Operating Instructions for Digital Mass Flow Meter and Controller Model: DMS

Operating Instructions for Digital Mass Flow Meter and Controller Model: DMS

Operating Instructions for Digital Mass Flow Meter and Controller Model: DMS

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Kobold Messring GmbH Chapter 2 Installation<br />

Installing the Instrument—Plumbing<br />

® ®<br />

<strong>DMS</strong> instruments are supplied with compression, VCO , VCR , or<br />

female NPT process connections. To ensure a successful installation, inlet<br />

<strong>and</strong> outlet tubing should be in a clean state prior to plumbing the instrument<br />

into the system. The shipping caps covering the inlet/outlet fittings<br />

should not be removed until immediately be<strong>for</strong>e installation.<br />

Follow the installation instructions that are applicable to your instrument’s<br />

process connection. Ensure that the tubing is free from burrs, or sharp rims<br />

that may result from cutting.<br />

CAUTION: Be<strong>for</strong>e use, all plumbing should be checked carefully <strong>for</strong><br />

leaks, especially at the connecting fittings. All instruments are leaktested<br />

prior to shipping. It is not a requirement to leak test your instrument.<br />

Do not use liquid leak detectors to search <strong>for</strong> leaks<br />

inside or outside the <strong>DMS</strong>. Instead, monitor pressure decay.<br />

Compression Fittings<br />

1. Position the instrument with the flow direction arrow pointing in<br />

the direction of flow.<br />

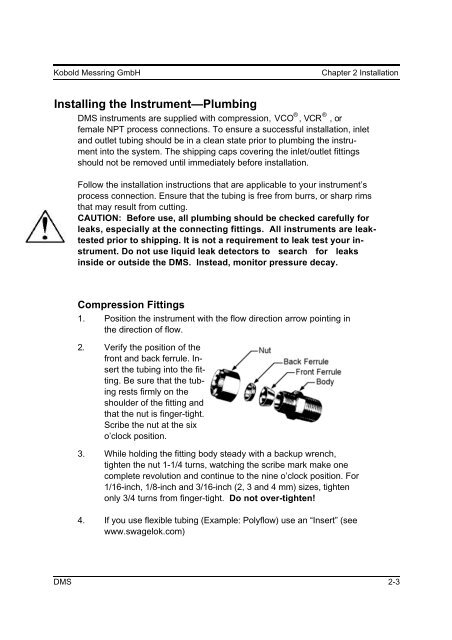

2. Verify the position of the<br />

front <strong>and</strong> back ferrule. Insert<br />

the tubing into the fitting.<br />

Be sure that the tubing<br />

rests firmly on the<br />

shoulder of the fitting <strong>and</strong><br />

that the nut is finger-tight.<br />

Scribe the nut at the six<br />

o’clock position.<br />

3. While holding the fitting body steady with a backup wrench,<br />

tighten the nut 1-1/4 turns, watching the scribe mark make one<br />

complete revolution <strong>and</strong> continue to the nine o’clock position. For<br />

1/16-inch, 1/8-inch <strong>and</strong> 3/16-inch (2, 3 <strong>and</strong> 4 mm) sizes, tighten<br />

only 3/4 turns from finger-tight. Do . not over-tighten!<br />

4. If you use flexible tubing (Example: Polyflow) use an “Insert” (see<br />

www.swagelok.com)<br />

<strong>DMS</strong> 2-3