<br />

The material shall be stored in a way, which prevents from adverse effects (this applies also to<br />

client supplied material). Moreover, some materials seem to be quite similar but possess very<br />

different properties; thus, identification shall be maintained at least during the storage.<br />

Even if it is not specifically required, a written procedure, which has to be prepared or is to be<br />

approved by the welding coordinator and has to be made available to the parent material<br />

warehouse, is suggested to cover this point of the standard.<br />

In order to be sure that the product delivered by the supplier complies with the Manufacturer’s<br />

needs and orders, references to the “certificates for the conformance of the furnished product to<br />

the order” can be made according to EN 10204 “Metallic products - Types of inspection<br />

documents”.<br />

In accordance with such a standard, inspection documents are divided in two groups, based on the<br />

following conditions:<br />

Istituto Italiano della Saldatura Lungobisagno Istria, 15 - 16141 Genova (I) - Tel. 01083411 - Fax 0108367780