ECL Comfort 110 Application 116 Constant temperature control of ...

ECL Comfort 110 Application 116 Constant temperature control of ...

ECL Comfort 110 Application 116 Constant temperature control of ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

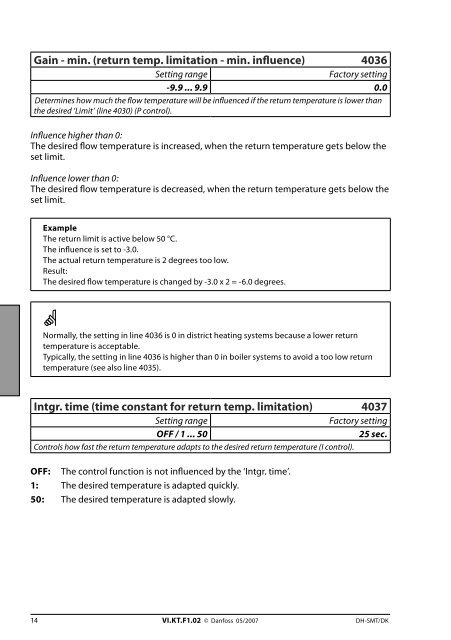

Gain - min. (return temp. limitation - min. influence) 4036<br />

Setting range Factory setting<br />

-9.9 ... 9.9 0.0<br />

Determines how much the flow <strong>temperature</strong> will be influenced if the return <strong>temperature</strong> is lower than<br />

the desired ‘Limit’ (line 4030) (P <strong>control</strong>).<br />

Influence higher than 0:<br />

The desired flow <strong>temperature</strong> is increased, when the return <strong>temperature</strong> gets below the<br />

set limit.<br />

Influence lower than 0:<br />

The desired flow <strong>temperature</strong> is decreased, when the return <strong>temperature</strong> gets below the<br />

set limit.<br />

Example<br />

The return limit is active below 50 °C.<br />

The influence is set to -3.0.<br />

The actual return <strong>temperature</strong> is 2 degrees too low.<br />

Result:<br />

The desired flow <strong>temperature</strong> is changed by -3.0 x 2 = -6.0 degrees.<br />

Normally, the setting in line 4036 is 0 in district heating systems because a lower return<br />

<strong>temperature</strong> is acceptable.<br />

Typically, the setting in line 4036 is higher than 0 in boiler systems to avoid a too low return<br />

<strong>temperature</strong> (see also line 4035).<br />

Intgr. time (time constant for return temp. limitation) 4037<br />

Setting range Factory setting<br />

OFF / 1 ... 50 25 sec.<br />

Controls how fast the return <strong>temperature</strong> adapts to the desired return <strong>temperature</strong> (I <strong>control</strong>).<br />

OFF: The <strong>control</strong> function is not influenced by the ‘Intgr. time’.<br />

1: The desired <strong>temperature</strong> is adapted quickly.<br />

50: The desired <strong>temperature</strong> is adapted slowly.<br />

14 VI.KT.F1.02 © Danfoss 05/2007 DH-SMT/DK<br />

Control param. (<strong>control</strong> parameters) 6000<br />

Auto tuning 6173<br />

Setting range Factory setting<br />

ON / OFF OFF<br />

Automatically determines the <strong>control</strong> parameters for the DHW <strong>control</strong>. Lines 6184, 6185, 6186 and 6187<br />

do not need to be set, when using auto tuning.<br />

OFF: Auto tuning is not activated.<br />

ON: Auto tuning is activated.<br />

The auto tuning function automatically determines the <strong>control</strong> parameters for DHW<br />

<strong>control</strong>. Thus you do not need to set the lines 6184 and 6185, as they are automatically<br />

set to the auto tuning function.<br />

Auto tuning is typically used in connection with the installation <strong>of</strong> the <strong>control</strong>ler, but it<br />

can be activated when needed, e.g. for an extra check <strong>of</strong> the <strong>control</strong> parameters.<br />

Before starting the auto tuning, the tapping flow should be adjusted to the relevant<br />

value (see table below).<br />

Recommended tapping load<br />

No. <strong>of</strong> apartments Heat transfer (kW) <strong>Constant</strong> tapping load (l / min)<br />

1-2 30-49 3 (or 1 tap 25% open)<br />

3-9 50-79 6 (or 1 tap 50% open)<br />

10-49 80-149 12 (or 1 tap 100% open)<br />

50-129 150-249 18 (or 1 tap 100% + 1 tap 50% open)<br />

130-210 250-350 24 (or 2 taps 100% open)<br />

If possible, any additional DHW consumption should be avoided during the auto tuning<br />

process. Should the tapping load vary too much, the auto tuning and <strong>control</strong>ler will<br />

return to the default settings.<br />

Auto tuning is activated by setting the function to ON. When the auto tuning is ended,<br />

the function is automatically converted to OFF (default setting). This will be indicated in<br />

the display.<br />

The auto tuning process takes up to 25 minutes.<br />

The motor protection function (line 6174) has to be deactivated during auto tuning.<br />

During auto tuning the circulation pump for tap water must be switched <strong>of</strong>f. This is done<br />

automatically if the pump is <strong>control</strong>led by the <strong>ECL</strong> <strong>control</strong>ler.<br />

Auto tuning is only applicable in connection with valves that are approved for auto tuning,<br />

i.e. the Danfoss types VB 2 and VM 2 with split characteristic.<br />

DH-SMT/DK VI.KT.F1.02 © Danfoss 05/2007 15