Bulletin 1/2010 - Siempelkamp NIS

Bulletin 1/2010 - Siempelkamp NIS

Bulletin 1/2010 - Siempelkamp NIS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

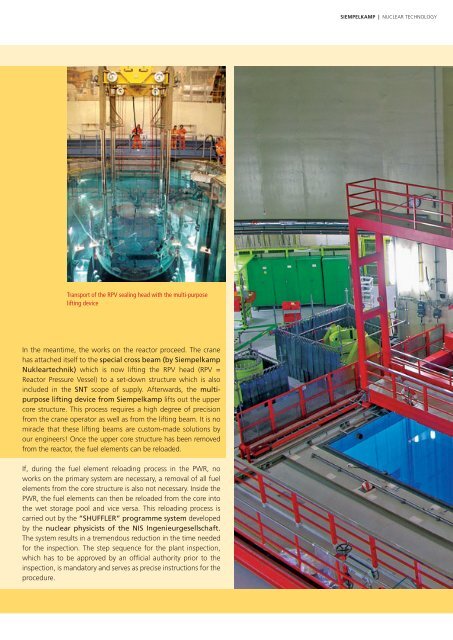

Transport of the RPV sealing head with the multi-purpose<br />

lifting device<br />

In the meantime, the works on the reactor proceed. The crane<br />

has attached itself to the special cross beam (by <strong>Siempelkamp</strong><br />

Nukleartechnik) which is now lifting the RPV head (RPV =<br />

Reactor Pressure Vessel) to a set-down structure which is also<br />

included in the SNT scope of supply. Afterwards, the multipurpose<br />

lifting device from <strong>Siempelkamp</strong> lifts out the upper<br />

core structure. This process requires a high degree of precision<br />

from the crane operator as well as from the lifting beam. It is no<br />

miracle that these lifting beams are custom-made solutions by<br />

our engineers! Once the upper core structure has been removed<br />

from the reactor, the fuel elements can be reloaded.<br />

If, during the fuel element reloading process in the PWR, no<br />

works on the primary system are necessary, a removal of all fuel<br />

elements from the core structure is also not necessary. Inside the<br />

PWR, the fuel elements can then be reloaded from the core into<br />

the wet storage pool and vice versa. This reloading process is<br />

carried out by the “SHUFFLER” programme system developed<br />

by the nuclear physicists of the <strong>NIS</strong> Ingenieurgesellschaft.<br />

The system results in a tremendous reduction in the time needed<br />

for the inspection. The step sequence for the plant inspection,<br />

which has to be approved by an offi cial authority prior to the<br />

inspection, is mandatory and serves as precise instructions for the<br />

procedure.<br />

SIEMPELKAMP | NUCLEAR TECHNOLOGY