v=c§J - Memorial University of Newfoundland DAI

v=c§J - Memorial University of Newfoundland DAI

v=c§J - Memorial University of Newfoundland DAI

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

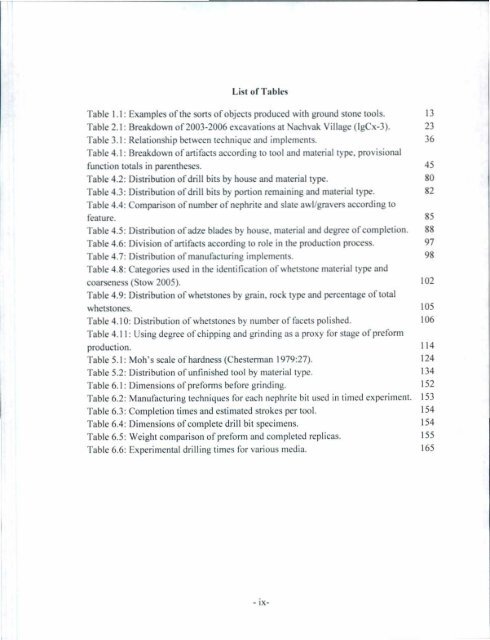

List <strong>of</strong> Tables<br />

Table 1.1: Examples <strong>of</strong> the sorts <strong>of</strong>objects produced with ground stone tools. 13<br />

Table 2.1: Breakdown <strong>of</strong>2003·2006 excavations at achvak Village (lgCx·3). 23<br />

Table 3.1 : Relationship between technique and implements. 36<br />

Table 4.1 : Breakdown <strong>of</strong>artifacts according to tool and material type. provisional<br />

function totals in parenlheses. 45<br />

Table 4.2: Distribution <strong>of</strong>drill bits by house and material type. 80<br />

Table 4.3: Distribution <strong>of</strong>drill bits by portion remaining and material type. 82<br />

Table 4.4: Comparison <strong>of</strong> number <strong>of</strong> nephrite and slate awl/gravers according to<br />

feature. 85<br />

Table 4.5: Distribution <strong>of</strong>adze blades by house, material and degree <strong>of</strong>completion. 88<br />

Table 4.6: Division <strong>of</strong>artifacts according to role in the production process. 97<br />

Table 4.7: Distribution <strong>of</strong> manufacturing implements. 98<br />

Table 4.8: Categories used in the identification <strong>of</strong>whetstone material type and<br />

coarseness (Stow 2005). 102<br />

Table 4.9: Distribution <strong>of</strong> whetstones by grain. rock type and percentage <strong>of</strong> total<br />

whetstones. 105<br />

Table 4.10: Distribution <strong>of</strong> whetstones by number <strong>of</strong> facets polished. 106<br />

Table 4.11: Using degree <strong>of</strong>chipping and grinding as a proxy for stage <strong>of</strong> prefonn<br />

production. 114<br />

Table 5. I: Moh's scale <strong>of</strong> hardness (Chestennan 1979:27). 124<br />

Table 5.2: Distribution <strong>of</strong> unfinished tool by matcrialtype. 134<br />

Table 6. I: Dimensions <strong>of</strong>prefonns before grinding. 152<br />

Table 6.2: Manufacturing techniques for each nephrite bit used in timed experiment. 153<br />

Table 6.3: Completion times and estimated strokes per tool. 154<br />

Table 6.4: Dimensions <strong>of</strong>complete drill bit specimens. 154<br />

Table 6.5: Weight comparison <strong>of</strong> prefonn and completed replicas. 155<br />

Table 6.6: Experimental drilling times for various media. 165<br />

- ix-