CONVERSION AND REACTOR SIZING

CONVERSION AND REACTOR SIZING

CONVERSION AND REACTOR SIZING

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

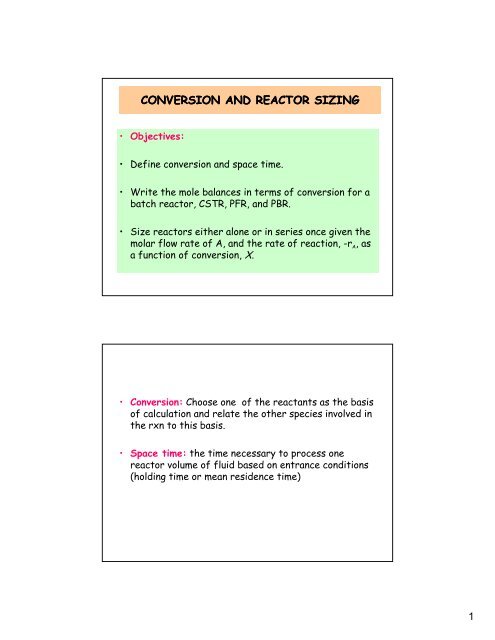

<strong>CONVERSION</strong> <strong>AND</strong> <strong>REACTOR</strong> <strong>SIZING</strong><br />

• Objectives:<br />

• Define conversion and space time.<br />

• Write the mole balances in terms of conversion for a<br />

batch reactor, CSTR, PFR, and PBR.<br />

• Size reactors either alone or in series once given the<br />

molar flow rate of A, and the rate of reaction, -r A, as<br />

a function of conversion, X.<br />

• Conversion: Choose one of the reactants as the basis<br />

of calculation and relate the other species involved in<br />

the rxn to this basis.<br />

• Space time: the time necessary to process one<br />

reactor volume of fluid based on entrance conditions<br />

(holding time or mean residence time)<br />

1

<strong>CONVERSION</strong> <strong>AND</strong> <strong>REACTOR</strong> <strong>SIZING</strong><br />

1. Conversion<br />

Consider the general equation<br />

aA A + bB → cCC<br />

+ dD<br />

We will choose A as our basis of calculation.<br />

b c<br />

A + B → C +<br />

a a<br />

The basis of calculation is most always the limiting reactant. The<br />

conversion of species A in a reaction is equal to the number of moles of A<br />

reacted per mole of A fed.<br />

d<br />

a<br />

D<br />

Batch Flow<br />

( NA0<br />

− NA)<br />

( FA0<br />

− FA<br />

X =<br />

X =<br />

N<br />

F<br />

A0<br />

A0<br />

X = Moles of A reacted<br />

Moles of A fed<br />

For irreversible reactions, the maximum value of conversion, X, is<br />

that for complete conversion, i.e. X = 1.0.<br />

For reversible reactions, the maximum value of conversion, X, is the<br />

equilibrium conversion, i.e. X = X e.<br />

)<br />

2

2. Design Equations<br />

Batch Reactor Design Equations:<br />

⎡Moles<br />

of A⎤<br />

⎢ ⎥ ⎡ ⎡Moles<br />

of<br />

=<br />

⎥ ⎢<br />

⎣<br />

⎥<br />

⎢<br />

⎦<br />

⎢<br />

Moles of<br />

reacted<br />

fed<br />

⎣(<br />

consumed)<br />

= ⋅ [ X ]<br />

[ N ]<br />

A0<br />

A ⎤ ⎡ Moles of A reacted ⎤<br />

⎥<br />

⋅ ⎢<br />

⎥<br />

⎦ ⎣ Moles of A fed ⎦<br />

Now the # of moles of A that remain in the reactor after a time t, NA can be<br />

expressed in terms of N A0 and X;<br />

[ N ] = [ N ] − [ N ⋅ X ]<br />

N<br />

A<br />

A<br />

= N<br />

dN<br />

dt<br />

dN<br />

−<br />

dt<br />

A0<br />

A0<br />

A<br />

A<br />

A0<br />

⋅ ( 1 − X )<br />

= r ⋅V<br />

( prefect mixing)<br />

[3]<br />

A<br />

= −r<br />

⋅V<br />

A<br />

For batch reactors, we are interested in determining how long to leave the<br />

reactants in the reactor to achieve a certain conversion X.<br />

− N<br />

N<br />

A0<br />

A0<br />

dN<br />

dt<br />

dX<br />

⋅<br />

dt<br />

dX<br />

⋅<br />

dt<br />

= 0 − N A0<br />

A ⋅<br />

= r<br />

A<br />

= −r<br />

⋅V<br />

A<br />

⋅V<br />

dX<br />

dt<br />

(Since N A0 is constant) [4]<br />

Batch reactor design eq’n<br />

(in differential form)<br />

[5]<br />

[1]<br />

[2]<br />

3

For a constant volume batch reactor: (V = V 0)<br />

1 dN<br />

⋅<br />

V dt<br />

0<br />

dC<br />

dt<br />

A<br />

A<br />

d ( N A / V0<br />

) dC<br />

=<br />

=<br />

dt dt<br />

= r<br />

A<br />

dt = N<br />

t = N<br />

A0<br />

A0<br />

dX<br />

⋅<br />

− r ⋅V<br />

A<br />

A<br />

From [3]<br />

Constant volume batch<br />

reactor<br />

From [5]<br />

X<br />

dX<br />

Batch time, t, required<br />

⋅ ∫ to achieve a<br />

− r rA<br />

⋅ V<br />

0 conversion X.<br />

Flow Reactor Design Equations:<br />

X<br />

As t X<br />

For continuous-flow systems, time usually increases with increasing reactor<br />

volume.<br />

F<br />

F<br />

A0<br />

A0<br />

inlet molar<br />

flow rate<br />

F<br />

F<br />

moles of A fed moles of A reacted<br />

⋅ X =<br />

⋅<br />

time moles of A fed<br />

A<br />

− F<br />

A 0<br />

=<br />

A0<br />

=<br />

F<br />

⋅ X = F<br />

A<br />

Outlet flow rate<br />

Molar flow rate at which A is<br />

consumed within the system<br />

A 0<br />

C<br />

A 0<br />

moles /volume<br />

⋅ ( 1 −<br />

⋅ v<br />

0<br />

X<br />

)<br />

volume / time (volumetric flow rate, dm 3 /s)<br />

t<br />

4

For liquid systems, CA0 is usually given in terms of molarity (mol/dm3)<br />

For gas systems, CA0 can be calculated using gas laws.<br />

F<br />

C<br />

A0<br />

Entering molar flow rate is<br />

A0<br />

= v ⋅C<br />

0<br />

A0<br />

y yA0<br />

⋅ P P0<br />

= v0<br />

⋅<br />

R⋅T<br />

CSTR (Design Equation)<br />

For a rxn:<br />

Substitute for F A<br />

P PA<br />

0 =<br />

R ⋅T<br />

0<br />

0<br />

Partial pressure<br />

=<br />

y A0<br />

⋅ P<br />

R ⋅T<br />

y A0<br />

0<br />

0<br />

= entering mole fraction of A<br />

P = entering t i ttotal t l pressure (kP (kPa) )<br />

P 0<br />

b c<br />

A + B → C +<br />

a a<br />

F<br />

V<br />

V<br />

A<br />

=<br />

V<br />

=<br />

F<br />

=<br />

F<br />

A0<br />

CA0 = entering conc’n (mol/dm3 )<br />

R = 8.314 kPa dm3 / mol K<br />

T = T(K)<br />

d<br />

a<br />

F A 0 − F<br />

− r<br />

A0<br />

A<br />

− F<br />

−<br />

FA0<br />

⋅ X<br />

=<br />

( −r<br />

)<br />

A<br />

A<br />

D<br />

⋅ X<br />

A0<br />

( FA0<br />

− FA0<br />

exit<br />

−<br />

r<br />

A<br />

⋅ X )<br />

5

PFR (Design Equation)<br />

Substitute back:<br />

dFA<br />

− = −rA<br />

dV<br />

F = F − F<br />

A<br />

dF<br />

A<br />

A0<br />

= −F<br />

A0<br />

dF<br />

− 0<br />

dV<br />

Seperate the variables V = 0 when X = 0<br />

V<br />

A0<br />

⋅ dX<br />

dX<br />

dV<br />

⋅ X<br />

A = FA<br />

⋅ = −rA<br />

=<br />

F<br />

A 0<br />

X<br />

dX<br />

⋅ ∫ − r<br />

Applications of Design Equations for<br />

Continuous Flow Reactors<br />

3. Reactor Sizing<br />

Given –r A as a function of conversion, -r A = f(X), one can size any type of<br />

reactor. We do this by constructing a Levenspiel Plot. Here we plot either<br />

F A0 / -r A or 1 / -r A as a function of X. For F A0 / -r A vs. X, the volume of a<br />

CSTR and the volume of a PFR can be represented as the shaded areas<br />

in the Levelspiel Plots shown below:<br />

0<br />

Levenspiel Plots<br />

A<br />

6

A particularly simple functional dependence is the first order dependence:<br />

−<br />

rA = k ⋅C<br />

A = k ⋅C<br />

A0<br />

Specific rxn rate<br />

(function ( of T) )<br />

⋅(<br />

1−<br />

X )<br />

initial conc’n<br />

For this first order rxn, a plot of 1/-r A as a function of X yields :<br />

1 1<br />

− =<br />

k ⋅C<br />

-1/r A<br />

rA A0<br />

⎛ 1<br />

⋅⎜<br />

⎝1−<br />

X<br />

Example: Let’s consider the isothermal gas-phase isomerization:<br />

A → B<br />

X -rA(mol/m3s) 0 045 0.45<br />

0.1 0.37<br />

0.2 0.30<br />

0.4 0.195<br />

0.6 0.113<br />

0.7 0.079<br />

08 0.8 005 0.05<br />

X<br />

⎞<br />

⎟<br />

⎠<br />

[T = 500 K]<br />

[P = 830 kPa = 8.2 atm]<br />

initial charge was pure A<br />

7

Example: Let’s consider the isothermal gas-phase isomerization:<br />

A → B<br />

Draw -1/r 1/rA vs X:<br />

-1/r A<br />

X<br />

X -rA(mol/m3s) 1 / -rA 0 045 0.45 222 2.22<br />

0.1 0.37 2.70<br />

0.2 0.30 3.33<br />

0.4 0.195 5.13<br />

0.6 0.113 8.85<br />

0.7 0.079 12.7<br />

08 0.8 005 0.05 20 20.0 0<br />

[T = 500 K]<br />

[P = 830 kPa = 8.2 atm]<br />

initial charge was pure A<br />

We can use this figure to size flow reactors for<br />

different entering molar flow rates.<br />

Keep in mind :<br />

1. if a rxn is carried out isothermally, y, the rate is<br />

usually greatest at the start of the rxn, when<br />

the conc’n of reactant is greatest. (when x ≈<br />

0 → -1/rA is small)<br />

2. As x → 1, –rA → 0 thus 1/-rA → ∞ & V → ∞<br />

→ An infinite reactor volume is needed to reach complete conversion.<br />

For reversible reactions (A ↔ B), the max X is the equilibrium conversion<br />

Xe. At equilibrium, rA ≈ 0.<br />

As X → Xe, –rA → 0 thus 1/-rA → ∞ & V → ∞<br />

→ An infinite reactor volume is needed to obtain X e.<br />

8

if FA0 = 0.4 mol/s, we can calculate [FA/-rA](m3) Plot FA0/-rA vs X obtain Levenspiel Plot!<br />

Example: Calculate volume to achieve 80 % conversion in CSTR.<br />

For instance:<br />

1.5 m 3<br />

find − rA<br />

at X = 0.<br />

8<br />

3<br />

⎛ 1 ⎞ m<br />

⎜<br />

⎜−<br />

20<br />

r ⎟ =<br />

⎝ A ⎠ mol ⋅ s<br />

0.<br />

8<br />

FA0<br />

⋅ X<br />

V =<br />

( −r<br />

)<br />

A<br />

exit<br />

3<br />

mol m<br />

= 0 0. 4 ⋅ 20 ⋅ 0 0.<br />

8 = 6 6.<br />

4 m<br />

s mol ⋅ s<br />

3.6 m 3<br />

4. Numerical Evaluation of Intergrals<br />

CSTRs are usually used for liquid-phase rxns.<br />

The integral to calculate the PFR volume can be evaluated using a<br />

method such as Simpson’s One-Third Rule.<br />

3<br />

NOTE: The intervals (∆X) shown in the<br />

sketch are not drawn to scale. They<br />

should be equal.<br />

Simpson’s One-Third Rule is one of the most common numerical methods. It<br />

uses three data points. One numerical methods for evaluating integrals are:<br />

1. Trapezoidal Rule (uses two data points)<br />

2. Simpson’s Three-Eighth’s Rule (uses four data points)<br />

3. Five-Point Quadrature Formula<br />

9

Trapezoidal Rule<br />

f(x 1)<br />

f(x 0)<br />

f(x)<br />

x 0<br />

A 1<br />

h<br />

Five Point Quadrature formula:<br />

x4<br />

∫<br />

x0<br />

xN<br />

∫<br />

x0<br />

A 2<br />

x 1<br />

x<br />

x1<br />

∫<br />

x0<br />

h<br />

f ( x)<br />

⋅ dx = ⋅(<br />

f0<br />

+ 4 f1<br />

+ 2 f 2 + 4 f3<br />

+ f4<br />

)<br />

3<br />

1<br />

f ( x)<br />

⋅ dx = [ f ( x0)<br />

+ f ( x1)]<br />

h<br />

A = f ( x ) ⋅h<br />

1<br />

0<br />

[ f ( x1)<br />

− f ( x0)]<br />

⋅ h<br />

A2<br />

2 =<br />

2<br />

A = A + A<br />

where<br />

3h<br />

f ( x)<br />

⋅ dx = ⋅(<br />

f0<br />

+ 3 f1<br />

+ 3 f2<br />

+ 2 f3<br />

+ 3 f 4 + 3 f5<br />

+ 2 f6.....)<br />

8<br />

1<br />

2<br />

⎡ f ( x1)<br />

f ( x0)<br />

⎤<br />

= h ⋅<br />

⎢<br />

f ( x0)<br />

+ −<br />

2 2 ⎥<br />

⎣<br />

⎦<br />

h<br />

= ⋅[<br />

f ( x0)<br />

+ f ( x1)]<br />

2<br />

x4<br />

− x0<br />

h =<br />

4<br />

For N+1 points, where<br />

N is an integer.<br />

Example: Consider the liquid phase reaction;<br />

A → Products<br />

which is to take place in a PFR. The following data was obtained in a<br />

batch reactor.<br />

X 0 0.4 0.8<br />

-rA(mol/dm3s) 0.01 0.008 0.002<br />

If the molar feed of A to the PFR is 2 mol/s, what PFR volume is<br />

necessary to achieve 80 % conversion under identical conditions as<br />

those under which the batch data was obtained?<br />

10

Hint :<br />

FA0 = 2 mol/s, fed to a plug flow reactor<br />

X<br />

1<br />

PFR∴V<br />

= F 0 dX Thus one needs (1/-r<br />

r<br />

A) as a function of X.<br />

A ∫ − 0<br />

X<br />

dX<br />

PFR : V = FA<br />

0 ∫ = F A 0<br />

− r 0 A<br />

A<br />

For Simpson’s three point formula we have:<br />

PFR : V = F<br />

X 1 4 1<br />

A ⎥ ⎤<br />

∆ ⎡<br />

⋅ ⎢ + + ⎥<br />

3 ⎣−<br />

rA(<br />

X = 0)<br />

− rA(<br />

X1)<br />

− rA(<br />

X 2)<br />

⎦<br />

0.<br />

8<br />

∫<br />

A0<br />

0<br />

dX<br />

− r<br />

A<br />

mol ⎧0.<br />

4<br />

= 2 ⋅ ⎨<br />

s ⎩ 3<br />

3<br />

dm s ⎫<br />

⎬<br />

mol ⎭<br />

3<br />

[ 100 + 4⋅<br />

( 125)<br />

+ 500]<br />

= 293dm<br />

To reach 80 % conversion your PFR must be 293 3 dm3 To reach 80 % conversion, your PFR must be 293.3 dm3 .<br />

11

Sizing in PFR<br />

Example: Determine the volume in PFR to achieve a 80 % conversion.<br />

dX<br />

For PFR : FA0<br />

⋅ = −rA<br />

dV<br />

0 0.<br />

8 0 0.<br />

8<br />

dX F FA0<br />

Re arranging : V = FA0<br />

⋅ ∫ = ⋅ dX<br />

− r ∫ − r<br />

Let’s numerically evaluate the integral with trapezoidal rule<br />

0.<br />

8<br />

∫<br />

0<br />

FA0<br />

⋅ dX<br />

− r<br />

A<br />

⇒<br />

FA0<br />

f ( X ) = =<br />

− r<br />

0<br />

A X = 0<br />

FA0<br />

f ( X ) = =<br />

− r<br />

A<br />

A X = 0.<br />

8<br />

0<br />

0.<br />

89<br />

8.<br />

0<br />

0.<br />

8<br />

3<br />

V = ⋅(<br />

0.<br />

89 + 8.<br />

0)<br />

= 8.<br />

89⋅<br />

0.<br />

4 = 3.<br />

556m<br />

2<br />

With five point quadrature V = 2.165 m3 Comparing CSTR & PFR Sizing<br />

V CSTR > V PFR for the same conversion and rxn conditions.<br />

The reason is that CSTR always operates at lowest rxn rate. PFR starts at a high<br />

y p g<br />

rate, then gradually decreases to the exit rate.<br />

A<br />

12

Reactors in Series: The exit of one reactor is fed to the next one.<br />

Given –rA as a function of conversion, one can design any sequence of<br />

reactors.<br />

moles of A reacted up to point<br />

i<br />

X i =<br />

moles of A fed to first reactor<br />

Only valid if there are no side streams.<br />

F ⋅ X<br />

Ai = FA0<br />

− FA0<br />

Example: Using Levenspiel plots to calculate conversion from known<br />

reactor volumes.<br />

Pure A is fed at a volumetric flow rate 1000 dm 3 /h and at a concentration of 0.005<br />

mol/dm 3 to an existing CSTR, which is connected in series to an existing tubular<br />

reactor If the volume of the CSTR is 1200 dm 3 and the tubular reactor volume is<br />

reactor. If the volume of the CSTR is 1200 dm 3 and the tubular reactor volume is<br />

600 dm 3 , what are the intermediate and final conversions that can be achieved<br />

with the existing system? The reciprocal rate is plotted in the figure below as a<br />

function of conversion for the conditions at which the reaction is to be carried out.<br />

i<br />

13

Solution:<br />

By trial and error, we find that a conversion of 0.6 gives the appropriate<br />

CSTR volume of 1200 dm 3 .<br />

Therefore, the intermediate conversion is X = 0.6<br />

Similarly for the PFR, through trial and error, we find that a conversion<br />

of 0.8 gives the appropriate PFR volume of 600 dm 3 .<br />

Therefore, the final conversion is X = 0.8<br />

14

CSTRs in Series<br />

Two CSTRs in series<br />

F A0<br />

-r A1<br />

F A1<br />

X 1 = 0.4<br />

-r A2<br />

A2<br />

F A2<br />

X 1 = 0.8<br />

Reactor 1:<br />

Mole Balance: FA0 –FA1 + rA1 V1 = 0 [1]<br />

FA1 = FA0 –FA0 X1 Combining [1] & [2]:<br />

[2]<br />

Reactor 2:<br />

V 1 = F A0 (1 / -r A1) X 1<br />

[3]<br />

Mole Balance: F A1 –F A2 + r A2 V 2 = 0 [4]<br />

Combining [4] & [5]:<br />

A2<br />

F A2 = F A0 – F A0 X 2 [5]<br />

FA1<br />

− FA2<br />

( FA0<br />

− FA0<br />

⋅ X1)<br />

− ( FA0<br />

− FA0<br />

⋅ X 2)<br />

FA0<br />

V2<br />

= =<br />

= ( X 2 − X1)<br />

− r<br />

− r<br />

− r<br />

if we have the data:<br />

X =<br />

0.<br />

4<br />

⎛ F<br />

⎜<br />

⎝ −<br />

⎞<br />

⎟<br />

=<br />

⎛<br />

= ⎜<br />

A0<br />

3<br />

A0<br />

2.<br />

05m<br />

V1<br />

X1<br />

0.<br />

82<br />

r ⎟<br />

⎜<br />

1<br />

r ⎟ ⋅ =<br />

A ⎠ X 0.<br />

4<br />

⎝ −<br />

=<br />

A1<br />

⎠0.<br />

4<br />

⎛ F ⎞<br />

3 ⎛ F ⎞<br />

0 F ⎞<br />

A A0<br />

X = 0. 8 ⎜<br />

8.<br />

0m<br />

V ⎜ 2 ⋅(<br />

X 2 − X1)<br />

= 3.<br />

2m<br />

r ⎟ =<br />

= ⎜<br />

A2<br />

r ⎟<br />

⎝ − ⎠<br />

⎝ − A2<br />

⎠<br />

-F A0/r A<br />

0.4 0.8<br />

X = 0.<br />

8<br />

Total V = V 1 + V 2 = 4.02 m 3 < 6.4 m 3<br />

X<br />

F<br />

⎞<br />

⎟<br />

V CSTR,2 > V CSTR,1<br />

A2<br />

m<br />

volume necessary to get 80 %<br />

conversion with one CSTR<br />

3<br />

3<br />

15

One can approximate a PFR by a large # of CSTRs in series:<br />

F A0<br />

1 2 3 4<br />

PFRs in Series<br />

X 2<br />

-r A1<br />

F A1<br />

X 1 =0.4<br />

X1<br />

X 2<br />

∫ ∫ ∫ −<br />

⋅ +<br />

FA0<br />

⋅ = FA0<br />

⋅ FA0<br />

− r − r<br />

0<br />

dX<br />

A<br />

0<br />

-r A2<br />

dX<br />

F A2<br />

X 1 = 0.8<br />

A<br />

dX<br />

r<br />

X1 A<br />

Reactors in Series: CSTR – PFR – CSTR<br />

-F A0/r A<br />

V<br />

PFR<br />

=<br />

n<br />

∑<br />

i=<br />

1<br />

V<br />

CSTR , i<br />

V TOTAL = V PFR,1 + V PFR,2<br />

The overall conversion of<br />

two PFRs in series is the<br />

same as one PFR with the<br />

same total volume<br />

Using the data in the table, calculate the reactor volumes V 1, V 2 and V 3<br />

for the CSTR/PFR/CSTR reactors in series sequence along with the<br />

corresponding conversion.<br />

X<br />

16

Use<br />

the<br />

plot<br />

of<br />

⎛ F ⎞ A 0<br />

⎜ vs.<br />

r ⎟<br />

⎝ − A ⎠<br />

(a) The CSTR design equation for Reactor 1 is:<br />

V<br />

X<br />

1<br />

⎛ F ⋅ ⎞ A0<br />

X ⎞ A0<br />

X<br />

= ⎜<br />

⎟<br />

⎝ − rA1<br />

⎠<br />

at X = X 1 = 0.4 the (F A0 / -r A1) = 300 dm 3<br />

V 1 = (300 dm 3 ) (0.4) = 120 dm 3<br />

The volume of the first CSTR is 120 dm 3<br />

(b) Reactor 2: PFR The differential form of the PFR design is<br />

dX − r<br />

=<br />

dV F<br />

A<br />

A 0<br />

Rearranging and intergrating with limits<br />

when V = 0 X = X1 = 0.4<br />

when V = V2 X = X2 = 0.7<br />

V<br />

=<br />

X<br />

2 ⎛ F ⎞ A0<br />

⎜<br />

⎟<br />

⎟⋅<br />

dX =<br />

⎝ − r ⎠<br />

∫<br />

X A<br />

1<br />

0 0.<br />

7<br />

∫<br />

0.<br />

4<br />

⎛ FA<br />

⎜<br />

⎝ − r<br />

0<br />

A<br />

⎞<br />

⎟<br />

⎟⋅<br />

dX<br />

⎠<br />

17

Choose three point quadrature formula with<br />

V<br />

2<br />

X 2 − X1<br />

0.<br />

7 − 0.<br />

4<br />

∆X<br />

= = =<br />

2 2<br />

0.<br />

15<br />

∆ X ⎡ F 4 F F ⎤<br />

A0<br />

4⋅<br />

FA0<br />

FA0<br />

= ⎢ + + ⎥<br />

3 ⎣−<br />

rA(<br />

0.<br />

4)<br />

− rA(<br />

0.<br />

55)<br />

− rA(<br />

0.<br />

7)<br />

⎦<br />

Interpreting for (F A0/-r A) at X = 0.55 we obtain<br />

⎛ F ⎞ A<br />

⎜ =<br />

⎝ − =<br />

0 3<br />

= 370dm<br />

rA ⎠ X 0.<br />

55<br />

3<br />

3<br />

3<br />

3<br />

[ 300dm<br />

+ 4⋅<br />

( 370dm<br />

) + 600dm<br />

] 119dm<br />

0.<br />

15<br />

V 2 =<br />

=<br />

3<br />

The volume of the PFR is V 2 = 119 dm 3<br />

(c) Reactor 3: CSTR<br />

Balance<br />

F<br />

F<br />

V<br />

V<br />

A2<br />

A3<br />

3<br />

3<br />

= F<br />

= F<br />

F<br />

=<br />

− r<br />

A0<br />

A0<br />

A0<br />

A3<br />

⋅(<br />

1−<br />

X<br />

⋅(<br />

1−<br />

X<br />

⋅(<br />

X<br />

3<br />

2<br />

3<br />

in − out + generation<br />

F<br />

V<br />

)<br />

)<br />

− X<br />

A2<br />

3<br />

2<br />

− F<br />

A3<br />

+ r<br />

FA2<br />

− F<br />

=<br />

− r<br />

)<br />

A3<br />

A3<br />

A3<br />

⋅V<br />

3<br />

3<br />

= 600dm<br />

⋅(<br />

0.<br />

7 − 0.<br />

4)<br />

= 180dm<br />

3<br />

= 0<br />

The volume of last CSTR is 180 dm 3<br />

18

Summary:<br />

CSTR X1 = 0.4 V1 = 120 dm3 PFR X2 = 07 V2 = 119 dm3 PFR X2 0.7 V2 119 dm<br />

CSTR X3 = 0.8 V3 = 180 dm3 Total volume = 120 + 119 + 180 = 419 dm 3<br />

Reactor Sequencing<br />

Is there any differences between having a CSTR – PFR system & PFR –<br />

CSTR system? Which arrangement is best?<br />

V 1 V 2 V 3 V 4<br />

For isothermal rxns<br />

F A0<br />

Adiabatic rxns<br />

X<br />

or<br />

The volumes are different!<br />

V1 + V2 =? V3 + V4 The choice of reactors depend on ;<br />

the Levenspiel plots<br />

relative reactor sizes.<br />

19

Space Time<br />

The space time, tau, is obtained by dividing the reactor volume by<br />

the volumetric flow rate entering the reactor:<br />

V<br />

τ =<br />

v 0<br />

Space time is the time necessary to process one volume of reactor<br />

fluid at the entrance conditions. This is the time it takes for the amount<br />

of fluid that takes up the entire volume of the reactor to either<br />

completely enter or completely exit the reactor. It is also called holding<br />

time or mean residence time.<br />

Example: v 0 = 0.01 m 3 /s and V = 0.2 m 3 → τ = 0.2 m 3 / 0.01 m 3 /s = 20 s<br />

It would take 20 s for the fluid at the entrance to move to the exit.<br />

Typical space time for different reactors:<br />

Batch : 15 min – 20 h (few kg/day – 100,000 tons/year ≈ 280 tons/day)<br />

CSTR : 10 min – 4 h (10 to 3 x 10 6 tons/yr)<br />

Tubular: 05s– 1h (50 to 5 x 106 Tubular: 0.5s 1h (50 to 5 x 10 tons/yr)<br />

20

Space Velocity (SV) is defined as:<br />

SV<br />

v0<br />

= =<br />

V<br />

instead of using volumetric flow rate at the entrance, you use liquid –<br />

hourly & gas – hourly space velocities (LHSV, GHSV).<br />

v 0 (for LHSV) is that of a liquid feed rate at 60°F or 75°F.<br />

v 0 (for GHSV) is that of the one that measured at STP.<br />

v0<br />

LHSV =<br />

V<br />

1<br />

τ<br />

v<br />

GHSV =<br />

V<br />

liq 0 STP<br />

21

• HW (due date: Feb 25):<br />

• SSolve l th the prpblem bl iin<br />

your own way.<br />

• http://www.engin.umich.edu/~cre/web_mod/hippo/index.htm<br />

• Suggested problems from the web:<br />

• htt http://www.engin.umich.edu/~cre/<br />

// i i h d / /<br />

• Additional Homework Problems at each<br />

chapter<br />

Example: Consider cell as a reactor. The nutrient corn steep liquor enters the cell of the<br />

microorganism Penicillium chrysogenum and is decomposed to form such products as<br />

amino acids, RNA and DNA. Write an unsteady mass balance on (a) the corn steep liquor,<br />

(b) RNA, and (c) pencillin. Assume the cell is well mixed and that RNA remains inside the<br />

cell.<br />

In Out<br />

Corn Steep Liquor Penicillin<br />

Penicillium chrysogenum<br />

Assumption:<br />

Penicillin is produced in the stationary state.<br />

→ no cell growth & nutrients are used in making the product.<br />

22

Mass balance for penicillin:<br />

In − Out + Generation<br />

dN p<br />

Fin<br />

+ Fout<br />

+ G p =<br />

dt<br />

= Accumulati on<br />

F = 0 ( no penicilin in _ flow)<br />

in<br />

V<br />

V<br />

dN p<br />

G p = ∫ r rp<br />

⋅ dV ⇒ ∫ r rp<br />

⋅ dV − F Fout<br />

=<br />

dt<br />

Assuming steady state for the rate of production of penicilin in the cells<br />

stationary state,<br />

dN p<br />

= 0<br />

dt<br />

Fin<br />

− Fout<br />

V =<br />

− r<br />

⇒<br />

Fout<br />

V =<br />

r<br />

Similarity, for Corn Steep Liquor with F C = 0<br />

No RNA is generated or destroyed.<br />

FC<br />

0 − FC<br />

F<br />

V = =<br />

− r − r<br />

p<br />

C<br />

Summary<br />

C 0<br />

Batch Flow<br />

( NA0<br />

− NA)<br />

( FA0<br />

− FA<br />

X =<br />

X =<br />

N<br />

A0<br />

A0<br />

X = Moles of A reacted<br />

Moles of A fed<br />

For irreversible reactions, the maximum value of conversion, X, is<br />

that for complete conversion, i.e. X = 1.0.<br />

For reversible reactions, the maximum value of conversion, X, is the<br />

equilibrium conversion, i.e. X = X e.<br />

C<br />

F<br />

p<br />

)<br />

23

dX<br />

N A0<br />

⋅ = −rA<br />

⋅V<br />

dt<br />

F<br />

X<br />

A 0 ⋅<br />

V =<br />

CSTR<br />

( −rA<br />

) exit<br />

V<br />

=<br />

F<br />

A 0<br />

X<br />

dX<br />

⋅ ∫ − r<br />

Reactors in series<br />

Space time<br />

0<br />

A<br />

Batch reactor design eq’n<br />

(in differential form)<br />

τ =<br />

PFR<br />

V<br />

v 0<br />

24

![]_[O](https://img.yumpu.com/10363126/1/190x138/-o.jpg?quality=85)