Download PDF - Voith Turbo

Download PDF - Voith Turbo

Download PDF - Voith Turbo

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

5. Economical considerations<br />

Development costs money. It can only<br />

be financed today if there is a financing<br />

concept that is suitable for small lot<br />

production as found in the rail vehicle<br />

sector. Taking into account market appreciation<br />

of high-quality components<br />

would be desirable, but there are no<br />

signs that it might ever be possible under<br />

the current competitive conditions.<br />

There is a wide variety of fan types and<br />

designs available. Cheap offers are<br />

based on standard modules for different<br />

applications and will rarely be suitable<br />

for rail vehicles. Just comparing<br />

prices is not the way to find a suitable<br />

fan. An analysis of the price/benefit ratio<br />

and of life cycle costs is indispensable.<br />

The price difference of a few thousand<br />

Euro between a fan with a high overall<br />

efficiency of up to 90 % - such efficiency<br />

levels are possible by using slim blade<br />

profiles with optimum twist - and one<br />

of 50 to 60 % efficiency is often compensated<br />

by fuel savings already after<br />

two to three years.<br />

An example of a railcar with 480 kW<br />

engine output illustrates this. With a<br />

cooling requirement of 2 x 5 m 3 /s and a<br />

total pressure of about 1000 Pa, the use<br />

of high-efficiency fans permits fuel savings<br />

of about 2400 l/yr. (tables 4<br />

and 5).<br />

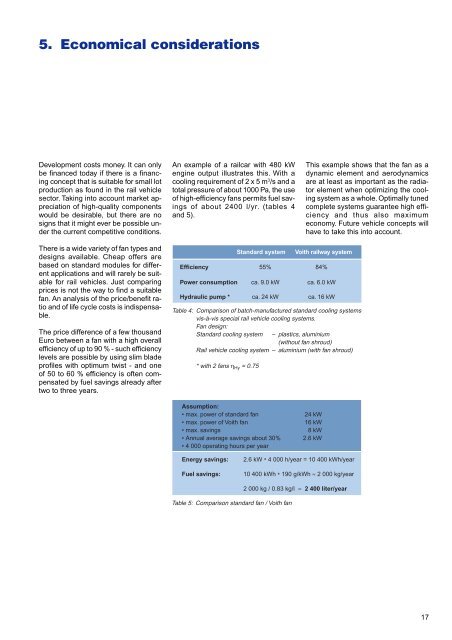

Standard system<br />

<strong>Voith</strong> railway system<br />

Efficiency 55% 84%<br />

Power consumption ca. 9.0 kW ca. 6.0 kW<br />

Hydraulic pump * ca. 24 kW ca. 16 kW<br />

Table 4: Comparison of batch-manufactured standard cooling systems<br />

vis-à-vis special rail vehicle cooling systems.<br />

Fan design:<br />

Standard cooling system – plastics, aluminium<br />

(without fan shroud)<br />

Rail vehicle cooling system – aluminium (with fan shroud)<br />

* with 2 fans η Hy = 0.75<br />

Assumption:<br />

• max. power of standard fan 24 kW<br />

• max. power of <strong>Voith</strong> fan 16 kW<br />

• max. savings 8 kW<br />

• Annual average savings about 30% 2.6 kW<br />

• 4 000 operating hours per year<br />

Energy savings: 2.6 kW * 4 000 h/year = 10 400 kWh/year<br />

Fuel savings: 10 400 kWh * 190 g/kWh ≈ 2 000 kg/year<br />

Table 5: Comparison standard fan / <strong>Voith</strong> fan<br />

2 000 kg / 0.83 kg/l ≈ 2 400 liter/year<br />

This example shows that the fan as a<br />

dynamic element and aerodynamics<br />

are at least as important as the radiator<br />

element when optimizing the cooling<br />

system as a whole. Optimally tuned<br />

complete systems guarantee high efficiency<br />

and thus also maximum<br />

economy. Future vehicle concepts will<br />

have to take this into account.<br />

17