SIMATIC HMI WinCC V7.0 System Description - DCE FEL ČVUT v ...

SIMATIC HMI WinCC V7.0 System Description - DCE FEL ČVUT v ...

SIMATIC HMI WinCC V7.0 System Description - DCE FEL ČVUT v ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

3.2 Increased availability Options <strong>SIMATIC</strong> <strong>WinCC</strong><br />

With <strong>SIMATIC</strong> Maintenance Station, you can perform<br />

intelligent, preventive maintenance with minimal resource<br />

utilization, for example, less staff, material, energy, and cost<br />

with the following options:<br />

● Overview of information for assessment of plant and<br />

component status and comprehensive analysis of weaknesses<br />

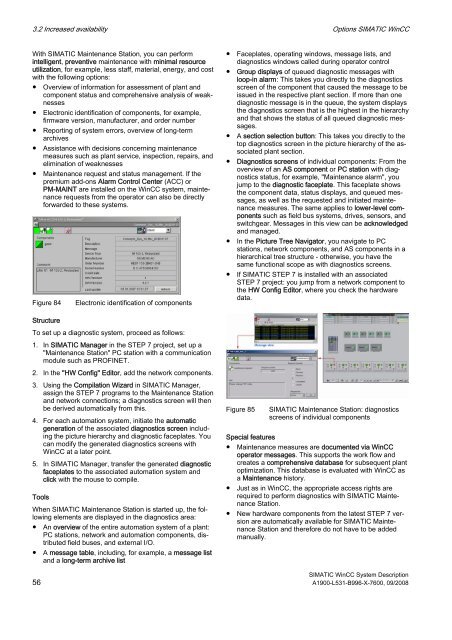

● Electronic identification of components, for example,<br />

firmware version, manufacturer, and order number<br />

● Reporting of system errors, overview of long-term<br />

archives<br />

● Assistance with decisions concerning maintenance<br />

measures such as plant service, inspection, repairs, and<br />

elimination of weaknesses<br />

● Maintenance request and status management. If the<br />

premium add-ons Alarm Control Center (ACC) or<br />

PM-MAINT are installed on the <strong>WinCC</strong> system, maintenance<br />

requests from the operator can also be directly<br />

forwarded to these systems.<br />

Figure 84 Electronic identification of components<br />

Structure<br />

To set up a diagnostic system, proceed as follows:<br />

1. In <strong>SIMATIC</strong> Manager in the STEP 7 project, set up a<br />

"Maintenance Station" PC station with a communication<br />

module such as PROFINET.<br />

2. In the "HW Config" Editor, add the network components.<br />

3. Using the Compilation Wizard in <strong>SIMATIC</strong> Manager,<br />

assign the STEP 7 programs to the Maintenance Station<br />

and network connections; a diagnostics screen will then<br />

be derived automatically from this.<br />

4. For each automation system, initiate the automatic<br />

generation of the associated diagnostics screen including<br />

the picture hierarchy and diagnostic faceplates. You<br />

can modify the generated diagnostics screens with<br />

<strong>WinCC</strong> at a later point.<br />

5. In <strong>SIMATIC</strong> Manager, transfer the generated diagnostic<br />

faceplates to the associated automation system and<br />

click with the mouse to compile.<br />

Tools<br />

When <strong>SIMATIC</strong> Maintenance Station is started up, the following<br />

elements are displayed in the diagnostics area:<br />

● An overview of the entire automation system of a plant:<br />

PC stations, network and automation components, distributed<br />

field buses, and external I/O.<br />

● A message table, including, for example, a message list<br />

and a long-term archive list<br />

● Faceplates, operating windows, message lists, and<br />

diagnostics windows called during operator control<br />

● Group displays of queued diagnostic messages with<br />

loop-in alarm: This takes you directly to the diagnostics<br />

screen of the component that caused the message to be<br />

issued in the respective plant section. If more than one<br />

diagnostic message is in the queue, the system displays<br />

the diagnostics screen that is the highest in the hierarchy<br />

and that shows the status of all queued diagnostic messages.<br />

● A section selection button: This takes you directly to the<br />

top diagnostics screen in the picture hierarchy of the associated<br />

plant section.<br />

● Diagnostics screens of individual components: From the<br />

overview of an AS component or PC station with diagnostics<br />

status, for example, "Maintenance alarm", you<br />

jump to the diagnostic faceplate. This faceplate shows<br />

the component data, status displays, and queued messages,<br />

as well as the requested and initiated maintenance<br />

measures. The same applies to lower-level components<br />

such as field bus systems, drives, sensors, and<br />

switchgear. Messages in this view can be acknowledged<br />

and managed.<br />

● In the Picture Tree Navigator, you navigate to PC<br />

stations, network components, and AS components in a<br />

hierarchical tree structure - otherwise, you have the<br />

same functional scope as with diagnostics screens.<br />

● If <strong>SIMATIC</strong> STEP 7 is installed with an associated<br />

STEP 7 project: you jump from a network component to<br />

the HW Config Editor, where you check the hardware<br />

data.<br />

Figure 85 <strong>SIMATIC</strong> Maintenance Station: diagnostics<br />

screens of individual components<br />

Special features<br />

● Maintenance measures are documented via <strong>WinCC</strong><br />

operator messages. This supports the work flow and<br />

creates a comprehensive database for subsequent plant<br />

optimization. This database is evaluated with <strong>WinCC</strong> as<br />

a Maintenance history.<br />

● Just as in <strong>WinCC</strong>, the appropriate access rights are<br />

required to perform diagnostics with <strong>SIMATIC</strong> Maintenance<br />

Station.<br />

● New hardware components from the latest STEP 7 version<br />

are automatically available for <strong>SIMATIC</strong> Maintenance<br />

Station and therefore do not have to be added<br />

manually.<br />

<strong>SIMATIC</strong> <strong>WinCC</strong> <strong>System</strong> <strong>Description</strong><br />

56 A1900-L531-B996-X-7600, 09/2008