SIMATIC HMI WinCC V7.0 System Description - DCE FEL ČVUT v ...

SIMATIC HMI WinCC V7.0 System Description - DCE FEL ČVUT v ...

SIMATIC HMI WinCC V7.0 System Description - DCE FEL ČVUT v ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

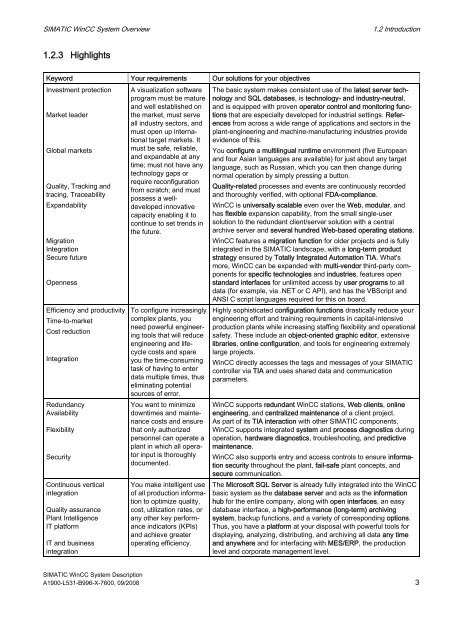

<strong>SIMATIC</strong> <strong>WinCC</strong> <strong>System</strong> Overview 1.2 Introduction<br />

1.2.3 Highlights<br />

Keyword Your requirements Our solutions for your objectives<br />

Investment protection A visualization software The basic system makes consistent use of the latest server tech-<br />

program must be mature nology and SQL databases, is technology- and industry-neutral,<br />

and well established on and is equipped with proven operator control and monitoring func-<br />

Market leader<br />

the market, must serve tions that are especially developed for industrial settings. Refer-<br />

all industry sectors, and ences from across a wide range of applications and sectors in the<br />

must open up interna- plant-engineering and machine-manufacturing industries provide<br />

tional target markets. It evidence of this.<br />

Global markets<br />

Quality, Tracking and<br />

tracing, Traceability<br />

Expandability<br />

must be safe, reliable,<br />

and expandable at any<br />

time; must not have any<br />

technology gaps or<br />

require reconfiguration<br />

from scratch; and must<br />

possess a welldeveloped<br />

innovative<br />

capacity enabling it to<br />

continue to set trends in<br />

the future.<br />

You configure a multilingual runtime environment (five European<br />

and four Asian languages are available) for just about any target<br />

language, such as Russian, which you can then change during<br />

normal operation by simply pressing a button.<br />

Quality-related processes and events are continuously recorded<br />

and thoroughly verified, with optional FDA-compliance.<br />

<strong>WinCC</strong> is universally scalable even over the Web, modular, and<br />

has flexible expansion capability, from the small single-user<br />

solution to the redundant client/server solution with a central<br />

archive server and several hundred Web-based operating stations.<br />

Migration<br />

<strong>WinCC</strong> features a migration function for older projects and is fully<br />

Integration<br />

integrated in the <strong>SIMATIC</strong> landscape, with a long-term product<br />

Secure future<br />

strategy ensured by Totally Integrated Automation TIA. What's<br />

more, <strong>WinCC</strong> can be expanded with multi-vendor third-party components<br />

for specific technologies and industries, features open<br />

Openness<br />

standard interfaces for unlimited access by user programs to all<br />

data (for example, via .NET or C API), and has the VBScript and<br />

ANSI C script languages required for this on board.<br />

Efficiency and productivity To configure increasingly Highly sophisticated configuration functions drastically reduce your<br />

Time-to-market<br />

Cost reduction<br />

complex plants, you<br />

need powerful engineering<br />

tools that will reduce<br />

engineering effort and training requirements in capital-intensive<br />

production plants while increasing staffing flexibility and operational<br />

safety. These include an object-oriented graphic editor, extensive<br />

engineering and life- libraries, online configuration, and tools for engineering extremely<br />

Integration<br />

cycle costs and spare<br />

you the time-consuming<br />

task of having to enter<br />

data multiple times, thus<br />

eliminating potential<br />

sources of error.<br />

large projects.<br />

<strong>WinCC</strong> directly accesses the tags and messages of your <strong>SIMATIC</strong><br />

controller via TIA and uses shared data and communication<br />

parameters.<br />

Redundancy<br />

You want to minimize <strong>WinCC</strong> supports redundant <strong>WinCC</strong> stations, Web clients, online<br />

Availability<br />

downtimes and mainte- engineering, and centralized maintenance of a client project.<br />

nance costs and ensure As part of its TIA interaction with other <strong>SIMATIC</strong> components,<br />

Flexibility<br />

that only authorized <strong>WinCC</strong> supports integrated system and process diagnostics during<br />

personnel can operate a operation, hardware diagnostics, troubleshooting, and predictive<br />

plant in which all opera- maintenance.<br />

Security<br />

tor input is thoroughly<br />

documented.<br />

<strong>WinCC</strong> also supports entry and access controls to ensure information<br />

security throughout the plant, fail-safe plant concepts, and<br />

secure communication.<br />

Continuous vertical You make intelligent use The Microsoft SQL Server is already fully integrated into the <strong>WinCC</strong><br />

integration<br />

of all production informa- basic system as the database server and acts as the information<br />

tion to optimize quality, hub for the entire company, along with open interfaces, an easy<br />

Quality assurance cost, utilization rates, or database interface, a high-performance (long-term) archiving<br />

Plant Intelligence any other key perform- system, backup functions, and a variety of corresponding options.<br />

IT platform<br />

ance indicators (KPIs) Thus, you have a platform at your disposal with powerful tools for<br />

and achieve greater displaying, analyzing, distributing, and archiving all data any time<br />

IT and business<br />

operating efficiency. and anywhere and for interfacing with MES/ERP, the production<br />

integration<br />

level and corporate management level.<br />

<strong>SIMATIC</strong> <strong>WinCC</strong> <strong>System</strong> <strong>Description</strong><br />

A1900-L531-B996-X-7600, 09/2008 3