Issue 11 - Upstream's Upswing - Lockwood International

Issue 11 - Upstream's Upswing - Lockwood International

Issue 11 - Upstream's Upswing - Lockwood International

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Power Group Generates New Vision For 20<strong>11</strong> by Jim Garza<br />

With the start of a new year, change<br />

has come to the Power Group. Emphasis<br />

is being placed on our core products (TY,<br />

IIshin, OMB, Tomoe, Perar and Rotork)<br />

which are the valve and automation lines<br />

that build the base of our foundation in the<br />

valve marketplace. In promoting these lines,<br />

there have been additional changes to our<br />

website and current product line sheet as<br />

well as presentation materials. We appreciate<br />

the role Marketing has shared in making<br />

this transition possible. The long term<br />

success of <strong>Lockwood</strong> Power Group is reliant<br />

on our ability in the field to seek valve<br />

approvals for our major lines (commonly<br />

referred to as ‘AML approval’) This is necessary<br />

both in the Engineering Firms and<br />

the Major Utilities across the country. We<br />

have had recent success with Kiewit, Kan-<br />

As the marketplace continues to shift,<br />

<strong>Lockwood</strong> <strong>International</strong> is evolving into<br />

focusing more on specialty products and<br />

automation.<br />

With the addition of the Tomoe Triple<br />

Offset in 2010 we began addressing more<br />

engineered product applications. Tomoe<br />

sas City on the Wayne County – Progress<br />

Energy Project and the upcoming Sutton<br />

County Project with Matt Cassidy handling<br />

the lead on these projects. With additional<br />

approvals at B&W in Ohio this begins to<br />

snowball into a very positive process along<br />

the road to building a resume of major account<br />

approvals. This process is one of our<br />

main priorities in 20<strong>11</strong> along with landing<br />

additional projects. In our goal to grow the<br />

Power Group we have targeted key Utility<br />

accounts – Southern Company, Duke Energy,<br />

Progress Energy (Recently bought by<br />

Duke Energy), Florida Power&Light/NEX-<br />

TERA, TVA Tennessee Valley Authority. By<br />

doing this we will build a resume of success<br />

that will carry into our other geographic locations.<br />

The engineering firms, where we<br />

have a very successful history with on re-<br />

Speciality Products & Actuation by Randy Wilson<br />

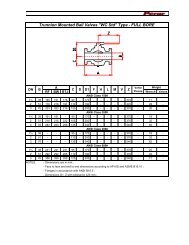

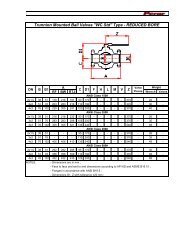

offers the most complete range in size<br />

and pressure class in the market today.<br />

We are presently reviewing several quality<br />

products of Knife Gates, Severe Service<br />

Metal Seated Ball Valves, Lift Plugs,<br />

Segmented Ball Valves and Globe Control<br />

Valves.<br />

The Hot and Cold of It...in Baton Rouge by Tim Yon<br />

Kenny Simoneaux on site at ExxonMobil’s<br />

Chalmette, Louisiana refinery.<br />

During the year the Baton Rouge Branch<br />

completed the Jacobs ExxonMobil Non<br />

Road Diesel project at the ExxonMobil Baton<br />

Rouge Refinery, a $550 million project<br />

to comply with federal low sulfur specifications<br />

of non-road diesel (think locomotives).<br />

The project activities originated from the<br />

corporate office in Houston but were transitioned<br />

to Baton Rouge after field installation<br />

began and more day-to-day contact and interaction<br />

was needed to effectively and efficiently<br />

facilitate the project milestones. The<br />

Non Road Diesel process was characterized<br />

by high heat applications and included<br />

high pressure alloy (347 stainless, WC6 and<br />

C12) valves.<br />

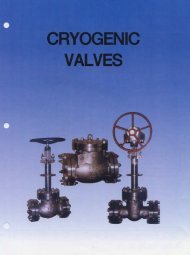

At the other end of the temperature spectrum,<br />

the branch, in coordination with ExxonMobil,<br />

has begun valve planning on the<br />

EPLA-WNOX project at the Baton Rouge<br />

Chemical Plant that includes cryogenic cold<br />

service valves. In cryogenic service, ice or<br />

ice balls can form around the valve with normal<br />

hand wheel heights making the valve inoperable.<br />

Cryogenic valves (typically stainless)<br />

have an extended bonnet or gas vapor<br />

column to elevate the operation of the valve<br />

to a warmer area … away from the cold me-<br />

finery/petrochemical projects, is where we<br />

must work very hard to seek approvals for<br />

Power. This is one of the main challenges<br />

we face daily and the effort is beginning to<br />

be rewarded.<br />

The Power industry is the one market that<br />

remains strong in our weak economy and<br />

with continual growth in the Southwest and<br />

Southeast it appears the next 10-15 years<br />

will be strong for Power Construction and<br />

for <strong>Lockwood</strong>. As we venture into more<br />

Power related projects we will share the<br />

different types of Power plants that are being<br />

built today along with the Eco-Friendly<br />

Solar and Wind Turbine projects. The 20<strong>11</strong><br />

Project list is quite extensive and with our<br />

overall team approach we will have a very<br />

productive year.<br />

These products coupled with TY-Italy<br />

ball valves will give us a very comprehensive<br />

product offering and will provide<br />

<strong>Lockwood</strong> with the capabilities to sell<br />

and solve customer issues.<br />

dia. <strong>Lockwood</strong>’s early involvement in the<br />

planning stages with the customer and the<br />

manufacturer assist in the timely manufacturing<br />

and delivery of these special valves<br />

hopefully preventing or minimizing the need<br />

to modify stock valves to cryogenic applications.<br />

Simultaneous with Baton Rouge’s participation<br />

in cryogenic service, Beaumont has<br />

also been involved in a cryogenic application<br />

with the Golden Pass LNG terminal near<br />

Sabine Pass, Texas. The Golden Pass LNG<br />

project is a joint venture of Qatar Petroleum<br />

<strong>International</strong>, ExxonMobil and ConocoPhillips<br />

and has the capacity to deliver the annual<br />

equivalent of 2.5 Bcf/day of natural gas.<br />

The Beaumont branch was instrumental in<br />

choreographing the supply, modification<br />

and testing of what became time sensitive<br />

cryogenic requirements of the Golden Pass<br />

project.<br />

Down on the bayou, Kenny Simoneaux<br />

offices in <strong>Lockwood</strong>’s only on-site arrangement<br />

at a customer’s facility. Kenny’s offices<br />

are inside of ExxonMobil’s Chalmette,<br />

LA refinery. Pictured here in the Alky Unit,<br />

Kenny continues to work with ExxonMobil in<br />

valve application and problem solving.