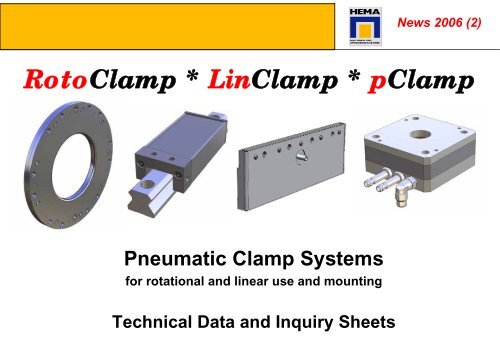

RotoClamp * LinClamp * pClamp

RotoClamp * LinClamp * pClamp

RotoClamp * LinClamp * pClamp

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Pneumatic Clamp Systems<br />

for rotational and linear use and mounting<br />

Technical Data and Inquiry Sheets<br />

News 2006 (2)<br />

<strong>RotoClamp</strong> * <strong>LinClamp</strong> * <strong>pClamp</strong>

<strong>RotoClamp</strong> S<br />

<strong>RotoClamp</strong> – Standard sizes<br />

<strong>RotoClamp</strong> S is available in standard sizes with an internal diameter from 50 to 90 mm. Clamps with other dimensions to provide appropriate clamping<br />

performance can be developed to suit customer requirements. The required clamping performance can be increased by stacking and series connecting<br />

<strong>RotoClamp</strong> S type clamps. The application of additional pneumatic back pressure on the lamella diaphragms can be used to increase the clamping torque.<br />

The assembled thickness of the <strong>RotoClamp</strong> S is 15 mm, please consider for future designs 22 mm.<br />

Sizes Ø D1 Recommended<br />

flange diameter<br />

Ø D2 Ø D3 E F Elastic moment Elastic moment<br />

with additional<br />

air (booster)<br />

Maximum<br />

clamping<br />

moment<br />

The stated clamping moments apply with an operating pressure of 5.5 bar – 6.5 bar, clamping moment is reduced to<br />

approx. 70% of listed values for 4 bar versions. Please ask your sales consultant if your required size is available with<br />

additional air.<br />

Maximum<br />

clamping<br />

moment with<br />

additional air<br />

(booster)<br />

Tolerance +0,04 bis +0,06 -0,01 bis -0,025 ±0,1<br />

Concentricity 0.010 0.010<br />

<br />

Roughness Ra 0,8 1,6<br />

µm µm<br />

RC 50 S 50 50 134 145 63.5 67.5 60 108 100 180<br />

RC 60 S 60 60 144 155 68.5 72.5 84 153 140 255<br />

RC 70 S 70 70 154 165 73.5 77.5 114 210 190 350<br />

RC 80 S 80 80 164 175 78.5 82.5 150 270 250 450<br />

RC 90 S 90 90 174 185 83.5 87.5 189 342 315 570<br />

The friction surface of the <strong>RotoClamp</strong> is hardened and tempered (Material: Steel heat treated to 1,000 to 1,100 N/mm 2).<br />

The shaft can be supplied in any steel material, but it should be nitrided in order to guard against fretting corrosion.<br />

Product line S<br />

050 - 095<br />

<strong>RotoClamp</strong> S

<strong>RotoClamp</strong> S<br />

Product line S<br />

50 - 65<br />

<strong>RotoClamp</strong> S

<strong>RotoClamp</strong> S<br />

Product line S<br />

70 - 95<br />

<strong>RotoClamp</strong> S

<strong>RotoClamp</strong> N<br />

<strong>RotoClamp</strong> N – Standard Sizes<br />

Product line N<br />

100 - 340<br />

<strong>RotoClamp</strong> N<br />

<strong>RotoClamp</strong> N is available in standard sizes with an internal diameter from 100 to 340 mm. Clamps with other dimensions to provide appropriate clamping<br />

performance can be developed to suit customer requirements. The requisite clamping performance can be increased by stacking and multiple connecting<br />

<strong>RotoClamp</strong> N type clamps. The application of additional pneumatic back pressure on the lamella diaphragms can be used to increase the clamping torque. The<br />

assembled thickness B of the <strong>RotoClamp</strong> N is depending on the diameter and varies from 16 to 22 mm, alternative thickness in brackets.<br />

Sizes Ø D1 Recommded<br />

flange diameter<br />

Ø D2 Ø D3 B E F Elastic moment Elastic moment<br />

with additional<br />

air (booster)<br />

Maximum<br />

clamping<br />

moment<br />

Maximum<br />

clamping<br />

moment with<br />

additional air<br />

(booster)<br />

Roughness Ra 0,8 1,6<br />

µm µm<br />

Tolerance +0,04 bis +0,06 -0,01 bis -0,025 ±0,1<br />

Concentricity 0.010 0.010<br />

<br />

RC 100 N 100 100 210 228 16 (20) 103 103 240 420 400 700<br />

RC 120 N 120 120 230 248 16 (20) 113 113 336 600 560 1000<br />

RC 140 N 140 140 250 268 16 (20) 123 123 456 840 760 1400<br />

RC 160 N 160 160 270 288 16 (20) 133 133 600 1080 1000 1800<br />

RC 180 N 180 180 290 308 20 (28) 137 143 750 1380 1250 2300<br />

Tolerance +0,05 bis +0,07 -0,01 bis -0,03 ±0,1<br />

Concentricity 0.015 0.015<br />

<br />

RC 200 N 200 200 310 328 20 (28) 147 153 930 1680 1550 2800<br />

RC 220 N 220 220 330 348 20 (28) 157 163 1110 2040 1850 3400<br />

RC 240 N 240 240 350 368 20 (28) 167 173 1350 2400 2250 4000<br />

RC 260 N 260 260 370 388 22 (28) 177 183 1560 2820 2600 4700<br />

RC 280 N 280 280 390 408 22 (28) 187 193 1800 3240 3000 5400<br />

RC 300 N 300 300 410 428 22 (28) 197 203 2100 3720 3500 6200<br />

RC 320 N 320 320 430 448 22 (28) 207 213 2340 4200 3900 7000<br />

RC 340 N 340 340 450 468 22 (28) 217 223 2580 4680 4300 7800<br />

The stated clamping moments apply with an operating pressure of 5.5 bar – 6.5 bar, clamping moment is reduced to approx. 70%<br />

of listed values for 4 bar versions. Please ask your sales consultant if your required size is available with additional air.<br />

The friction surface of the <strong>RotoClamp</strong> is hardened and tempered (Material: Steel heat treated to 1,000 to 1,100 N/mm 2). The shaft<br />

can be supplied in any steel quality, but it should be nitrided in order to guard against fretting corrosion.

<strong>RotoClamp</strong> N<br />

Product line N<br />

100 - 160<br />

<strong>RotoClamp</strong> N

<strong>RotoClamp</strong> N<br />

Product line N<br />

180 - 220<br />

<strong>RotoClamp</strong> N

<strong>RotoClamp</strong> N<br />

Product line N<br />

240 - 340<br />

<strong>RotoClamp</strong> N

<strong>RotoClamp</strong> L<br />

<strong>RotoClamp</strong> – L Special sizes<br />

The stated clamping moments apply with an operating pressure of 4 bar, clamping moment without booster can be higher for 5.5<br />

bar versions. Please ask your sales consultant if your required size is available with additional air.<br />

The friction surface of the <strong>RotoClamp</strong> is hardened and tempered (Material: Steel heat treated to 1,000 to 1,100 N/mm 2). The shaft<br />

can be supplied in any steel quality, but it should be nitrided in order to guard against fretting corrosion.<br />

Options<br />

<strong>RotoClamp</strong><br />

<strong>RotoClamp</strong> L is available in listed standard sizes. Clamps with other dimensions to provide appropriate clamping performance can be<br />

developed to suit customer requirements. The requisite clamping performance can be optimally achieved by stacking and multiple connecting<br />

<strong>RotoClamp</strong> L type clamps. The application of additional pneumatic back pressure on the lamella diaphragms can be used to increase the<br />

clamping torque. The assembled thickness B of the <strong>RotoClamp</strong> L is 22 mm.<br />

Sizes Ø D1 Recommded flange<br />

diameter<br />

Ø D2 Ø D3 B E F Elastic moment Elastic moment<br />

with additional<br />

air (booster)<br />

Maximum<br />

clamping<br />

moment<br />

Maximum<br />

clamping<br />

moment with<br />

additional air<br />

(booster)<br />

Roughness Ra 0,8 1,6<br />

µm µm<br />

Tolerance +0,04 bis +0,06 -0,01 bis -0,025 ±0,1<br />

Concentricity 0.010 0.010<br />

<br />

RC 70 L 70 70 204 225 22 100 100 114 210 190 350<br />

RC 140 L 140 140 274 295 22 135 135 456 840 760 1400<br />

RC 180 L 180 180 314 335 22 155 155 750 1380 1250 2300<br />

Tolerance +0,04 bis +0,06 -0,01 bis -0,025 ±0,1<br />

Concentricity 0.010 0.010<br />

<br />

RC 200 L 200 200 334 355 22 165 165 930 1680 1550 2800<br />

RC 220 L 220 220 354 375 22 175 175 1110 2040 1850 3400<br />

RC 240 L 240 240 374 395 22 185 185 1350 2400 2250 4000<br />

RC 280 L 280 280 414 435 22 205 205 1800 3240 3000 5400<br />

RC 320 L 320 320 454 475 22 225 225 2340 4200 3900 7000<br />

RC 340 L 340 340 474 495 22 235 235 2580 4680 4300 7800

<strong>RotoClamp</strong><br />

<strong>RotoClamp</strong> – Option: shaft flange for standard sizes<br />

<strong>RotoClamp</strong> is also available as a complete unit with adapter rings according to your shaft requirements and in different materials.<br />

Options: Flanges (to be mounted on to the shaft) of<br />

following qualities:<br />

- C45 in standard version, suited for most applications<br />

-Other:ideal gliding qualities<br />

Options<br />

<strong>RotoClamp</strong><br />

Sizes Ø A Ø B<br />

n counter<br />

sink<br />

Tolerance H7 ± 0.1 mm<br />

Cylinder shape 0.015 mm<br />

100 60 80 8<br />

120 80 100 8<br />

140 100 120 8<br />

160 110 136 12<br />

180 130 156 12<br />

200 150 176 12<br />

220 170 196 12<br />

240 190 216 12<br />

260 210 236 12<br />

280 230 256 12<br />

300 250 276 12<br />

320 270 296 12

<strong>RotoClamp</strong><br />

<strong>RotoClamp</strong><br />

<strong>RotoClamp</strong> – Installation and Assembly<br />

Optional shaft ring<br />

Locating pins<br />

Shaft<br />

Ensure rigid connection for effective force transfer !<br />

Counter bore for<br />

screws according<br />

DIN 6912 / DIN 7984,<br />

Mounting taps<br />

as option<br />

RC should never be supported<br />

completely, allow area to<br />

move freely: Consider<br />

diameter D3 minus 60 mm<br />

Installation / Assembly<br />

<strong>RotoClamp</strong><br />

General:<br />

• To maximize clamping force transfer, a rigid<br />

connection to the machine structure is necessary.<br />

• Especially with large <strong>RotoClamp</strong>, from 160 mm<br />

on, clamping leads to radial expansion of the<br />

case. This expansion reduces the clamping force.<br />

• The clamping moments stated in the catalogue<br />

can only be obtained with the proper construction.<br />

We are always willing to assist.<br />

Assembly procedure shaft flange:<br />

• The shaft seat should be an g6 fitting. The shaft<br />

ring is screwed on and concentrically aligned.<br />

• Finally the remaining gap (approx. 0.1 mm) is<br />

filled with compound filler, such as Loctite 638.<br />

Assembly procedure <strong>RotoClamp</strong>:<br />

• Connect air to <strong>RotoClamp</strong>, this must be in<br />

unclamped mode. Then move it over shaft in the<br />

desired position, adjust it and tighten screws with<br />

reduced torque moment.<br />

• After you have built in the <strong>RotoClamp</strong>, reduce air<br />

pressure to 0 Bar until <strong>RotoClamp</strong> is centered<br />

fully onto shaft.<br />

• When <strong>RotoClamp</strong> is placed in the final position<br />

tighten screws fully with the defined required<br />

torque moment<br />

• Additional pins can be used.

<strong>RotoClamp</strong><br />

Technical Notes<br />

Construction<br />

Details<br />

<strong>RotoClamp</strong><br />

1. The accuracy of the clamping surfaces is<br />

obtained by internal cylindrical grinding to the<br />

given dimensions. The axial concentricity of the<br />

clamping surfaces to the bolt-on surfaces is less<br />

than 0.015 mm.<br />

2. The width of the clamping surface is approx. 7<br />

mm. Based on analysis of supporting images it<br />

can be seen that in the region between 2.5 and<br />

3 mm a high surface pressure is produced.<br />

3. The maximum bending stress on the clamping<br />

lips of the <strong>RotoClamp</strong> (without shaft) is approx.<br />

600 N/mm². The bending stress with a solid<br />

shaft is approx. 30 to 40 N/mm², with a hollow<br />

shaft, the values should lie in between. The<br />

hollow shaft must be designed to overtake the<br />

forces applied by the clamp.<br />

4. Applicable torque (example):<br />

Use of 12.9 screws M8 with a pre-tensioning<br />

force 30,700 N per screw, a friction value of<br />

µ=0,1 and Radius 100mm a transferable torque<br />

of 307 Nm per screw is achieved.<br />

5. Concentricity of the shaft when assembled<br />

should be less than 0.010 mm.<br />

6. Monitor the alignment and mounting of the<br />

clamps during procedure.<br />

7. Check the air flow in stacked clamps. Ideally<br />

stacked clamp solutions must be delivered preassembled<br />

by us. Please inform us if you intend<br />

to use this version.<br />

8. <strong>RotoClamp</strong> cannot be supported from the<br />

outside diameter.

<strong>RotoClamp</strong><br />

Warranty and how to enable long trouble-free operation<br />

1. Check mounting and installation of RC: Tightening moments,<br />

select suitable property classes of screws, make sure that the<br />

machine surface for RC is surface grinded<br />

2. The area where RC is mounted needs to have a minimum free<br />

area of 0.1 mm (D3 - 60mm), so that the RC is not supported<br />

completely.<br />

3. The locating surface for <strong>RotoClamp</strong> must be geometrically<br />

perfect, ideally surface ground.<br />

4. Consider and specify tightening moments of screws<br />

5. Respect shaft tolerances, concentricity, surface conditions,<br />

shaft and mounting area for clamp, gap tolerances between<br />

shaft and clamp<br />

6. Check and select suitable air supply , length of air hoses, type<br />

of valves<br />

7. All <strong>RotoClamp</strong> needs to be tested for life-time, precision,<br />

clamping forces and speed of clamping when usage in massproduction<br />

is considered, clamping forces and clamping<br />

behavior can change depending on the ambient influences of<br />

the system<br />

8. Specify expected number of clamping cycles per year and<br />

clamping cycle rate<br />

9. Specify the maximum required clamping force in the application,<br />

estimate the average clamping force, give the calculated safety<br />

factor to determine the ideal clamping type combination<br />

(consider 60% as safety factor), consider Elastic moment and<br />

holding forces.<br />

10. Customer machine design should support easy (de)mounting of<br />

<strong>RotoClamp</strong> and good access to allow quick and cost-effective<br />

service<br />

11. Warranty 12 months according our general terms of business<br />

and supply.<br />

Inquiry sheet<br />

<strong>RotoClamp</strong><br />

Name of company : _______________________________________<br />

Contact: _______________________________________<br />

Phone/Fax: ___________________ / ___________________<br />

E-Mail/Internet: ___________________ / ___________________<br />

Important questions for your <strong>RotoClamp</strong> – solution:<br />

Application: _______________________________________<br />

_______________________________________<br />

(Drawing of application to be attached or to be e-mailed to info@hema-schutz.de)<br />

Project partner (e.g. supplier of different construction parts): _________________<br />

Clamping cycles: ________ per year, special requirements __________<br />

Clamping torque: ________ Nm<br />

Dimensions (all specifications in mm):<br />

Outer diameter D3: ___________ Inside diameter D1: ___________<br />

Flange diameter D2: ___________ Height: ___________<br />

Standard hole positioning as shown in drawing : YES / NO<br />

For deviating options: Please send drawing or e-mail to info@hema-schutz.de)<br />

Optional adapter ring of _____________<br />

Number of pieces: ______________ Delivery date: _______________<br />

Additional data:<br />

Visit is needed / We wish a return call for further information __________________

<strong>LinClamp</strong> S<br />

Standard sizes<br />

Linear Rail Version<br />

Rail sizes<br />

20<br />

25<br />

30<br />

35<br />

45<br />

55<br />

65<br />

Technical data:<br />

L<br />

97.5<br />

117.5<br />

126.5<br />

156.5<br />

176.5<br />

202.5<br />

259.5<br />

Technical data<br />

<strong>LinClamp</strong> S <strong>LinClamp</strong> S<br />

B<br />

43<br />

47<br />

59<br />

69<br />

80<br />

98<br />

120<br />

H<br />

High<br />

Carriage<br />

30<br />

40<br />

45<br />

55<br />

70<br />

80<br />

100<br />

H1<br />

29<br />

32.5<br />

42<br />

52<br />

59<br />

74<br />

A<br />

19.5<br />

20<br />

29.5<br />

36.5<br />

38<br />

48<br />

H<br />

Large<br />

Carriage<br />

30<br />

36<br />

42<br />

48<br />

60<br />

70<br />

90<br />

H1<br />

19.5<br />

25<br />

29.5<br />

35<br />

42<br />

49<br />

64<br />

A<br />

13.5<br />

15.5<br />

17<br />

22.5<br />

26.5<br />

28<br />

38<br />

B1<br />

6<br />

6<br />

10<br />

10<br />

10<br />

12.5<br />

15<br />

C<br />

15<br />

20<br />

24<br />

24<br />

26<br />

30<br />

40<br />

G<br />

M5<br />

M5<br />

M5<br />

1/8"<br />

1/8"<br />

1/8"<br />

1/4“<br />

M<br />

M5<br />

M6<br />

M8<br />

M8<br />

M10<br />

M12<br />

M12<br />

Holding Force*<br />

900 N<br />

1.200 N<br />

1.800 N<br />

2.800 N<br />

4.000 N<br />

6.000 N<br />

10.000 N<br />

*Holding forces are valid for roller guide ways (INA, STAR) on dry rail, other conditions and rail types upon request. Consider only about 60% of listed holding<br />

forces for greasy rails depending on type of grease used. Special clamp pads with 100% holding forces (not for braking) are available for greasy rails. Clamp is<br />

released at an operating pressure of 5.5 – 6 bar, other operating pressures available on request

<strong>LinClamp</strong> SA / SK<br />

<strong>LinClamp</strong> SK (Safety Clamp)<br />

<strong>LinClamp</strong> SA (Clamps with Air)<br />

New Types<br />

<strong>LinClamp</strong> SA /SK<br />

Rail version<br />

Type Rail sizes L B H H1 A B1 C G M<br />

Holding<br />

forces*<br />

SA 25 40 75 36 23 15 5 20 M5 M6 500 N - 800 N<br />

SK 25 55,5 75 36 32,5 16 5 20 M5 M6 upon request<br />

SK 35 67 96 48 40 20 8,75 24 G 1/8 M8 upon request<br />

*Holding forces are valid for roller guide ways (INA, STAR) on dry rail, other conditions and rail types upon request. Consider only about 60% of listed holding<br />

forces for greasy rails depending on type of grease used. Special clamp pads with 100% clamping force (not for braking) are available for greasy rails. Clamp is<br />

released at an operating pressure of 5.5 – 6 bar, other operating pressures available on request

Types 25, 35 Types 35, 45 Type 25<br />

Technical Data<br />

Types<br />

25<br />

35<br />

45<br />

<strong>LinClamp</strong> A<br />

L<br />

140<br />

212<br />

262<br />

B<br />

28.15<br />

29.45<br />

29.2<br />

H<br />

60<br />

81<br />

91<br />

H1<br />

36<br />

55<br />

65<br />

*Braking forces are depending on the surface material, clamp is released at an operating pressure of 4 bar.<br />

Type 25 has a holding force of 500 N and type 35 of 800 N.<br />

A<br />

17<br />

19<br />

19<br />

C<br />

4<br />

8<br />

8<br />

D<br />

6.8<br />

6.8<br />

8.5<br />

E<br />

50<br />

50<br />

60<br />

F<br />

80<br />

150<br />

180<br />

G<br />

3.5<br />

3.5<br />

3.5<br />

I<br />

17<br />

14<br />

14<br />

J<br />

19<br />

22<br />

22.5<br />

K<br />

18<br />

18<br />

18<br />

<strong>LinClamp</strong> A

<strong>LinClamp</strong><br />

Important questions for your <strong>LinClamp</strong> – solution:<br />

Name of company: _______________________________________<br />

Contact: _______________________________________<br />

Phone/Fax: ___________________ / ___________________<br />

E-Mail/Internet: ___________________ / ___________________<br />

<strong>LinClamp</strong> Type according data table: ___________________________<br />

Number of pieces: ______________<br />

Delivery date: _______________<br />

Additional data:<br />

Visit is needed _____________<br />

We wish a return call for further information ______________<br />

Others __________________<br />

<strong>LinClamp</strong> systems can be modified for different applications.<br />

Inquiry sheet<br />

<strong>LinClamp</strong><br />

The following criteria are the basis for the individual configuration of the system.<br />

Provide as much as possible detailed and complete information:<br />

Usage horizontal vertical (with PLC) vertical (uncontrolled, free fall)<br />

System should open with air clamp with air<br />

Holding force ________ N Air pressure: ________ bar<br />

Required braking distance ____ mm Reaction time (customer system) ____ sec.<br />

Used as a) Brake b) Emergency brake c) Safety catch<br />

d) Clamp e) Operating (process) clamp<br />

Number of clamping cycles per hour : __________________<br />

Required minimum lifetime (Number of cycles) ________________<br />

Operating condition: dry oiled with grease<br />

Exact type of oil/grease : ______________________________________________<br />

Rail manufacturer, Type, Size __________________________________________<br />

Type of carriage (high/wide): ___________________________________________<br />

Other clamp types used/considered _____________________________________

<strong>pClamp</strong> N<br />

(P) Pneumatic Cylinder -<br />

(K) Piston Rod -<br />

(M) Number of Clamping<br />

Moduls A B C D Air supply E<br />

Holding<br />

force in N<br />

with 4 bar<br />

opening<br />

pressure<br />

Forces and Sizes<br />

Holding<br />

force in N<br />

with 6 bar<br />

opening<br />

pressure<br />

<strong>pClamp</strong><br />

Standard<br />

rod<br />

diameter in<br />

mm<br />

PC 63-20-1 75 56.5 8.5 39.5 M5 2.1 1400 2000 20<br />

PC 63-20-2 75 56.5 8.5 57.5 M5 2.1 2520 3600 20<br />

PC 63-20-3 75 56.5 8.5 75.5 M5 2.1 3780 5400 20<br />

PC 80-25-1 96 72 10.5 41.5 G 1/8 2.14 2100 3000 25<br />

PC 80-25-2 96 72 10,5 61.5 G 1/8 2.14 3780 5400 25<br />

PC 80-25-3 96 72 10.5 81.5 G 1/8 2.14 5670 8100 25<br />

PC 125-40-1 145 110 13 53 G 1/8 3 7000 10000 40<br />

PC 125-40-2 145 110 13 78 G 1/8 3 12600 18000 40<br />

PC 125-40-3 145 110 13 103 G 1/8 3 18900 27000 40<br />

Listed holding forces can be reached under optimal conditions, we recommend to calculate with a minimum safety factor of 10%. Please pay attention<br />

to surface conditions, material, wearing and cleanness of the rod and rod wipers which will lead to different holding forces. Please determine for safety<br />

or mass production applications the real holding force in your later application environment.

p-Clamp<br />

Inquiry sheet<br />

p-Clamp<br />

Company name: _______________________________________<br />

Contact person: _______________________________________<br />

Phone/Fax: ___________________ / ___________________<br />

E-Mail/Internet: ___________________ / ___________________<br />

PClamp-systems can be modified for different applications.<br />

The following criteria are the basis for the individual configuration of the system.<br />

Provide as much as possible detailed and complete information:<br />

PClamp-Type according data table: _______ N-Type X-Type<br />

System can only open with air, standard air pressure 4 bar 6 bar<br />

Usage horizontal vertical (with PLC) vertical (uncontrolled, free fall)<br />

Required holding force ________ N Number of modules: ____________<br />

Required holding distance ____ mm Reaction time (customer system) ____ sec.<br />

Number of clamping cycles per hour: __________________<br />

Requested minimum life cycles (Number of cycles) ________________<br />

Operating conditions: dry oil grease<br />

Exact type of oil/grease : ___________________________________<br />

Piston diameter: ________ mm<br />

Manufacturer of cylinder: ___________________________________________<br />

Description of cylinder: ____________________________________________<br />

Piston rod wiper:_ _________________________________________________<br />

Quantity: ______________ Delivery Date : _______________<br />

Visit is needed ____ We wish a return call for further information ____<br />

Others __________________________________________________________

<strong>RotoClamp</strong> * p-Clamp * <strong>LinClamp</strong><br />

Hema Maschinen- und Apparateschutz GmbH Hema Representative:<br />

Seligenstädter Strasse 82<br />

D – 63500 Seligenstadt<br />

Phone: +49-(0)6182-773-0<br />

Fax: +49-(0)6182-773-35<br />

Internet: www.hema-gmbh.com<br />

Email: info@hema-schutz.de<br />

Release: February 2006, subject to change without prior notice. Publication only with written authorisation from Hema and InnoTech.<br />

All technical data and drawings in the catalogue are standard values, which might be different in the actual customer application. Listed<br />

data are not binding, final binding values are confirmed on the actual sales order. Please pay extra care to mounting holes and<br />

assembly details.<br />

<strong>RotoClamp</strong>, p-Clamp and <strong>LinClamp</strong> are developments of InnoTech Engineering GmbH.