Chapter -1 final last new font final - petrofed.winwinho...

Chapter -1 final last new font final - petrofed.winwinho...

Chapter -1 final last new font final - petrofed.winwinho...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

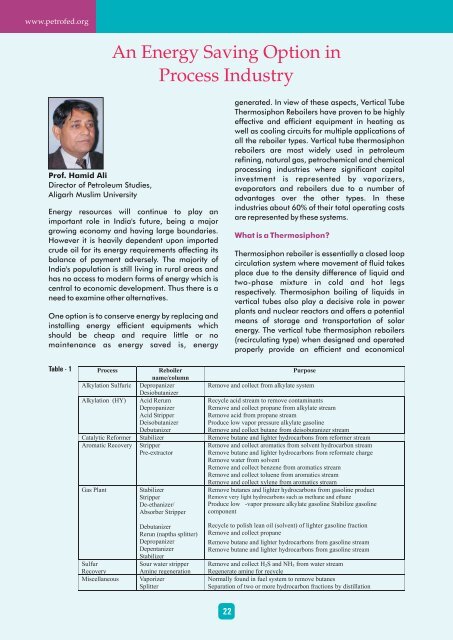

www.<strong>petrofed</strong>.org<br />

Prof. Hamid Ali<br />

Director of Petroleum Studies,<br />

Aligarh Muslim University<br />

An Energy Saving Option in<br />

Process Industry<br />

Energy resources will continue to play an<br />

important role in India's future, being a major<br />

growing economy and having large boundaries.<br />

However it is heavily dependent upon imported<br />

crude oil for its energy requirements affecting its<br />

balance of payment adversely. The majority of<br />

India's population is still living in rural areas and<br />

has no access to modern forms of energy which is<br />

central to economic development. Thus there is a<br />

need to examine other alternatives.<br />

One option is to conserve energy by replacing and<br />

installing energy efficient equipments which<br />

should be cheap and require little or no<br />

maintenance as energy saved is, energy<br />

Table - 1 Process Reboiler<br />

name/column<br />

Alkylation Sulfuric Depropanizer<br />

Desiobutanizer<br />

Alkylation (HY) Acid Rerum<br />

Depropanizer<br />

Acid Stripper<br />

Deisobutanizer<br />

Debutanizer<br />

Catalytic Reformer Stabilizer<br />

Aromatic Recovery Stripper<br />

Pre-extractor<br />

Gas Plant Stabilizer<br />

Stripper<br />

De-ethanizer/<br />

Absorber Stripper<br />

Debutanizer<br />

Rerun (naptha splitter)<br />

Depropanizer<br />

Depentanizer<br />

Stabilizer<br />

Sulfur<br />

Sour water stripper<br />

Recovery<br />

Amine regeneration<br />

Miscellaneous Vaporizer<br />

Splitter<br />

22<br />

generated. In view of these aspects, Vertical Tube<br />

Thermosiphon Reboilers have proven to be highly<br />

effective and efficient equipment in heating as<br />

well as cooling circuits for multiple applications of<br />

all the reboiler types. Vertical tube thermosiphon<br />

reboilers are most widely used in petroleum<br />

refining, natural gas, petrochemical and chemical<br />

processing industries where significant capital<br />

investment is represented by vaporizers,<br />

evaporators and reboilers due to a number of<br />

advantages over the other types. In these<br />

industries about 60% of their total operating costs<br />

are represented by these systems.<br />

What is a Thermosiphon?<br />

Thermosiphon reboiler is essentially a closed loop<br />

circulation system where movement of fluid takes<br />

place due to the density difference of liquid and<br />

two-phase mixture in cold and hot legs<br />

respectively. Thermosiphon boiling of liquids in<br />

vertical tubes also play a decisive role in power<br />

plants and nuclear reactors and offers a potential<br />

means of storage and transportation of solar<br />

energy. The vertical tube thermosiphon reboilers<br />

(recirculating type) when designed and operated<br />

properly provide an efficient and economical<br />

Purpose<br />

Remove and collect from alkylate system<br />

Recycle acid stream to remove contaminants<br />

Remove and collect propane from alkylate stream<br />

Remove acid from propane stream<br />

Produce low vapor pressure alkylate gasoline<br />

Remove and collect butane from deisobutanizer stream<br />

Remove butane and lighter hydrocarbons from reformer stream<br />

Remove and collect aromatics from solvent hydrocarbon stream<br />

Remove butane and lighter hydrocarbons from reformate charge<br />

Remove water from solvent<br />

Remove and collect benzene from aromatics stream<br />

Remove and collect toluene from aromatics stream<br />

Remove and collect xylene from aromatics stream<br />

Remove butanes and lighter hydrocarbons from gasoline product<br />

Remove very light hydrocarbons such as methane and ethane<br />

Produce low -vapor pressure alkylate gasoline Stabilize gasoline<br />

component<br />

Recycle to polish lean oil (solvent) of lighter gasoline fraction<br />

Remove and collect propane<br />

Remove butane and lighter hydrocarbons from gasoline stream<br />

Remove butane and lighter hydrocarbons from gasoline stream<br />

Remove and collect H2S and NH3 from water stream<br />

Regenerate amine for recycle<br />

Normally found in fuel system to remove butanes<br />

Separation of two or more hydrocarbon fractions by distillation