SIMATIC HMI WinCC V7.0 System Description - DCE FEL ČVUT v ...

SIMATIC HMI WinCC V7.0 System Description - DCE FEL ČVUT v ...

SIMATIC HMI WinCC V7.0 System Description - DCE FEL ČVUT v ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

3.3 Plant Intelligence Options <strong>SIMATIC</strong> <strong>WinCC</strong><br />

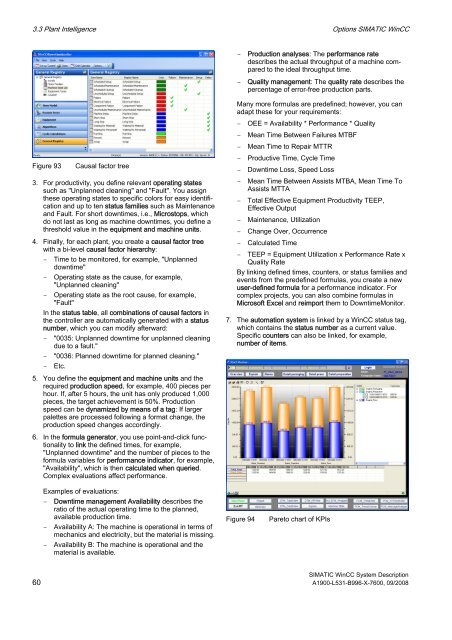

Figure 93 Causal factor tree<br />

3. For productivity, you define relevant operating states<br />

such as "Unplanned cleaning" and "Fault". You assign<br />

these operating states to specific colors for easy identification<br />

and up to ten status families such as Maintenance<br />

and Fault. For short downtimes, i.e., Microstops, which<br />

do not last as long as machine downtimes, you define a<br />

threshold value in the equipment and machine units.<br />

4. Finally, for each plant, you create a causal factor tree<br />

with a bi-level causal factor hierarchy:<br />

– Time to be monitored, for example, "Unplanned<br />

downtime"<br />

– Operating state as the cause, for example,<br />

"Unplanned cleaning"<br />

– Operating state as the root cause, for example,<br />

"Fault"<br />

In the status table, all combinations of causal factors in<br />

the controller are automatically generated with a status<br />

number, which you can modify afterward:<br />

– "0035: Unplanned downtime for unplanned cleaning<br />

due to a fault."<br />

– "0036: Planned downtime for planned cleaning."<br />

– Etc.<br />

5. You define the equipment and machine units and the<br />

required production speed, for example, 400 pieces per<br />

hour. If, after 5 hours, the unit has only produced 1,000<br />

pieces, the target achievement is 50%. Production<br />

speed can be dynamized by means of a tag: If larger<br />

palettes are processed following a format change, the<br />

production speed changes accordingly.<br />

6. In the formula generator, you use point-and-click functionality<br />

to link the defined times, for example,<br />

"Unplanned downtime" and the number of pieces to the<br />

formula variables for performance indicator, for example,<br />

"Availability", which is then calculated when queried.<br />

Complex evaluations affect performance.<br />

Examples of evaluations:<br />

– Downtime management Availability describes the<br />

ratio of the actual operating time to the planned,<br />

available production time.<br />

– Availability A: The machine is operational in terms of<br />

mechanics and electricity, but the material is missing.<br />

– Availability B: The machine is operational and the<br />

material is available.<br />

– Production analyses: The performance rate<br />

describes the actual throughput of a machine compared<br />

to the ideal throughput time.<br />

– Quality management: The quality rate describes the<br />

percentage of error-free production parts.<br />

Many more formulas are predefined; however, you can<br />

adapt these for your requirements:<br />

– OEE = Availability * Performance * Quality<br />

– Mean Time Between Failures MTBF<br />

– Mean Time to Repair MTTR<br />

– Productive Time, Cycle Time<br />

– Downtime Loss, Speed Loss<br />

– Mean Time Between Assists MTBA, Mean Time To<br />

Assists MTTA<br />

– Total Effective Equipment Productivity TEEP,<br />

Effective Output<br />

– Maintenance, Utilization<br />

– Change Over, Occurrence<br />

– Calculated Time<br />

– TEEP = Equipment Utilization x Performance Rate x<br />

Quality Rate<br />

By linking defined times, counters, or status families and<br />

events from the predefined formulas, you create a new<br />

user-defined formula for a performance indicator. For<br />

complex projects, you can also combine formulas in<br />

Microsoft Excel and reimport them to DowntimeMonitor.<br />

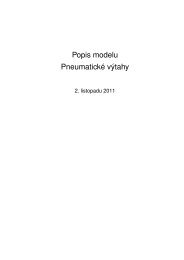

7. The automation system is linked by a <strong>WinCC</strong> status tag,<br />

which contains the status number as a current value.<br />

Specific counters can also be linked, for example,<br />

number of items.<br />

Figure 94 Pareto chart of KPIs<br />

<strong>SIMATIC</strong> <strong>WinCC</strong> <strong>System</strong> <strong>Description</strong><br />

60 A1900-L531-B996-X-7600, 09/2008