Welding Fabrication Standards - EWF

Welding Fabrication Standards - EWF

Welding Fabrication Standards - EWF

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Welding</strong> <strong>Fabrication</strong> <strong>Standards</strong> Page 34<br />

other applications of the instruments. “Normal” ( standardised) procedures for calibration,<br />

verification and validation of the instruments may be too stringent and costly, if applied for welding<br />

purposes.<br />

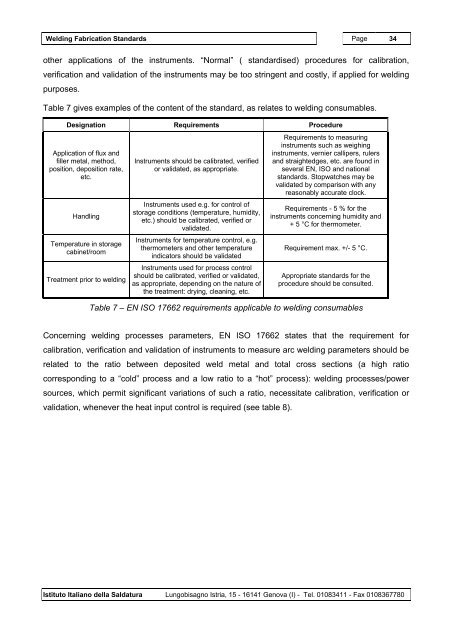

Table 7 gives examples of the content of the standard, as relates to welding consumables.<br />

Designation Requirements Procedure<br />

Application of flux and<br />

filler metal, method,<br />

position, deposition rate,<br />

etc.<br />

Handling<br />

Temperature in storage<br />

cabinet/room<br />

Treatment prior to welding<br />

Instruments should be calibrated, verified<br />

or validated, as appropriate.<br />

Instruments used e.g. for control of<br />

storage conditions (temperature, humidity,<br />

etc.) should be calibrated, verified or<br />

validated.<br />

Instruments for temperature control, e.g.<br />

thermometers and other temperature<br />

indicators should be validated<br />

Instruments used for process control<br />

should be calibrated, verified or validated,<br />

as appropriate, depending on the nature of<br />

the treatment: drying, cleaning, etc.<br />

Requirements to measuring<br />

instruments such as weighing<br />

instruments, vernier callipers, rulers<br />

and straightedges, etc. are found in<br />

several EN, ISO and national<br />

standards. Stopwatches may be<br />

validated by comparison with any<br />

reasonably accurate clock.<br />

Requirements - 5 % for the<br />

instruments concerning humidity and<br />

+ 5 °C for thermometer.<br />

Requirement max. +/- 5 °C.<br />

Appropriate standards for the<br />

procedure should be consulted.<br />

Table 7 – EN ISO 17662 requirements applicable to welding consumables<br />

Concerning welding processes parameters, EN ISO 17662 states that the requirement for<br />

calibration, verification and validation of instruments to measure arc welding parameters should be<br />

related to the ratio between deposited weld metal and total cross sections (a high ratio<br />

corresponding to a “cold” process and a low ratio to a “hot” process): welding processes/power<br />

sources, which permit significant variations of such a ratio, necessitate calibration, verification or<br />

validation, whenever the heat input control is required (see table 8).<br />

Istituto Italiano della Saldatura Lungobisagno Istria, 15 - 16141 Genova (I) - Tel. 01083411 - Fax 0108367780