impact of microvia-in-pad design on void formation - Sanmina-SCI

impact of microvia-in-pad design on void formation - Sanmina-SCI

impact of microvia-in-pad design on void formation - Sanmina-SCI

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

•<br />

•<br />

•<br />

Support surface mount comp<strong>on</strong>ents and DCA<br />

devices;<br />

Provide for better reliability <str<strong>on</strong>g>in</str<strong>on</strong>g> comparis<strong>on</strong> to through<br />

hole vias due to lowest aspect ratio. A typical aspect<br />

ratio for through holes is 4 - 8 and for micro-vias is<br />

between 0.5 – 0.7; and<br />

Can be fabricated <str<strong>on</strong>g>in</str<strong>on</strong>g> rigid, flex or rigid/flex<br />

substrates.<br />

EXPERIMENT<br />

The ma<str<strong>on</strong>g>in</str<strong>on</strong>g> focus <str<strong>on</strong>g>of</str<strong>on</strong>g> this project is to determ<str<strong>on</strong>g>in</str<strong>on</strong>g>e the<br />

optimum <str<strong>on</strong>g>design</str<strong>on</strong>g> criteria when <str<strong>on</strong>g>in</str<strong>on</strong>g>corporat<str<strong>on</strong>g>in</str<strong>on</strong>g>g via-<str<strong>on</strong>g>in</str<strong>on</strong>g>-<str<strong>on</strong>g>pad</str<strong>on</strong>g><br />

technology <str<strong>on</strong>g>in</str<strong>on</strong>g> a board <str<strong>on</strong>g>design</str<strong>on</strong>g>. The goal was to accomplish<br />

this by vary<str<strong>on</strong>g>in</str<strong>on</strong>g>g both the via-hole size and the locati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

the via-hole <str<strong>on</strong>g>in</str<strong>on</strong>g> the <str<strong>on</strong>g>pad</str<strong>on</strong>g> al<strong>on</strong>g with assembl<str<strong>on</strong>g>in</str<strong>on</strong>g>g these <strong>on</strong> a<br />

standard Surface Mount Technology (SMT) l<str<strong>on</strong>g>in</str<strong>on</strong>g>e. The data<br />

generated from this would then be given to the Sanm<str<strong>on</strong>g>in</str<strong>on</strong>g>a-<br />

<strong>SCI</strong> PCB <str<strong>on</strong>g>design</str<strong>on</strong>g> group.<br />

With this <str<strong>on</strong>g>in</str<strong>on</strong>g> m<str<strong>on</strong>g>in</str<strong>on</strong>g>d a test-vehicle PCB was <str<strong>on</strong>g>design</str<strong>on</strong>g>ed for<br />

this evaluati<strong>on</strong> that was 8 layers with dimensi<strong>on</strong>s <str<strong>on</strong>g>of</str<strong>on</strong>g> 6.5”<br />

X 10”. The use <str<strong>on</strong>g>of</str<strong>on</strong>g> 8 layers allowed the <str<strong>on</strong>g>design</str<strong>on</strong>g>ers to best<br />

simulate the via-hole c<strong>on</strong>figurati<strong>on</strong>s currently be<str<strong>on</strong>g>in</str<strong>on</strong>g>g used.<br />

Dummy <str<strong>on</strong>g>in</str<strong>on</strong>g>ner layer planes were used for thermal load<str<strong>on</strong>g>in</str<strong>on</strong>g>g<br />

characteristics. PCBs <str<strong>on</strong>g>of</str<strong>on</strong>g> two different thicknesses (0.062”<br />

and 0.093”) were used and two surface f<str<strong>on</strong>g>in</str<strong>on</strong>g>ishes -<br />

Immersi<strong>on</strong> Ag and Ni-Au - are used <str<strong>on</strong>g>in</str<strong>on</strong>g> this <str<strong>on</strong>g>in</str<strong>on</strong>g>vestigati<strong>on</strong>.<br />

The PCB was split <str<strong>on</strong>g>in</str<strong>on</strong>g>to 4 secti<strong>on</strong>s, with each secti<strong>on</strong><br />

c<strong>on</strong>sist<str<strong>on</strong>g>in</str<strong>on</strong>g>g <str<strong>on</strong>g>of</str<strong>on</strong>g> a different via <str<strong>on</strong>g>design</str<strong>on</strong>g>.<br />

Figure 1: Via-In-Pad PCB<br />

• 56 ball, 0.5 mm pitch BGA<br />

• 208 lead, QFP 0.5 mm pitch QFP<br />

• 0805s, 0603s, and 0402s capacitors<br />

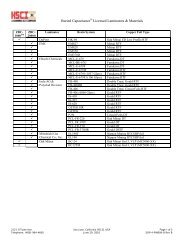

The different via <str<strong>on</strong>g>design</str<strong>on</strong>g>s for the BGAs are shown <str<strong>on</strong>g>in</str<strong>on</strong>g><br />

Figure 2 below. BGA 1 was used twice <str<strong>on</strong>g>in</str<strong>on</strong>g> the <str<strong>on</strong>g>design</str<strong>on</strong>g> –<br />

<strong>on</strong>ce for a micro-via and then aga<str<strong>on</strong>g>in</str<strong>on</strong>g> for a through hole<br />

c<strong>on</strong>figurati<strong>on</strong>. See Table 1 for a complete list <str<strong>on</strong>g>of</str<strong>on</strong>g> the<br />

<str<strong>on</strong>g>design</str<strong>on</strong>g>s used. The images below show the BGA <str<strong>on</strong>g>pad</str<strong>on</strong>g> styles<br />

used and via-holes.<br />

BGA 1<br />

BGA 2<br />

BGA3<br />

BGA Pad<br />

Via<br />

BGA Pad<br />

Via<br />

BGA Pad<br />

Via<br />

Figure 2: BGA Design Patterns Used<br />

The via-hole <str<strong>on</strong>g>design</str<strong>on</strong>g> for the QFP is shown <str<strong>on</strong>g>in</str<strong>on</strong>g> Figure 3. For<br />

the QFP <strong>on</strong>ly 1 via-hole locati<strong>on</strong> was used.<br />

Figure 3: QFP Design Patterns Used<br />

The via-hole <str<strong>on</strong>g>design</str<strong>on</strong>g> for the passive devices is shown <str<strong>on</strong>g>in</str<strong>on</strong>g><br />

Figure 4:<br />

For this evaluati<strong>on</strong>, the follow<str<strong>on</strong>g>in</str<strong>on</strong>g>g comp<strong>on</strong>ents were used:<br />

• 615 ball, 1.27 mm pitch BGA<br />

• 548 ball, 1.00 mm pitch BGA<br />

• 64 ball, 0.8 mm pitch BGA Figure 4: Passive Design Patterns Used