Telecommunication Copper Cables - PENGG KABEL GmbH

Telecommunication Copper Cables - PENGG KABEL GmbH

Telecommunication Copper Cables - PENGG KABEL GmbH

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

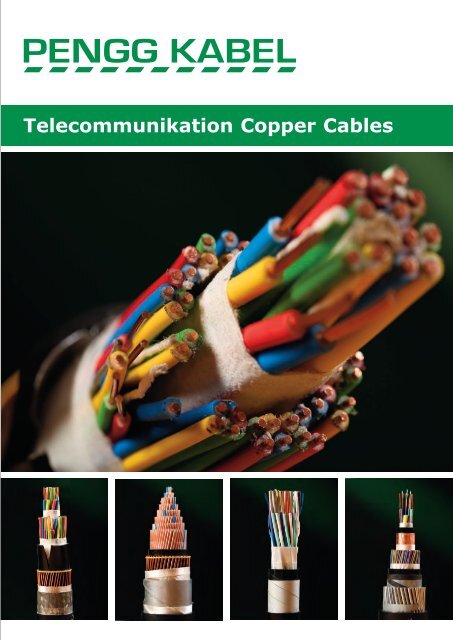

Telecommunikation <strong>Copper</strong> <strong>Cables</strong>

Introduction<br />

<strong>Telecommunication</strong> <strong>Copper</strong> <strong>Cables</strong><br />

Plant Kapfenberg-Einöd<br />

1999<br />

2002<br />

2005<br />

Pengg Kabel <strong>GmbH</strong> is an Austrian cable manufacturer and a member<br />

of the german Wilms group with two plants in Styria. At the<br />

location in Kapfenberg-Einöd we have been producing telecommunication<br />

coppercables for more than 40 years.<br />

In addition to a quality management system, which is certified<br />

according to ISO 9001, Pengg Kabel <strong>GmbH</strong> set a high value on the<br />

fact that the loads of the environment are kept as small as possible.<br />

With our production equipment we are able to produce all usual<br />

kinds of stranding such as layer-stranding, SZ-stranding and random<br />

stranding. On this basis, we are able to produce the main<br />

types of telecommunications cables.<br />

<strong>Telecommunication</strong> cables:<br />

•conductor diameter 0.4 mm up to 1.8 mm<br />

•symmetric local and district cables<br />

•symmetric indoor cables<br />

•all types of jumper wires according to national and international<br />

standards and/or customers specifications.<br />

Differential protection cables:<br />

•conductor diameter 0.4 mm and 1.8 mm<br />

<strong>Cables</strong> for watersupply- as well as for power-supply companies:<br />

•with pairs, triples or quads<br />

•special filling materials<br />

•different kinds of electrical shielding<br />

Control cables for railway applications, special cables:<br />

•with plastic insulation<br />

•with cores, pairs or quads<br />

•spare cables in plastic version for paper-lead cables<br />

Flexibility and customer proximity are the bases for a successful<br />

development on the market. New developments and product<br />

improvements are always necessary. Apart of the permanent<br />

search for improvements of our products, our efforts for the future<br />

run towards reduction of production time, increase of flexibility and<br />

constant improvement of quality, in order to be a reliable partner<br />

for our customers.<br />

<strong>Telecommunication</strong> <strong>Copper</strong> <strong>Cables</strong> • 09/2012 • © by <strong>PENGG</strong> <strong>KABEL</strong> <strong>GmbH</strong> • Subject to technical alterations 3

Contact Persons<br />

<strong>Telecommunication</strong> <strong>Copper</strong> <strong>Cables</strong><br />

Managing Director:<br />

Product Manager:<br />

Sales Director:<br />

Max Rothwangl<br />

Managing Director<br />

(+43) (0)3862 23990 410<br />

(+43) (0)3862 23990 452<br />

@ max.rothwangl@penggkabel.at<br />

Werner Lenger<br />

Product Manager - Railway cables<br />

(+43) (0)3862 23990 418<br />

(+43) (0)3862 23990 444<br />

@ werner.lenger@penggkabel.at<br />

Uwe Löcker<br />

Key Account Manager<br />

(B, BG, BY, CH, CY, CZ, D, DK, E, EST, FIN, GB, GR, H, I, IRL,<br />

IS, L, LT, LV, MD, N, NL, P, PL, RO, RUS, S, SK, UA)<br />

(+43) (0)3862 23990 690<br />

(+43) (0)3862 23990 672<br />

@ uwe.loecker@penggkabel.at<br />

Key Accounts:<br />

Brigitte Wenzl<br />

Key Account Manager (A, D, F)<br />

(+43) (0)3862 23990 666<br />

(+43) (0)3862 23990 672<br />

@ brigitte.wenzl@penggkabel.at<br />

Robert Hofreiter<br />

Key Account Manager<br />

(A, AL, BIH, HR, KOS, MK, MNE, SLO, SRB)<br />

(+43) (0)3862 23990 683<br />

(+43) (0)3862 23990 672<br />

@ robert.hofreiter@penggkabel.at<br />

Holger Quest<br />

Key Account Manager (D)<br />

(+49) (0)172 95 99 471<br />

(+43) (0)3862 23990 672<br />

@ holger.quest@penggkabel.at<br />

Addresses<br />

<strong>PENGG</strong> <strong>KABEL</strong> <strong>GmbH</strong><br />

Mariazellerstraße 125<br />

A-8605 Kapfenberg, Austria<br />

Area representatives:<br />

PROCABLE S.A.<br />

Isabelle & Udo Guldner<br />

Area representative (F, LU)<br />

7, Z.I. Bombicht<br />

L-6947 Niederanven, Luxembourg<br />

Interteam Srl<br />

Mauro Rota<br />

Area representative (I)<br />

Via C. Battisti, 50<br />

I-24019 Zogno (BG), Italy<br />

Sasta/Sakelliou Spyros & CO OE<br />

Spyros Sakelliou<br />

Area representative (GR)<br />

15B, Konstantinidou Str.<br />

GR-104 45 K.Patissia, Athen, Greece<br />

(+43) (0)3862 23990 0<br />

(+43) (0)3862 23990 424<br />

@ info@penggkabel.at<br />

URL: www.penggkabel.at<br />

(+352) (0)263 40244<br />

(+352) (0)263 40245<br />

@ procable@pt.lu<br />

URL: www.procable.lu<br />

(+39) 0345 90938<br />

(+39) 0345 50684<br />

@ rota.mauro@inter-team.it<br />

URL: www.inter-team.it<br />

(+30) (0)210 8322611612<br />

(+30) (0)210 8325444<br />

@ sasta@otenet.gr<br />

4 <strong>Telecommunication</strong> <strong>Copper</strong> <strong>Cables</strong> • 09/2012 • © by <strong>PENGG</strong> <strong>KABEL</strong> <strong>GmbH</strong> • Subject to technical alterations

Index<br />

<strong>Telecommunication</strong> <strong>Copper</strong> <strong>Cables</strong><br />

<strong>Telecommunication</strong>-Outdoor <strong>Cables</strong> Page 7<br />

<strong>Telecommunication</strong>-Indoor <strong>Cables</strong> Page 35<br />

General Information Page 47<br />

<strong>Telecommunication</strong> <strong>Copper</strong> <strong>Cables</strong> • 09/2012 • © by <strong>PENGG</strong> <strong>KABEL</strong> <strong>GmbH</strong> • Subject to technical alterations 5

<strong>Telecommunication</strong> <strong>Cables</strong><br />

Note<br />

6 <strong>Telecommunication</strong> <strong>Copper</strong> <strong>Cables</strong> • 09/2012 • © by <strong>PENGG</strong> <strong>KABEL</strong> <strong>GmbH</strong> • Subject to technical alterations

<strong>Telecommunication</strong>-Outdoor <strong>Cables</strong><br />

F-2YA2Y ..x2x.. Page 8<br />

F-2YC2Y ..x2x.. Page 9<br />

F-2YJ2Y / F-2YJA2Y ..x2x.. Page 10<br />

A-2Y(L)2Y ..x2x.. STIII BD Page 11<br />

A-2YF(L)2Y ..x2x.. STIII BD Page 12<br />

A-02Y(L)2Y ..x2x.. STIII BD Page 13<br />

A-02YSF(L)2Y ..x2x.. STIII BD C42 Page 14<br />

A-02YSF(L)2Y ..x2x.. STIII BD C52/55 Page 15<br />

A-02YSOF(L)2Y ..x2x.. STIII BD Page 16<br />

AD-2YF(L)2Y Page 17<br />

CU/SPE/SWM/FOL/AL/FRNC 4x2x0.5 + 2xG657A BAL-Kabel Page 19<br />

CU/SPE/FOL/AL+PE (unfilled, 40nF) Page 20<br />

CU/SPE/VAS/FOL/AL+PE (filled, 40nF) Page 21<br />

CU/SPE/VAS/FOL/AL+PE/ARM/PE (filled, 40nF) Page 22<br />

CU+TIN/PE/VAS/FOL/PE (filled, 70nF) Page 23<br />

CU+TIN/PE/VAS/FOL/AL+PE (filled, 70nF) Page 24<br />

TK- ..x4/.. -PE-ALT Page 25<br />

TK- ..x4/.. -PE-ALT-CLT Page 26<br />

TK- ..x4/.. -PE4-ALT Page 27<br />

QV ..x4x.. Page 28<br />

QL ..x4x.. Page 29<br />

TK59 ..x4x.. M/GM Page 30<br />

TD59 ..x4x.. Page 31<br />

VMOU-AQ ..x2x.. Page 32<br />

µ-copper ..2x0.6 Page 33<br />

<strong>Telecommunication</strong> <strong>Copper</strong> <strong>Cables</strong> • 09/2012 • © by <strong>PENGG</strong> <strong>KABEL</strong> <strong>GmbH</strong> • Subject to technical alterations 7

<strong>Telecommunication</strong>-Outdoor <strong>Cables</strong><br />

Polyethylen-insulated, local telecommunication cable with static shield F-2YA2Y ..x2x..<br />

conductor diameter 0.6 mm conductor diameter 0.8 mm<br />

Type number of outer diameter weight outer diameter weight<br />

double cores approx. mm approx. kg/km approx. mm approx. kg/km<br />

F-2YA2Y 2x2x.. 2 6.9 43 7.3 55<br />

F-2YA2Y 4x2x.. 4 8.2 65 9.9 91<br />

F-2YA2Y 6x2x.. 6 9.1 81 10.4 115<br />

F-2YA2Y 8x2x.. 8 9.8 105 12.4 160<br />

F-2YA2Y 10x2x.. 10 10.5 120 12.0 170<br />

F-2YA2Y 20x2x.. 20 13.7 200 15.9 300<br />

F-2YA2Y 30x2x.. 30 15.4 275 18.0 425<br />

F-2YA2Y 40x2x.. 40 16.1 340 19.0 535<br />

F-2YA2Y 50x2x.. 50 18.9 420 22.6 665<br />

F-2YA2Y 60x2x.. 60 19.5 485 23.1 780<br />

F-2YA2Y 80x2x.. 80 21.4 625 27.0 1030<br />

F-2YA2Y 100x2x.. 100 24.8 795 29.6 1260<br />

Application<br />

In all kinds of operating premises (excepted locations with special protection<br />

demands - like in fire or highly combustible premises); e.g. for local area networks<br />

of the telecom, as station communication cables and for small telephone<br />

networks of industry, traffic and public utilities.<br />

Construction<br />

Conductor: solid, bare copper wire Ø 0.6 / 0.8 mm<br />

Insulation: PE (2Y)<br />

Core colours: natural (counter quad black), red, green, blue<br />

Cable make up: 4 cores twisted to quads, quads cabled together in<br />

concentric layers to cable core,<br />

wrapping with plastic foil<br />

Drain wire: tinned copper wire Ø 0.5 mm<br />

Screening: alu minium laminated plastic foil (A)<br />

Sheath: PE (2Y), black<br />

Laying<br />

suitable for underground installation and pulling into conduits, ducts<br />

Marking<br />

<br />

Note<br />

other number of pairs or conductor diameters on request<br />

dimension of<br />

conductor<br />

cable elements<br />

number of<br />

double cores<br />

8 <strong>Telecommunication</strong> <strong>Copper</strong> <strong>Cables</strong> • 09/2012 • © by <strong>PENGG</strong> <strong>KABEL</strong> <strong>GmbH</strong> • Subject to technical alterations<br />

C55<br />

Ø<br />

0.6<br />

mutual capacitance<br />

Ø<br />

0.8<br />

DC<br />

n<br />

filling<br />

overall shield,<br />

armouring<br />

Technical Details (at 20°C)<br />

standard TLB X5019 (03.67)<br />

conductor diameter 0.6 0.8 mm<br />

loop resistance ≤ 130 ≤ 73.2 Ω/km<br />

insulation resistance ≥ 10 ≥ 10 GΩkm<br />

mutual capacitance (at f=800Hz)<br />

capacitance unbalance k1 ≤ 55 ≤ 55 nF/km<br />

(at f=800Hz) 100 % ≤ 1500 ≤ 1500 pF/300m<br />

97%<br />

capacitance unbalance k9-12 ≤ 800 ≤ 800 pF/300m<br />

(at f=800Hz) 100% ≤ 1500 ≤ 1500 pF/300m<br />

97%<br />

capacitance unbalance e1,2 ≤ 800 ≤ 800 pF/300m<br />

(at f=800Hz) 100% ≤ 1500 ≤ 1500 pF/300m<br />

97% ≤ 800 ≤ 800 pF/300m<br />

operating voltage 200 VAC<br />

300 VDC<br />

dielectric strength conductor/conductor 500 V/50Hz<br />

conductor/shield 2000 V/50Hz<br />

temperature range<br />

during installation -20 up to +50°C<br />

for stationary conditions up to +70 °C

<strong>Telecommunication</strong>-Outdoor <strong>Cables</strong><br />

Polyethylen-insulated, local telecommunication cable with copper shield F-2YC2Y ..x2x..<br />

conductor diameter 0.6 mm conductor diameter 0.8 mm<br />

Type number of outer diameter weight outer diameter weight<br />

double cores approx. mm approx. kg/km approx. mm approx. kg/km<br />

F-2YC2Y 2x2x.. 2 8.7 82 9.3 98<br />

F-2YC2Y 4x2x.. 4 9.4 97 10.3 125<br />

F-2YC2Y 6x2x.. 6 9.6 105 10.8 145<br />

F-2YC2Y 10x2x.. 10 10.9 145 12.4 210<br />

F-2YC2Y 20x2x.. 20 14.1 240 16.3 350<br />

F-2YC2Y 30x2x.. 30 15.8 325 18.4 485<br />

F-2YC2Y 40x2x.. 40 16.5 390 19.3 600<br />

F-2YC2Y 50x2x.. 50 19.3 480 22.8 745<br />

F-2YC2Y 60x2x.. 60 19.9 550 23.6 865<br />

F-2YC2Y 80x2x.. 80 22.1 700 26.3 1110<br />

F-2YC2Y 100x2x.. 100 25.0 865 29.6 1360<br />

Application<br />

In all kinds of operating premises (excepted locations with special protection<br />

demands - like in fire or highly combustible premises); e.g. for local area networks<br />

of the telecom, as station communication cables and for small telephone<br />

networks of industry, traffic and public utilities.<br />

Construction<br />

Conductor: solid, bare copper wire Ø 0.6 / 0.8 mm<br />

Insulation: PE (2Y)<br />

Colour code: natural (tracer quad black), red, green, blue<br />

Cable make up: 4 cores twisted to quads, quads cabled together in<br />

concentric layers to cable core,<br />

wrapping with plastic foil<br />

Screening: copper tape (C)<br />

Sheath: PE (2Y), black<br />

Laying<br />

suitable for underground installation and pulling into conduits, ducts<br />

Marking<br />

<br />

Note<br />

other number of pairs or conductor diameters on request<br />

C55<br />

Ø<br />

0.6<br />

mutual capacitance<br />

Ø<br />

0.8<br />

dimension of<br />

conductor<br />

cable elements<br />

Technical Details (at 20°C)<br />

standard TLB X5019 (03.67)<br />

conductor diameter 0.6 0.8 mm<br />

loop resistance ≤ 130 ≤ 73.2 Ω/km<br />

insulation resistance ≥ 10 ≥ 10 GΩkm<br />

mutual capacitance (at f=800Hz)<br />

capacitance unbalance k1 ≤ 55 ≤ 55 nF/km<br />

(at f=800Hz) 100% ≤ 1500 ≤ 1500 pF/300m<br />

97%<br />

capacitance unbalance k9-12 ≤ 800 ≤ 800 pF/300m<br />

(at f=800Hz) 100% ≤ 1500 ≤ 1500 pF/300m<br />

97%<br />

capacitance unbalance e1,2 ≤ 800 ≤ 800 pF/300m<br />

(at f=800Hz) 100% ≤ 1500 ≤ 1500 pF/300m<br />

97% ≤ 800 ≤ 800 pF/300m<br />

operating voltage 200 VAC<br />

300 VDC<br />

dielectric strength conductor/conductor 500 V/50Hz<br />

conductor/shield 2000 V/50Hz<br />

temperature range<br />

during installation -20 up to +50°C<br />

for stationary conditions up to +70 °C<br />

<strong>Telecommunication</strong> <strong>Copper</strong> <strong>Cables</strong> • 09/2012 • © by <strong>PENGG</strong> <strong>KABEL</strong> <strong>GmbH</strong> • Subject to technical alterations 9<br />

DC<br />

n<br />

number of<br />

double cores<br />

filling<br />

overall shield,<br />

armouring

<strong>Telecommunication</strong>-Outdoor <strong>Cables</strong><br />

Polyethylen-insulated, local telecommunication cable F-2YJ2Y ..2x.. E / F-2YJA2Y ..x2x..<br />

conductor diameter 0.6 mm conductor diameter 0.8 mm<br />

Type number of outer diameter weight outer diameter weight<br />

double cores approx. mm approx. kg/km approx. mm approx. kg/km<br />

F-2YJ2Y 2x2x.. E 2 - - 9.0 80<br />

F-2YJ2Y 4x2x.. E 4 - - 11.7 140<br />

F-2YJ2Y 6x2x.. E 6 10.5 115 12.2 165<br />

F-2YJA2Y 10x2x.. 10 12.3 165 14.2 240<br />

F-2YJA2Y 20x2x.. 20 16.0 290 18.9 435<br />

F-2YJA2Y 30x2x.. 30 18.1 390 21.5 590<br />

F-2YJA2Y 40x2x.. 40 18.9 460 22.6 720<br />

F-2YJA2Y 50x2x.. 50 22.0 590 26.9 950<br />

F-2YJA2Y 70x2x.. 70 25.0 790 29.2 1200<br />

F-2YJA2Y 100x2x.. 100 28.7 1075 35.5 1750<br />

F-2YJA2Y 150x2x.. 150 34.0 1550 - -<br />

Application<br />

In all kinds of operating premises (excepted locations with special protection<br />

demands - like in fire or highly combustible premises); e.g. for local area networks<br />

of the telecom, as station communication cables and for small telephone<br />

networks of industry, traffic and public utilities.<br />

Construction<br />

Conductor: solid, bare copper wire Ø 0.6 / 0.8 mm<br />

Insulation: PE (2Y)<br />

Colour code: natural (tracer quad black), red, green, blue<br />

Cable make up: 4 cores twisted to quads, quads cabled together in<br />

concentric layers to cable core, cable core filled with<br />

petrol jelly (J), wrapping of paper tape<br />

Drain wire: tinned copper wire Ø 0.8 mm (E) (2 up to 6 pairs)<br />

Sheath: PE (2Y), black (2 up to 6 pairs)<br />

Al/PE-composite layer sheath (A2Y), black (≥ 10 pairs)<br />

Laying<br />

suitable for underground installation and pulling into conduits, ducts<br />

Marking<br />

<br />

Note<br />

other number of pairs or conductor diameters on request<br />

10 <strong>Telecommunication</strong> <strong>Copper</strong> <strong>Cables</strong> • 09/2012 • © by <strong>PENGG</strong> <strong>KABEL</strong> <strong>GmbH</strong> • Subject to technical alterations<br />

C52<br />

Ø<br />

0.6<br />

C55<br />

Ø<br />

0.8<br />

mutual capacitance<br />

dimension of<br />

conductor<br />

cable elements<br />

Technical Details (at 20°C)<br />

standard TLB X0009 (12.76)<br />

conductor diameter 0.6 0.8 mm<br />

loop resistance ≤ 130 ≤ 73.2 Ω/km<br />

insulation resistance<br />

mutual capacitance (at f=800Hz)<br />

≥ 5 ≥ 5 GΩkm<br />

2 up to 6 pairs ≤ 55 ≤ 55 nF/km<br />

≥ 10 pairs<br />

capacitance unbalance k1 ≤ 52 ≤ 52 nF/km<br />

(at f=800Hz) 100% ≤ 800 ≤ 800 pF/300m<br />

95% ≤ 400 ≤ 400 pF/300m<br />

capacitance unbalance k9-12 (at f=800Hz) 100% ≤ 300 ≤ 300 pF/300m<br />

capacitance unbalance e1,2 (at f=800Hz) 100% ≤ 800 ≤ 800 pF/300m<br />

operating voltage 200 VAC<br />

300 VDC<br />

dielectric strength conductor/conductor 500 V/50Hz<br />

conductor/shield 2000 V/50Hz<br />

temperature range<br />

during installation -20 up to +50°C<br />

for stationary conditions up to +70 °C<br />

DC<br />

n<br />

number of<br />

double cores<br />

filling<br />

overall shield,<br />

armouring

<strong>Telecommunication</strong>-Outdoor <strong>Cables</strong><br />

Polyethylen-insulated, local telecommunication cable A-2Y(L)2Y ..x2x... STIII BD<br />

Application<br />

In all kinds of operating premises (excepted locations with special protection<br />

demands - like in fire or highly combustible premises); e.g. for local area networks<br />

of the telecom, as station communication cables and for small telephone<br />

networks of industry, traffic and public utilities.<br />

Construction<br />

Conductor: solid, bare copper wire Ø 0.6 / 0.8 mm<br />

Insulation: PE (2Y)<br />

Core colours: basic colours of quads: RD, GN, GY, YE, WT<br />

Group mark: side circuit 1 a-core<br />

side circuit 1 b-core<br />

side circuit 2 a-core<br />

side circuit 2 b-core<br />

Cable make up: 4 cores twisted to quads (STIII), 5 quads cabled<br />

together to basic units (BD), tracer units and tracer main<br />

units are marked with an open red helix in each layer, all<br />

other basic and main units are identified with an open<br />

white or natural coloured helix. 5 basic units cabled<br />

together to main units (from 150 DC upwards). Basic-<br />

/main units cabled together in layers to cable core.<br />

Cable core wrapping of plastic tapes.<br />

Sheath: PE double-coated aluminium foil bonded with the PEouter<br />

sheath ((L)2Y), black<br />

Laying<br />

suitable for underground installation and pulling into conduits, ducts<br />

Marking<br />

<br />

Note<br />

other number of pairs or conductor diameters on request<br />

Ø<br />

0.4<br />

mutual capacitance<br />

Ø<br />

0.6<br />

Ø<br />

0.8<br />

cable elements<br />

dimension of<br />

conductor<br />

Technical Details (at 20°C)<br />

standard VDE 0816/part 1<br />

conductor diameter 0.4 0.6 0.8 mm<br />

loop resistance ≤ 300 ≤ 130 ≤ 73.2 Ω/km<br />

insulation resistance<br />

mutual capacitance<br />

≥ 5 ≥ 5 ≥ 5 GΩkm<br />

(at f=800Hz) 100 % ≤ 50 ≤ 52 ≤ 55 nF/km<br />

95 % ≤ 48 ≤ 50 ≤ 53 nF/km<br />

80 % ≤ 48 ≤ 50 nF/km<br />

capacitance unbalance k1 (at f=800Hz) 100 % ≤ 800 ≤ 800 ≤ 800 pF/300m<br />

98 % ≤ 400 ≤ 400 ≤ 400 pF/300m<br />

capacitance unbalance k9-12 (at f=800Hz) 100 % ≤ 300 ≤ 300 ≤ 300 pF/300m<br />

98 % ≤ 100 ≤ 100 ≤ 100 pF/300m<br />

operating voltage (peak value) ≤ 150 ≤ 225 ≤ 225 V<br />

dielectric strength conductor conductor – 500 500 V/50Hz<br />

conductor/shield 2000 2000 2000 V/50Hz<br />

temperature range<br />

during installation -20 up to +50°C<br />

for stationary conditions up to +70 °C<br />

<strong>Telecommunication</strong> <strong>Copper</strong> <strong>Cables</strong> • 09/2012 • © by <strong>PENGG</strong> <strong>KABEL</strong> <strong>GmbH</strong> • Subject to technical alterations 11<br />

DC<br />

n<br />

number of<br />

double cores<br />

filling<br />

overall shield,<br />

armouring<br />

conductor diameter 0.4 mm conductor diameter 0.6 mm conductor diameter 0.8 mm<br />

Type number of outer diameter weight outer diameter weight outer diameter weight<br />

double cores approx. mm approx. kg/km approx. mm approx. kg/km approx. mm approx. kg/km<br />

A-2Y(L)2Y 2x2x.. STIII BD 2 – – 7.7 60 8.3 73<br />

A-2Y(L)2Y 4x2x.. STIII BD 4 – – 9.8 89 10.9 115<br />

A-2Y(L)2Y 6x2x.. STIII BD 6 9.0 77 10.2 106 11.4 142<br />

A-2Y(L)2Y 10x2x.. STIII BD 10 9.8 94 11.5 143 13.0 201<br />

A-2Y(L)2Y 20x2x.. STIII BD 20 12.2 146 14.7 232 16.9 342<br />

A-2Y(L)2Y 30x2x.. STIII BD 30 13.5 184 16.4 311 19.0 470<br />

A-2Y(L)2Y 40x2x.. STIII BD 40 14.7 232 17.1 383 19.9 588<br />

A-2Y(L)2Y 50x2x.. STIII BD 50 16.0 269 19.9 470 23.2 722<br />

A-2Y(L)2Y 70x2x.. STIII BD 70 17.8 346 21.9 611 26.2 976<br />

A-2Y(L)2Y 100x2x.. STIII BD 100 20.0 466 25.8 850 30.4 1340<br />

A-2Y(L)2Y 120x2x.. STIII BD 120 21.7 547 28.4 1025 32.3 1580<br />

A-2Y(L)2Y 150x2x.. STIII BD 150 23.9 633 31.4 1250 37.5 2015<br />

A-2Y(L)2Y 200x2x.. STIII BD 200 26.9 840 35.8 1620 42.4 2605<br />

A-2Y(L)2Y 250x2x.. STIII BD 250 29.7 1000 38.2 1990 47.5 3250<br />

A-2Y(L)2Y 300x2x.. STIII BD 300 32.1 1180 40.9 2330 51.4 3840<br />

A-2Y(L)2Y 350x2x.. STIII BD 350 34.2 1360 45.6 2740 55.0 4420<br />

A-2Y(L)2Y 400x2x.. STIII BD 400 36.5 1540 48.3 3070 59.1 5070<br />

A-2Y(L)2Y 500x2x.. STIII BD 500 40.2 1870 53.9 3775 65.2 6235<br />

A-2Y(L)2Y 600x2x.. STIII BD 600 42.3 2200 57.4 4540 71.4 7520<br />

A-2Y(L)2Y 700x2x.. STIII BD 700 46.0 2580 61.4 5220 76.5 8670<br />

A-2Y(L)2Y 800x2x.. STIII BD 800 48.7 2960 65.2 5840 82.0 9920<br />

A-2Y(L)2Y 900x2x.. STIII BD 900 51.2 3240 69.5 6600 84.5 10100<br />

A-2Y(L)2Y 1000x2x.. STIII BD 1000 53.6 3620 74.2 7340 88.7 12245<br />

A-2Y(L)2Y 1200x2x.. STIII BD 1200 58.9 4350 79.7 8710 – –<br />

A-2Y(L)2Y 1500x2x.. STIII BD 1500 64.9 5255 – – – –<br />

A-2Y(L)2Y 1800x2x.. STIII BD 1800 71.2 6300 – – – –<br />

A-2Y(L)2Y 2000x2x.. STIII BD 2000 74.6 7070 – – – –

<strong>Telecommunication</strong>-Outdoor <strong>Cables</strong><br />

Polyethylen-insulated, jelly filled, local telecommunication cable A-2YF(L)2Y ..x2x... STIII BD<br />

conductor diameter 0.4 mm conductor diameter 0.6 mm conductor diameter 0.8 mm<br />

Type number of outer diameter weight outer diameter weight outer diameter weight<br />

double cores approx. mm approx. kg/km approx. mm approx. kg/km approx. mm approx. kg/km<br />

A-2YF(L)2Y 2x2x.. STIII BD 2 – – 8.2 67 9.1 85<br />

A-2YF(L)2Y 4x2x.. STIII BD 4 9.3 82 10.8 112 12.4 155<br />

A-2YF(L)2Y 6x2x.. STIII BD 6 9.6 89 11.2 130 12.9 180<br />

A-2YF(L)2Y 10x2x.. STIII BD 10 11.3 123 12.8 180 14.9 260<br />

A-2YF(L)2Y 20x2x.. STIII BD 20 13.3 182 16.5 305 19.6 460<br />

A-2YF(L)2Y 30x2x.. STIII BD 30 14.9 240 18.6 410 22.2 620<br />

A-2YF(L)2Y 40x2x.. STIII BD 40 16.8 303 19.4 480 23.3 745<br />

A-2YF(L)2Y 50x2x.. STIII BD 50 17.6 350 22.7 625 27.8 1000<br />

A-2YF(L)2Y 70x2x.. STIII BD 70 19.9 455 25.5 820 30.9 1290<br />

A-2YF(L)2Y 100x2x.. STIII BD 100 21.8 568 29.6 1120 36.4 1830<br />

A-2YF(L)2Y 120x2x.. STIII BD 120 27.1 743 33.0 1310 38.6 2100<br />

A-2YF(L)2Y 150x2x.. STIII BD 150 28.0 906 37.9 1740 46.8 2835<br />

A-2YF(L)2Y 200x2x.. STIII BD 200 31.4 1130 42.6 2240 52.8 3675<br />

A-2YF(L)2Y 250x2x.. STIII BD 250 34.1 1340 47.1 2780 58.4 4555<br />

A-2YF(L)2Y 300x2x.. STIII BD 300 38.3 1690 51.3 3390 63.1 5370<br />

A-2YF(L)2Y 350x2x.. STIII BD 350 40.8 1950 54.3 3760 68.3 6280<br />

A-2YF(L)2Y 400x2x.. STIII BD 400 43.1 2170 58.8 4340 72.4 7105<br />

A-2YF(L)2Y 500x2x.. STIII BD 500 48.2 2720 64.7 5330 80.6 8830<br />

A-2YF(L)2Y 600x2x.. STIII BD 600 50.2 3140 68.3 6180 87.3 10490<br />

A-2YF(L)2Y 700x2x.. STIII BD 700 53.7 3620 73.1 7140 – –<br />

A-2YF(L)2Y 800x2x.. STIII BD 800 57.7 4160 78.3 8170 – –<br />

A-2YF(L)2Y 900x2x.. STIII BD 900 60.2 4850 82.9 9130 – –<br />

A-2YF(L)2Y 1000x2x.. STIII BD 1000 64.3 5170 86.3 10030 – –<br />

A-2YF(L)2Y 1200x2x.. STIII BD 1200 70.3 6050 – – – –<br />

A-2YF(L)2Y 1500x2x.. STIII BD 1500 72.5 6900 – – – –<br />

A-2YF(L)2Y 1800x2x.. STIII BD 1800 78.0 9250 – – – –<br />

A-2YF(L)2Y 2000x2x.. STIII BD 2000 80.9 10100 – – – –<br />

Application<br />

In all kinds of operating premises (excepted locations with special protection<br />

demands - like in fire or highly combustible premises); e.g. for local area networks<br />

of the telecom, as station communication cables and for small telephone<br />

networks of industry, traffic and public utilities.<br />

Construction<br />

Conductor: solid, bare copper wire Ø 0.4 / 0.6 / 0.8 mm<br />

Insulation: PE (2Y)<br />

Core colours: basic colours of quads: RD, GN, GY, YE, WT<br />

Group mark: side circuit 1 a-core<br />

side circuit 1 b-core<br />

side circuit 2 a-core<br />

side circuit 2 b-core<br />

Cable make up: 4 cores twisted to quads (STIII), 5 quads cabled<br />

together to basic units (BD), tracer units and tracer<br />

main units are marked with an open red helix in each<br />

layer, all other basic and main units are identified with<br />

an open white or natural coloured helix. 5 basic units<br />

cabled together to main units (from 150 DC upwards).<br />

Basic-/main units cabled together in layers to cable<br />

core. The cable core is filled with petrol jelly (F). Cable<br />

core wrapping of plastic tapes.<br />

Sheath: PE double-coated aluminium foil bonded with the PEouter<br />

sheath ((L)2Y), black<br />

Laying<br />

suitable for underground installation and pulling into conduits, ducts<br />

Marking<br />

<br />

12 <strong>Telecommunication</strong> <strong>Copper</strong> <strong>Cables</strong> • 09/2012 • © by <strong>PENGG</strong> <strong>KABEL</strong> <strong>GmbH</strong> • Subject to technical alterations<br />

Ø<br />

0.4<br />

mutual capacitance<br />

Ø<br />

0.6<br />

Ø<br />

0.8<br />

cable elements<br />

dimension of<br />

conductor<br />

Technical Details (at 20°C)<br />

standard VDE 0816/part 1<br />

conductor diameter 0.4 0.6 0.8 mm<br />

loop resistance ≤ 300 ≤ 130 ≤ 73.2 Ω/km<br />

insulation resistance<br />

mutual capacitance<br />

≥ 5 ≥ 5 ≥ 5 GΩkm<br />

(at f=800Hz) 100% ≤ 50 ≤ 52 ≤ 55 nF/km<br />

95 % ≤ 48 ≤ 50 ≤ 50 nF/km<br />

80 % ≤ 48 ≤ 50 nF/km<br />

capacitance unbalance k1 (at f=800Hz) 100% ≤ 800 ≤ 800 ≤ 800 pF/300m<br />

98 % ≤ 400 ≤ 400 ≤ 400 pF/300m<br />

capacitance unbalance k9-12 (at f=800Hz) 100% ≤ 300 ≤ 300 ≤ 300 pF/300m<br />

Impedance<br />

98 % ≤ 100 ≤ 100 ≤ 100 pF/300m<br />

(at f= 1MHz) (approx. value) - 130 120 Ω<br />

operating voltage (peak value) ≤ 150 ≤ 225 ≤ 225 V<br />

dielectric strength conductor conductor – 500 500 V/50Hz<br />

conductor/shield 2000 2000 2000 V/50Hz<br />

temperature range<br />

during installation -20 up to +50°C<br />

for stationary conditions up to +70 °C<br />

DC<br />

n<br />

number of<br />

double cores<br />

filling<br />

overall shield,<br />

armouring

<strong>Telecommunication</strong>-Outdoor <strong>Cables</strong><br />

Foam-PE-insulated, local telecommunication cable A-02Y(L)2Y ..x2x... STIII BD<br />

conductor diameter 0.6 mm conductor diameter 0.8 mm<br />

Type number of outer diameter weight outer diameter weight<br />

double cores approx. mm approx. kg/km approx. mm approx. kg/km<br />

A-02Y(L)2Y 2x2x.. STIII BD 2 7.1 37 7.7 63<br />

A-02Y(L)2Y 4x2x.. STIII BD 4 9.5 67 10.9 96<br />

A-02Y(L)2Y 6x2x.. STIII BD 6 10.3 106 12.0 141<br />

A-02Y(L)2Y 10x2x.. STIII BD 10 11.7 137 13.9 202<br />

A-02Y(L)2Y 20x2x.. STIII BD 20 14.6 221 17.1 334<br />

A-02Y(L)2Y 30x2x.. STIII BD 30 16.2 292 19.8 464<br />

A-02Y(L)2Y 40x2x.. STIII BD 40 18.0 366 22.1 590<br />

A-02Y(L)2Y 50x2x.. STIII BD 50 19.5 436 24.6 728<br />

A-02Y(L)2Y 70x2x.. STIII BD 70 22.2 580 28.1 971<br />

A-02Y(L)2Y 100x2x.. STIII BD 100 26.0 808 32.6 1319<br />

A-02Y(L)2Y 120x2x.. STIII BD 120 28.0 951 35.6 1587<br />

A-02Y(L)2Y 150x2x.. STIII BD 150 30.6 1156 39.1 1920<br />

A-02Y(L)2Y 200x2x.. STIII BD 200 35.0 1511 44.3 2519<br />

A-02Y(L)2Y 250x2x.. STIII BD 250 39.9 1890 50.6 3180<br />

A-02Y(L)2Y 300x2x.. STIII BD 300 43.1 2220 55.7 3840<br />

A-02Y(L)2Y 350x2x.. STIII BD 350 46.8 2600 60.1 4440<br />

Application<br />

In all kinds of operating premises (excepted locations with special protection<br />

demands - like in fire or highly combustible premises); e.g. for local area networks<br />

of the telecom, as station communication cables and for small telephone<br />

networks of industry, traffic and public utilities.<br />

Construction<br />

Conductor: solid, bare copper wire Ø 0.6 / 0.8 mm<br />

Insulation: foam-PE (02Y)<br />

Core colours: basic colours of quads: RD, GN, GY, YE, WT<br />

Group mark: side circuit 1 a-core<br />

side circuit 1 b-core<br />

side circuit 2 a-core<br />

side circuit 2 b-core<br />

Cable make up: 4 cores twisted to quads (STIII), 5 quads cabled<br />

together to basic units (BD), tracer units and tracer<br />

main units are marked with an open red helix in each<br />

layer, all other basic and main units are identified with<br />

an open white or natural coloured helix. 5 basic units<br />

cabled together to main units (from 150 DC upwards).<br />

Basic-/main units cabled together in layers to cable<br />

core. Cable core wrapping of plastic tape.<br />

Sheath: PE double-coated aluminium foil bonded with the PEouter<br />

sheath ((L)2Y), black<br />

Laying<br />

suitable for underground installation and pulling into conduits, ducts<br />

Marking<br />

<br />

Note<br />

other number of pairs or conductor diameters on request<br />

C42<br />

Ø<br />

0.6<br />

mutual capacitance<br />

Ø<br />

0.8<br />

dimension of<br />

conductor<br />

cable elements<br />

Technical Details (at 20°C)<br />

standard similar to VDE 0816/part 1<br />

conductor diameter 0.6 0.8 mm<br />

loop resistance ≤ 130 ≤ 73.2 Ω/km<br />

insulation resistance<br />

mutual capacitance<br />

≥ 5 ≥ 5 GΩkm<br />

(at f=800Hz) 100% ≤ 42 ≤ 42 nF/km<br />

95 % ≤ 40 ≤ 40 nF/km<br />

80 % ≤ 38 ≤ 38 nF/km<br />

capacitance unbalance k1 (at f=800Hz) 100% ≤ 800 ≤ 800 pF/300m<br />

98 % ≤ 400 ≤ 400 pF/300m<br />

capacitance unbalance k9-12 (at f=800Hz) 100% ≤ 300 ≤ 300 pF/300m<br />

98 % ≤ 100 ≤ 100 pF/300m<br />

operating voltage (peak value) ≤ 225 ≤ 225 V<br />

dielectric strength conductor/conductor 500 500 V/50Hz<br />

conductor/shield 2000 2000 V/50Hz<br />

temperature range<br />

during installation -20 up to +50°C<br />

for stationary conditions up to +70 °C<br />

<strong>Telecommunication</strong> <strong>Copper</strong> <strong>Cables</strong> • 09/2012 • © by <strong>PENGG</strong> <strong>KABEL</strong> <strong>GmbH</strong> • Subject to technical alterations 13<br />

DC<br />

n<br />

number of<br />

double cores<br />

filling<br />

overall shield,<br />

armouring

<strong>Telecommunication</strong>-Outdoor <strong>Cables</strong><br />

Foam-skin-PE-insulated, jelly filled, local telecommunication cable A-02YSF(L)2Y ..x2x... STIII BD C42<br />

conductor diameter 0.4 mm conductor diameter 0.6 mm conductor diameter 0.8 mm<br />

Type number of outer diameter weight outer diameter weight outer diameter weight<br />

double cores approx. mm approx. kg/km approx. mm approx. kg/km approx. mm approx. kg/km<br />

A-02YSF(L)2Y 2x2x.. STIII BD 2 – – 8.2 66 9.8 70<br />

A-02YSF(L)2Y 4x2x.. STIII BD 4 – – 9.8 95 12.9 159<br />

A-02YSF(L)2Y 6x2x.. STIII BD 6 9.7 88 11.3 130 12.9 177<br />

A-02YSF(L)2Y 10x2x.. STIII BD 10 10.8 111 12.7 170 15.4 255<br />

A-02YSF(L)2Y 20x2x.. STIII BD 20 13.3 172 16.2 285 20.1 450<br />

A-02YSF(L)2Y 30x2x.. STIII BD 30 14.6 220 18.0 370 22.7 605<br />

A-02YSF(L)2Y 40x2x.. STIII BD 40 15.2 252 18.8 435 23.3 710<br />

A-02YSF(L)2Y 50x2x.. STIII BD 50 17.3 320 21.8 565 28.3 965<br />

A-02YSF(L)2Y 70x2x.. STIII BD 70 19.0 400 24.5 740 31.4 1240<br />

A-02YSF(L)2Y 100x2x.. STIII BD 100 21.7 535 28.2 1010 36.9 1740<br />

A-02YSF(L)2Y 150x2x.. STIII BD 150 26.8 810 35.0 1535 46.0 2680<br />

A-02YSF(L)2Y 200x2x.. STIII BD 200 30.4 1040 39.3 1970 52.8 3490<br />

A-02YSF(L)2Y 250x2x.. STIII BD 250 33.8 1320 43.1 2405 58.0 4290<br />

A-02YSF(L)2Y 300x2x.. STIII BD 300 35.6 1475 47.4 2900 63.1 5125<br />

A-02YSF(L)2Y 350x2x.. STIII BD 350 37.5 1680 50.6 3330 68.0 5910<br />

A-02YSF(L)2Y 400x2x.. STIII BD 400 40.0 1860 53.7 3760 71.6 6675<br />

A-02YSF(L)2Y 450x2x.. STIII BD 450 42.2 2150 56.2 4150 76.2 7920<br />

A-02YSF(L)2Y 500x2x.. STIII BD 500 43.9 2315 59.7 4680 80.6 8830<br />

A-02YSF(L)2Y 600x2x.. STIII BD 600 47.1 2720 62.9 5400 87.3 10490<br />

A-02YSF(L)2Y 700x2x.. STIII BD 700 50.3 3130 68.0 6305 – –<br />

A-02YSF(L)2Y 800x2x.. STIII BD 800 53.2 3530 76.8 7530 – –<br />

A-02YSF(L)2Y 900x2x.. STIII BD 900 56.8 4000 – – – –<br />

A-02YSF(L)2Y 1000x2x.. STIII BD 1000 59.4 4395 – – – –<br />

A-02YSF(L)2Y 1200x2x.. STIII BD 1200 64.3 5200 – – – –<br />

Application<br />

In all kinds of operating premises (excepted locations with special protection<br />

demands - like in fire or highly combustible premises); e.g. for local area networks<br />

of the telecom, as station communication cables and for small telephone<br />

networks of industry, traffic and public utilities.<br />

Construction<br />

Conductor: solid, bare copper wire Ø 0.4 / 0.6 / 0.8 mm<br />

Insulation: foam-skin-PE (02YS)<br />

Colour code: basic colours of quads: RD, GN, GY, YE, WT<br />

Group mark: side circuit 1 a-core<br />

side circuit 1 b-core<br />

side circuit 2 a-core<br />

side circuit 2 b-core<br />

Cable make up: 4 cores twisted to quads (STIII), 5 quads cabled together to<br />

basic units (BD), tracer units and tracer main units are marked<br />

with an open red helix in each layer, all other basic and<br />

main units are identified with an open white or natural<br />

coloured helix. 5 basic units cabled together to main units<br />

(from 150 DC upwards). Basic-/main units cabled together<br />

in layers to cable core, cable core filled with petrol jelly (F).<br />

Cable core wrapping of paper tape.<br />

Sheath: PE double-coated aluminium foil bonded with the PE-outer<br />

sheath ((L)2Y), black<br />

Laying<br />

suitable for underground laying and pulling into conduits, ducts<br />

Marking<br />

<br />

Technical Details (at 20°C)<br />

standard similar to VDE 0816/part 1<br />

conductor diameter 0.4 0.6 0.8 mm<br />

loop resistance ≤ 300 ≤ 130 ≤ 73.2 Ω/km<br />

insulation resistance<br />

mutual capacitance<br />

≥ 1.5 ≥ 1.5 ≥ 1.5 GΩkm<br />

(at f=800Hz) ≤ 42 ≤ 42 ≤ 42 nF/km<br />

capacitance unbalance k1 (at f=800Hz) 100% ≤ 800 ≤ 800 ≤ 800 pF/300m<br />

98 % ≤ 400 ≤ 400 ≤ 400 pF/300m<br />

capacitance unbalance k9-12 (at f=800Hz) 100% ≤ 300 ≤ 300 ≤ 300 pF/300m<br />

98 % ≤ 100 ≤ 100 ≤ 100 pF/300m<br />

operating voltage (peak value)<br />

dielectric strength<br />

≤ 225 ≤ 225 ≤ 225 V<br />

conductor/conductor 500 500 500 V/50Hz<br />

conductor/shield 2000 2000 2000 V/50Hz<br />

temperature range<br />

during installation -20 up to +50°C<br />

for stationary conditions up to +70 °C<br />

14 <strong>Telecommunication</strong> <strong>Copper</strong> <strong>Cables</strong> • 09/2012 • © by <strong>PENGG</strong> <strong>KABEL</strong> <strong>GmbH</strong> • Subject to technical alterations<br />

C42<br />

Ø<br />

0.4<br />

mutual capacitance<br />

Ø<br />

0.6<br />

Ø<br />

0.8<br />

cable elements<br />

dimension of<br />

conductor<br />

DC<br />

n<br />

number of<br />

double cores<br />

filling<br />

overall shield,<br />

armouring

<strong>Telecommunication</strong>-Outdoor <strong>Cables</strong><br />

Foam-skin-PE-insulated, jelly filled local telecommunication cable A-02YSF(L)2Y ..x2x... STIII BD C52/55<br />

conductor diameter 0.6 mm conductor diameter 0.8 mm<br />

Type number of outer diameter weight outer diameter weight<br />

double cores approx. mm approx. kg/km approx. mm approx. kg/km<br />

A-02YSF(L)2Y 2x2x.. STIII BD 2 8.0 60 9.0 75<br />

A-02YSF(L)2Y 6x2x.. STIII BD 6 10.5 115 12.0 160<br />

A-02YSF(L)2Y 10x2x.. STIII BD 10 12.0 170 13.5 230<br />

A-02YSF(L)2Y 20x2x.. STIII BD 20 15.0 260 17.5 390<br />

A-02YSF(L)2Y 30x2x.. STIII BD 30 16.2 340 19.0 510<br />

A-02YSF(L)2Y 40x2x.. STIII BD 40 17.5 410 21.5 660<br />

A-02YSF(L)2Y 50x2x.. STIII BD 50 19.5 500 24.5 840<br />

A-02YSF(L)2Y 70x2x.. STIII BD 70 21.5 660 26.5 1100<br />

A-02YSF(L)2Y 100x2x.. STIII BD 100 25.5 900 31.0 1500<br />

A-02YSF(L)2Y 150x2x.. STIII BD 150 29.5 1300 40.0 2320<br />

A-02YSF(L)2Y 200x2x.. STIII BD 200 33.0 1700 45.0 3000<br />

A-02YSF(L)2Y 250x2x.. STIII BD 250 36.5 2100 50.0 3740<br />

A-02YSF(L)2Y 300x2x.. STIII BD 300 43.0 2650 54.0 4420<br />

A-02YSF(L)2Y 350x2x.. STIII BD 350 47.0 3100 58.0 5160<br />

Application<br />

In all kinds of operating premises (excepted locations with special protection<br />

demands - like in fire or highly combustible premises); e.g. for local area networks<br />

of the telecom, as station communication cables and for small telephone<br />

networks of industry, traffic and public utilities.<br />

Construction<br />

Conductor: solid, bare copper wire Ø 0.6 / 0.8 mm<br />

Insulation: foam-skin-PE (02YS)<br />

Colour code: basic colours of quads: RD, GN, GY, YE, WT<br />

Group mark: side circuit 1 a-core<br />

side circuit 1 b-core<br />

side circuit 2 a-core<br />

side circuit 2 b-core<br />

Cable make up: 4 cores twisted to quads (STIII), 5 quads cabled together to<br />

basic units (BD), tracer units and tracer main units are marked<br />

with an open red helix in each layer, all other basic and<br />

main units are identified with an open white or natural<br />

coloured helix. 5 basic units cabled together to main units<br />

(from 150 DC upwards). Basic-/main units cabled together<br />

in layers to cable core, cable core filled with petrol jelly (F).<br />

Cable core wrapping of paper tape.<br />

Sheath: PE double-coated aluminium foil bonded with the PE-outer<br />

sheath ((L)2Y), black<br />

Laying<br />

suitable for underground laying and pulling into conduits, ducts<br />

Marking<br />

<br />

C52<br />

Ø<br />

0.6<br />

C55<br />

Ø<br />

0.8<br />

cable elements<br />

Technical Details (at 20°C)<br />

mutual capacitance<br />

dimension of<br />

conductor<br />

standard similar to VDE 0816/part 1<br />

conductor diameter 0.6 0.8 mm<br />

loop resistance ≤ 130 ≤ 73.2 Ω/km<br />

insulation resistance ≥ 1.5 ≥ 1.5 GΩkm<br />

mutual capacitance<br />

(at f=800Hz) 100% ≤ 52 ≤ 55 nF/km<br />

95 % ≤ 50 ≤ 53 nF/km<br />

80 % ≤ 48 ≤ 50 nF/km<br />

capacitance unbalance k1 (at f=800Hz) 100% ≤ 800 ≤ 800 pF/300m<br />

98 % ≤ 400 ≤ 400 pF/300m<br />

capacitance unbalance k9-12 (at f=800Hz) 100% ≤ 300 ≤ 300 pF/300m<br />

98 % ≤ 100 ≤ 100 pF/300m<br />

operating voltage (peak value)<br />

dielectric strength<br />

≤ 225 ≤ 225 V<br />

conductor/conductor 500 500 V/50Hz<br />

conductor/shield 2000 2000 V/50Hz<br />

temperature range<br />

during installation -20 up to +50 °C<br />

for stationary conditions up to +70 °C<br />

<strong>Telecommunication</strong> <strong>Copper</strong> <strong>Cables</strong> • 09/2012 • © by <strong>PENGG</strong> <strong>KABEL</strong> <strong>GmbH</strong> • Subject to technical alterations 15<br />

DC<br />

n<br />

number of<br />

double cores<br />

filling<br />

overall shield,<br />

armouring

<strong>Telecommunication</strong>-Outdoor <strong>Cables</strong><br />

Foam-skin-PE-insulated, jelly filled local telecommunication cable A-02YSOF(L)2Y ..x2x.. STIII BD<br />

conductor diameter 0.6 mm conductor diameter 0.8 mm<br />

Type number of outer diameter weight outer diameter weight<br />

double cores approx. mm approx. kg/km approx. mm approx. kg/km<br />

A-02YSOF(L)2Y 6x2x.. STIII BD 6 10.0 115 11.5 150<br />

A-02YSOF(L)2Y 10x2x.. STIII BD 10 11.5 150 13.5 215<br />

A-02YSOF(L)2Y 20x2x.. STIII BD 20 14.0 235 17.0 360<br />

A-02YSOF(L)2Y 30x2x.. STIII BD 30 16.0 320 19.5 490<br />

A-02YSOF(L)2Y 40x2x.. STIII BD 40 17.5 400 21.5 630<br />

A-02YSOF(L)2Y 50x2x.. STIII BD 50 19.0 480 23.5 770<br />

A-02YSOF(L)2Y 70x2x.. STIII BD 70 21.5 630 27.0 1020<br />

A-02YSOF(L)2Y 100x2x.. STIII BD 100 25.0 870 31.5 1400<br />

A-02YSOF(L)2Y 150x2x.. STIII BD 150 30.0 1240 37.5 2050<br />

A-02YSOF(L)2Y 200x2x.. STIII BD 200 34.0 1610 42.5 2700<br />

Application<br />

In all kinds of operating premises (excepted locations with special protection<br />

demands - like in fire or highly combustible premises); e.g. for local area networks<br />

of the telecom, as station communication cables and for small telephone<br />

networks of industry, traffic and public utilities.<br />

Construction<br />

Conductor: solid, bare copper wire Ø 0.6 / 0.8 mm<br />

Insulation: foam-skin-PE (02YS)<br />

Colour code: basic colours of quads: RD, GN, GY, YE, WT<br />

Group mark: side circuit 1 a-core<br />

side circuit 1 b-core<br />

side circuit 2 a-core<br />

side circuit 2 b-core<br />

Cable make up: 4 cores twisted to quads (STIII), 5 quads cabled together to<br />

basic units (BD), tracer units and tracer main units are marked<br />

with an open red helix in each layer, all other basic and<br />

main units are identified with an open white or natural<br />

coloured helix. 5 basic units cabled together to main units<br />

(from 150 DC upwards). Basic-/main units cabled together<br />

in layers to cable core, cable core is filled with a special filling<br />

material (OF). Cable core wrapping of paper tape.<br />

Sheath: PE double-coated aluminium foil bonded with the PE-outer<br />

sheath ((L)2Y), black<br />

Laying<br />

suitable for underground laying and pulling into conduits, ducts<br />

Marking<br />

<br />

Technical Details (at 20°C)<br />

standard similar to VDE 0816/part 1<br />

conductor diameter 0.6 0.8 mm<br />

loop resistance ≤ 130 ≤ 73.2 Ω/km<br />

insulation resistance<br />

mutual capacitance<br />

≥ 1.5 ≥ 1.5 GΩkm<br />

(at f=800Hz) ≤ 52 ≤ 55 nF/km<br />

capacitance unbalance k1 (at f=800Hz) ≤ 800 ≤ 800 pF/300m<br />

capacitance unbalance k9-12 (at f=800Hz) ≤ 300 ≤ 300 pF/300m<br />

operating voltage (peak value)<br />

Dielectric strength<br />

≤ 225 ≤ 225 V<br />

conductor/conductor 500 V/50Hz<br />

conductor/shield 2000 V/50Hz<br />

temperature range<br />

during installation -20 up to +50 °C<br />

for stationary conditions up to +70 °C<br />

16 <strong>Telecommunication</strong> <strong>Copper</strong> <strong>Cables</strong> • 09/2012 • © by <strong>PENGG</strong> <strong>KABEL</strong> <strong>GmbH</strong> • Subject to technical alterations<br />

C52<br />

Ø<br />

0.6<br />

C55<br />

Ø<br />

0.8<br />

cable elements<br />

mutual capacitance<br />

dimension of<br />

conductor<br />

DC<br />

n<br />

number of<br />

double cores<br />

filling<br />

overall shield,<br />

armouring

<strong>Telecommunication</strong>-Outdoor <strong>Cables</strong><br />

Polyethylen-insulated, jelly filled power line protection cable AD-2YF(L)2Y ..<br />

Type number outer diameter weight<br />

triples/pairs approx. mm approx. kg/km<br />

AD-2YF(L)2Y 1/ 9 1/ 9 16.9 330<br />

AD-2YF(L)2Y 1/24 1/24 22.0 596<br />

AD-2YF(L)2Y 3/ 3 3/ 3 18.4 394<br />

AD-2YF(L)2Y 3/18 3/18 25.5 739<br />

AD-2YF(L)2Y 3/42 3/42 28.7 1078<br />

AD-2YF(L)2Y 4/19 4/19 24.0 793<br />

AD-2YF(L)2Y 7/22 7/22 27.6 1024<br />

AD-2YF(L)2Y 7/24 7/24 30.6 1131<br />

AD-2YF(L)2Y 7/50 7/50 33.1 1482<br />

Application<br />

For connecting of power line protection equipment, e.g. differential protection<br />

equipment in power systems, for telephone purposes and for transmission of<br />

signals.<br />

Construction<br />

Conductor: solid, bare copper wire Ø 0.8 and Ø 1.4 mm<br />

Insulation: PE (2Y)<br />

Colour code: basic colours of pair: YE, RD<br />

basic colours of triples: YE, RD, GN<br />

the tracer triple and the tracer pair are marked with a<br />

red helix<br />

Cable make up: 3 cores twisted to triples (diameter 1.4),<br />

2 cores twisted to pairs (diameter 0.8),<br />

triples and pairs cabled together in layers to cable core,<br />

cable core filled with petrol jelly (F), cable core wrapping<br />

with paper tape<br />

Sheath: PE double-coated aluminium foil bonded with the PEouter<br />

sheath ((L)2Y), black<br />

Laying<br />

suitable for underground laying and pulling into conduits, ducts<br />

Marking<br />

<br />

C60<br />

Ø<br />

0.8<br />

mutual capacitance<br />

Ø<br />

1.4<br />

dimension of<br />

conductor<br />

cable elements<br />

Technical Details (at 20°C)<br />

standard -<br />

conductor diameter 0.8 1.4 mm<br />

conductor resistance – ≤ 11.9 Ω/km<br />

loop resistance ≤ 73.2 – Ω/km<br />

insulation resistance<br />

mutual capacitance (H60)<br />

≥ 5 ≥ 5 GΩkm<br />

(at f=800Hz), max. 60 – nF/km<br />

dielectric strength<br />

temperature range<br />

2000V/50Hz conductor/conductor (pair)<br />

2000V/50Hz pair/pair<br />

2000V/50Hz conductor (pair)/shield<br />

2500V/50Hz conductor/conductor (triples)<br />

8000V/50Hz triples/triples<br />

8000V/50Hz pair/triples<br />

8000V/50Hz core (triples)/shield<br />

during installation –20 up to +50 °C<br />

for stationary conditions up to +70 °C<br />

<strong>Telecommunication</strong> <strong>Copper</strong> <strong>Cables</strong> • 09/2012 • © by <strong>PENGG</strong> <strong>KABEL</strong> <strong>GmbH</strong> • Subject to technical alterations 17<br />

DC<br />

n<br />

number of<br />

double cores<br />

filling<br />

overall shield,<br />

armouring

<strong>Telecommunication</strong>-Outdoor <strong>Cables</strong><br />

Note<br />

18 <strong>Telecommunication</strong> <strong>Copper</strong> <strong>Cables</strong> • 09/2012 • © by <strong>PENGG</strong> <strong>KABEL</strong> <strong>GmbH</strong> • Subject to technical alterations

<strong>Telecommunication</strong>-Outdoor <strong>Cables</strong><br />

Foam-skin-PE-insulated, armoured telecom hybrid cable BAL<br />

Type number of outer diameter weight<br />

double cores approx. mm approx. kg/km<br />

CU/SPE/SWM/FOL/AL/FRNC/SR/FRNC 4x2x0.5 + 2xG657A 4 13.0 179<br />

Application<br />

This hybrid cable is designed for outdoor application in high speed access<br />

telecommunication networks in customer premises.<br />

Construction<br />

Conductor: solid, bare copper wire Ø 0.5 mm<br />

Insulation: PE foam skin<br />

Colour code: WT/BU, WT/OR, WT/GN, WT/BN<br />

Cable make up: cores twisted to pairs, pairs and fiber optic duplex cable<br />

(I-VQH 2E9/125) stranded around a central element, wrapped<br />

with swellable tape, plus 1 tinned copper wire.<br />

Sheath: Aluminium laminated FRNC sheath, orange.<br />

Armouring: corrugated steel tape<br />

Protective cover: FRNC sheath, orange<br />

Marking<br />

according customers requirements<br />

C49 mutual capacitance<br />

4<br />

Ø<br />

0.5<br />

dimension of<br />

conductor<br />

cable elements<br />

Technical Details (at 20°C)<br />

standard TDK-TS 900 010<br />

conductor diameter 0.5 mm<br />

conductor resistance ≤ 95.1 Ω/km<br />

resistance unbalance ≤ 2 %<br />

insulation resistance ≥ 1.5 GΩkm<br />

mutual capacitance (at f=800Hz)<br />

capacitance unbalance<br />

≤ 49 nF/km<br />

K1 100% ≤ 250 pF/500m<br />

K1 90%<br />

dielectric strength<br />

≤ 150 pF/500m<br />

conductor/conductor 330 Veff/50Hz/1min<br />

conductor/conductor 670 Veff/50Hz/3sec<br />

conductor/screen 2000 Veff/50Hz/1min<br />

<strong>Telecommunication</strong> <strong>Copper</strong> <strong>Cables</strong> • 09/2012 • © by <strong>PENGG</strong> <strong>KABEL</strong> <strong>GmbH</strong> • Subject to technical alterations 19<br />

TF<br />

number of cores<br />

filling<br />

overall shield,<br />

armouring

<strong>Telecommunication</strong>-Outdoor <strong>Cables</strong><br />

Foam-PE-insulated local telecommunication cable CU/SPE/FOL/AL+PE<br />

conductor diameter 0.4 mm conductor diameter 0.5 mm conductor diameter 0.7 mm<br />

Type number of outer diameter weight outer diameter weight outer diameter weight<br />

double cores approx. mm approx. kg/km approx mm approx. kg/km approx. mm approx. kg/km<br />

CU/SPE/FOL/AL+PE 50x2x... 50 - - 20 370 - -<br />

CU/SPE/FOL/AL+PE 100x2x... 100 - - 26 670 - -<br />

CU/SPE/FOL/AL+PE 200x2x... 200 - - 36 1220 49 2270<br />

CU/SPE/FOL/AL+PE 300x2x... 300 - - - - 59 3320<br />

CU/SPE/FOL/AL+PE 400x2x... 400 - - - - 67 4380<br />

CU/SPE/FOL/AL+PE 600x2x... 600 - - 59 3410 81 6340<br />

CU/SPE/FOL/AL+PE 800x2x... 800 - - 68 4470 - -<br />

CU/SPE/FOL/AL+PE 1000x2x... 1000 - - 75 5490 - -<br />

CU/SPE/FOL/AL+PE 1200x2x... 1200 70 4430 - - - -<br />

CU/SPE/FOL/AL+PE 2000x2x... 2000 88 7100 - - - -<br />

Application<br />

In all kinds of operating premises (excepted locations with special protection<br />

demands - like in fire or highly combustible premises); e.g. for local area networks<br />

of the telecom, as station communication cables and for small telephone<br />

networks of industry, traffic and public utilities.<br />

Construction<br />

Conductor: solid, bare copper wire Ø 0.4 / 0.5 / 0.7mm (CU)<br />

Insulation: Foam-PE (SPE)<br />

Colour code: WT/BU, WT/OR, WT/GN, WT/BN, WT/GY, RD/BU,<br />

RD/OR, RD/GN, RD/BN, RD/GY<br />

Cable make up: 2 cores twisted to pairs, 10 pairs stranded together to<br />

units, units stranded together in concentric layers to<br />

cable core (≤ 200 pairs), unit identification with<br />

numbers, cables with ≥ 200 pairs: groups with 50 or 100<br />

pairs, in each group the units are identified with numbers<br />

(1-5 bzw. 1-10, first group red, the last green coloured),<br />

wrapping with plastic foil (FOL)<br />

Drain wire: tinned copper wire Ø 0.6 mm<br />

Sheath: PE single-coated aluminium foil bonded with the PEouter<br />

sheath (AL+PE), orange<br />

Laying<br />

suitable for underground laying and pulling into conduits, ducts<br />

Marking<br />

<br />

Technical Details (at 20°C)<br />

standard TDK-TS 900 010<br />

conductor diameter 0.4 0.5 0.7 mm<br />

conductor resistance core ≤ 150.0 ≤ 95.9 ≤ 49.0 Ω/km<br />

mean value ≤ 144.0 ≤ 92.1 ≤ 47.0 Ω/km<br />

conductor resistance difference of ≤ 2% ≤ 2% ≤ 2%<br />

insulation resistance ≥ 5 ≥ 5 ≥ 5 GΩkm<br />

mutual capacitance nominal value 40 40 40 nF/km<br />

(at f=800Hz) pair ≤ 49 ≤ 49 ≤ 49 nF/km<br />

mean v. (≥ 20 pairs) ≤ 42<br />

capacitance unbalance<br />

≤ 42 ≤ 42 nF/km<br />

(at f=800Hz) 100 % ≤ 250 ≤ 250 ≤ 250 pF/500m<br />

95% ≤ 150 ≤ 150 ≤ 150 pF/500m<br />

operating voltage ≤ 50 ≤ 50 ≤ 50 V AC<br />

dielectric strength<br />

≤ 75 ≤ 75 ≤ 75 V DC<br />

conductor/conductor 330 330 330 V/50Hz<br />

conductor/shield 2000 2000 2000 V/50Hz<br />

temperature range<br />

during installation -20 up to +50 °C<br />

for stationary conditions up to +70 °C<br />

20 <strong>Telecommunication</strong> <strong>Copper</strong> <strong>Cables</strong> • 09/2012 • © by <strong>PENGG</strong> <strong>KABEL</strong> <strong>GmbH</strong> • Subject to technical alterations<br />

C40<br />

Ø<br />

0.4<br />

mutual capacitance<br />

Ø<br />

0.5<br />

Ø<br />

0.7<br />

cable elements<br />

dimension of<br />

conductor<br />

DC<br />

n<br />

number of<br />

double cores<br />

filling<br />

overall shield,<br />

armouring

<strong>Telecommunication</strong>-Outdoor <strong>Cables</strong><br />

Foam-PE-insulated, filled local telecommunication cable CU/SPE/VAS/FOL/AL+PE<br />

conductor diameter 0.4 mm conductor diameter 0.5mm conductor diameter 0.7 mm<br />

Type number of outer diameter weight outer diameter weight outer diameter weight<br />

double cores approx. mm approx. kg/km approx. mm approx. kg/km approx. mm approx. kg/km<br />

CU/SPE/VAS/FOL/AL+PE 2x2x... 2 - - 9.0 70 - -<br />

CU/SPE/VAS/FOL/AL+PE 4x2x... 4 - - 9.0 80 - -<br />

CU/SPE/VAS/FOL/AL+PE 5x2x... 5 9.0 70 10.0 90 - -<br />

CU/SPE/VAS/FOL/AL+PE 10x2x... 10 10.0 100 12.0 140 15.0 215<br />

CU/SPE/VAS/FOL/AL+PE 20x2x... 20 13.0 160 15.0 220 19.0 360<br />

CU/SPE/VAS/FOL/AL+PE 30x2x... 30 15.0 220 17.0 295 20.0 500<br />

CU/SPE/VAS/FOL/AL+PE 50x2x... 50 18.0 330 20.0 440 27.0 790<br />

CU/SPE/VAS/FOL/AL+PE 100x2x... 100 23.0 570 27.0 805 36.0 1490<br />

CU/SPE/VAS/FOL/AL+PE 200x2x... 200 31.0 1050 36.0 1510 - -<br />

CU/SPE/VAS/FOL/AL+PE 400x2x... 400 42.0 1970 50.0 2890 - -<br />

CU/SPE/VAS/FOL/AL+PE 600x2x... 600 50.0 2900 60.0 4250 - -<br />

CU/SPE/VAS/FOL/AL+PE 700x2x... 700 - - 64.0 4913<br />

CU/SPE/VAS/FOL/AL+PE 800x2x... 800 58.0 3830 68.0 5590 - -<br />

CU/SPE/VAS/FOL/AL+PE 1000x2x... 1000 64.0 4690 76.0 6880 - -<br />

Application<br />

In all kinds of operating premises (excepted locations with special protection<br />

demands - like in fire or highly combustible premises); e.g. for local area networks<br />

of the telecom, as station communication cables and for small telephone<br />

networks of industry, traffic and public utilities.<br />

Construction<br />

Conductor: solid, bare copper wire Ø 0.4 / 0.5 / 0.7 mm (CU)<br />

Insulation: foam-PE (SPE)<br />

Colour code: WT/BU, WT/OR, WT/GN, WT/BN, WS/GY, RD/BU,<br />

RD/OR, RD/GN, RD/BN, RD/GY<br />

Cable make up: 2 cores twisted to pairs, 10 pairs stranded together to<br />

units, units stranded together in concentric layers to<br />

cable core (≤ 200 pairs), unit identification with<br />

numbers, cables with ≥ 200 pairs: groups with 50 or<br />

100 pairs, in each group the units are identified with<br />

numbers (1-5 bzw. 1-10; first group red, the last green<br />

coloured), cable core filled with petrol jelly (VAS), wrapping<br />

with plastic foil (FOL)<br />

Drain wire: tinned copper wire Ø 0.6 mm<br />

Sheath: PE single-coated aluminium foil bonded with the PEouter<br />

sheath (AL+PE), orange<br />

Laying<br />

suitable for underground laying and pulling into conduits, ducts<br />

Marking<br />

<br />

<br />

C40<br />

Ø<br />

0.4<br />

mutual capacitance<br />

Ø<br />

0.5<br />

Ø<br />

0.7<br />

cable elements<br />

dimension of<br />

conductor<br />

Technical Details (at 20°C)<br />

standard TDK-TS 900 010<br />

conductor diameter 0.4 0.5 0.7 mm<br />

conductor resistance core ≤ 150.0 ≤ 95.9 ≤ 49.0 Ω/km<br />

mean value ≤ 144.0 ≤ 92.1 ≤ 47.0 Ω/km<br />

conductor resistance difference of ≤ 2% ≤ 2% ≤ 2%<br />

insulation resistance ≥ 1.5 ≥ 1.5 ≥ 1.5 GΩkm<br />

mutual capacitance nominal value 40 40 40 nF/km<br />

(at f=800Hz) pair ≤ 49 ≤ 49 ≤ 49 nF/km<br />

mean V. (≥ 20 pairs) ≤ 42<br />

capacitance unbalance<br />

≤ 42 ≤ 42 nF/km<br />

(at f=800Hz) 100% ≤ 250 ≤ 250 ≤ 250 pF/500m<br />

95% ≤ 150 ≤ 150 ≤ 150 pF/500m<br />

operating voltage ≤ 50 ≤ 50 ≤ 50 V AC<br />

dielectric strength<br />

≤ 75 ≤ 75 ≤ 75 V DC<br />

conductor/conductor 330 330 330 V/50Hz<br />

conductor/shield 2000 2000 2000 V/50Hz<br />

temperature range<br />

during installation -20 up to +50 °C<br />

for stationary conditions up to +70 °C<br />

<strong>Telecommunication</strong> <strong>Copper</strong> <strong>Cables</strong> • 09/2012 • © by <strong>PENGG</strong> <strong>KABEL</strong> <strong>GmbH</strong> • Subject to technical alterations 21<br />

DC<br />

n<br />

F<br />

number of<br />

double cores<br />

filling<br />

overall shield,<br />

armouring

<strong>Telecommunication</strong>-Outdoor <strong>Cables</strong><br />

Foam-PE-insulated, filled and armoured local telecomm. cable CU/SPE/VAS/FOL/AL+PE/ARM/PE<br />

Type number of outer diameter weight<br />

double cores approx. mm approx. kg/km<br />

CU/SPE/VAS/FOL/AL+PE /ARM/PE 4x2x0.5 4 14.0 220<br />

CU/SPE/VAS/FOL/AL+PE /ARM/PE 5x2x0.5 5 15.0 250<br />

CU/SPE/VAS/FOL/AL+PE /ARM/PE 10x2x0.5 10 16.0 310<br />

CU/SPE/VAS/FOL/AL+PE /ARM/PE 20x2x0.5 20 19.0 430<br />

CU/SPE/VAS/FOL/AL+PE /ARM/PE 30x2x0.5 30 21.0 550<br />

CU/SPE/VAS/FOL/AL+PE /ARM/PE 50x2x0.5 50 26.0 760<br />

CU/SPE/VAS/FOL/AL+PE /ARM/PE 1002x0.5 100 32.0 1200<br />

Application<br />

In all kinds of operating premises (excepted locations with special protection<br />

demands - like in fire or highly combustible premises); e.g. for local area networks<br />

of the telecom, as station communication cables and for small telephone<br />

networks of industry, traffic and public utilities.<br />

Construction<br />

Conductor: solid, bare copper wire Ø 0.5 mm (CU)<br />

Insulation: foam-PE (SPE)<br />

Colour code: WT/BU, WT/OR, WT/GN, WT/BN, WS/GY, RD/BU,<br />

RD/OR, RD/GN, RD/BN, RD/GY<br />

Cable make up: 2 cores twisted to pairs, 10 pairs stranded together to<br />

units, units stranded together in concentric layers to<br />

cable core (≤ 200 pairs), unit identification with<br />

numbers, cables with ≥ 200 pairs: groups with 50 or<br />

100 pairs, in each group the units are identified with<br />

numbers (1-5 bzw. 1-10; first group red, the last green<br />

coloured), cable core filled with petrol jelly (VAS),<br />

wrapping with plastic foil (FOL)<br />

Drain wire: tinned copper wire Ø 0.6 mm<br />

Sheath: PE single-coated aluminium foil bonded with the PEouter<br />

sheath (AL+PE), orange<br />

Armouring: 2 layers galvanized steel tape (ARM)<br />

Protective cover: PE, orange (PE)<br />

Laying<br />

suitable for underground laying and pulling into conduits, ducts<br />

Marking<br />

<br />

<br />

Technical Details (at 20°C)<br />

standard TDK-TS 900 010<br />

conductor diameter 0.5 mm<br />

conductor resistance core ≤ 95.9 Ω/km<br />

mean value ≤ 92.1 Ω/km<br />

conductor resistance difference of ≤ 2%<br />

insulation resistance ≥ 1.5 GΩkm<br />

mutual capacitance nominal value 40 nF/km<br />

(at f=800Hz) pair ≤ 49 nF/km<br />

mean value (≥ 20 pairs) ≤ 42 nF/km<br />

capacitance unbalance<br />

(at f=800Hz) 100% ≤ 250 pF/500m<br />

95% ≤ 150 pF/500m<br />

operating voltage ≤ 50 V AC<br />

≤ 75 V DC<br />

dielectric strength conductor/conductor 330 V/50Hz<br />

conductor/shield 2000 V/50Hz<br />

temperature range<br />

during installation -20 up to +50 °C<br />

for stationary conditions up to +70 °C<br />

22 <strong>Telecommunication</strong> <strong>Copper</strong> <strong>Cables</strong> • 09/2012 • © by <strong>PENGG</strong> <strong>KABEL</strong> <strong>GmbH</strong> • Subject to technical alterations<br />

C40<br />

Ø<br />

0.5<br />

mutual capacitance<br />

dimension of<br />

conductor<br />

cable elements<br />

DC<br />

n<br />

F<br />

number of<br />

double cores<br />

filling<br />

overall shield,<br />

armouring

<strong>Telecommunication</strong>-Outdoor <strong>Cables</strong><br />

Polyethylene-insulated, filled telecommunication- and signal cable CU+TIN/PE/VAS/FOL/PE<br />

Type number of outer diameter weight<br />

double cores approx. mm approx. kg/km<br />

CU+TIN/PE/VAS/FOL/PE 5x2x0.7 4 8.0 88<br />

CU+TIN/PE/VAS/FOL/PE 10x2x0.7 5 11.0 132<br />

CU+TIN/PE/VAS/FOL/PE 20x2x0.7 20 14.0 264<br />

CU+TIN/PE/VAS/FOL/PE 30x2x0.7 30 16.0 379<br />

CU+TIN/PE/VAS/FOL/PE 50x2x0.7 50 21.0 617<br />

CU+TIN/PE/VAS/FOL/PE 100x2x0.7 100 26.8 1150<br />

Application<br />

In all kinds of operating premises (excepted locations with special protection<br />

demands - like in fire or highly combustible premises); e.g. for local area networks<br />

of the telecom, as station communication cables and for small telephone<br />

networks of industry, traffic and public utilities.<br />

Construction<br />

Conductor: solid, tinned copper wire Ø 0.7 mm (CU+TIN)<br />

Insulation: PE (PE)<br />

Colour code: WT/BU, WT/OR, WT/GN, WT/BN, WT/GY, RD/BU,<br />

RD/OR, RD/GN, RD/BN, RD/GY<br />

Cable make up: 2 cores twisted to pairs, 10 pairs stranded together to<br />

units, units stranded together in concentric layers to<br />

cable core, unit identification with numbers, cable core<br />

filled with petrol jelly (VAS), wrapping with plastic foil<br />

(FOL)<br />

Sheath: PE, black (PE)<br />

Laying<br />

suitable for underground laying and pulling into conduits, ducts<br />

Marking<br />

<br />

<br />

Note<br />

other sheath colour on request<br />

C70<br />

Ø<br />

0.7<br />

mutual capacitance<br />

dimension of<br />

conductor<br />

cable elements<br />

Technical Details (at 20°C)<br />

standard NKT, IEC60708-1<br />

<strong>Telecommunication</strong> <strong>Copper</strong> <strong>Cables</strong> • 09/2012 • © by <strong>PENGG</strong> <strong>KABEL</strong> <strong>GmbH</strong> • Subject to technical alterations 23<br />

DC<br />

n<br />

conductor diameter 0.7 mm<br />

conductor resistance (core) ≤ 48.0 Ω/km<br />

insulation resistance ≥ 1.5 GΩkm<br />

mutual capacitance nominal value 70 nF/km<br />

(at f=800Hz) pair ≤ 84 nF/km<br />

mean value ≤ 77 nF/km<br />

capacitance unbalance k<br />

(at f=800Hz) 100% ≤ 250 pF/500m<br />

capacitance unbalance e<br />

(at f=800Hz) 100% ≤ 1700 pF/500m<br />

operating voltage ≤ 50 V AC<br />

≤ 75 V DC<br />

dielectric strength conductor/conductor 1200 V DC<br />

bending radius > 15x outer diameter<br />

tensile strength ≤ 10 N/mm2 temperature range<br />

during installation -20 up to +50 °C<br />

for stationary conditions up to +70 °C<br />

F<br />

number of<br />

double cores<br />

filling<br />

overall shield,<br />

armouring

<strong>Telecommunication</strong>-Outdoor <strong>Cables</strong><br />

Polyethylene-insulated, filled telecommunication- and signal cable CU+TIN/PE/VAS/FOL/AL+PE<br />

Type number of outer diameter weight<br />

double cores (DC) approx. mm approx. kg/km<br />

CU+TIN/PE/VAS/FOL/AL+PE 5x2x0,7 4 10,0 122<br />

CU+TIN/PE/VAS/FOL/AL+PE 10x2x0,7 5 12,0 168<br />

CU+TIN/PE/VAS/FOL/AL+PE 20x2x0,7 20 15,0 299<br />

CU+TIN/PE/VAS/FOL/AL+PE 30x2x0,7 30 17,0 419<br />

CU+TIN/PE/VAS/FOL/AL+PE 40x2x0,7 Green 40 18,0 517<br />

CU+TIN/PE/VAS/FOL/AL+PE 50x2x0,7 50 23,0 679<br />

Application<br />

In all kinds of operating premises (excepted locations with special protection<br />

demands - like in fire or highly combustible premises); e.g. for local area networks<br />

of the telecom, as station communication cables and for small telephone<br />

networks of industry, traffic and public utilities.<br />

Construction<br />

Conductor: solid, tinned copper wire Ø 0.7 mm (CU+TIN)<br />

Insulation: PE (PE)<br />

Colour code: WT/BU, WT/OR, WT/GN, WT/BN, WT/GY, RD/BU,<br />

RD/OR, RD/GN, RD/BN, RD/GY<br />

Cable make up: 2 cores twisted to pairs, 10 pairs stranded together to<br />

units, units stranded together in concentric layers to<br />

cable core, unit identification with numbers, cable core<br />

filled with petrol jelly (VAS), wrapping with plastic foil<br />

(FOL)<br />

Drain wire: tinned copper wire Ø 0.6 mm<br />

Sheath: PE single-coated aluminium foil bonded with the PEouter<br />

sheath (AL+PE), black<br />

Laying<br />

suitable for underground laying and pulling into conduits, ducts<br />

Marking<br />

<br />

<br />

Note<br />

other sheath colour on request<br />

24 <strong>Telecommunication</strong> <strong>Copper</strong> <strong>Cables</strong> • 09/2012 • © by <strong>PENGG</strong> <strong>KABEL</strong> <strong>GmbH</strong> • Subject to technical alterations<br />

C70<br />

Ø<br />

0.7<br />

mutual capacitance<br />

dimension of<br />

conductor<br />

cable elements<br />

Technical Details (at 20°C)<br />

standard NKT, IEC60708-1<br />

DC<br />

n<br />

conductor diameter 0.7 mm<br />

conductor resistance (core) ≤ 48.0 Ω/km<br />

insulation resistance ≥ 1.5 GΩkm<br />

mutual capacitance nominal value 70 nF/km<br />

(at f=800Hz) pair ≤ 84 nF/km<br />

mean value ≤ 77 nF/km<br />

capacitance unbalance k<br />

(at f=800Hz) 100 % ≤ 250 pF/500m<br />

capacitance unbalance e<br />

(at f=800Hz) 100 % ≤ 1700 pF/500m<br />

operating voltage ≤ 50 V AC<br />

≤ 75 V DC<br />

dielectric strength conductor/conductor 1200 V DC<br />

bending radius > 15x outer diameter<br />

tensile strength ≤ 10 N/mm2 temperature range<br />

during installation -20 up to +40 °C<br />

for stationary conditions up to +70 °C<br />

F<br />

number of<br />

double cores<br />

filling<br />

overall shield,<br />

armouring

<strong>Telecommunication</strong>-Outdoor <strong>Cables</strong><br />

Polyethylene-insulated subscriber cable TK-..x4/..-PE-ALT<br />

conductor diameter 0.6 mm conductor diameter 0.8 mm<br />

Type number of outer diameter weight outer diameter weight<br />

double cores approx. mm approx. kg/km approx. mm approx. kg/km<br />

TK 1x4/..-PE-ALT 2 7.8 65 8.8 83<br />

TK 3x4/..-PE-ALT 6 10.6 112 12.6 164<br />

TK 5x4/..-PE-ALT 10 12.1 159 15.3 250<br />

TK10x4/..-PE-ALT 20 16.6 270 20.1 406<br />

TK15x4/..-PE-ALT 30 18.4 356 22.7 541<br />

TK20x4/..-PE-ALT 40 21.4 453 26.8 731<br />

TK30x4/..-PE-ALT 60 22.9 590 29.0 975<br />

TK40x4/..-PE-ALT 80 25.7 773 32.1 1242<br />

TK50x4/..-PE-ALT 100 28.6 926 36.4 1543<br />

TK60x4/..-PE-ALT 120 30.2 1076 38.5 1802<br />

TK100x4/..-PE-ALT 200 38.5 1726 49.6 2912<br />

Application<br />

In all kinds of operating premises (excepted locations with special protection<br />

demands - like in fire or highly combustible premises). In telecommunication<br />

network systems and similar systems, for example as PTT subscriber’s cable.<br />

Construction<br />

Conductor: solid, bare copper wire Ø 0.6 / 0.8 mm<br />

Insulation: PE (PE)<br />

Colour code: tracer quad: WT-OR-TQ-VI<br />

counter quad: WT-GN-TQ-VI<br />

standard quad 1: WT-BN-TQ-VI<br />

standard quad 2: WT-GY-TQ-VI<br />

Cable make up: 4 cores twisted to quads, quads stranded together in<br />

concentric layers to cable core, cable core wrapping<br />

with plastic foil<br />

Sheath: PE single-coated aluminium foil bonded with the PEouter<br />

sheath (ALT), black, one or two drain wire(s)<br />

Design<br />

2-200 DC (1 up to 100 quads)<br />

Laying<br />

suitable for underground laying and pulling into conduits, ducts<br />

Marking<br />

< ..x4/.. PE-ALT> <br />

<br />

C40<br />

Ø<br />

0.6<br />

mutual capacitance<br />

Ø<br />

0.8<br />

dimension of<br />

conductor<br />

cable elements<br />

Technical Details (at 20°C)<br />

standard acc. PTT 844.14<br />

conductor diameter 0.6 0.8 mm<br />

loop resistance ≤ 133 ≤ 73.5 Ω/km<br />

insulation resistance ≥ 10 ≥ 10 GΩkm<br />

mutual capacitance spec.value 40±9 40±9 nF/km<br />

(at f=800Hz) mean value 1) 40±3 40±3 nF/km<br />

capacitance unbalance k 1<br />

(at f=800Hz) mean value 1) ≤ 50 ≤ 50 pF/230m<br />

capacitance unbalance k 9-12<br />

(at f=800Hz) mean value 1) ≤ 30 ≤ 30 pF/230m<br />

capacitance unbalance e a1<br />

(at f=800Hz) ≤ 400 ≤ 400 pF/230m<br />

mean value 1) ≤ 100 ≤ 100 pF/230m<br />

dielectric strength<br />

conductor/conductor 500V/50Hz<br />

conductor/shield 2000V/50Hz<br />

1) for cables with 20 and more elements<br />

<strong>Telecommunication</strong> <strong>Copper</strong> <strong>Cables</strong> • 09/2012 • © by <strong>PENGG</strong> <strong>KABEL</strong> <strong>GmbH</strong> • Subject to technical alterations 25<br />

DC<br />

n<br />

number of<br />

double cores<br />

filling<br />

overall shield,<br />

armouring

<strong>Telecommunication</strong>-Outdoor <strong>Cables</strong><br />

Polyethylene-insulated subscriber cable TK-..x4/..-PE-ALT-CLT<br />

conductor diameter 0.6 mm conductor diameter 0.8 mm<br />

Type number of outer diameter weight outer diameter weight<br />

double cores approx. mm approx. kg/km approx. mm approx. kg/km<br />

TK1x4/..-PE-ALT-CLT 2 12.0 161 13.0 190<br />

TK3x4/..-PE-ALT-CLT 6 14.8 238 16.8 310<br />

TK5x4/..-PE-ALT-CLT 10 16.3 300 19.5 425<br />

TK10x4/..-PE-ALT-CLT 20 20.8 459 24.3 631<br />

TK15x4/..-PE-ALT-CLT 30 22.6 564 26.9 794<br />

TK20x4/..-PE-ALT-CLT 40 25.6 692 31.0 1027<br />

TK30x4/..-PE-ALT-CLT 60 27.1 846 33.2 1295<br />

TK40x4/..-PE-ALT-CLT 80 29.9 1058 36.3 1594<br />

TK50x4/..-PE-ALT-CLT 100 32.8 1241 40.6 1940<br />

TK60x4/..-PE-ALT-CLT 120 34.4 1408 42.7 2221<br />

TK100x4/..-PE-ALT-CLT 200 42.7 2145 54.4 3496<br />

Application<br />

In all kinds of operating premises (excepted locations with special protection<br />

demands - like in fire or highly combustible premises). In telecommunication<br />

network systems and similar systems, for example as PTT subscriber’s cable.<br />

Construction<br />

Conductor: solid, bare copper wire Ø 0.6 / 0.8 mm<br />

Insulation: PE (PE)<br />

Colour code: tracer quad: WT-OR-TQ-VI<br />

counter quad: WT-GN-TQ-VI<br />

standard quad 1: WT-BN-TQ-VI<br />

standard quad 2: WT-GY-TQ-VI<br />

Cable make up: 4 cores twisted to quads, quads stranded together in<br />

concentric layers to cable core, cable core wrapping<br />

with plastic foil<br />

Sheath: PE single-coated aluminium foil bonded with the PEouter<br />

sheath (ALT), black, one or two drain wire(s)<br />

Armouring: 2 layers of galvanized steel tape (CL)<br />

Protective cover: PE, black (T)<br />

Design<br />

2-200 DC (1 up to 100 quads)<br />

Laying<br />

suitable for underground laying and pulling into conduits, ducts<br />

Marking<br />

< ..x4/.. PE-ALT-CLT> <br />

<br />

C40<br />

Ø<br />

0.6<br />

mutual capacitance<br />

Technical Details (at 20°C)<br />

standard acc. PTT 844.14<br />

conductor diameter 0.6 0.8 mm<br />

loop resistance ≤ 133 ≤ 73.5 Ω/km<br />

insulation resistance ≥ 10 ≥ 10 GΩkm<br />

mutual capacitance spec. value 40±9 40±9 nF/km<br />

(at f=800Hz) mean value 1) 40±3 40±3 nF/km<br />

capacitance unbalance k 1<br />

(at f=800Hz) mean value 1) ≤ 50 ≤ 50 pF/230m<br />

capacitance unbalance k 9-12<br />

(at f=800Hz) mean value 1) ≤ 30 ≤ 30 pF/230m<br />

capacitance unbalance e a1<br />

(at f=800Hz) ≤ 400 ≤ 400 pF/230m<br />

mean value 1) ≤ 100 ≤ 100 pF/230m<br />

dielectric strength<br />

conductor/conductor 500V/50Hz<br />

conductor/shield 2000V/50Hz<br />

1) for cables with 20 and more elements<br />

26 <strong>Telecommunication</strong> <strong>Copper</strong> <strong>Cables</strong> • 09/2012 • © by <strong>PENGG</strong> <strong>KABEL</strong> <strong>GmbH</strong> • Subject to technical alterations<br />

Ø<br />

0.8<br />

dimension of<br />

conductor<br />

cable elements<br />

DC<br />

n<br />

number of<br />

double cores<br />

filling<br />

overall shield,<br />

armouring

<strong>Telecommunication</strong>-Outdoor <strong>Cables</strong><br />

Foam-skin-PE-insulated subscriber cable, filled with swellable materials TK-..x4/.. PE4-ALT<br />

conductor diameter 0.4 mm conductor diameter 0.6 mm conductor diameter 0.8 mm<br />

Type number of outer diameter weight outer diameter weight outer diameter weight<br />

double cores approx. mm approx. kg/km approx. mm approx. kg/km approx. mm approx. kg/km<br />

TK-3x4x.. PE4-ALT 6 - - 12 130 14 170<br />

TK-5x4x.. PE4-ALT 10 - - 13 170 16 240<br />

TK-10x4x.. PE4-ALT 20 - - 18 270 21 400<br />

TK-25(26)x4x.. PE4-ALT 50(52) 18 310 23 540 30 850<br />

TK-50(51)x4x.. PE4-ALT 100(102) 23 520 30 960 40 1600<br />

TK-75(77)x4x.. PE4-ALT 150(154) 28 790 39 1460 51 2440<br />

TK-100(102)x4x.. PE4-ALT 200(204) 34 1030 45 1920 59 3260<br />

TK-150(153)x4x.. PE4-ALT 300(306) 40 1510 53 2760 69 4680<br />

TK-200(204)x4x.. PE4-ALT 400(408) 46 1910 61 3560 79 6100<br />

TK-300(306)x4x.. PE4-ALT 600(612) 55 2690 72 5160 95 8810<br />

TK-450(459)x4x.. PE4-ALT 900(918) 66 3870 87 7510 - -<br />

Application<br />

In all kinds of operating premises (excepted locations with special protection<br />