Clamping/Braking Systems HMSB Electromagnetic Rod brake

Clamping/Braking Systems HMSB Electromagnetic Rod brake

Clamping/Braking Systems HMSB Electromagnetic Rod brake

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

10<br />

<strong>Clamping</strong> and<br />

<strong>Braking</strong> <strong>Systems</strong><br />

Order and request forms available at: www.hema-schutz.de<br />

<strong>Clamping</strong>/<strong>Braking</strong> <strong>Systems</strong><br />

<strong>HMSB</strong> <strong>Electromagnetic</strong> <strong>Rod</strong> <strong>brake</strong><br />

The <strong>HMSB</strong> is a compact, electromagnetic rod <strong>brake</strong> that can<br />

be used as a service, retaining, or emergency stop <strong>brake</strong>.<br />

It operates with a spring energy<br />

storage device (with a tried and tested spring) and is vented<br />

electromagnetically. In the standard version, it can also be<br />

used as a safety <strong>brake</strong> (failsafe principle).<br />

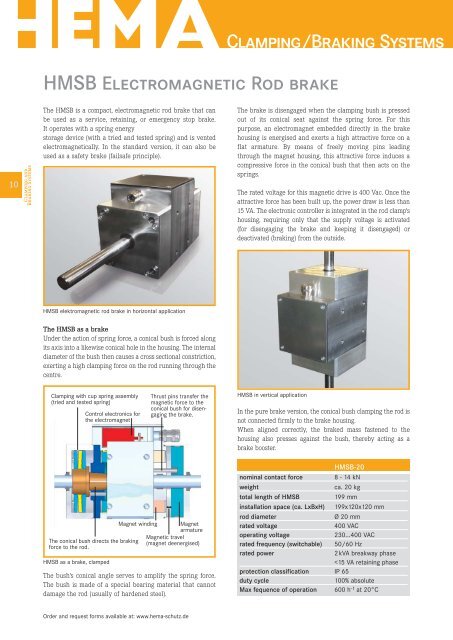

<strong>HMSB</strong> elektromagnetic rod <strong>brake</strong> in horizontal application<br />

The <strong>HMSB</strong> as a <strong>brake</strong><br />

Under the action of spring force, a conical bush is forced along<br />

its axis into a likewise conical hole in the housing. The internal<br />

diameter of the bush then causes a cross sectional constriction,<br />

exerting a high clamping force on the rod running through the<br />

centre.<br />

<strong>Clamping</strong> with cup spring assembly<br />

(tried and tested spring)<br />

<strong>HMSB</strong> as a <strong>brake</strong>, clamped<br />

Control electronics for<br />

the electromagnet<br />

Magnet winding<br />

The conical bush directs the braking<br />

force to the rod.<br />

Thrust pins transfer the<br />

magnetic force to the<br />

conical bush for disengaging<br />

the <strong>brake</strong>.<br />

The bush's conical angle serves to amplify the spring force.<br />

The bush is made of a special bearing material that cannot<br />

damage the rod (usually of hardened steel).<br />

►<br />

►<br />

Magnet<br />

armature<br />

Magnetic travel<br />

(magnet deenergised)<br />

The <strong>brake</strong> is disengaged when the clamping bush is pressed<br />

out of its conical seat against the spring force. For this<br />

purpose, an electromagnet embedded directly in the <strong>brake</strong><br />

housing is energised and exerts a high attractive force on a<br />

flat armature. By means of freely moving pins leading<br />

through the magnet housing, this attractive force induces a<br />

compressive force in the conical bush that then acts on the<br />

springs.<br />

The rated voltage for this magnetic drive is 400 Vac. Once the<br />

attractive force has been built up, the power draw is less than<br />

15 VA. The electronic controller is integrated in the rod clamp's<br />

housing, requiring only that the supply voltage is activated<br />

(for disengaging the <strong>brake</strong> and keeping it disengaged) or<br />

deactivated (braking) from the outside.<br />

<strong>HMSB</strong> in vertical application<br />

In the pure <strong>brake</strong> version, the conical bush clamping the rod is<br />

not connected firmly to the <strong>brake</strong> housing.<br />

When aligned correctly, the <strong>brake</strong>d mass fastened to the<br />

housing also presses against the bush, thereby acting as a<br />

<strong>brake</strong> booster.<br />

<strong>HMSB</strong>-20<br />

nominal contact force 8 - 14 kN<br />

weight ca. 20 kg<br />

total length of <strong>HMSB</strong> 199 mm<br />

installation space (ca. LxBxH) 199x120x120 mm<br />

rod diameter Ø 20 mm<br />

rated voltage 400 VAC<br />

operating voltage 230...400 VAC<br />

rated frequency (switchable) 50/60 Hz<br />

rated power 2kVA breakway phase<br />

<strong>HMSB</strong> <strong>Electromagnetic</strong> <strong>Rod</strong> <strong>brake</strong><br />

This self locking mechanism can be utilised for emergency<br />

braking (e.g. as an antifall device on a vertical arrangement).<br />

This causes such a high clamping force that the magnet is no<br />

longer able to disengage the <strong>brake</strong>.<br />

The <strong>brake</strong> must then be moved counter to the direction of<br />

braking so that the magnet can overcome this clamping force.<br />

When the max aggregate load (static and dynamic loads) does<br />

not exceed the <strong>brake</strong>'s nominal force, the magnetic force can<br />

disengage the <strong>brake</strong> without the need to move it.<br />

The pure <strong>brake</strong> version features a conical bush that moves<br />

relative to the housing, so the <strong>HMSB</strong> cannot be positioned to<br />

any precision. This, however, is not a necessity for braking, i.e.<br />

stopping within a particular braking distance.<br />

The <strong>HMSB</strong> as a rod clamp<br />

Applications requiring high precision positioning can use<br />

the rod clamp version. In this version, the conical bush is<br />

connected firmly to the housing. This also means that there is<br />

no self boosting from the working load.<br />

The spring presses against a freely moving hub with internal<br />

cone that also receives the magnetic force for disengaging the<br />

<strong>brake</strong>.<br />

<strong>HMSB</strong> as a rod clamp, disengaged<br />

<strong>HMSB</strong> as a rod clamp, engaged<br />

All dimensions in mm if not marked otherwise. Errors and omissions excepted.<br />

Dimensions <strong>HMSB</strong><br />

80<br />

45°<br />

rod Ø 20<br />

M10<br />

69,5<br />

80<br />

reference circle Ø 132<br />

(4xM10)<br />

120<br />

60<br />

4 x M8<br />

199<br />

4 x M8<br />

90<br />

69,5<br />

42 115 42<br />

54<br />

12<br />

60<br />

length of thread 12<br />

screw-in depth 54<br />

69,5<br />

M10<br />

120<br />

reference circle Ø 132<br />

(4xM10)<br />

45°<br />

<strong>Clamping</strong> and<br />

<strong>Braking</strong> <strong>Systems</strong><br />

11