The Haynes Welding Manual - VolksPage.Net

The Haynes Welding Manual - VolksPage.Net

The Haynes Welding Manual - VolksPage.Net

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

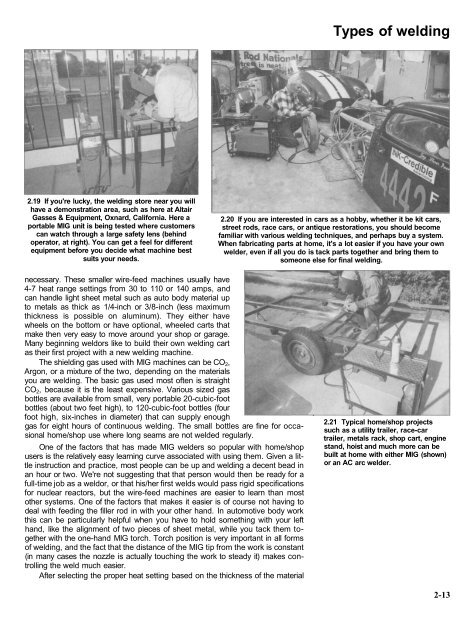

2.19 If you're lucky, the welding store near you will<br />

have a demonstration area, such as here at Altair<br />

Gasses & Equipment, Oxnard, California. Here a<br />

portable MIG unit is being tested where customers<br />

can watch through a large safety lens (behind<br />

operator, at right). You can get a feel for different<br />

equipment before you decide what machine best<br />

suits your needs.<br />

necessary. <strong>The</strong>se smaller wire-feed machines usually have<br />

4-7 heat range settings from 30 to 110 or 140 amps, and<br />

can handle light sheet metal such as auto body material up<br />

to metals as thick as 1/4-inch or 3/8-inch (less maximum<br />

thickness is possible on aluminum). <strong>The</strong>y either have<br />

wheels on the bottom or have optional, wheeled carts that<br />

make then very easy to move around your shop or garage.<br />

Many beginning weldors like to build their own welding cart<br />

as their first project with a new welding machine.<br />

<strong>The</strong> shielding gas used with MIG machines can be CO2,<br />

Argon, or a mixture of the two, depending on the materials<br />

you are welding. <strong>The</strong> basic gas used most often is straight<br />

CO2, because it is the least expensive. Various sized gas<br />

bottles are available from small, very portable 20-cubic-foot<br />

bottles (about two feet high), to 120-cubic-foot bottles (four<br />

foot high, six-inches in diameter) that can supply enough<br />

gas for eight hours of continuous welding. <strong>The</strong> small bottles are fine for occasional<br />

home/shop use where long seams are not welded regularly.<br />

One of the factors that has made MIG welders so popular with home/shop<br />

users is the relatively easy learning curve associated with using them. Given a little<br />

instruction and practice, most people can be up and welding a decent bead in<br />

an hour or two. We're not suggesting that that person would then be ready for a<br />

full-time job as a weldor, or that his/her first welds would pass rigid specifications<br />

for nuclear reactors, but the wire-feed machines are easier to learn than most<br />

other systems. One of the factors that makes it easier is of course not having to<br />

deal with feeding the filler rod in with your other hand. In automotive body work<br />

this can be particularly helpful when you have to hold something with your left<br />

hand, like the alignment of two pieces of sheet metal, while you tack them together<br />

with the one-hand MIG torch. Torch position is very important in all forms<br />

of welding, and the fact that the distance of the MIG tip from the work is constant<br />

(in many cases the nozzle is actually touching the work to steady it) makes controlling<br />

the weld much easier.<br />

After selecting the proper heat setting based on the thickness of the material<br />

Types of welding<br />

2.20 If you are interested in cars as a hobby, whether it be kit cars,<br />

street rods, race cars, or antique restorations, you should become<br />

familiar with various welding techniques, and perhaps buy a system.<br />

When fabricating parts at home, it's a lot easier if you have your own<br />

welder, even if all you do is tack parts together and bring them to<br />

someone else for final welding.<br />

2.21 Typical home/shop projects<br />

such as a utility trailer, race-car<br />

trailer, metals rack, shop cart, engine<br />

stand, hoist and much more can be<br />

built at home with either MIG (shown)<br />

or an AC arc welder.<br />

2-13