December 2004 - Materials Science Institute - University of Oregon

December 2004 - Materials Science Institute - University of Oregon

December 2004 - Materials Science Institute - University of Oregon

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

SA 50<br />

(business leader <strong>of</strong> the year)<br />

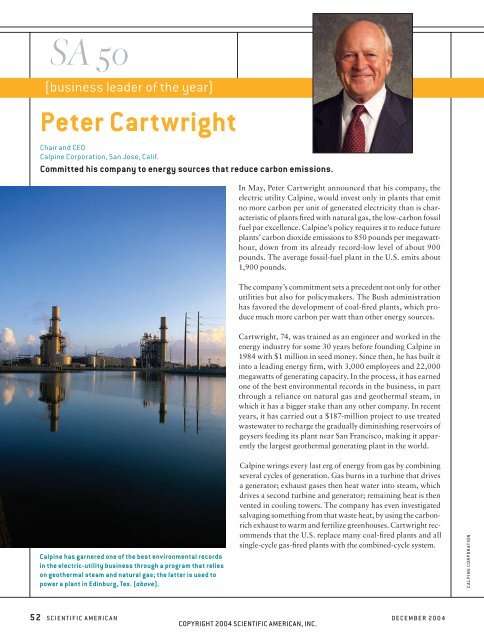

Peter Cartwright<br />

Chair and CEO<br />

Calpine Corporation, San Jose, Calif.<br />

Committed his company to energy sources that reduce carbon emissions.<br />

In May, Peter Cartwright announced that his company, the<br />

electric utility Calpine, would invest only in plants that emit<br />

no more carbon per unit <strong>of</strong> generated electricity than is characteristic<br />

<strong>of</strong> plants fi red with natural gas, the low-carbon fossil<br />

fuel par excellence. Calpine’s policy requires it to reduce future<br />

plants’ carbon dioxide emissions to 850 pounds per megawatthour,<br />

down from its already record-low level <strong>of</strong> about 900<br />

pounds. The average fossil-fuel plant in the U.S. emits about<br />

1,900 pounds.<br />

The company’s commitment sets a precedent not only for other<br />

utilities but also for policymakers. The Bush administration<br />

has favored the development <strong>of</strong> coal-fi red plants, which produce<br />

much more carbon per watt than other energy sources.<br />

Cartwright, 74, was trained as an engineer and worked in the<br />

energy industry for some 30 years before founding Calpine in<br />

1984 with $1 million in seed money. Since then, he has built it<br />

into a leading energy fi rm, with 3,000 employees and 22,000<br />

megawatts <strong>of</strong> generating capacity. In the process, it has earned<br />

one <strong>of</strong> the best environmental records in the business, in part<br />

through a reliance on natural gas and geothermal steam, in<br />

which it has a bigger stake than any other company. In recent<br />

years, it has carried out a $187-million project to use treated<br />

wastewater to recharge the gradually diminishing reservoirs <strong>of</strong><br />

geysers feeding its plant near San Francisco, making it apparently<br />

the largest geothermal generating plant in the world.<br />

Calpine wrings every last erg <strong>of</strong> energy from gas by combining<br />

several cycles <strong>of</strong> generation. Gas burns in a turbine that drives<br />

a generator; exhaust gases then heat water into steam, which<br />

drives a second turbine and generator; remaining heat is then<br />

vented in cooling towers. The company has even investigated<br />

salvaging something from that waste heat, by using the carbonrich<br />

exhaust to warm and fertilize greenhouses. Cartwright recommends<br />

that the U.S. replace many coal-fi red plants and all<br />

single-cycle gas-fi red plants with the combined-cycle system.<br />

Calpine has garnered one <strong>of</strong> the best environmental records<br />

in the electric-utility business through a program that relies<br />

CORPORATION<br />

on geothermal steam and natural gas; the latter is used to<br />

power a plant in Edinburg, Tex. (above). CALPINE<br />

52 SCIENTIFIC AMERICAN DECEMBER <strong>2004</strong><br />

COPYRIGHT <strong>2004</strong> SCIENTIFIC AMERICAN, INC.