Pages • Multi-Mat® Concept • Lamina Multi-Mat® full ... - Tikontools

Pages • Multi-Mat® Concept • Lamina Multi-Mat® full ... - Tikontools

Pages • Multi-Mat® Concept • Lamina Multi-Mat® full ... - Tikontools

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

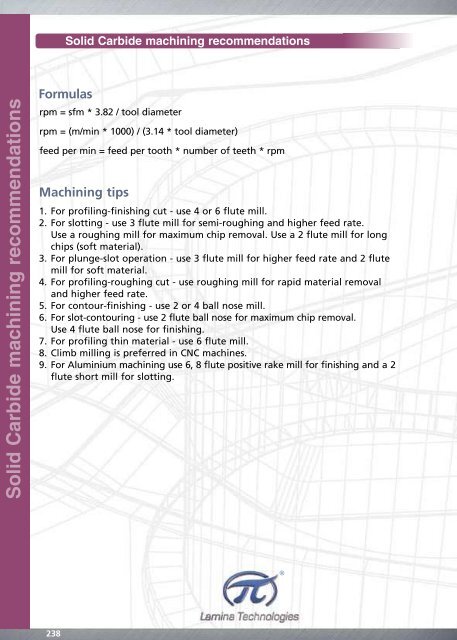

Solid Carbide machining recommendations<br />

238<br />

Solid Carbide machining recommendations<br />

Formulas<br />

rpm = sfm * 3.82 / tool diameter<br />

rpm = (m/min * 1000) / (3.14 * tool diameter)<br />

feed per min = feed per tooth * number of teeth * rpm<br />

Machining tips<br />

1. For profiling-finishing cut - use 4 or 6 flute mill.<br />

2. For slotting - use 3 flute mill for semi-roughing and higher feed rate.<br />

Use a roughing mill for maximum chip removal. Use a 2 flute mill for long<br />

chips (soft material).<br />

3. For plunge-slot operation - use 3 flute mill for higher feed rate and 2 flute<br />

mill for soft material.<br />

4. For profiling-roughing cut - use roughing mill for rapid material removal<br />

and higher feed rate.<br />

5. For contour-finishing - use 2 or 4 ball nose mill.<br />

6. For slot-contouring - use 2 flute ball nose for maximum chip removal.<br />

Use 4 flute ball nose for finishing.<br />

7. For profiling thin material - use 6 flute mill.<br />

8. Climb milling is preferred in CNC machines.<br />

9. For Aluminium machining use 6, 8 flute positive rake mill for finishing and a 2<br />

flute short mill for slotting.<br />

terial<br />

Reference<br />

List<br />

® ®<br />

<strong>Pages</strong> 240 to 245<br />

239