Product brochure - Wilo-EMUport solids separation system

Product brochure - Wilo-EMUport solids separation system

Product brochure - Wilo-EMUport solids separation system

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

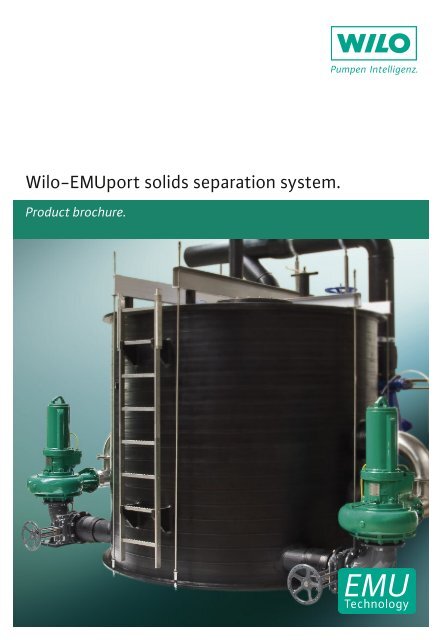

<strong>Wilo</strong>-<strong>EMUport</strong> <strong>solids</strong> <strong>separation</strong> <strong>system</strong>.<br />

<strong>Product</strong> <strong>brochure</strong>.

2<br />

Pumpen Intelligenz.

<strong>Wilo</strong> is synonymous throughout the<br />

world with the tradition of first-class<br />

German engineering. <strong>Wilo</strong> pumps and<br />

<strong>system</strong>s set new standards in terms<br />

of technical performance and<br />

efficiency for municipal water and<br />

sewage management. Sewage<br />

disposal currently plays a major<br />

role with regard to protection of the<br />

environment and maintenance of<br />

resources. Continuous challenges<br />

such as increasing solid contents<br />

in sewage, which hinder operating<br />

conditions for <strong>system</strong>s, require<br />

new and innovative solutions to<br />

constantly improve the processes<br />

and the corresponding products.<br />

One innovation in the field of sewage<br />

disposal is the <strong>Wilo</strong>-<strong>EMUport</strong> <strong>solids</strong><br />

<strong>separation</strong> <strong>system</strong>. The <strong>solids</strong> <strong>separation</strong><br />

<strong>system</strong> is distinguished from<br />

conventional sewage disposal <strong>system</strong>s<br />

by its energy efficient function,<br />

extremely durable, corrosionresistant<br />

PE-HD components and<br />

low life cycle costs. Far-sighted?<br />

We call it Pumpen Intelligenz.<br />

3

4<br />

Intelligent sewage disposal.<br />

2<br />

1<br />

3<br />

4

1 2<br />

<strong>Wilo</strong>-DrainLift<br />

M 2/8<br />

<strong>Wilo</strong>-DrainLift<br />

FTS MG 750<br />

3<br />

5<br />

<strong>Wilo</strong>-<strong>EMUport</strong> FTS FS<br />

with PE-HD sump<br />

4<br />

<strong>Wilo</strong>-<strong>EMUport</strong> FTS FG<br />

in fixed structures<br />

5<br />

<strong>Wilo</strong>-DrainLift<br />

WS 830<br />

5

Pumping stations – an overview.<br />

Solids <strong>separation</strong> <strong>system</strong> –<br />

The premium solution for sewage pumping.<br />

<strong>Wilo</strong> provides the right solution for all<br />

your sewage disposal requirements.<br />

Based on an extensive product range,<br />

pumping stations can be individually<br />

planned and assembled. Whether in<br />

a prefabricated, concrete or plastic<br />

sump – <strong>Wilo</strong> will work out the most<br />

economic solution for you.<br />

Wet well installation<br />

With wet well installation, costs are<br />

saved above all by the simple construction.<br />

The pumps stand directly<br />

in the sewage and can be assembled<br />

without having to climb into the sump<br />

by using a self-coupling <strong>system</strong>.<br />

Dry well installation<br />

With the dry well installation version,<br />

the sewage is collected unfiltered in<br />

a reservoir. The pumps are located<br />

outside the reservoir. This means that<br />

maintenance work on the pumps can<br />

be carried out conveniently without<br />

coming into contact with the sewage.<br />

Dry well installation is suitable for<br />

uncritical sewage with a low <strong>solids</strong><br />

content.<br />

Solids <strong>separation</strong> <strong>system</strong><br />

This innovative <strong>Wilo</strong> technology<br />

separates the <strong>solids</strong> from the sewage<br />

and holds them back in separate<br />

<strong>solids</strong> tanks upstream of the pumps.<br />

Only prepurified sewage comes into<br />

direct contact with the pumps on<br />

the way to the combined collection<br />

space. Once the coarse <strong>solids</strong> have<br />

been eliminated from the sewage<br />

using this technique, the sewage is<br />

transported by the dry well pumps<br />

and pumped out into the collection<br />

tank. On the way to the outgoing<br />

pressure pipeline, the sewage flows<br />

through the <strong>solids</strong> <strong>separation</strong> tank,<br />

pressing the <strong>solids</strong> out into the<br />

pressure pipeline. Sewage and <strong>solids</strong><br />

remain in the <strong>system</strong>. The pumps<br />

remain dry due to their location<br />

outside the tank. This allows<br />

maintenance work on the pumps<br />

to be carried out conveniently and<br />

hygienically.<br />

Wet well installation<br />

• Pumps stand in the fluid<br />

• Usually without operating building<br />

• Cost-effective due to simple<br />

construction<br />

Dry well installation<br />

• Pumps do not stand in the fluid<br />

• Technology accessible at all times<br />

• Simple and hygienic maintenance<br />

Solids <strong>separation</strong> <strong>system</strong><br />

• Pumps do not stand in the fluid<br />

• Unrestricted function thanks to<br />

double-pump station<br />

• Optimised plugging immunity<br />

• Maximum level of hygiene<br />

7

The <strong>Wilo</strong>-<strong>EMUport</strong> <strong>solids</strong> <strong>separation</strong> <strong>system</strong>.<br />

Innovative technology for cost-cutting<br />

operation.<br />

From a technological and economical<br />

viewpoint, completely preassembled<br />

pumping stations with <strong>Wilo</strong>-<strong>EMUport</strong><br />

<strong>solids</strong> <strong>separation</strong> <strong>system</strong>s are the best<br />

choice for drainage for entire localities<br />

or larger industrial and commercial<br />

complexes via conventional gravityflow<br />

drainage <strong>system</strong>s.<br />

Economical:<br />

Thanks to their small free ball passage.<br />

Since only prepurified sewage without<br />

coarse <strong>solids</strong> flows through the pump<br />

hydraulics, the free ball passage of<br />

the pumps can be designed to be<br />

considerably smaller than in traditional<br />

<strong>system</strong>s, so that the pumps are significantly<br />

more efficient. This leads to<br />

significant savings on energy and thus<br />

on operating costs.<br />

Operational reliability:<br />

Thanks to optimised plugging immunity<br />

The <strong>solids</strong> are held back in the <strong>solids</strong><br />

<strong>separation</strong> tank and pumped directly<br />

into the pressure pipeline during each<br />

pumping sequence, without coming<br />

directly into contact with the pump.<br />

This prevents plugging and immensely<br />

increases realiability and operational<br />

safety. Since the inside of the pump<br />

is protected from contact with coarse<br />

<strong>solids</strong>, its service life is also significantly<br />

prolonged. The result: fewer breakdowns<br />

and less servicing, and much<br />

more efficient operation.<br />

Long service life:<br />

Thanks to PE-HD components<br />

<strong>Wilo</strong>-<strong>EMUport</strong> products have to<br />

function reliably for long periods of<br />

time under difficult environmental<br />

influences. This can only be achieved<br />

by using high-quality materials. For<br />

this reason, a large proportion of the<br />

material is made of polyethylene<br />

(PE-HD) which, according to a study in<br />

the city of Göttingen, has a resistance<br />

of approx. 70–100 years. The material<br />

is made exclusively of hydrogen and<br />

carbon, and contains non-poisonous<br />

colourings. For manufacturing and<br />

processing, PE-HD is completely<br />

environmentally friendly and can be<br />

recycled up to seven times without<br />

suffering a reduction in quality.<br />

Easy to maintain:<br />

Thanks to dry well installation.<br />

The pumps are always dry and clean.<br />

This makes maintenance much more<br />

pleasant, hygienic and efficient, as all<br />

of the mechanical components can be<br />

accessed quickly and easily from the<br />

outside.<br />

"Non-stop“:<br />

Thanks to individual blocking<br />

The <strong>Wilo</strong>-<strong>EMUport</strong> <strong>solids</strong> <strong>separation</strong><br />

<strong>system</strong> is a double-pump station<br />

which uses two pumps in alternation.<br />

Each pump is assigned its own <strong>solids</strong><br />

<strong>separation</strong> tank which can be individually<br />

blocked off. This means there<br />

are no interruptions to operation<br />

during maintenance and repair work.<br />

Economical<br />

• More efficient due to smaller pump<br />

free ball passages<br />

• Increased pump service life<br />

• Non-stop operation due to individual<br />

blocking<br />

Long service life<br />

• 10-year guarantee on all PE-HD<br />

components<br />

• Environmentally-friendly material,<br />

corrosion-resistant and recyclable<br />

Operational reliability and easy maintenance<br />

• Optimised plugging immunity<br />

• Dry, clean and odour-free<br />

• Hygienic assembly and maintenance<br />

conditions<br />

9

10<br />

Schematic diagram of function.<br />

1<br />

2<br />

Pump ON Pump OFF<br />

3<br />

4<br />

4<br />

5<br />

8<br />

I 6<br />

II<br />

I<br />

II<br />

Pumping sequence<br />

Filling sequence<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

7<br />

Inlet<br />

Distribution tank<br />

Shut-off ball<br />

Separation flaps<br />

Solids <strong>separation</strong> tank<br />

Collection reservoir<br />

Pressure pipeline<br />

Ventilation and exhaust

Function of the <strong>Wilo</strong>-<strong>EMUport</strong> <strong>solids</strong><br />

<strong>separation</strong> <strong>system</strong>.<br />

Technology that sets standards.<br />

With the <strong>solids</strong> <strong>separation</strong> <strong>system</strong>,<br />

the inflowing sewage flows into the<br />

distribution tank and from there into<br />

the open <strong>solids</strong> <strong>separation</strong> tank.<br />

The <strong>solids</strong> are kept back here. Only<br />

prepurified sewage is now able to<br />

pass through the pump into the large,<br />

combined collection reservoir.<br />

While the collection reservoir is filled,<br />

the water level in the <strong>solids</strong> <strong>separation</strong><br />

tank rises. The shut-off ball automatically<br />

closes the inlet.<br />

Now, pumping starts when the correct<br />

level has been reached. The pump<br />

pumps in the reverse direction.<br />

The sewage flows through the <strong>solids</strong><br />

<strong>separation</strong> tank and thus conveys the<br />

"filtered-out" <strong>solids</strong> into the outgoing<br />

pressure pipe.<br />

Then, the entire <strong>solids</strong> <strong>separation</strong> <strong>system</strong><br />

is flushed and cleaned. Pumping is<br />

stopped again when the correct level<br />

has been reached. The shut-off ball<br />

drops, leaving the path free for a new<br />

filling sequence. During this pumping<br />

sequence, the sewage is pumped into<br />

the other <strong>solids</strong> <strong>separation</strong> tank.<br />

Advantages of the <strong>solids</strong> <strong>separation</strong><br />

<strong>system</strong>:<br />

• Uses pumps with free ball passage<br />

< 80 mm, thus reducing fuel requirements<br />

and operating costs while<br />

increasing efficiency<br />

• Hygienic conditions for maintenance<br />

and assembly work<br />

• Pump room is dry, clean and odourless<br />

• Less wear, since the <strong>solids</strong> are not<br />

pumped by the hydraulic unit<br />

• Submersible sewage pump with<br />

adjusted impeller and protection<br />

class IP 68 (submersible)<br />

• No corrosion problems, no effect<br />

from the formation of hydrogen<br />

sulphide<br />

Filling process<br />

• Inflowing sewage flows into the <strong>solids</strong><br />

<strong>separation</strong> reservoir<br />

• Solids are held back<br />

• Prepurified sewage continues into the<br />

combined collection reservoir<br />

Reservoir filled<br />

• Collection reservoir filled<br />

• Shut-off ball automatically closes the<br />

inlet<br />

• Pumping sequence begins<br />

Pumping sequence<br />

• Pump pumps in the reverse direction<br />

• Sewage flows through the <strong>solids</strong><br />

<strong>separation</strong> tank, pumping the <strong>solids</strong><br />

into the outgoing pressure pipeline<br />

11

12<br />

Intelligent energy cost saving.<br />

Maximum efficiency.<br />

Energy costs [€]<br />

700.000<br />

600.000<br />

500.000<br />

400.000<br />

300.000<br />

200.000<br />

Example<br />

Sewage pumping station in Lauter,<br />

Germany<br />

2<br />

100.000<br />

1<br />

2<br />

0<br />

0 1 2 3 4 5 6 7 8 9 10<br />

Years<br />

Conventional<br />

dry well installation<br />

with free ball passage 100 mm<br />

Up to<br />

€ 87,310.00 Euro*<br />

in 10 years.<br />

Conventional<br />

dry well installation<br />

with free ball passage 80 mm<br />

dry well installation<br />

with 100 mm free ball passage<br />

dry well installation<br />

with 80 mm free ball passage<br />

<strong>solids</strong> <strong>separation</strong> <strong>system</strong><br />

profit zone<br />

<strong>solids</strong> <strong>separation</strong> <strong>system</strong><br />

vs. dry well installation<br />

with 100 mm free ball passage<br />

profit zone<br />

<strong>solids</strong> <strong>separation</strong> <strong>system</strong><br />

vs. dry well installation<br />

with 80 mm free ball passage<br />

1<br />

payback time**<br />

<strong>solids</strong> <strong>separation</strong> <strong>system</strong><br />

vs. dry well installation<br />

with 100 mm free ball passage<br />

payback time**<br />

<strong>solids</strong> <strong>separation</strong> <strong>system</strong><br />

vs. dry well installation<br />

with 80 mm free ball passage<br />

**for additional investment<br />

needs<br />

Pumping station<br />

with <strong>solids</strong> <strong>separation</strong> <strong>system</strong><br />

with free ball passage 50 mm<br />

<strong>Wilo</strong>-EMU sewage pump type FA 30.78 D FA 20.98 D FA 15.99 D<br />

Impeller type Multi-channel impeller Multi-channel impeller Multi-channel impeller<br />

Free ball passage of pump type [mm] 100 80 50<br />

Power requirements at duty point P1 [kW] 110 98 87<br />

Annual energy costs [€] 41,756.00 37,201.00 33,025.00<br />

Extra energy costs [%]<br />

compared to <strong>solids</strong> <strong>separation</strong> <strong>system</strong><br />

26% 13%<br />

*At an energy cost of 0.13 €/kWh (actual energy costs without basic fees, charged according to the specified rated power)<br />

Please note that maintenance costs are the same for all <strong>system</strong>s. However, pump wear is much lower for the <strong>solids</strong> <strong>separation</strong> <strong>system</strong>.

Amortisation and life cycle costs.<br />

Long-term economic efficiency.<br />

Maximum efficiency.<br />

How economical a pumping station<br />

actually is can only be seen when<br />

all additional costs are considered.<br />

Investment costs alone are only the<br />

tip of the iceberg. Much more decisive<br />

are the life cycle costs that arise during<br />

a long pump life.<br />

Only <strong>solids</strong> <strong>separation</strong> <strong>system</strong>s can use<br />

pumps with small free ball passages<br />

which lead to a higher degree of<br />

efficiency and lower energy costs.<br />

The example calculations for the<br />

pumping station in Lauter, in the<br />

German Ore Mountains, show the<br />

enormous savings which are possible.<br />

Renew your pumping station.<br />

With the retrofit <strong>system</strong>, <strong>Wilo</strong> offers<br />

you the most economical solution for<br />

reconstructing old pumping stations.<br />

Our experienced employees take the<br />

exact dimension of the existing<br />

installation on site, including all inlets<br />

and pipe outlets. This data can then<br />

be used together with individual<br />

customer requirements to plan and<br />

produce a new pumping station<br />

together with all the necessary<br />

equipment.<br />

Once the old installation has been<br />

dismantled, a new base is constructed<br />

using sand and concrete. The new<br />

<strong>Wilo</strong>-<strong>EMUport</strong> pumping station is<br />

then inserted into the base. Next,<br />

the connections are re-established,<br />

meaning the new <strong>system</strong> can usually<br />

be commissioned the same day, before<br />

any necessary filling and surface work<br />

is carried out. Using this method, the<br />

amount of sewage which is pumped<br />

out or repumped is restricted to a<br />

minimum, or sometimes eliminated<br />

completely.<br />

Life cycle costs<br />

• LCC analysis is an especially efficient<br />

method for monitoring total costs<br />

• For new <strong>system</strong>s or also for optimising<br />

existing installations<br />

Reference installation in Lauter, Germany<br />

• <strong>Wilo</strong>-<strong>EMUport</strong> pumping station with<br />

<strong>solids</strong> <strong>separation</strong> <strong>system</strong><br />

• Innovative <strong>Wilo</strong> technology allows<br />

enormous savings on energy costs –<br />

up to € 87,310 in 10 years<br />

Retrofit <strong>system</strong><br />

• Economical renewal of pumping<br />

stations<br />

• Reconstruction in one day<br />

13

Expert support.<br />

From planning to maintenance.<br />

Consulting and planning<br />

Optimum solutions come from<br />

objective-oriented planning. Our<br />

employees are here for you and will<br />

draw up an exact assessment of what<br />

you require. The cheapest duty point<br />

of a pump is the key factor in deciding<br />

whether to install a pumping station<br />

with or without a <strong>solids</strong> <strong>separation</strong><br />

<strong>system</strong>.<br />

This requires a longitudinal section of<br />

the planned pipe and a decision as to<br />

whether to construct a closed <strong>system</strong><br />

without ventilation and exhaust or<br />

half-closed <strong>system</strong> with ventilation<br />

and exhaust.<br />

If all the basic parameters and planning<br />

data are available, we will make a<br />

hydraulic calculation, contrasting all<br />

the <strong>system</strong>s in order to find the most<br />

economical solution for you. Using<br />

modern software, we calculate all the<br />

relevant measurements for you such as<br />

delivery head, head loss, volume flow,<br />

flow velocity, Reynolds number etc.,<br />

from the flow calculations in impellers,<br />

housings, inlet constructions and<br />

pressure pipes to pipe calculations.<br />

Installation and assembly<br />

The installation and the complete<br />

assembly for the pumping station are<br />

performed by qualified construction<br />

personnel with many years of experience.<br />

<strong>Wilo</strong> takes personal supervision<br />

on site as a given, right up to commissioning.<br />

<strong>Wilo</strong> customer service<br />

At <strong>Wilo</strong>, we have a long tradition of<br />

customer support. A major component<br />

of our partnership philosophy is our<br />

own customer service, which is unique<br />

in the market.<br />

52 <strong>Wilo</strong> customer service technicians<br />

are available with their practical<br />

support 365 days a year, all across<br />

Germany. In addition, we have all<br />

common spare parts in stock and<br />

we are able to deliver within 24 hours,<br />

if required.<br />

Consulting and planning<br />

• Individual planning and configuration<br />

Installation and assembly<br />

• Expert installation and assembly of all<br />

<strong>system</strong> parts in co-operation with the<br />

customer on-site<br />

<strong>Wilo</strong> customer service<br />

• Maintenance of the <strong>solids</strong> <strong>separation</strong><br />

<strong>system</strong> and switching <strong>system</strong>s by <strong>Wilo</strong><br />

customer service<br />

15

Technology and service.<br />

From <strong>system</strong> technology to accessories.<br />

Pumping stations from <strong>Wilo</strong> can be<br />

reconfigured to meet individual<br />

requirements on their processing and<br />

performance functions. We produce<br />

within a standard programm:<br />

from the mini-<strong>system</strong> for the smallest<br />

volumes (inlet pipes up to 10 m³/h) to<br />

<strong>system</strong>s with delivery heads of up to<br />

80 m and inflows of up to 600 m³/h.<br />

What is more, <strong>Wilo</strong> also supplies<br />

customer-specific switching <strong>system</strong>s<br />

and operating buildings.<br />

Submersible sewage pumps<br />

The numerous combinations of fluids<br />

and <strong>solids</strong> in our sewage place many<br />

different demands on a pump solution.<br />

The <strong>Wilo</strong>-EMU FA series offers an<br />

extensive portfolio for a wide range<br />

of applications. Through the perfect<br />

combination of modern submersible<br />

motor technology, high-quality<br />

treated hydraulic components and the<br />

solvent-free two-component Ceram<br />

coating, <strong>Wilo</strong>-EMU sewage pumps<br />

guarantee long-term safe operation –<br />

even for the most demanding fluids.<br />

Switching <strong>system</strong>s<br />

Modern pumping <strong>system</strong>s require<br />

electrical/electronic components<br />

to control the mechanical parts such<br />

as the pumps and slide valves. <strong>Wilo</strong><br />

supplies customer-specific, preassembled<br />

switching <strong>system</strong>s and control<br />

<strong>system</strong>s. The range of functions of the<br />

switching <strong>system</strong>s and control <strong>system</strong>s<br />

stretches from simple pump control to<br />

complex remote control <strong>system</strong>s.<br />

Operating buildings<br />

Large pumps installed in soil often<br />

require an operating structure. <strong>Wilo</strong><br />

offers various preassembled operating<br />

buildings. From the size of the structure<br />

to the colour of the roof brick, there<br />

are a wide range of options available<br />

for you to customise your building.<br />

The operating building is delivered by<br />

lorry to the site and placed in its final<br />

position with the aid of a mobile crane.<br />

Sewage pumps<br />

• Operational reliability thanks to<br />

high-quality materials and technical<br />

components<br />

Switching <strong>system</strong>s<br />

• Standing cabinets for the entire<br />

electrical <strong>system</strong><br />

• Safe housing for highly delicate<br />

electronics<br />

• Simple and safe<br />

Operating buildings<br />

• Sturdy design<br />

• Short construction time<br />

• Weathering and break-in protection<br />

17

Usedom – Island of sun.<br />

Reliable sewage disposal –<br />

even in the high season.<br />

About 15 years ago,<br />

work began on the island of Usedom<br />

to renew the sewage <strong>system</strong> step by<br />

step. For economic reasons, the<br />

supervisory association relied heavily<br />

on pressure drainage. <strong>Wilo</strong>-<strong>EMUport</strong><br />

supplied the pumps stations with<br />

<strong>solids</strong> <strong>separation</strong> <strong>system</strong>s for this<br />

<strong>system</strong>.<br />

High demands on the sewage structure.<br />

With an area of 373 km² (plus 72 km²<br />

on the Polish side), Usedom, in the<br />

district of Eastern Pomerania, is<br />

Germany's second biggest island.<br />

Although very sparsely populated on<br />

the German side with 31,000 inhabitants<br />

(approx. 83 inhabitants/km²),<br />

its infrastructure needs to meet the<br />

seasonal demands of high numbers<br />

of guests, particularly in summer.<br />

On average, around 40 per cent more<br />

sewage is produced at this time of<br />

year. Measurements of the inflow<br />

amounts in the major treatment<br />

plant in Swinemünde show inflows of<br />

between 3,500 and 4,500 m³ per day<br />

on the German side in the summer<br />

months. Out of season, the figures<br />

are usually 2,500 to 3,000 m³ per day.<br />

Due to this, both the sewer <strong>system</strong> and<br />

the pumping stations must be designed<br />

to cope with the maximum amount<br />

of sewage. However, the maximum<br />

inflow amount is very hard to calculate,<br />

as the numbers of guests increase year<br />

upon year. In addition to this, the<br />

quantity of sewage also changes<br />

depending on the usage behaviour of<br />

the inhabitants and tourists.<br />

Demanding <strong>system</strong> planning.<br />

As there are no concrete figures for the<br />

influencing factors, the long-term<br />

measurements recorded at the beginning<br />

of renewal work on the Usedom<br />

sewage <strong>system</strong> were taken at different<br />

collection points.<br />

This at least gave the association<br />

guideline figures for calculating<br />

the capacity of the <strong>system</strong>s. These<br />

surveys and the figures on the average<br />

consumption of water per head served<br />

as the basis from which <strong>Wilo</strong>-<strong>EMUport</strong><br />

developed tailor-made solutions for<br />

the pressure drainage on Usedom.<br />

All the pumps stations were individually<br />

planned and designed for the projected<br />

inflow quantities and the calculated<br />

inflow depth. Then, of course, they<br />

were fitted with a <strong>Wilo</strong>-<strong>EMUport</strong> <strong>solids</strong><br />

<strong>separation</strong> <strong>system</strong>.<br />

The large range of <strong>Wilo</strong>-EMU sewage<br />

pumps from pump specialist WILO SE<br />

allows customers to choose the pump<br />

they need from pumps designed for<br />

the pumping requirements in question.<br />

Transport<br />

• The eighth pumps station leaves the<br />

factory in Minden.<br />

Assembly<br />

• Installing the PE-HD collection<br />

reservoir in the sump<br />

Commissioning<br />

• Checking the <strong>system</strong> after the first<br />

test run<br />

19

<strong>Wilo</strong> – International (Subsidiaries)<br />

Argentina<br />

WILO SALMSON<br />

Argentina S.A.<br />

C1295ABI Ciudad<br />

Autónoma de Buenos Aires<br />

T+ 54 11 4361 5929<br />

info@salmson.com.ar<br />

Austria<br />

WILO Pumpen<br />

Österreich GmbH<br />

1230 Wien<br />

T +43 507 507-0<br />

office@wilo.at<br />

Azerbaijan<br />

WILO Caspian LLC<br />

1065 Baku<br />

T +994 12 5962372<br />

info@wilo.az<br />

Belarus<br />

WILO Bel OOO<br />

220035 Minsk<br />

T +375 17 2503393<br />

wilobel@wilo.by<br />

Belgium<br />

WILO SA/NV<br />

1083 Ganshoren<br />

T +32 2 4823333<br />

info@wilo.be<br />

Bulgaria<br />

WILO Bulgaria Ltd.<br />

1125 Sofia<br />

T +359 2 9701970<br />

info@wilo.bg<br />

Canada<br />

WILO Canada Inc.<br />

Calgary, Alberta T2A 5L4<br />

T +1 403 2769456<br />

bill.lowe@wilo-na.com<br />

China<br />

WILO China Ltd.<br />

101300 Beijing<br />

T +86 10 80493900<br />

wilobj@wilo.com.cn<br />

<strong>Wilo</strong> – International (Representation offices)<br />

Algeria<br />

Bad Ezzouar, Dar El Beida<br />

T +213 21 247979<br />

chabane.hamdad@salmson.fr<br />

Armenia<br />

375001 Yerevan<br />

T +374 10 544336<br />

info@wilo.am<br />

Croatia<br />

WILO Hrvatska d.o.o.<br />

10090 Zagreb<br />

T +38 51 3430914<br />

wilo-hrvatska@wilo.hr<br />

Czech Republic<br />

WILO Praha s.r.o.<br />

25101 Cestlice<br />

T +420 234 098711<br />

info@wilo.cz<br />

Denmark<br />

WILO Danmark A/S<br />

2690 Karlslunde<br />

T +45 70 253312<br />

wilo@wilo.dk<br />

Estonia<br />

WILO Eesti OÜ<br />

12618 Tallinn<br />

T +372 6509780<br />

info@wilo.ee<br />

Finland<br />

WILO Finland OY<br />

02330 Espoo<br />

T +358 207401540<br />

wilo@wilo.fi<br />

France<br />

Pompes Salmson<br />

78403 Chatou<br />

T +33 820 0000 44<br />

service.conso@salmson.fr<br />

Great Britain<br />

WILO (U.K.) Ltd.<br />

DE14 2WJ Burton-<br />

Upon-Trent<br />

T +44 1283 523000<br />

sales@wilo.co.uk<br />

Greece<br />

WILO Hellas AG<br />

14569 Anixi (Attika)<br />

T +302 10 6248300<br />

wilo.info@wilo.gr<br />

Bosnia and Herzegovina<br />

71000 Sarajevo<br />

T +387 33 714510<br />

zeljko.cvjetkovic@wilo.ba<br />

Georgia<br />

0179 Tbilisi<br />

T +995 32 306375<br />

info@wilo.ge<br />

Subject to technical changes without prior notice.<br />

Hungary<br />

WILO Magyarország Kft<br />

2045 Törökbálint<br />

(Budapest)<br />

T +36 23 889500<br />

wilo@wilo.hu<br />

Ireland<br />

WILO Engineering Ltd.<br />

Limerick<br />

T +353 61 227566<br />

sales@wilo.ie<br />

Italy<br />

WILO Italia s.r.l.<br />

20068 Peschiera<br />

Borromeo (Milano)<br />

T +39 25538351<br />

wilo.italia@wilo.it<br />

Kazakhstan<br />

WILO Central Asia<br />

050002 Almaty<br />

T +7 727 2785961<br />

in.pak@wilo.kz<br />

Korea<br />

WILO Pumps Ltd.<br />

621-807 Gimhae<br />

Gyeongnam<br />

T +82 55 3405800<br />

wilo@wilo.co.kr<br />

Latvia<br />

WILO Baltic SIA<br />

1019 Riga<br />

T +371 67 145229<br />

mail@wilo.lv<br />

Lebanon<br />

WILO SALMSON<br />

Lebanon<br />

12022030 El Metn<br />

T +961 4 722280<br />

wsl@cyberia.net.lb<br />

Macedonia<br />

1000 Skopje<br />

T +389 2 3122058<br />

valerij.vojneski@wilo.com.mk<br />

Mexico<br />

07300 Mexico<br />

T +52 55 55863209<br />

roberto.valenzuela@wilo.com.mx<br />

Lithuania<br />

WILO Lietuva UAB<br />

03202 Vilnius<br />

T +370 5 2136495<br />

mail@wilo.lt<br />

The Netherlands<br />

WILO Nederland b.v.<br />

1551 NA Westzaan<br />

T +31 88 9456 000<br />

info@wilo.nl<br />

Norway<br />

WILO Norge AS<br />

0975 Oslo<br />

T +47 22 804570<br />

wilo@wilo.no<br />

Poland<br />

WILO Polska Sp. z.o.o.<br />

05-090 Raszyn<br />

T +48 22 7026161<br />

wilo@wilo.pl<br />

Portugal<br />

Bombas <strong>Wilo</strong>-Salmson<br />

Portugal Lda.<br />

4050-040 Porto<br />

T +351 22 2080350<br />

bombas@wilo.pt<br />

Romania<br />

WILO Romania s.r.l.<br />

077040 Com. Chiajna<br />

Jud. Ilfov<br />

T +40 21 3170164<br />

wilo@wilo.ro<br />

Russia<br />

WILO Rus ooo<br />

123592 Moscow<br />

T +7 495 7810690<br />

wilo@wilo.ru<br />

Saudi Arabia<br />

WILO ME - Riyadh<br />

Riyadh 11465<br />

T +966 1 4624430<br />

wshoula@wataniaind.com<br />

Moldova<br />

2012 Chisinau<br />

T +373 2 223501<br />

sergiu.zagurean@wilo.md<br />

Rep. Mongolia<br />

Ulaanbaatar<br />

T +976 11 314843<br />

wilo@magicnet.mn<br />

Serbia and Montenegro<br />

WILO Beograd d.o.o.<br />

11000 Beograd<br />

T +381 11 2851278<br />

office@wilo.co.yu<br />

Slovakia<br />

WILO Slovakia s.r.o.<br />

82008 Bratislava 28<br />

T +421 2 45520122<br />

wilo@wilo.sk<br />

Slovenia<br />

WILO Adriatic d.o.o.<br />

1000 Ljubljana<br />

T +386 1 5838130<br />

wilo.adriatic@wilo.si<br />

South Africa<br />

Salmson South Africa<br />

1610 Edenvale<br />

T +27 11 6082780<br />

errol.cornelius@<br />

salmson.co.za<br />

Spain<br />

WILO Ibérica S.A.<br />

28806 Alcalá de Henares<br />

(Madrid)<br />

T +34 91 8797100<br />

wilo.iberica@wilo.es<br />

Sweden<br />

WILO Sverige AB<br />

35246 Växjö<br />

T +46 470 727600<br />

wilo@wilo.se<br />

Switzerland<br />

EMB Pumpen AG<br />

4310 Rheinfelden<br />

T +41 61 83680-20<br />

info@emb-pumpen.ch<br />

Tajikistan<br />

734025 Dushanbe<br />

T +992 37 2232908<br />

farhod.rahimov@wilo.tj<br />

Turkmenistan<br />

744000 Ashgabad<br />

T +993 12 345838<br />

wilo@wilo-tm.info<br />

WILO SE<br />

Nortkirchenstraße 100<br />

44263 Dortmund<br />

Germany<br />

T +49 231 4102-0<br />

F +49 231 4102-7363<br />

wilo@wilo.com<br />

www.wilo.com<br />

WILO EMUPORT GmbH<br />

Zechenstr. 54<br />

32429 Minden<br />

Germany<br />

T +49 571 5055070<br />

F +49 571 5055079<br />

info@emuport.de<br />

www.wilo.com<br />

Taiwan<br />

WILO-EMU Taiwan Co. Ltd.<br />

110 Taipeh<br />

T +886 227 391655<br />

nelson.wu@<br />

wiloemutaiwan.com.tw<br />

Turkey<br />

WILO Pompa Sistemleri<br />

San. ve Tic. A.S¸.<br />

34530 Istanbul<br />

T +90 216 6610211<br />

wilo@wilo.com.tr<br />

Ukraina<br />

WILO Ukraina t.o.w.<br />

01033 Kiew<br />

T +38 044 2011870<br />

wilo@wilo.ua<br />

Vietnam<br />

Pompes Salmson Vietnam<br />

Ho Chi Minh-Ville Vietnam<br />

T +84 8 8109975<br />

nkm@salmson.com.vn<br />

United Arab Emirates<br />

WILO Middle East FZE<br />

Jebel Ali - Dubai<br />

T +971 4 886 4771<br />

info@wilo.com.sa<br />

USA<br />

WILO-EMU USA LLC<br />

Thomasville,<br />

Georgia 31792<br />

T +1 229 5840097<br />

info@wilo-emu.com<br />

USA<br />

WILO USA LLC<br />

Melrose Park, Illinois 60160<br />

T +1 708 3389456<br />

mike.easterley@<br />

wilo-na.com<br />

Uzbekistan<br />

100015 Tashkent<br />

T +998 71 1206774<br />

info@wilo.uz<br />

June 2009