Download PDF - Voith Turbo

Download PDF - Voith Turbo

Download PDF - Voith Turbo

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

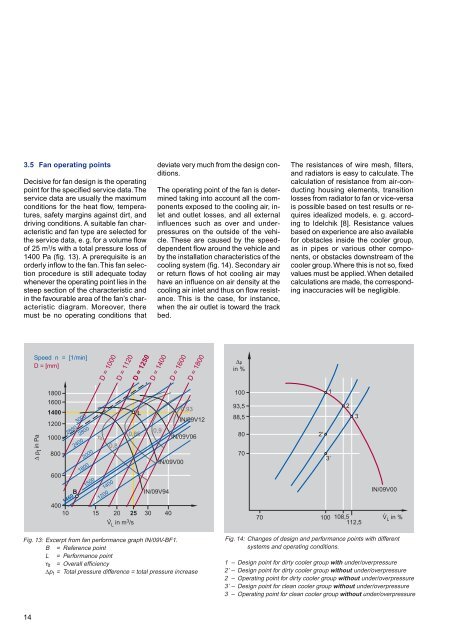

3.5 Fan operating points<br />

Decisive for fan design is the operating<br />

point for the specified service data. The<br />

service data are usually the maximum<br />

conditions for the heat flow, temperatures,<br />

safety margins against dirt, and<br />

driving conditions. A suitable fan characteristic<br />

and fan type are selected for<br />

the service data, e. g. for a volume flow<br />

of 25 m 3 /s with a total pressure loss of<br />

1400 Pa (fig. 13). A prerequisite is an<br />

orderly inflow to the fan. This fan selection<br />

procedure is still adequate today<br />

whenever the operating point lies in the<br />

steep section of the characteristic and<br />

in the favourable area of the fan’s characteristic<br />

diagram. Moreover, there<br />

must be no operating conditions that<br />

14<br />

Speed n = [1/min]<br />

D = [mm]<br />

∆ p t in Pa<br />

1800<br />

1600<br />

1400<br />

1200<br />

1000<br />

800<br />

600<br />

1460<br />

3000<br />

2850<br />

2800<br />

2400<br />

B<br />

2000<br />

1800<br />

1500<br />

ηt<br />

D = 1000<br />

0,8<br />

1400<br />

1200<br />

D = 1120<br />

400<br />

10 15 20 25 30 40<br />

V L in m 3 /s<br />

D = 1250<br />

Fig. 13: Excerpt from fan performance graph IN/09V-BF1.<br />

B = Reference point<br />

L = Performance point<br />

ηt = Overall efficiency<br />

∆pt = Total pressure difference = total pressure increase<br />

L<br />

0,85<br />

deviate very much from the design conditions.<br />

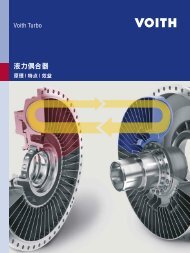

The operating point of the fan is determined<br />

taking into account all the components<br />

exposed to the cooling air, inlet<br />

and outlet losses, and all external<br />

influences such as over and underpressures<br />

on the outside of the vehicle.<br />

These are caused by the speeddependent<br />

flow around the vehicle and<br />

by the installation characteristics of the<br />

cooling system (fig. 14). Secondary air<br />

or return flows of hot cooling air may<br />

have an influence on air density at the<br />

cooling air inlet and thus on flow resistance.<br />

This is the case, for instance,<br />

when the air outlet is toward the track<br />

bed.<br />

D = 1400<br />

0,9<br />

IN/09V94<br />

D = 1600<br />

IN/09V00<br />

0,93<br />

IN/09V06<br />

D = 1800<br />

IN/09V12<br />

∆p<br />

in %<br />

100<br />

93,5<br />

88,5<br />

80<br />

70<br />

70<br />

The resistances of wire mesh, filters,<br />

and radiators is easy to calculate. The<br />

calculation of resistance from air-conducting<br />

housing elements, transition<br />

losses from radiator to fan or vice-versa<br />

is possible based on test results or requires<br />

idealized models, e. g. according<br />

to Idelchik [8]. Resistance values<br />

based on experience are also available<br />

for obstacles inside the cooler group,<br />

as in pipes or various other components,<br />

or obstacles downstream of the<br />

cooler group. Where this is not so, fixed<br />

values must be applied. When detailed<br />

calculations are made, the corresponding<br />

inaccuracies will be negligible.<br />

2’<br />

1<br />

3’<br />

100<br />

2<br />

3<br />

108,5 112,5<br />

IN/09V00<br />

V L in %<br />

Fig. 14: Changes of design and performance points with different<br />

systems and operating conditions.<br />

1 – Design point for dirty cooler group with under/overpressure<br />

2’ – Design point for dirty cooler group without under/overpressure<br />

2 – Operating point for dirty cooler group without under/overpressure<br />

3’ – Design point for clean cooler group without under/overpressure<br />

3 – Operating point for clean cooler group without under/overpressure