Mechanical shaft seals for pumps - Grundfos

Mechanical shaft seals for pumps - Grundfos

Mechanical shaft seals for pumps - Grundfos

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

70<br />

Tribology<br />

The lapped surface has a plateau with some valleys. Consequently, the bearing area rapidly<br />

increases with the depth until a large area has been reached. As opposed to the lapped<br />

surface, the area of the grinded surface is slowly increasing with depths indicating a more<br />

even distribution of valleys and peaks.<br />

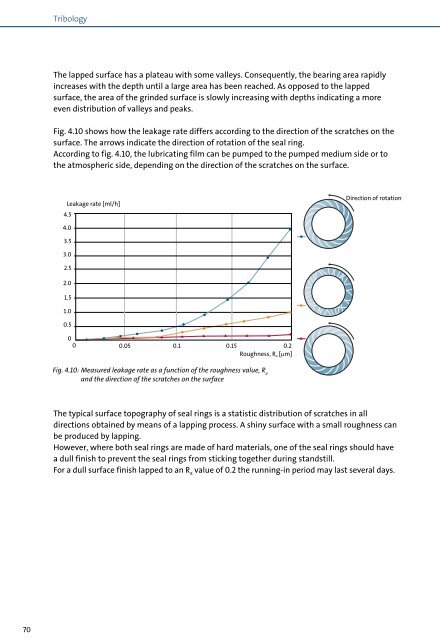

Fig. 4.10 shows how the leakage rate differs according to the direction of the scratches on the<br />

surface. The arrows indicate the direction of rotation of the seal ring.<br />

According to fig. 4.10, the lubricating film can be pumped to the pumped medium side or to<br />

the atmospheric side, depending on the direction of the scratches on the surface.<br />

Leakage rate [ml/h]<br />

4.5<br />

4.0<br />

3.5<br />

3.0<br />

2.5<br />

2.0<br />

1.5<br />

1.0<br />

0.5<br />

0<br />

0 0.05 0.1 0.15<br />

0.2<br />

Roughness, Ra [µm]<br />

Fig. 4.10: Measured leakage rate as a function of the roughness value, R a<br />

and the direction of the scratches on the surface<br />

Direction of rotation<br />

TheLeakage typical rate surface [ml/h] topography of seal rings is a statistic distribution of scratches in all<br />

directions 1.8 obtained by means of a lapping process. A shiny surface with a small roughness can<br />

1.6<br />

be produced by lapping.<br />

1.4<br />

However, where both seal rings are made of hard materials, one of the seal rings should have<br />

1.2<br />

a dull 1.0 finish to prevent the seal rings from sticking together during standstill.<br />

For0.8 a dull surface finish lapped to an Ra value of 0.2 the running-in period may last several days.<br />

0.6<br />

0.4<br />

0.2<br />

0<br />

0 0.2 0.4 0.6 0.8 1.0 1.2 1.4<br />

Waviness [µm]