The Haynes Welding Manual - VolksPage.Net

The Haynes Welding Manual - VolksPage.Net

The Haynes Welding Manual - VolksPage.Net

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

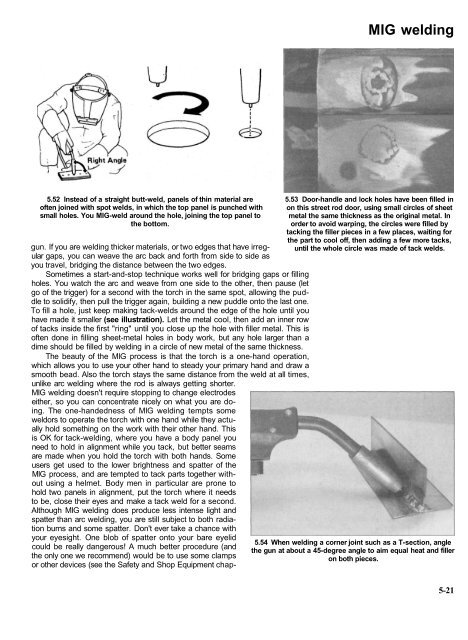

5.52 Instead of a straight butt-weld, panels of thin material are<br />

often joined with spot welds, in which the top panel is punched with<br />

small holes. You MIG-weld around the hole, joining the top panel to<br />

the bottom.<br />

gun. If you are welding thicker materials, or two edges that have irregular<br />

gaps, you can weave the arc back and forth from side to side as<br />

you travel, bridging the distance between the two edges.<br />

Sometimes a start-and-stop technique works well for bridging gaps or filling<br />

holes. You watch the arc and weave from one side to the other, then pause (let<br />

go of the trigger) for a second with the torch in the same spot, allowing the puddle<br />

to solidify, then pull the trigger again, building a new puddle onto the last one.<br />

To fill a hole, just keep making tack-welds around the edge of the hole until you<br />

have made it smaller (see illustration). Let the metal cool, then add an inner row<br />

of tacks inside the first "ring" until you close up the hole with filler metal. This is<br />

often done in filling sheet-metal holes in body work, but any hole larger than a<br />

dime should be filled by welding in a circle of new metal of the same thickness.<br />

<strong>The</strong> beauty of the MIG process is that the torch is a one-hand operation,<br />

which allows you to use your other hand to steady your primary hand and draw a<br />

smooth bead. Also the torch stays the same distance from the weld at all times,<br />

unlike arc welding where the rod is always getting shorter.<br />

MIG welding doesn't require stopping to change electrodes<br />

either, so you can concentrate nicely on what you are doing.<br />

<strong>The</strong> one-handedness of MIG welding tempts some<br />

weldors to operate the torch with one hand while they actually<br />

hold something on the work with their other hand. This<br />

is OK for tack-welding, where you have a body panel you<br />

need to hold in alignment while you tack, but better seams<br />

are made when you hold the torch with both hands. Some<br />

users get used to the lower brightness and spatter of the<br />

MIG process, and are tempted to tack parts together without<br />

using a helmet. Body men in particular are prone to<br />

hold two panels in alignment, put the torch where it needs<br />

to be, close their eyes and make a tack weld for a second.<br />

Although MIG welding does produce less intense light and<br />

spatter than arc welding, you are still subject to both radiation<br />

burns and some spatter. Don't ever take a chance with<br />

your eyesight. One blob of spatter onto your bare eyelid<br />

could be really dangerous! A much better procedure (and<br />

the only one we recommend) would be to use some clamps<br />

or other devices (see the Safety and Shop Equipment chap-<br />

MIG welding<br />

5.53 Door-handle and lock holes have been filled in<br />

on this street rod door, using small circles of sheet<br />

metal the same thickness as the original metal. In<br />

order to avoid warping, the circles were filled by<br />

tacking the filler pieces in a few places, waiting for<br />

the part to cool off, then adding a few more tacks,<br />

until the whole circle was made of tack welds.<br />

5.54 When welding a corner joint such as a T-section, angle<br />

the gun at about a 45-degree angle to aim equal heat and filler<br />

on both pieces.<br />

5-21