CODE OF PRACTICE FOR METAL SCAFFOLDING SAFETY

CODE OF PRACTICE FOR METAL SCAFFOLDING SAFETY

CODE OF PRACTICE FOR METAL SCAFFOLDING SAFETY

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>CODE</strong> <strong>OF</strong> <strong>PRACTICE</strong> <strong>FOR</strong> <strong>METAL</strong> <strong>SCAFFOLDING</strong> <strong>SAFETY</strong><br />

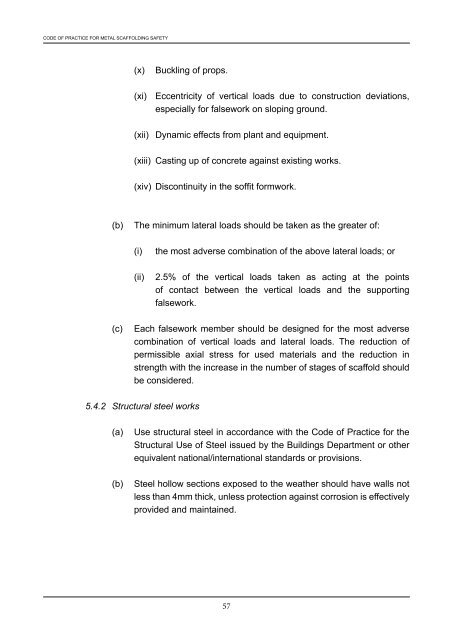

(x) Buckling of props.<br />

(xi) Eccentricity of vertical loads due to construction deviations,<br />

especially for falsework on sloping ground.<br />

(xii) Dynamic effects from plant and equipment.<br />

(xiii) Casting up of concrete against existing works.<br />

(xiv) Discontinuity in the soffit formwork.<br />

(b) The minimum lateral loads should be taken as the greater of:<br />

(i) the most adverse combination of the above lateral loads; or<br />

(ii) 2.5% of the vertical loads taken as acting at the points<br />

of contact between the vertical loads and the supporting<br />

falsework.<br />

(c) Each falsework member should be designed for the most adverse<br />

combination of vertical loads and lateral loads. The reduction of<br />

permissible axial stress for used materials and the reduction in<br />

strength with the increase in the number of stages of scaffold should<br />

be considered.<br />

5.4.2 Structural steel works<br />

(a) Use structural steel in accordance with the Code of Practice for the<br />

Structural Use of Steel issued by the Buildings Department or other<br />

equivalent national/international standards or provisions.<br />

(b) Steel hollow sections exposed to the weather should have walls not<br />

less than 4mm thick, unless protection against corrosion is effectively<br />

provided and maintained.<br />

57