Download PDF - Voith Turbo

Download PDF - Voith Turbo

Download PDF - Voith Turbo

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

The core component of the mechanical/hydrodynamic<br />

drive system is the<br />

<strong>Voith</strong> variable-speed fan, which is available<br />

in various versions. Its distinctive<br />

feature is that it forms an integral unit<br />

with a filling-controlled Föttinger coupling.<br />

A pneumatic system is used for<br />

filling control - and thus for control of<br />

the fan speed - that uses the coolant<br />

temperature of the components to be<br />

cooled as output variable [4, 5].<br />

The advantages of the <strong>Voith</strong> variablespeed<br />

fan can be summarized as follows:<br />

- The system permits a constant<br />

coolant and component temperature<br />

to be maintained.<br />

-Fan speed can be varied within<br />

certain limits and is only dependent<br />

on diesel engine speed to a certain<br />

extent.<br />

- The efficiency maximum of about<br />

90 % for the entire driveline is<br />

reached at maximum fan speed,<br />

i. e. when the coupling is full.<br />

-Power consumption is matched to<br />

the operating conditions.<br />

- The system is self-sufficient.<br />

- The system is considered robust,<br />

long-lived, low-maintenance, and<br />

vibration-resistant.<br />

The disadvantages are:<br />

- Lack of flexibility with regard to arrangement<br />

in the vehicle due to the<br />

mechanical drive.<br />

- High cost and weight.<br />

The hydrodynamic fan drive was therefore<br />

replaced by the hydrostatic one.<br />

8<br />

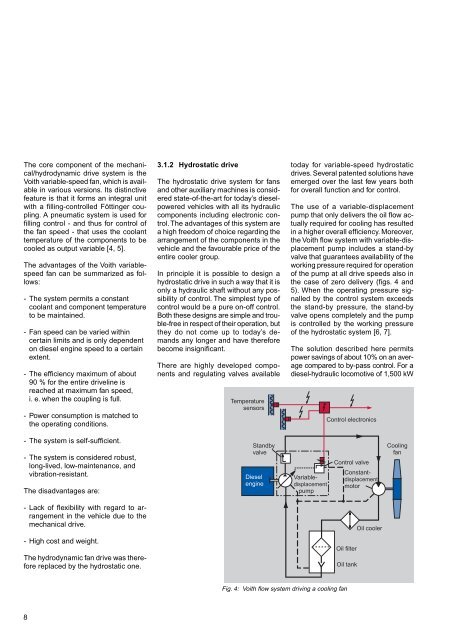

3.1.2 Hydrostatic drive<br />

The hydrostatic drive system for fans<br />

and other auxiliary machines is considered<br />

state-of-the-art for today’s dieselpowered<br />

vehicles with all its hydraulic<br />

components including electronic control.<br />

The advantages of this system are<br />

a high freedom of choice regarding the<br />

arrangement of the components in the<br />

vehicle and the favourable price of the<br />

entire cooler group.<br />

In principle it is possible to design a<br />

hydrostatic drive in such a way that it is<br />

only a hydraulic shaft without any possibility<br />

of control. The simplest type of<br />

control would be a pure on-off control.<br />

Both these designs are simple and trouble-free<br />

in respect of their operation, but<br />

they do not come up to today’s demands<br />

any longer and have therefore<br />

become insignificant.<br />

There are highly developed components<br />

and regulating valves available<br />

Temperature<br />

sensors<br />

Standby<br />

valve<br />

Diesel<br />

engine<br />

Variabledisplacement<br />

pump<br />

Control electronics<br />

Control valve<br />

Constantdisplacement<br />

motor<br />

Oil filter<br />

Oil tank<br />

Fig. 4: <strong>Voith</strong> flow system driving a cooling fan<br />

today for variable-speed hydrostatic<br />

drives. Several patented solutions have<br />

emerged over the last few years both<br />

for overall function and for control.<br />

The use of a variable-displacement<br />

pump that only delivers the oil flow actually<br />

required for cooling has resulted<br />

in a higher overall efficiency. Moreover,<br />

the <strong>Voith</strong> flow system with variable-displacement<br />

pump includes a stand-by<br />

valve that guarantees availability of the<br />

working pressure required for operation<br />

of the pump at all drive speeds also in<br />

the case of zero delivery (figs. 4 and<br />

5). When the operating pressure signalled<br />

by the control system exceeds<br />

the stand-by pressure, the stand-by<br />

valve opens completely and the pump<br />

is controlled by the working pressure<br />

of the hydrostatic system [6, 7].<br />

The solution described here permits<br />

power savings of about 10% on an average<br />

compared to by-pass control. For a<br />

diesel-hydraulic locomotive of 1,500 kW<br />

Oil cooler<br />

Cooling<br />

fan