- Page 1 and 2: 2013 2014 Pistons, Liners and Assem

- Page 3 and 4: ENGINE EXPERTISE Driving OE technol

- Page 5 and 6: Contenido III Lista de constructore

- Page 7 and 8: AGCO SISU 1 ALFA ROMEO 3 ARO 29 AST

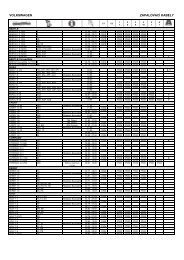

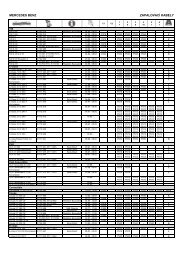

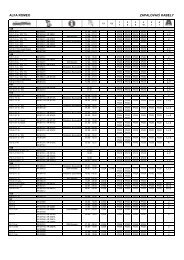

- Page 9 and 10: 87 - 114900 - 25 catalogue referenc

- Page 11 and 12: TEILENUMMERIERUNGSSYSTEM 87 - 11490

- Page 13 and 14: SISTEMA DI CATALOGAZIONE DEI RICAMB

- Page 15 and 16: 87 - 114900 - 25 Référence au cat

- Page 17 and 18: 87 - 114900 - 25 Referencia del cat

- Page 19 and 20: SYSTEM NUMEROWANIA CZĘŚCI 87 - 11

- Page 21 and 22: система нУмераЦии

- Page 23 and 24: XXI

- Page 25: 2010 PACE Award winner Federal-Mogu

- Page 29 and 30: Gewinner des PACE Award 2010 Der N

- Page 31 and 32: Der Goetze ® LKZ-Ring ® senkt den

- Page 33 and 34: Vincitore del PACE Award 2010 Il pi

- Page 35 and 36: Il segmento Goetze ® LKZ-Ring ® r

- Page 37 and 38: Lauréat du prix PACE Award 2010 Le

- Page 39 and 40: Le segment Goetze ® LKZ-Ring ® pe

- Page 41 and 42: Ganador del premio PACE en 2010 Los

- Page 43 and 44: Goetze ® LKZ-Ring ® reduce el con

- Page 45 and 46: Zdobywca nagrody 2010 PACE AWARD T

- Page 47 and 48: Pierścienie Goetze ® LKZ-Ring ®

- Page 49 and 50: Победитель PACE Award 201

- Page 51 and 52: Кольцо Goetze ® LKZ-Ring ®

- Page 54 and 55: LII

- Page 56 and 57: teRms of Business impoRtant Reprodu

- Page 58 and 59: teRms of Business Условия д

- Page 60 and 61: CHECK OUT OUR CATALOGUES CATAE901 C

- Page 62 and 63: ENGINE PART NUMBERING SYSTEM SETS P

- Page 64 and 65: NEW PARTS LIST Liste der Neuaufnahm

- Page 66 and 67: NEW PARTS LIST Liste der Neuaufnahm

- Page 68 and 69: NEW PARTS LIST Liste der Neuaufnahm

- Page 70 and 71: NEW PARTS LIST Liste der Neuaufnahm

- Page 72 and 73: NEW PARTS LIST Liste der Neuaufnahm

- Page 74 and 75: NEW PARTS LIST Liste der Neuaufnahm

- Page 76:

n 1 111.00 AGCO SISU 84 CTA 6 Cyl.

- Page 79 and 80:

Engine Index • Indice des moteurs

- Page 81 and 82:

n 3 78.00 75 1.6 05/89Ý02/92 AR 61

- Page 83 and 84:

n 6 80.00 33 1.4 i.e. 06/91Ý09/94

- Page 85 and 86:

n 8 82.00 10 ALFA ROMEO 156 2.4 JTD

- Page 87 and 88:

n 11 82.00 156 1.6 16V T.S. 09/97Ý

- Page 89 and 90:

n 14 82.00 14 ALFA ROMEO 145 1.9 JT

- Page 91 and 92:

n 17 82.60 16 ALFA ROMEO AR 6 Box 1

- Page 93 and 94:

145 2.0 16V T.S., 146 2.0 16V T.S.

- Page 95 and 96:

164 2.0 T.S. 09/92Ý09/98 AR 64103

- Page 97 and 98:

n 26 84.00 164 2.0 Turbo 10/87Ý09/

- Page 99 and 100:

n 29 92.00 24 ALFA ROMEO Alfetta 2.

- Page 101 and 102:

n 32 93.00 26 ALFA ROMEO AR8 8140.2

- Page 103 and 104:

n 34 93.00 28 ALFA ROMEO AR 6 Box 2

- Page 106 and 107:

n 1 73.00 ARO 100, 101, 103, 104 01

- Page 108:

87-318700-30 STD 08-318700-10 STD 8

- Page 111 and 112:

Engine Index • Indice des moteurs

- Page 113 and 114:

38 AUDI 80 1.6 D 08/80Ý08/91 JK 4

- Page 115 and 116:

AK KK RT 87-103000-10 2 STD 08-1030

- Page 117 and 118:

87-103000-40 2 STD 08-103000-00 STD

- Page 119 and 120:

44 AUDI A3 1.9 TDI 09/96Ý07/01 ALH

- Page 121 and 122:

AK NB RT 1 To cylinder 1 & 2 1 zum

- Page 123 and 124:

AK KK NB RT TP 48 07969L-102 87-114

- Page 125 and 126:

87-114900-85 2 3 STD 08-114900-00 S

- Page 127 and 128:

n 12 79.50 52 AUDI A3 1.9 TDI, A3 1

- Page 129 and 130:

AK KK NB RT TP 54 07901C106 1 To cy

- Page 131 and 132:

56 AUDI A6 2.5 TDI 08/94Ý10/97 AEL

- Page 133 and 134:

n 16 81.00 A4 1.6 11/94Ý10/00 ADP

- Page 135 and 136:

n 18 81.00 60 AUDI A4 1.8 T, A4 1.8

- Page 137 and 138:

62 AUDI A4 2.0 TDI, A4 Avant 2.0 TD

- Page 139 and 140:

n 21 81.00 64 AUDI A4 2.0 TDI 11/07

- Page 141 and 142:

66 AUDI A3 2.0 TDI 16V 05/03Ý CLJA

- Page 143 and 144:

68 AUDI 90 2.2 10/84Ý03/87 KV 90 2

- Page 145 and 146:

n 27 82.50 70 AUDI 80 2.8, 80 2.8 q

- Page 148:

Engine Index • Indice des moteurs

- Page 151 and 152:

Allegro Hatchback 1.1 05/73Ý10/81

- Page 153 and 154:

87-521707-10 1 .020 08-521700-00 ST

- Page 155 and 156:

n 7 73.50 Marina 01/64Ý12/91 A Ser

- Page 157 and 158:

n 10 83.32 3 Litre Saloon 01/68Ý12

- Page 160 and 161:

n 1 65.50 Rascal Box 1.0, Rascal Bu

- Page 162 and 163:

n 5 80.00 BEDFORD Astra Van Estate

- Page 164:

n 1 110.00 BELARUS 4.8D Tractor 4 C

- Page 168 and 169:

n 1 80.00 5 (E28) 520i 06/81Ý12/87

- Page 170 and 171:

n 5 80.00 BMW 3 (E46) 320 i 09/00Ý

- Page 172 and 173:

1 Steel 1 Stahl 1 Acier 1 Acciaio 1

- Page 174 and 175:

n 10 84.00 BMW 3 (E46) 318 d 03/03

- Page 176 and 177:

n 12 84.00 BMW 3 (E36) 325 i 09/90

- Page 178 and 179:

87-114400-60 STD 08-114400-40 STD 8

- Page 180:

n 16 92.00 7 (E32) 735 i,iL 09/86Ý

- Page 184 and 185:

Engine Index • Indice des moteurs

- Page 186 and 187:

n 1 72.00 AX 11 09/86Ý12/97 TU1 (H

- Page 188 and 189:

n 4 73.70 CITROËN C3 1.4 16V HDi 0

- Page 190 and 191:

CITROËN Berlingo 1.6 HDI 110 08/05

- Page 192 and 193:

CITROËN AX 14 04/87Ý04/97 TU3M/Z

- Page 194 and 195:

n 12 75.00 CITROËN C2 1.4 09/03Ý

- Page 196 and 197:

Xsara Picasso MPV 1.6 Chrono 09/01

- Page 198 and 199:

AK KK RT TP n 19 82.20 CITROËN Ber

- Page 200 and 201:

BX 16 10/82Ý12/92 XU52C 4 Cyl. 158

- Page 202 and 203:

n 23 83.00 CITROËN BX 19 D 09/83Ý

- Page 204 and 205:

n 25 84.00 C25 Box 1.8, C25 Bus 1.8

- Page 206 and 207:

CITROËN C8 2.0 HDi 07/02Ý DW10ATE

- Page 208 and 209:

n 31 86.00 CITROËN Jumper Box 2.2

- Page 210 and 211:

n 34 86.40 Jumpy 1.6 10/95Ý 220 A2

- Page 212 and 213:

n 37 92.00 CITROËN Jumper Box 2.5

- Page 214 and 215:

n 40 93.00 CITROËN C35 Box 2.5 D,

- Page 216 and 217:

n 43 94.40 CITROËN Jumper Box 2.8

- Page 218:

n 1 66.69 CLAYTON DEWANDRE 13.5 CU.

- Page 222 and 223:

n 1 75.00 COMPRESSOR Westinghouse W

- Page 224:

n 5 90.00 COMPRESSOR Mercedes Benz

- Page 228:

Engine Index • Indice des moteurs

- Page 231 and 232:

n 3 76.00 156 DACIA Duster 1.5 dCi

- Page 234 and 235:

Engine Index • Indice des moteurs

- Page 236 and 237:

n 1 70.00 DAF 110E 4 Cyl. 1108cc 35

- Page 238 and 239:

n 6 104.18 DF 615 6 Cyl. 16:1 6150c

- Page 240 and 241:

n 10 130.00 DK 1160 6 Cyl. 16:1 116

- Page 242 and 243:

n 12 130.00 DKX 1160 ATi 6 Cyl. 15:

- Page 244:

n 16 130.00 WS 242 M Euro 2 6 Cyl.

- Page 248 and 249:

Engine Index • Indice des moteurs

- Page 250 and 251:

n 1 91.00 DEUTZ/KHD BF 4L 1011 F 4

- Page 252 and 253:

n 5 94.00 DEUTZ/KHD F 2L 2011 2 Cyl

- Page 254 and 255:

n 9 100.00 DEUTZ/KHD F 2L 912 D 2 C

- Page 256 and 257:

n 11 101.00 DEUTZ/KHD BF 4M 2012 4

- Page 258 and 259:

n 14 102.00 DEUTZ/KHD BF 6L 913 C 6

- Page 260 and 261:

n 16 102.00 DEUTZ/KHD F 3L 913 3 Cy

- Page 262 and 263:

n 19 108.00 DEUTZ/KHD BF 4M 1013 C

- Page 264 and 265:

n 23 120.00 DEUTZ/KHD F 6L 413 V6 C

- Page 266:

n 26 125.00 DEUTZ/KHD F 4L 413 FR 4

- Page 269 and 270:

Engine Index • Indice des moteurs

- Page 272 and 273:

n 1 65.00 850 0.8 07/64Ý10/72 100

- Page 274 and 275:

n 4 65.00 Panda 750 01/86Ý01/95 15

- Page 276 and 277:

87-137600-00 STD 08-137600-00 STD 8

- Page 278 and 279:

n 11 70.00 FIAT Fiorino Box 1.0 iE

- Page 280 and 281:

n 15 70.80 Palio 1.2 06/98Ý 176 A8

- Page 282 and 283:

n 17 70.80 FIAT Brava 1.2 16V 80, B

- Page 284 and 285:

n 21 78.00 FIAT Uno 70 TD 1.4 10/86

- Page 286 and 287:

n 25 80.50 Tempra 1.4 i.e., Tempra

- Page 288 and 289:

n 28 82.00 FIAT Bravo I 2.0 HGT 20V

- Page 290 and 291:

AK RT n 32 82.00 FIAT Brava 1.9 JTD

- Page 292 and 293:

n 35 82.00 FIAT Marea 1.9 JTD 110,

- Page 294 and 295:

n 37 82.00 FIAT Stilo 1.9 JTD, 01/0

- Page 296 and 297:

n 40 82.60 FIAT Elba 1.7 D 04/89Ý1

- Page 298 and 299:

HA RT n 42 82.60 FIAT Regata 65 Die

- Page 300 and 301:

n 45 82.60 FIAT Tempra 1.9 TD 05/90

- Page 302 and 303:

n 47 83.00 FIAT Regata 60 Diesel 1.

- Page 304 and 305:

Croma 2000 i.e. 10/87Ý08/96 834 B.

- Page 306 and 307:

AK n 55 85.00 FIAT Ulysse 2.2 JTD 0

- Page 308 and 309:

AK KK RT TP 08517-103 n 58 85.00 FI

- Page 310 and 311:

n 61 86.00 FIAT Ducato Box 100 Mult

- Page 312 and 313:

n 64 86.40 Palio 1.6 16V 04/96Ý 17

- Page 314 and 315:

AK KK RT TP n 68 88.00 Ducato Box 2

- Page 316 and 317:

RT 1 Nitrided 1 Nitriert 1 Nitridé

- Page 318 and 319:

AK KK NB RT 1 Nitrided 1 Nitriert 1

- Page 320 and 321:

n 76 93.00 FIAT Croma 2500 D 12/85

- Page 322 and 323:

87-854700-00 STD 08-854700-00 STD 8

- Page 324 and 325:

Engine Index • Indice des moteurs

- Page 326 and 327:

Engine Index • Indice des moteurs

- Page 328 and 329:

n 1 68.70 Fiesta III 1.1 03/89Ý12/

- Page 330 and 331:

Fiesta Box 1.0 08/83Ý11/89 TKB Fie

- Page 332 and 333:

Fiesta IV 1.3 i 08/95Ý01/02 J4R En

- Page 334 and 335:

FORD EUROPE C-Max 1.6 TDCi 02/07Ý

- Page 336 and 337:

FORD EUROPE Escort Saloon 1.6 i 01/

- Page 338 and 339:

n 12 79.50 FORD EUROPE Galaxy 1.9 T

- Page 340 and 341:

AK NB RT FORD EUROPE 1 To cylinder

- Page 342 and 343:

n 15 79.96 FORD EUROPE Escort III 1

- Page 344 and 345:

n 16 79.96 FORD EUROPE Fiesta III 1

- Page 346 and 347:

Fiesta III 1.8 XR2i 16V 02/92Ý12/9

- Page 348 and 349:

n 21 80.98 Escort I 1300, Escort I

- Page 350 and 351:

1 Steel 1 Stahl 1 Acier 1 Acciaio 1

- Page 352 and 353:

FORD EUROPE Escort '95 Box 1.8 TD 0

- Page 354 and 355:

n 29 82.55 Escort Twin Cam 01/68Ý1

- Page 356 and 357:

Focus 2.0 16V 10/98Ý11/04 EDDC ZH2

- Page 358 and 359:

FORD EUROPE Mondeo III 2.0 TDCi, 10

- Page 360 and 361:

1 Steel 1 Stahl 1 Acier 1 Acciaio 1

- Page 362 and 363:

n 38 87.50 FORD EUROPE C-Max 2.0 02

- Page 364 and 365:

n 41 89.60 FORD EUROPE Transit Box

- Page 366 and 367:

KK RT TP FORD EUROPE 1 Piston Chamb

- Page 368 and 369:

n 46 89.90 FORD EUROPE Transit Box

- Page 370 and 371:

n 50 90.80 FORD EUROPE Sierra 2.0 I

- Page 372 and 373:

FORD EUROPE 1 Earlier pistons to be

- Page 374 and 375:

n 54 93.67 FORD EUROPE Transit Box

- Page 376 and 377:

87-784800-00 1 STD 08-784800-00 STD

- Page 378 and 379:

FORD EUROPE Transit Box 2.5 TD 06/9

- Page 380:

87-318700-30 STD 08-318700-10 STD 8

- Page 384 and 385:

n 1 91.49 FORD TRACTOR 3.152 3 Cyl.

- Page 386 and 387:

n 4 106.69 FORD TRACTOR 6Y series 3

- Page 388 and 389:

n 8 111.77 FORD TRACTOR 7A series 2

- Page 390:

Engine Index • Indice des moteurs

- Page 393 and 394:

n 3 104.77 318 FORD TRUCKS 2704ET 3

- Page 395 and 396:

n 8 106.69 320 FORD TRUCKS 2501E, 2

- Page 398:

n 1 87.00 HANOMAG OM 615.915 4 Cyl.

- Page 401 and 402:

n 3 90.00 326 HATZ E89/E89 FG/E89 F

- Page 404:

n 1 95.00 HINO B 4 Cyl. 21:1 2977cc

- Page 408:

Engine Index • Indice des moteurs

- Page 411 and 412:

n 3 91.10 336 HYUNDAI Galloper 2.4

- Page 413 and 414:

n 5 91.10 338 HYUNDAI Galloper II 2

- Page 416:

n 1 120.00 4VD14.5 4 Cyl. 6600cc Di

- Page 419 and 420:

n 3 98.42 D-179 3 Cyl. 16:1 2930cc

- Page 422 and 423:

n 1 76.00 ISUZU Gemini 1.5 D 02/88

- Page 424 and 425:

n 6 93.00 ISUZU Campo 2.5 D, Campo

- Page 426:

n 9 102.00 ISUZU Elf 250 09/83Ý04/

- Page 429 and 430:

Engine Index • Indice des moteurs

- Page 431 and 432:

Engine Index • Indice des moteurs

- Page 433 and 434:

Engine Index • Indice des moteurs

- Page 436 and 437:

n 1 88.00 IVECO F1AE 0481 A Euro 3

- Page 438 and 439:

n 5 93.00 IVECO 8140.27.210/8140.27

- Page 440 and 441:

n 8 93.00 IVECO 8140.61.200 4 Cyl.

- Page 442 and 443:

87-122200-10 STD 08-122200-00 STD 1

- Page 444 and 445:

87-122200-00 STD 08-122200-00 STD 1

- Page 446 and 447:

n 18 100.00 IVECO 8025.02 2 Cyl. 17

- Page 448 and 449:

n 20 100.00 IVECO 8040.02 4 Cyl. 17

- Page 450 and 451:

n 22 103.00 IVECO 8035.04 3 Cyl. 27

- Page 452 and 453:

n 24 103.00 IVECO 8060.24.601 6 Cyl

- Page 454 and 455:

n 27 104.00 IVECO 8040.05.4990 4 Cy

- Page 456 and 457:

n 29 104.00 IVECO 8040.25.4990 4 Cy

- Page 458 and 459:

n 32 104.00 IVECO 8040.45X.4180 4 C

- Page 460 and 461:

n 36 110.00 IVECO C03/C70/C100 4 Cy

- Page 462 and 463:

n 39 115.00 IVECO 8340.05 4 Cyl. 17

- Page 464 and 465:

n 42 115.00 IVECO C 03-13OT 4 Cyl.

- Page 466 and 467:

n 46 120.00 IVECO 8460.21.002 6 Cyl

- Page 468 and 469:

n 49 122.00 IVECO 8200.02 6 Cyl. 98

- Page 470 and 471:

n 54 125.00 IVECO 8220.22.002 6 Cyl

- Page 472 and 473:

87-420200-00 STD 08-420200-00 STD 0

- Page 474 and 475:

IVECO 8210.02.032 6 Cyl. 16:1 13798

- Page 476 and 477:

n 61 137.00 IVECO 8210.22.105 6 Cyl

- Page 478 and 479:

87-783000-15 STD 08-783000-00 STD A

- Page 480 and 481:

n 66 145.00 IVECO 8260.02 6 Cyl. 12

- Page 482:

15-680070-00 WH 1 3 B 158.50 C 262.

- Page 486 and 487:

n 1 81.00 JAGUAR XF 2.7 D 03/08Ý A

- Page 488 and 489:

n 5 86.99 JAGUAR E-Type Series I 01

- Page 490:

87-524000-10 2 3 STD 08-524000-00 S

- Page 494:

Engine Index • Indice des moteurs

- Page 497 and 498:

n 2 106.50 422 JOHN DEERE 300 T 6 C

- Page 500:

n 1 120.00 KAMAZ 53212 V8 Cyl. 1085

- Page 504 and 505:

n 1 83.00 KIA Carens II 2.0 CRDi 07

- Page 506:

n 5 100.00 KIA Jumbo Titan 3.5, P-W

- Page 510:

Engine Index • Indice des moteurs

- Page 513 and 514:

n 2 79.00 438 LADA 1200-1500 Estate

- Page 515 and 516:

n 6 83.00 440 LADA Niva 1900 Diesel

- Page 517 and 518:

Engine Index • Indice des moteurs

- Page 519 and 520:

n 2 65.00 A 112 0.9 Junior 03/81Ý0

- Page 521 and 522:

446 06933 n 6 70.00 Y10 1.0 Fire 03

- Page 523 and 524:

n 10 70.80 Y 1.2 16V 04/97Ý09/03 1

- Page 525 and 526:

n 14 80.50 Delta II 1.4 i.e. 10/94

- Page 527 and 528:

n 18 82.00 Lybra 2.0 20V, Lybra SW

- Page 529 and 530:

AK NB RT n 22 82.00 454 LANCIA Lybr

- Page 531 and 532:

n 25 82.00 456 LANCIA Lybra 1.9 JTD

- Page 533 and 534:

n 27 82.60 458 LANCIA Prisma 1.9 Di

- Page 535 and 536:

n 30 84.00 Prisma 2.0 i.e. 4WD 04/8

- Page 537 and 538:

Dedra 2.0 HF Integrale 11/90Ý07/94

- Page 539 and 540:

464 08517-103 n 35 85.00 LANCIA Phe

- Page 541 and 542:

1 Steel 1 Stahl 1 Acier 1 Acciaio 1

- Page 544:

Engine Index • Indice des moteurs

- Page 547 and 548:

n 3 80.00 Freelander 2.5 V6 11/00Ý

- Page 549 and 550:

n 7 84.45 474 LAND ROVER Defender 9

- Page 551 and 552:

n 10 89.90 476 LAND ROVER Defender

- Page 553 and 554:

n 13 90.47 478 LAND ROVER Defender

- Page 555 and 556:

n 16 90.47 90/110 2.5 09/85Ý07/90

- Page 557 and 558:

n 20 94.00 Range Rover I 4.3 Vogue

- Page 560:

n 1 LDV Maxus Box 2.5 CDi, Maxus Bu

- Page 564 and 565:

n 1 82.55 LEYLAND 22 UA 4 Cyl. 20:1

- Page 566 and 567:

n 6 94.00 LEYLAND XD3/XD3P / Convoy

- Page 568 and 569:

14-452080-00 WH B 109.04 C 220.73 D

- Page 570 and 571:

LEYLAND 1 Press fit cast iron liner

- Page 572:

n 1 87.32 LISTER PH1 1 Cyl. 659cc D

- Page 575 and 576:

n 3 82.55 500 LOTUS Cortina 01/63Ý

- Page 577 and 578:

Engine Index • Indice des moteurs

- Page 579 and 580:

Engine Index • Indice des moteurs

- Page 581 and 582:

Engine Index • Indice des moteurs

- Page 584 and 585:

n 1 102.00 MAN D 0226 MK 6 Cyl. 17.

- Page 586 and 587:

n 4 108.00 MAN D 0824 LF01 Euro 1 4

- Page 588 and 589:

MAN 87-285900-16 STD 08-285900-00 S

- Page 590 and 591:

n 6 108.00 MAN D 0826 OH 6 Cyl. 17:

- Page 592 and 593:

MAN 87-136500-10 STD 08-136500-10 S

- Page 594 and 595:

87-136500-60 STD 08-136500-30 STD A

- Page 596 and 597:

MAN D 0836 LOH64 Euro 5 6 Cyl. 6871

- Page 598 and 599:

n 11 108.00 MAN D 0846 HM2 6 Cyl. 1

- Page 600 and 601:

87-423000-11 STD 08-423000-00 STD A

- Page 602 and 603:

n 16 120.00 MAN D 2066 LF04 Euro 4

- Page 604 and 605:

MAN D 2156 MY 6 Cyl. 17:1 10344cc 1

- Page 606 and 607:

n 21 125.00 MAN D 2530 ME V10 Cyl.

- Page 608 and 609:

MAN D 2566 MT 6 Cyl. 17:1 11413cc 2

- Page 610 and 611:

12821 MAN 1 Water jacket chromed 1

- Page 612 and 613:

n 30 128.00 MAN D 2865 LF/260 5 Cyl

- Page 614 and 615:

MAN D 2866 LOH07 6 Cyl. 17:1 11967c

- Page 616 and 617:

MAN 87-283100-85 STD 08-283100-00 S

- Page 618 and 619:

n 34 128.00 MAN D 2866 KOH/373 6 Cy

- Page 620 and 621:

MAN 87-104300-10 STD 08-104300-00 S

- Page 622 and 623:

n 38 128.00 MAN D 2876 LF03 Euro 3

- Page 624:

87-143800-60 STD 08-143800-00 STD A

- Page 628 and 629:

n 1 65.00 MARELLI AC 60/903 1 Cyl.

- Page 630:

Engine Index • Indice des moteurs

- Page 633 and 634:

121 III 1.3 03/96Ý JJM 87-785000-0

- Page 635 and 636:

n 6 87.50 560 MAZDA 3 2.0 10/03Ý L

- Page 638 and 639:

Engine Index • Indice des moteurs

- Page 640 and 641:

Engine Index • Indice des moteurs

- Page 642 and 643:

n 1 63.50 MERCEDES-BENZ PKW Smart 0

- Page 644 and 645:

n 4 83.00 MERCEDES-BENZ PKW Smart F

- Page 646 and 647:

87-427400-30 2 3 STD 08-427400-00 S

- Page 648 and 649:

AK KK RT 08340F111 87-427400-10 2 S

- Page 650 and 651:

S-Class 280 SE,SEL 10/79Ý07/85 M 1

- Page 652 and 653:

MERCEDES-BENZ PKW G-Class 250 GD 06

- Page 654 and 655:

n 11 87.00 MERCEDES-BENZ PKW E-Clas

- Page 656 and 657:

n 13 87.00 MERCEDES-BENZ PKW T2/L B

- Page 658 and 659:

n 14 87.00 MERCEDES-BENZ PKW /8 200

- Page 660 and 661:

n 16 88.00 MERCEDES-BENZ PKW E-Clas

- Page 662 and 663:

87-117900-20 STD 08-117900-00 STD 8

- Page 664 and 665:

MERCEDES-BENZ PKW Vito Bus 109 CDI,

- Page 666 and 667:

MERCEDES-BENZ PKW E-Class E 300 4-m

- Page 668 and 669:

n 24 89.00 MERCEDES-BENZ PKW T1 Box

- Page 670 and 671:

n 25 89.00 MERCEDES-BENZ PKW V-Clas

- Page 672 and 673:

87-743107-50 0.50mm 08-743100-00 ST

- Page 674 and 675:

E-Class E 280 01/96Ý06/97 M 104.94

- Page 676 and 677:

n 31 89.90 MERCEDES-BENZ PKW Coupe

- Page 678 and 679:

C-Class C 43 AMG 08/97Ý05/00 M 113

- Page 680 and 681:

MERCEDES-BENZ PKW Sprinter 2-t Box

- Page 682 and 683:

MERCEDES-BENZ PKW G-Class 240 GD 03

- Page 684 and 685:

MERCEDES-BENZ PKW 87-173800-10 STD

- Page 686 and 687:

G-Class 230 GE 04/82Ý08/92 M 102.9

- Page 688 and 689:

Engine Index • Indice des moteurs

- Page 690 and 691:

Engine Index • Indice des moteurs

- Page 692 and 693:

Engine Index • Indice des moteurs

- Page 694 and 695:

Engine Index • Indice des moteurs

- Page 696 and 697:

Engine Index • Indice des moteurs

- Page 698 and 699:

Engine Index • Indice des moteurs

- Page 700 and 701:

Engine Index • Indice des moteurs

- Page 702:

Engine Index • Indice des moteurs

- Page 705 and 706:

n 4 89.00 630 MERCEDES-BENZ LKW OM

- Page 707 and 708:

n 6 90.90 632 MERCEDES-BENZ LKW OM

- Page 709 and 710:

634 MERCEDES-BENZ LKW OM 352.944 (O

- Page 711 and 712:

87-178800-00 STD 08-178800-00 STD 8

- Page 713 and 714:

n 10 97.00 638 MERCEDES-BENZ LKW OM

- Page 715 and 716:

n 11 97.50 640 MERCEDES-BENZ LKW OM

- Page 717 and 718:

87-740000-01 STD 08-740000-00 STD 0

- Page 719 and 720:

644 MERCEDES-BENZ LKW OM 366.963 (O

- Page 721 and 722:

646 MERCEDES-BENZ LKW OM 366.943 Eu

- Page 723 and 724:

87-740000-41 STD 08-740000-00 STD 0

- Page 725 and 726:

n 19 102.00 650 MERCEDES-BENZ LKW O

- Page 727 and 728:

652 MERCEDES-BENZ LKW OM 907.990 Eu

- Page 729 and 730:

654 MERCEDES-BENZ LKW OM 906.950 Eu

- Page 731 and 732:

656 MERCEDES-BENZ LKW OM 402.906 (O

- Page 733 and 734:

n 24 125.00 658 MERCEDES-BENZ LKW O

- Page 735 and 736:

n 26 125.00 660 MERCEDES-BENZ LKW O

- Page 737 and 738:

n 28 128.00 662 MERCEDES-BENZ LKW O

- Page 739 and 740:

664 MERCEDES-BENZ LKW OM 422.916 (O

- Page 741 and 742:

n 32 128.00 666 MERCEDES-BENZ LKW O

- Page 743 and 744:

n 35 128.00 668 MERCEDES-BENZ LKW O

- Page 745 and 746:

670 MERCEDES-BENZ LKW OM 442.999 Eu

- Page 747 and 748:

87-179300-87 STD 08-179300-10 STD 0

- Page 749 and 750:

674 MERCEDES-BENZ LKW 87-179300-65

- Page 751 and 752:

676 MERCEDES-BENZ LKW 87-179300-90

- Page 753 and 754:

n 42 128.00 678 MERCEDES-BENZ LKW O

- Page 755 and 756:

680 MERCEDES-BENZ LKW 87-179300-80

- Page 757 and 758:

n 43 128.00 682 MERCEDES-BENZ LKW O

- Page 759 and 760:

684 MERCEDES-BENZ LKW OM 446.920 Eu

- Page 761 and 762:

686 MERCEDES-BENZ LKW OM 447.995 Eu

- Page 763 and 764:

n 49 128.00 688 MERCEDES-BENZ LKW O

- Page 765 and 766:

n 52 128.00 690 MERCEDES-BENZ LKW O

- Page 767 and 768:

n 54 130.00 692 MERCEDES-BENZ LKW O

- Page 769 and 770:

694 MERCEDES-BENZ LKW OM 442.928 (O

- Page 771 and 772:

696 MERCEDES-BENZ LKW 87-289600-20

- Page 773 and 774:

698 MERCEDES-BENZ LKW 87-136000-10

- Page 776:

Engine Index • Indice des moteurs

- Page 779 and 780:

1 Pistons to be replaced in 1 Kolbe

- Page 781 and 782:

n 5 75.00 Express 1.4 03/03Ý05/05

- Page 783 and 784:

n 9 80.25 MGB, MGB GT 01/63Ý12/80

- Page 786:

n 1 75.00 MINI Mini Clubman Cooper

- Page 790 and 791:

n 1 91.10 MITSUBISHI L 200 2.3 10/8

- Page 792 and 793:

n 3 91.10 MITSUBISHI Canter Platfor

- Page 794 and 795:

n 5 100.00 MITSUBISHI Canter/Rosa 3

- Page 796 and 797:

n 9 104.00 MITSUBISHI Canter 3.9 4D

- Page 798:

n 1 105.00 MWM D 226-2 2 Cyl. 18:1

- Page 802 and 803:

n 1 82.00 NEW HOLLAND 605D/610D 4 C

- Page 804 and 805:

87-206800-10 STD 08-206800-00 STD 8

- Page 806 and 807:

n 7 103.00 NEW HOLLAND 8061 L 6 Cyl

- Page 808 and 809:

n 10 104.00 NEW HOLLAND 8045.25 4 C

- Page 810 and 811:

NEW HOLLAND 87-207500-30 STD 08-207

- Page 812 and 813:

n 18 115.00 NEW HOLLAND 8365.05.500

- Page 814 and 815:

n 21 120.00 NEW HOLLAND 8460.21/846

- Page 816:

Engine Index • Indice des moteurs

- Page 819 and 820:

n 2 77.00 744 NISSAN MICRA II 1.5 D

- Page 821 and 822:

n 6 85.00 746 NISSAN Bluebird 2.0 D

- Page 823 and 824:

n 9 89.00 748 NISSAN Interstar Box

- Page 825 and 826:

n 13 96.00 750 NISSAN Navara 2.7 D

- Page 827 and 828:

Engine Index • Indice des moteurs

- Page 829 and 830:

754 06933 n 3 72.50 Corsa B 1.0 i 1

- Page 831 and 832:

1 Steel 1 Stahl 1 Acier 1 Acciaio 1

- Page 833 and 834:

n 9 77.60 758 OPEL Astra F 1.4, Ast

- Page 835 and 836:

n 12 79.00 760 OPEL Ascona C 1.6, A

- Page 837 and 838:

n 14 79.00 762 OPEL Astra F 1.7 TDS

- Page 839 and 840:

n 16 79.00 Corsa B 1.6 GSI 16V 03/9

- Page 841 and 842:

1 Steel 1 Stahl 1 Acier 1 Acciaio 1

- Page 843 and 844:

n 22 80.00 768 OPEL Arena Box 1.9 D

- Page 845 and 846:

n 25 81.60 Calibra A 2.5 I V6 04/93

- Page 847 and 848:

87-146100-10 STD 08-146100-00 STD 8

- Page 849 and 850:

n 30 84.00 774 OPEL Vivaro Box 2.0

- Page 851 and 852:

n 33 84.00 776 OPEL Frontera B 2.2

- Page 853 and 854:

Ascona C 1.8, Ascona C Hatchback 1.

- Page 855 and 856:

1 Steel 1 Stahl 1 Acier 1 Acciaio 1

- Page 857 and 858:

n 41 87.00 782 OPEL Movano Box 2.2

- Page 859 and 860:

n 45 89.00 784 OPEL Movano Box 2.5

- Page 861 and 862:

n 49 93.00 786 OPEL Frontera 2.8TD

- Page 864:

Engine Index • Indice des moteurs

- Page 867 and 868:

n 4 91.49 792 PERKINS 3.152 3 Cyl.

- Page 869 and 870:

794 PERKINS 1 Push fit cast iron li

- Page 871 and 872:

n 9 98.48 796 PERKINS 4.212 4 Cyl.

- Page 873 and 874:

n 11 98.48 798 PERKINS 6.354 6 Cyl.

- Page 875 and 876:

n 14 98.48 800 PERKINS AT4.236 4 Cy

- Page 877 and 878:

n 18 100.00 802 PERKINS C4.40 4 Cyl

- Page 879 and 880:

n 22 101.05 804 PERKINS 6.372 6 Cyl

- Page 882 and 883:

Engine Index • Indice des moteurs

- Page 884 and 885:

n 1 72.00 PEUGEOT MAKE 205 Box 1.1

- Page 886 and 887:

PEUGEOT MAKE 206 Hatchback 1.4 HDi

- Page 888 and 889:

87-424000-00 STD 08-424000-00 STD 1

- Page 890 and 891:

87-138900-10 STD 08-138900-00 STD 1

- Page 892 and 893:

n 13 75.00 104 1.2 08/79Ý06/83 XZ5

- Page 894 and 895:

n 17 78.50 PEUGEOT 206 CC 1.6 16V 0

- Page 896 and 897:

87-323600-00 STD 08-323600-00 STD 1

- Page 898 and 899:

n 23 83.00 PEUGEOT 306 1.9 D 03/98

- Page 900 and 901:

n 25 83.00 PEUGEOT MAKE 205 I 1.6 0

- Page 902 and 903:

n 27 83.00 PEUGEOT 305 II 1.9 D 10/

- Page 904 and 905:

n 30 84.00 505 1.8 06/81Ý10/85 XM7

- Page 906 and 907:

87-114700-10 STD 08-114700-00 STD 8

- Page 908 and 909:

n 36 86.00 PEUGEOT Boxer Box 2.2 HD

- Page 910 and 911:

n 40 88.00 504 2.0 09/79Ý08/82 XN1

- Page 912 and 913:

n 43 90.00 PEUGEOT 504 2.1 D 02/71

- Page 914 and 915:

n 47 93.00 PEUGEOT J5 Box 2.5 D 09/

- Page 916 and 917:

n 51 94.00 PEUGEOT 505 2.5 Diesel 0

- Page 918:

n 1 121.00 RABA D10UT 150 Euro 1 6

- Page 921 and 922:

Engine Index • Indice des moteurs

- Page 923 and 924:

Engine Index • Indice des moteurs

- Page 925 and 926:

Engine Index • Indice des moteurs

- Page 927 and 928:

n 2 65.00 4 1.0 12/85Ý06/93 689 71

- Page 929 and 930:

Rapid Box 1.1 07/85Ý04/95 C1E 750

- Page 931 and 932:

n 6 74.00 Twingo 1.2 03/93Ý10/96 C

- Page 933 and 934:

n 9 75.80 858 RENAULT 19 I 1.4, 19

- Page 935 and 936:

18 1.4 04/78Ý07/86 847 720 18 Box

- Page 937 and 938:

862 RENAULT Clio 1.5 dCi 06/01Ý K9

- Page 939 and 940:

n 13 76.00 864 RENAULT Clio II 1.5

- Page 941 and 942:

n 16 78.00 866 RENAULT 9 1.6 D 10/8

- Page 943 and 944:

n 19 79.50 Logan 1.6 04/07Ý K4M 69

- Page 945 and 946:

Clio II 1.6 16V 09/98Ý K4M 748 870

- Page 947 and 948:

1 To cylinder 1 & 2 1 zum Zylinder

- Page 949 and 950:

874 RENAULT Rapid Box 1.9 D 09/91Ý

- Page 951 and 952:

n 26 80.00 876 RENAULT Laguna Grand

- Page 953 and 954:

19 I 1.7 09/88Ý04/92 F2N 728 Super

- Page 955 and 956:

Clio I 1.8 16V 01/91Ý03/96 F7P 722

- Page 957 and 958:

882 RENAULT Espace II 2.1 RTDT Quad

- Page 959 and 960:

884 RENAULT Espace II 2.1 TD 11/94

- Page 961 and 962:

886 RENAULT Vel Satis 2.2 dCi 06/02

- Page 963 and 964:

Trafic Box 2.0 4x4, Trafic Box 2.0,

- Page 965 and 966:

Espace II 2.0 01/91Ý10/96 J7R 768

- Page 967 and 968:

892 RENAULT Master 09/89Ý 8140.07.

- Page 969 and 970:

n 41 93.00 894 RENAULT B110 08/90Ý

- Page 971 and 972:

n 44 93.00 896 RENAULT Master I Box

- Page 973 and 974:

898 RENAULT Trafic Box 2.5 D 4x4, T

- Page 975 and 976:

n 49 94.40 900 RENAULT Mascott Box

- Page 977 and 978:

n 52 94.40 902 RENAULT Mascott Box

- Page 980 and 981:

n 1 64.56 Mini 1000 01/92Ý06/93 A+

- Page 982 and 983:

87-524100-00 1 STD 08-524100-00 STD

- Page 984 and 985:

n 7 75.00 ROVER 100 114 D 10/92Ý12

- Page 986 and 987:

87-521600-00 STD 08-521600-00 STD 1

- Page 988 and 989:

n 14 84.45 ROVER MAKE 25 2.0 iDT 10

- Page 990 and 991:

n 17 90.47 80 Mk II, 80 P4 01/58Ý1

- Page 992 and 993:

Engine Index • Indice des moteurs

- Page 994 and 995:

n 1 98.00 712 4 Cyl. 17.5:1 3320cc

- Page 996 and 997:

MIDS 06.02.12 C 6 Cyl. 5490cc 97-10

- Page 998 and 999:

n 10 120.00 MID 06.20.30 G 6 Cyl. 1

- Page 1000 and 1001:

n 13 120.00 MIDR 06.20.45 C/4 Euro

- Page 1002 and 1003:

n 16 120.00 MIDS 06.20.30 6 Cyl. 88

- Page 1004 and 1005:

n 20 135.00 MIDR 06.35.40 G 6 Cyl.

- Page 1006 and 1007:

n 1 81.60 900 II 2.5 -24 V6 07/93Ý

- Page 1008:

n 1 105.00 SAME 1054 P 4 Cyl. 17:1

- Page 1011 and 1012:

Engine Index • Indice des moteurs

- Page 1013 and 1014:

n 3 115.00 938 SCANIA DN 9.01 6 Cyl

- Page 1015 and 1016:

n 7 115.00 940 SCANIA DS 9.05 6 Cyl

- Page 1017 and 1018:

n 11 127.00 942 SCANIA DN 11.01 6 C

- Page 1019 and 1020:

n 14 127.00 944 SCANIA DS 11.01 6 C

- Page 1021 and 1022:

946 SCANIA DSC 11.17 6 Cyl. 16:1 11

- Page 1023 and 1024:

n 19 127.00 948 SCANIA DS 14.46 V8

- Page 1025 and 1026:

950 SCANIA 87-143600-30 1 2 STD 08-

- Page 1028 and 1029:

Engine Index • Indice des moteurs

- Page 1030 and 1031:

n 1 65.00 Ibiza, Marbella 01/71Ý12

- Page 1032 and 1033:

n 5 76.50 SEAT Arosa 1.4 05/97Ý06/

- Page 1034 and 1035:

n 7 79.50 SEAT Cordoba 1.9 D 02/93

- Page 1036 and 1037:

87-114900-70 2 3 STD 08-114900-00 S

- Page 1038 and 1039:

n 10 79.50 SEAT Cordoba 1.9 SDI 06/

- Page 1040 and 1041:

87-114900-50 2 3 STD 08-114900-00 S

- Page 1042 and 1043:

SEAT Altea 1.9 TDI, Altea XL 1.9 TD

- Page 1044 and 1045:

AK KK NB RT TP 07969K102 87-114900-

- Page 1046 and 1047:

87-114900-15 2 5 STD 08-114900-00 S

- Page 1048 and 1049:

n 17 81.00 Cordoba 1.8 i 02/93Ý06/

- Page 1050 and 1051:

n 20 81.00 SEAT Altea 2.0 TDI 03/04

- Page 1052 and 1053:

n 22 81.00 SEAT Exeo 2.0 TDI 03/09

- Page 1054 and 1055:

n 24 81.00 Toledo I 1.8 i 05/91Ý12

- Page 1056:

n 27 83.00 SEAT Ibiza I 1.7 D 06/84

- Page 1060 and 1061:

n 1 76.50 SKODA Felicia I 1.6 LX, F

- Page 1062 and 1063:

n 4 79.50 SKODA Octavia 1.9 SDI 06/

- Page 1064 and 1065:

87-114900-95 2 STD 08-114900-00 STD

- Page 1066 and 1067:

n 6 79.50 SKODA Fabia 1.4 TDI 04/03

- Page 1068 and 1069:

07901C106 SKODA 1 To cylinder 1 & 2

- Page 1070 and 1071:

n 9 81.00 Octavia 1.8 09/96Ý ADR 4

- Page 1072 and 1073:

n 12 81.00 SKODA Octavia 2.0 TDI, 0

- Page 1074 and 1075:

07901D834 SKODA 1 to cylinder 1 1 z

- Page 1076:

Engine Index • Indice des moteurs

- Page 1079 and 1080:

87-140600-00 STD 08-140600-00 STD A

- Page 1082:

Engine Index • Indice des moteurs

- Page 1085 and 1086:

87-743120-20 1 0.70mm 08-743100-00

- Page 1087 and 1088:

n 5 94.00 1012 SSANGYONG Korando 2.

- Page 1089 and 1090:

1014 STEYR MAKE WD 610.50 6 Cyl. 17

- Page 1092:

Engine Index • Indice des moteurs

- Page 1095 and 1096:

n 3 76.00 1020 SUZUKI Jimny 1.5 DDi

- Page 1098:

Engine Index • Indice des moteurs

- Page 1101 and 1102:

n 4 84.00 Express 1000 -1500 Bus 1.

- Page 1103 and 1104:

n 8 94.00 1028 TALBOT Tagora 2.3 Tu

- Page 1106 and 1107:

n 1 73.00 TOYOTA Corolla 1.3 08/83

- Page 1108 and 1109:

n 3 82.20 TOYOTA Avensis 1.9 D 09/0

- Page 1110 and 1111:

n 6 91.00 TOYOTA Land Cruiser 4.0 D

- Page 1112 and 1113:

TOYOTA 87-373800-00 STD 08-373800-0

- Page 1114 and 1115:

n 10 94.00 TOYOTA Land Cruiser 80 4

- Page 1116 and 1117:

87-528900-10 STD 87-528907-10 0.50m

- Page 1118 and 1119:

n 14 96.00 TOYOTA 4 Runner 3.0 Turb

- Page 1120:

RT n 18 102.00 TOYOTA Dyna Bus 3.4

- Page 1124:

n 1 70.99 TRIUMPH MOTOR CYCLES TR6

- Page 1128:

n 1 91.49 URSUS 3.152 3 Cyl. 17.4:1

- Page 1132 and 1133:

Engine Index • Indice des moteurs

- Page 1134 and 1135:

n 1 65.50 Rascal 01/90Ý F 10 A 87-

- Page 1136 and 1137:

1 Steel 1 Stahl 1 Acier 1 Acciaio 1

- Page 1138 and 1139:

VAUXHALL 1 Pistons to be replaced i

- Page 1140 and 1141:

87-307100-30 STD 08-307100-00 STD 8

- Page 1142 and 1143:

87-307600-20 STD 08-307600-00 STD 8

- Page 1144 and 1145:

n 17 79.00 Corsa Mk II 1.6 GSI 16V

- Page 1146 and 1147:

n 21 80.00 VAUXHALL Astra Estate 1.

- Page 1148 and 1149:

n 24 80.00 VAUXHALL Omega 2.5 TD 04

- Page 1150 and 1151:

n 28 82.00 VAUXHALL Astra Mk V 1.9

- Page 1152 and 1153:

n 31 84.00 VAUXHALL Vivaro Box 2.0

- Page 1154 and 1155:

n 34 84.00 VAUXHALL Frontera Mk II

- Page 1156 and 1157:

87-307200-10 STD 08-307200-00 STD 8

- Page 1158 and 1159:

87-306800-10 STD 08-306800-00 STD 8

- Page 1160 and 1161:

n 43 87.50 Omega 3.2 V6 02/01Ý03/0

- Page 1162 and 1163:

n 46 92.00 VAUXHALL Carlton Mk II 2

- Page 1164:

87-854700-00 STD 08-854700-00 STD 8

- Page 1168:

n 1 94.00 VOLGA XD2/XD2P/XD94 4 Cyl

- Page 1171 and 1172:

Engine Index • Indice des moteurs

- Page 1173 and 1174:

Engine Index • Indice des moteurs

- Page 1175 and 1176:

1100 VOLKSWAGEN Derby 1.3 08/83Ý12

- Page 1177 and 1178:

n 4 76.50 1102 VOLKSWAGEN LT 28-35

- Page 1179 and 1180:

1104 VOLKSWAGEN 1 With recesses on

- Page 1181 and 1182:

1106 VOLKSWAGEN Bora 1.4 16V 03/00

- Page 1183 and 1184:

87-103000-10 2 STD 08-103000-00 STD

- Page 1185 and 1186:

1110 VOLKSWAGEN Transporter IV Box

- Page 1187 and 1188:

1112 VOLKSWAGEN Bora 1.9 TDI 10/98

- Page 1189 and 1190:

87-114900-95 2 STD 08-114900-00 STD

- Page 1191 and 1192:

87-114900-30 2 3 STD 08-114900-00 S

- Page 1193 and 1194:

n 16 79.50 1118 VOLKSWAGEN Bora 1.9

- Page 1195 and 1196:

87-114900-56 2 3 6 STD 08-114900-00

- Page 1197 and 1198:

1122 VOLKSWAGEN Touran 1.9 TDI 02/0

- Page 1199 and 1200:

n 19 79.50 1124 VOLKSWAGEN Bora 1.9

- Page 1201 and 1202:

87-114900-46 2 3 STD 08-114900-00 S

- Page 1203 and 1204:

1128 VOLKSWAGEN Multivan V 1.9 TDI,

- Page 1205 and 1206:

n 23 81.00 1130 VOLKSWAGEN Caddy II

- Page 1207 and 1208:

1132 VOLKSWAGEN Golf III 1.8 11/91

- Page 1209 and 1210:

n 25 81.00 1134 VOLKSWAGEN Golf III

- Page 1211 and 1212:

1136 VOLKSWAGEN LT 28-35 II Bus 2.5

- Page 1213 and 1214:

New Beetle 1.6 10/99Ý09/00 AWH 87-

- Page 1215 and 1216:

1140 VOLKSWAGEN Golf IV 1.8 T 08/97

- Page 1217 and 1218:

87-421000-20 2 STD 08-421000-00 STD

- Page 1219 and 1220:

1144 08102-205 87-139500-40 2 3 STD

- Page 1221 and 1222:

1146 07901D834 VOLKSWAGEN 1 to cyli

- Page 1223 and 1224:

AK KK NB RT TP 1148 07901G220 VOLKS

- Page 1225 and 1226:

HA KK NB RT TP 1150 07901G202 VOLKS

- Page 1227 and 1228:

n 41 82.50 1152 VOLKSWAGEN Corrado

- Page 1229 and 1230:

n 43 82.50 1154 VOLKSWAGEN Golf III

- Page 1232:

Engine Index • Indice des moteurs

- Page 1235 and 1236:

n 3 76.00 340-360 1.4 08/75Ý12/88

- Page 1237 and 1238:

n 6 76.50 1162 VOLVO (CARS) 740 2.4

- Page 1239 and 1240:

n 9 81.00 1164 VOLVO (CARS) 850 2.5

- Page 1242 and 1243:

Engine Index • Indice des moteurs

- Page 1244:

Engine Index • Indice des moteurs

- Page 1247 and 1248:

n 4 98.43 1172 VOLVO (COMMERCIAL) D

- Page 1249 and 1250:

87-107200-10 3 STD 08-107200-00 STD

- Page 1251 and 1252:

n 11 104.775 1176 VOLVO (COMMERCIAL

- Page 1253 and 1254:

n 15 108.00 1178 VOLVO (COMMERCIAL)

- Page 1255 and 1256:

1180 VOLVO (COMMERCIAL) 87-136800-4

- Page 1257 and 1258:

n 21 120.65 1182 VOLVO (COMMERCIAL)

- Page 1259 and 1260:

n 24 120.65 1184 VOLVO (COMMERCIAL)

- Page 1261 and 1262:

n 27 120.65 1186 VOLVO (COMMERCIAL)

- Page 1263 and 1264:

n 30 130.175 1188 VOLVO (COMMERCIAL

- Page 1265 and 1266:

n 32 130.175 1190 VOLVO (COMMERCIAL

- Page 1268 and 1269:

n 1 80.00 101 1.1 06/73Ý01/90 128

- Page 1270 and 1271:

Lista de referencias • Lista nume

- Page 1272 and 1273:

Lista de referencias • Lista nume

- Page 1274 and 1275:

Lista de referencias • Lista nume

- Page 1276 and 1277:

Lista de referencias • Lista nume

- Page 1278 and 1279:

Lista de referencias • Lista nume

- Page 1280 and 1281:

Lista de referencias • Lista nume

- Page 1282 and 1283:

Lista de referencias • Lista nume

- Page 1284 and 1285:

Lista de referencias • Lista nume

- Page 1286 and 1287:

Lista de referencias • Lista nume

- Page 1288 and 1289:

Lista de referencias • Lista nume

- Page 1290 and 1291:

Lista de referencias • Lista nume

- Page 1292 and 1293:

Lista de referencias • Lista nume

- Page 1294 and 1295:

Lista de referencias • Lista nume

- Page 1296 and 1297:

Lista de referencias • Lista nume

- Page 1298 and 1299:

Lista de referencias • Lista nume

- Page 1300 and 1301:

Lista de referencias • Lista nume

- Page 1302 and 1303:

Lista de referencias • Lista nume

- Page 1304 and 1305:

Lista de referencias • Lista nume

- Page 1307 and 1308:

INTERCHANGE LIST Pistons 1639 1233-

- Page 1309 and 1310:

ef New Piston ref 24200 STD 87-2153

- Page 1311 and 1312:

ef New Cylinder Assembly ref ASA223

- Page 1313 and 1314:

ef New Rings ref * R42580 1.00MM 08

- Page 1315 and 1316:

ef New Rings ref * R66150 STD 08-33

- Page 1317 and 1318:

NÜ RAL PISTONS FITTED WITH GOETZE

- Page 1319 and 1320:

NÜRAL PISTONS FITTED WITH GOETZE

- Page 1321 and 1322:

NÜRAL PISTONS FITTED WITH GOETZE

- Page 1323 and 1324:

PISTON CLEARANCE DATA 87-100100-00

- Page 1325 and 1326:

PISTON CLEARANCE DATA 87-178800-00

- Page 1327 and 1328:

PISTON CLEARANCE DATA 87-426300-00

- Page 1329 and 1330:

PISTON PROTRUSION DATA 87-102800-10

- Page 1331 and 1332:

PISTON PROTRUSION DATA 87-425400-00

- Page 1333 and 1334:

Federal-Mogul Global Aftermarket EM